Nic SC-5 User manual

Sample Changer

SC-5

Instruction Manual

NIC-TD-0000008-04

Nippon Instruments Corporation

Instruction Manual: Sample Changer SC-5 NIC-TD-0000008-04

Nippon Instruments Corporation

Table of Contents

1. Introduction................................................................................................................. 1

1.1. Safety precautions................................................................................................. 1

2. Outline of instrument ................................................................................................. 2

2.1. External appearance of instrument....................................................................... 2

3. Installation and connection....................................................................................... 6

3.1. Installation of instrument ....................................................................................... 6

3.2. Fixing of cap unit (standard: 5mL) ........................................................................ 6

3.3. Fixing of cap unit (option: large capacity) ............................................................. 7

3.4. Connection on rear side ........................................................................................ 8

3.5. Fixing of table ........................................................................................................ 9

3.6. Fixing and adjusting of washing tank and rinse sleeve ...................................... 10

3.7. Connection of pure water tank and effluent tank ................................................ 12

3.8. Connection to main detector and RD-5 .............................................................. 12

4. Startup and shutdown.............................................................................................. 13

5. Maintenance .............................................................................................................. 13

5.1. Daily inspection ................................................................................................... 13

5.2. Time-change components................................................................................... 14

5.3. Yearly inspection ................................................................................................. 15

5.4. Replacement of components .............................................................................. 16

6. Detailed specification............................................................................................... 26

6.1. General performance .......................................................................................... 26

Instruction Manual: Sample Changer SC-5 NIC-TD-0000008-04

Nippon Instruments Corporation

6.2. Performance of each part.................................................................................... 26

6.3. Specification of external connection ................................................................... 27

6.4. Dimensions and weight ....................................................................................... 27

6.5. Power supply....................................................................................................... 27

6.6. Standard accessories.......................................................................................... 28

6.7. Options ................................................................................................................ 28

6.8. External appearance of instrument configuration ............................................... 29

7. Installation requirements......................................................................................... 30

7.1. Atmosphere ......................................................................................................... 30

7.2. Power requirements ............................................................................................ 30

7.3. Measures against electric noise.......................................................................... 30

8. Warranty .................................................................................................................... 31

8.1. Warranty period and relevant item...................................................................... 31

8.2. Warranty terms.................................................................................................... 31

9. Precautions concerning disposal of instrument................................................... 31

10. Contact address........................................................................................................ 32

Instruction Manual: Sample Changer SC-5 NIC-TD-0000008-04

Nippon Instruments Corporation 1

1. Introduction

1.1. Safety precautions

To use this product safely, observe the following precautions.

Nippon Instruments Corporation will not take any responsibility for accidents

caused by a user's carelessness.

Meanings and descriptions of symbols

In the case of mishandling, a user may be killed or suffer a

serious injury immediately.

In the case of mishandling, a user may be killed or suffer a

serious injury.

In the case of mishandling, a user may suffer an injury or

material damage is expected.

* Using this product involves no risk corresponding to "Danger".

Cautions concerning installation

Observe the installation requirements and power

requirements, or a failure may occur.

Install the instrument on a horizontal working table with

sufficient strength, or a slight injury or a failure caused by a

fall or a drop may result.

Cautions concerning handling

Before using a reagent, procure and administer the safety

data sheet (SDS).

When using a reagent, wear protective equipment and carry

out ventilation sufficiently. Reagents to be used for the

instrument include acute toxic and corrosive substances.

Do not disassemble or modify the instrument without

permission, or a failure may result.

Read this document carefully before using the instrument, or

a failure caused by an operational mistake may result.

Observe the range of the specification, or a failure may

result.

Do not operate the instrument with a wet hand.

Cut off the power supply before carrying out maintenance

work, or a failure caused by a short circuit may result.

Dispose of effluent appropriately after using the instrument.

Do not touch any driving unit intentionally. An injury is not

likely to occur because the speed and torque are low, but a

failure of the instrument may result.

Danger

Warning

Caution

Caution

Warning

Caution

Instruction Manual: Sample Changer SC-5 NIC-TD-0000008-04

2 Nippon Instruments Corporation

2. Outline of instrument

The sample changer SC-5 is an optional instrument for the reducing vaporization

mercury analyzer RA-5 or fully automatic heat vaporization mercury analyzer MA-

3000.

This instrument enables the automatic exchange of sample containers and the

automatic cleaning of the bubbler according to instructions received from the main

detector (RA-5 or MA-3000) in order to ease the user's burden and support analyses

with good reproducibility.

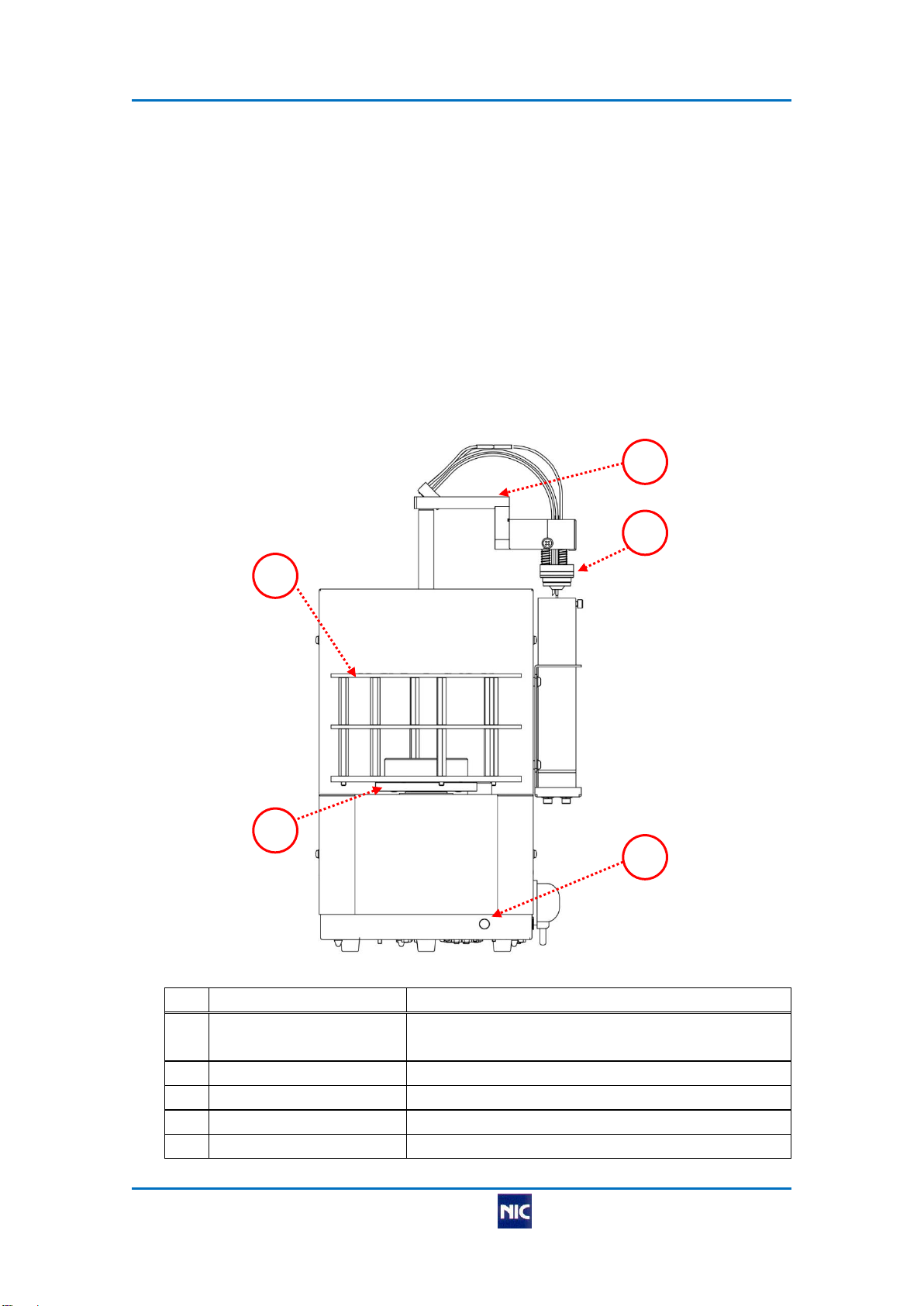

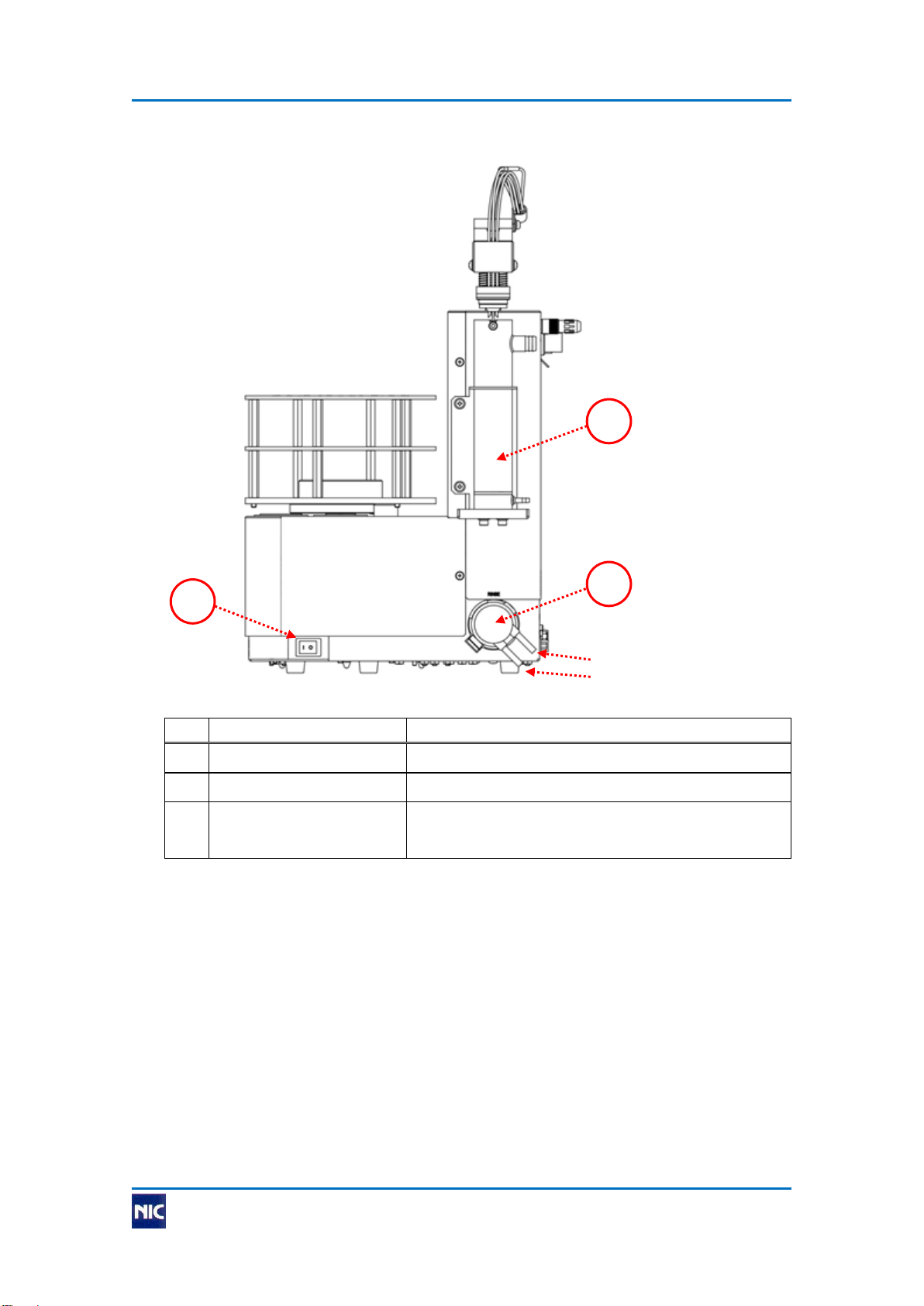

2.1. External appearance of instrument

2.1.1. Front

No.

Name

Description

1

Table

This is a turntable on which to set sample

containers.

2

Table holder

This is a holder for the positioning of the table.

3

Cap unit

Seals a sample container.

4

Arm

Holds the cap unit, moves vertically and turns.

5

Power pilot lamp

The blue lamp lights when the power is turned on.

1

2

3

4

5

Instruction Manual: Sample Changer SC-5 NIC-TD-0000008-04

Nippon Instruments Corporation 3

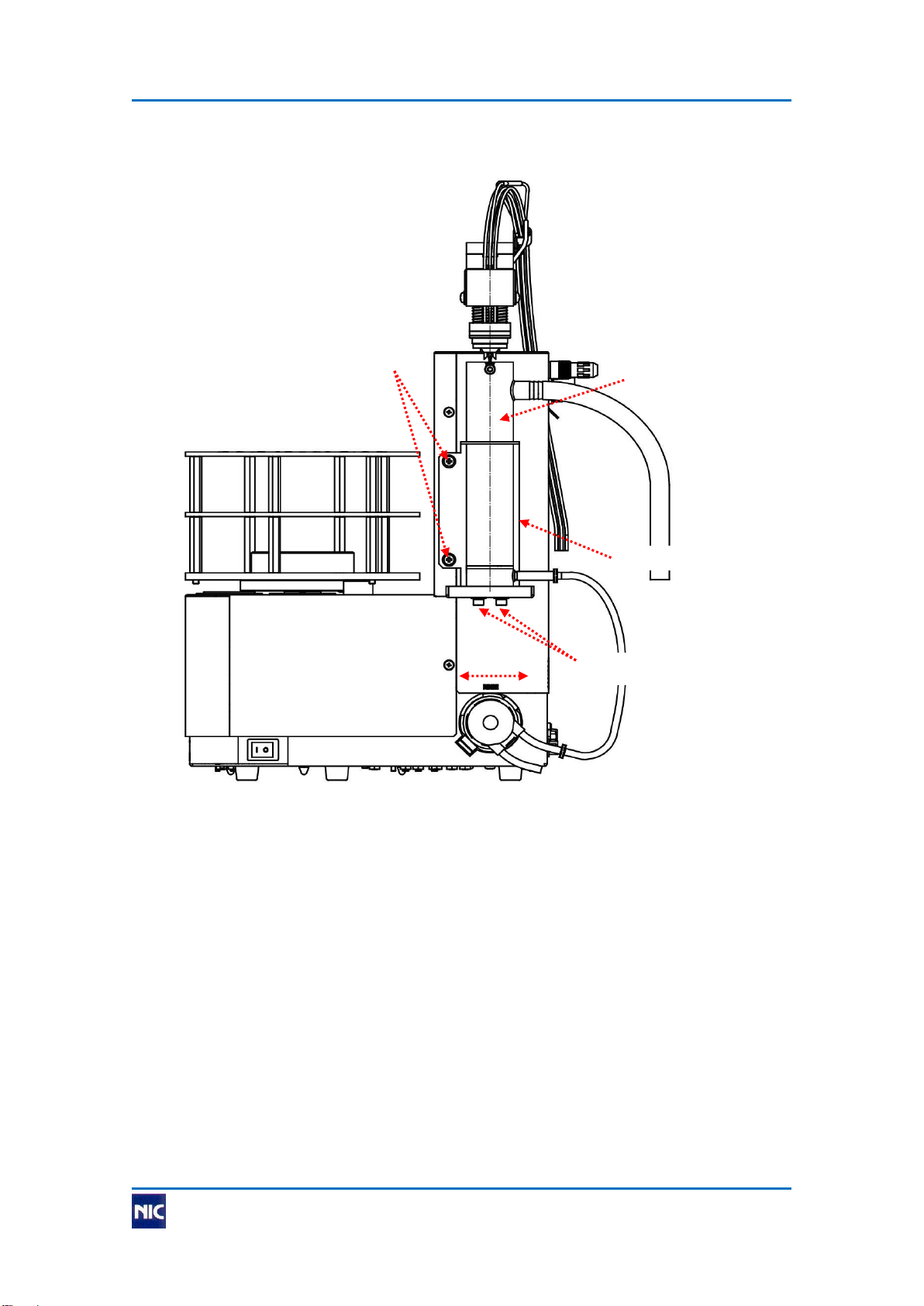

2.1.2. Right side

No.

Name

Description

1

Power switch

This turns on and off the instrument.

2

Rinse pump

This is a pump to supply pure water for cleaning.

3

Washing tank

The bubbler is washed using pure water supplied

from the rinse pump.

3

2

1

Rinse pump outlet side

Rinse pump inlet side

Instruction Manual: Sample Changer SC-5 NIC-TD-0000008-04

4 Nippon Instruments Corporation

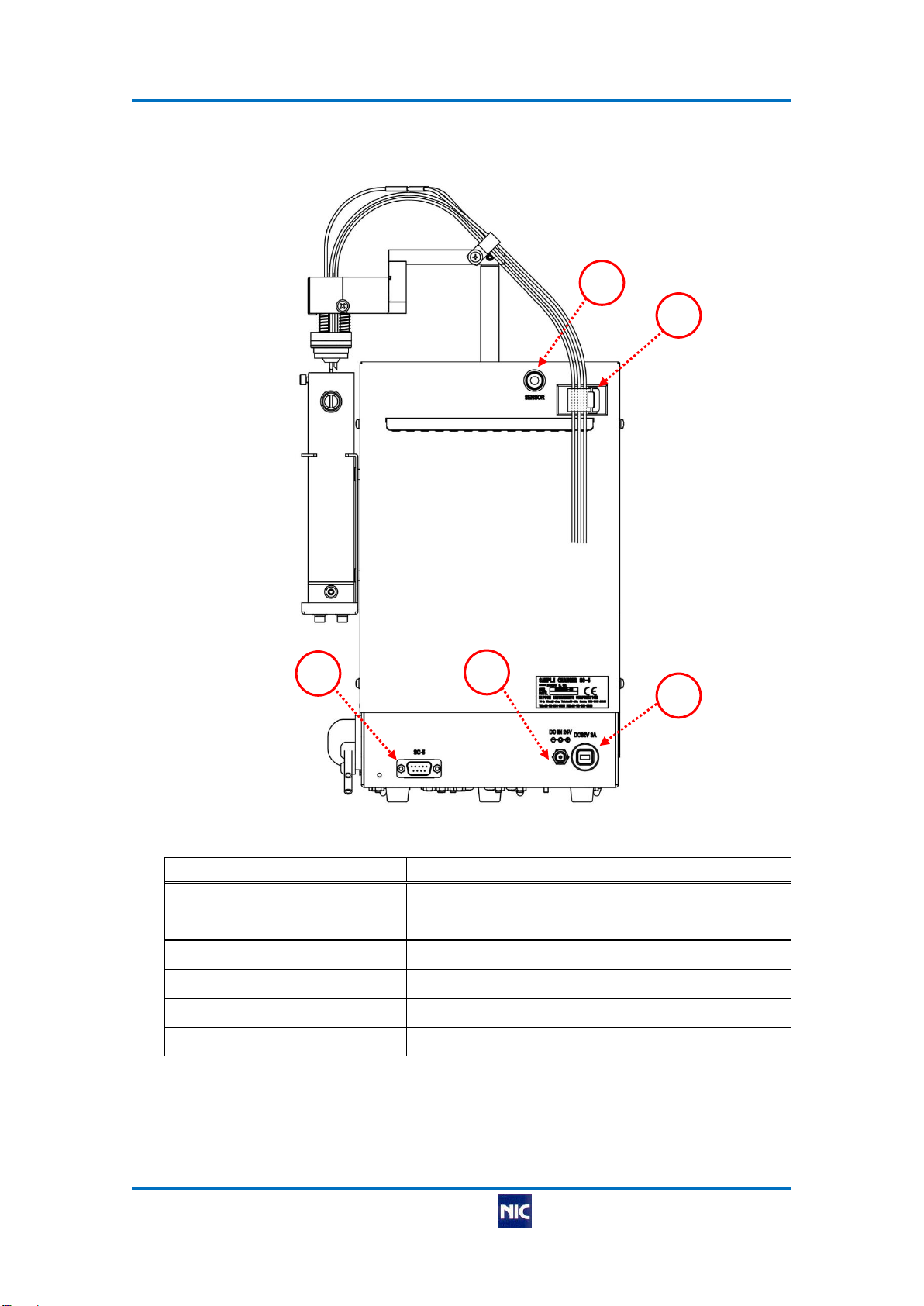

2.1.3. Rear

No.

Name

Description

1

Communication

connector

To be connected to the main detector using the

supplied communication cable.

2

DC jack

The supplied AC adapter is connected.

3

Circuit protector

This is an overcurrent protection device.

4

Seal sensor connector

The seal sensor of the cap unit is connected.

5

Clamp

Tubes of the cap unit are passed.

3

2

1

5

4

Instruction Manual: Sample Changer SC-5 NIC-TD-0000008-04

Nippon Instruments Corporation 5

2.1.4. Upper face

No.

Name

Description

1

Table shaft

This is a rotation driving shaft. The table holder is

attached.

2

Shaft cap

Covers an unused shaft to protect the inside.

1

2

Table shaft for standard

capacity (5 mL)

Table shaft for optional

large capacity

Instruction Manual: Sample Changer SC-5 NIC-TD-0000008-04

6 Nippon Instruments Corporation

3. Installation and connection

3.1. Installation of instrument

Observe the installation requirements, or a failure may occur.

Install the instrument on a horizontal working table with

sufficient strength, or a slight injury or a failure caused by a

fall or a drop may result.

Do not operate the instrument before installation and

connection are all completed.

1) Put the SC-5 in the installation position. When installing on the stand of the RD-5,

see the instruction manual of the RD-5.

2) Connect tubes and cables according to the following sections.

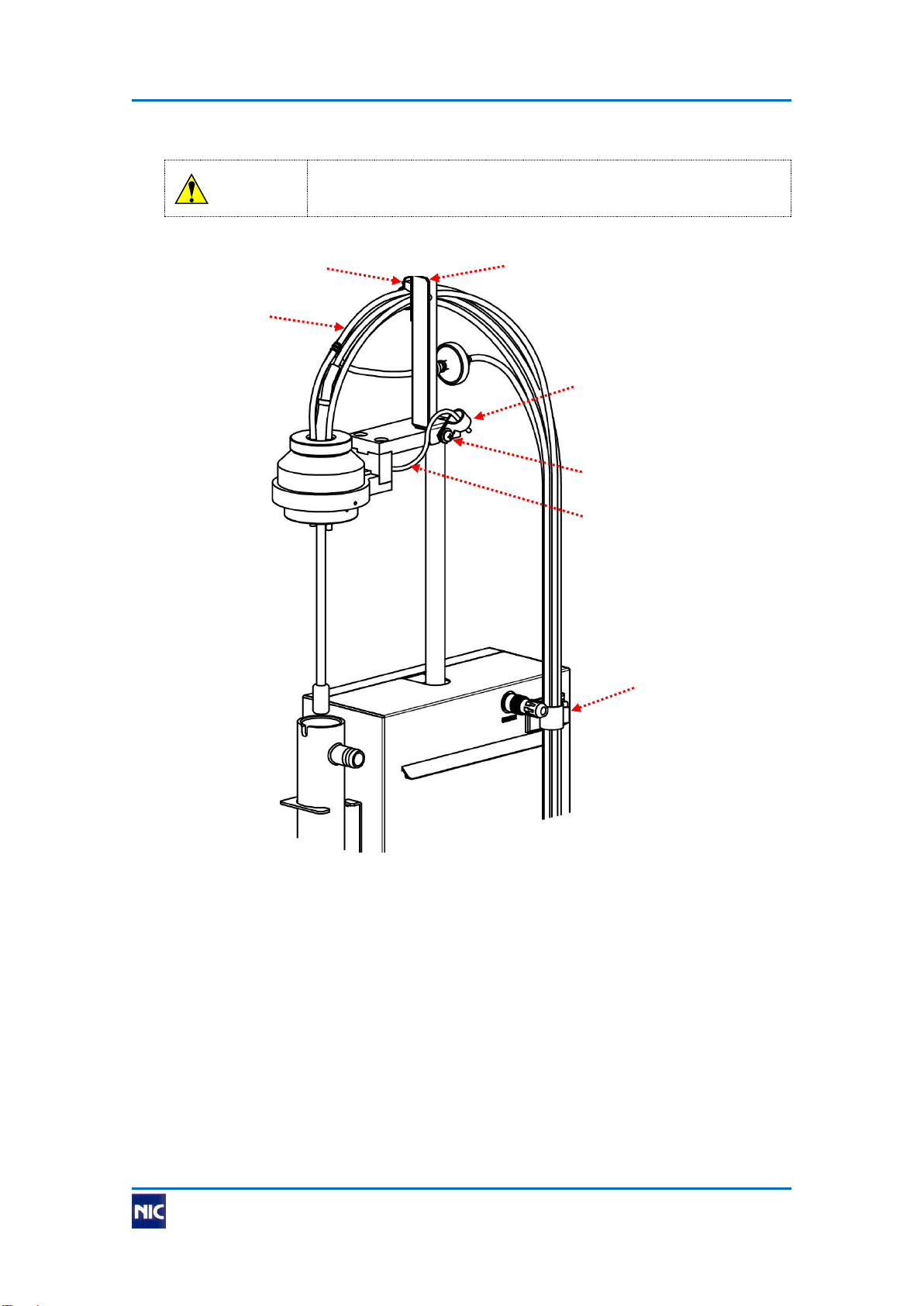

3.2. Fixing of cap unit (standard: 5mL)

Check that each tube is not wet or dirty.

Attach the cap unit to the arm using two M4 hexagon socket head cap screws and two

washers.

When attaching, push in the direction of the arm rotation axis (direction of the arrow),

and determine the position.

Caution

Caution

Arm

Hexagon socket head cap screw

Washer

Cap unit

Arm cover F

Seal packing

Bubbler

Screw fixing cover

(Also on opposite side)

Arm cover R

Arm rotation axis

Direction for pushing cap unit

Instruction Manual: Sample Changer SC-5 NIC-TD-0000008-04

Nippon Instruments Corporation 7

3.3. Fixing of cap unit (option: large capacity)

Check that each tube is not wet or dirty.

1) Remove the rinse sleeve from the washing tank.

2) Attach the cap unit to the arm in similar procedure of “5mL”.

3) Through the sensor cable to nylon clamp, and then fixed by M4 screw to the arm

with the tube holder.

4) Secure the reaction tube to both clamp (φ13) and (φ16).

5) Connect to the reaction tube to the main detector (RA-5 or MA-3000), and then

make sure the reaction tube move smoothly without any catch when the vertical

movement of the arm.

Caution

Reaction tube

Clamp (φ13)

Tube holder

Nylon cramp

M4 screw

Sensor cable

Clamp (φ16)

Instruction Manual: Sample Changer SC-5 NIC-TD-0000008-04

8 Nippon Instruments Corporation

3.4. Connection on rear side

1) Connect the supplied SCIF cable to the communication connector, and connect

the other side to the main detector.

2) Connect the AC adapter output plug in the accessories to the DC jack.

3) Connect the AC adapter to the outlet with the ground.

4) Connect the seal sensor of the cap unit to the seal sensor connector.

Continue to perform the following tasks in the case of 5mL cap.

5) Pass the cap tubes and the cable of the seal sensor through the nylon clamp, and

fix it to the arm using an M4 screw. In the case of the optional large cap, pass only

the cable of the seal sensor.

6) Pass the cap tubes through the clamp.

Nylon clamp

Reaction tube

Seal sensor cable

Clamp

AC adapter

output plug

Communication cable

M4 screw

Instruction Manual: Sample Changer SC-5 NIC-TD-0000008-04

Nippon Instruments Corporation 9

3.5. Fixing of table

1) As shown above, insert the table holder into the table shaft according to the

sample container and table to be used. Check that the table holder and the table

shaft engage correctly.

2) Cover the unused shaft with the shaft cap.

3) Align the guide pins of the table holder with the locating holes in the table, and set

the table on the table holder.

Standard

(5 mL sample container)

Option

(Large sample container)

Guide pins

(3 places)

Table

holder

Shaft cap

Shaft cap

Table

holder

Instruction Manual: Sample Changer SC-5 NIC-TD-0000008-04

10 Nippon Instruments Corporation

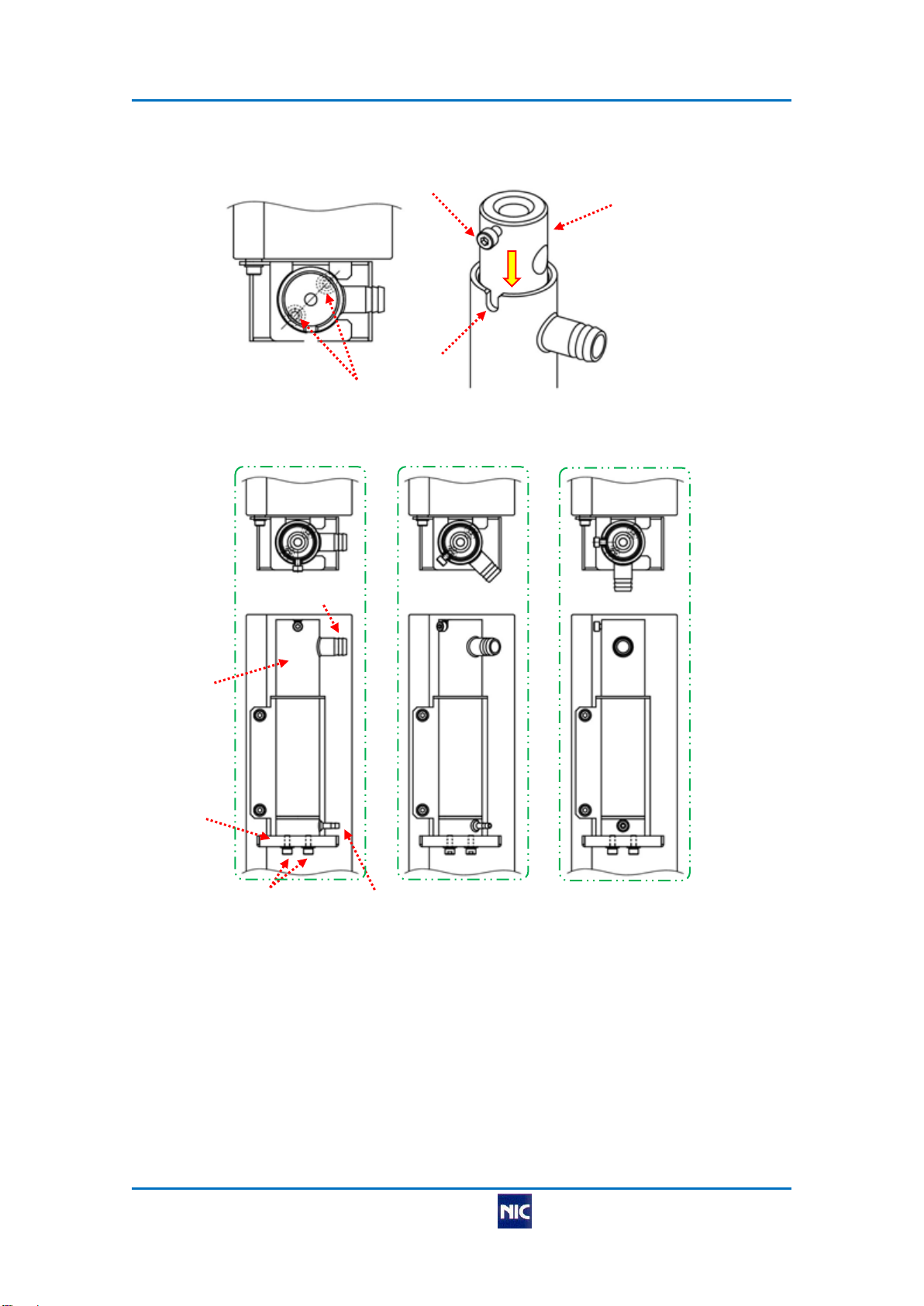

3.6. Fixing and adjusting of washing tank and rinse sleeve

Fix the washing tank to the washing tank holder using two M4 hexagon socket head cap

screws and two washers.

It is possible to change the directions of the joints for effluent and pure water to three

angles, as shown in the figure.

Select the angle according to the layout of the working table.

When using the standard cap unit (5 mL), attach the supplied rinse sleeve and insert it

with its locating bolt aligned with the locating notch in the washing tank.

* When using the optional large cap, be sure to remove the rinse sleeve.

M4 hexagon socket head cap screws

and washers

Locating notch

Rinse sleeve

Locating bolt

M4 hexagon socket head cap screws

and washers

Pure water joint

Effluent joint

Washing

tank

Washing tank

holder

On shipment

-45rotation

-90rotation

Instruction Manual: Sample Changer SC-5 NIC-TD-0000008-04

Nippon Instruments Corporation 11

Adjust the position of the washing tank in the following procedure.

1) After initialization, lower the arm to the rinse position.

2) Loosen M4 hexagon socket head cap screws, so that the washing tank center will

meet the cap portion center, to adjust the position of the washing tank holder.

Also adjustment of the right and left direction is done by loosening the M4 resin

screws.

Washing tank

M4 resin screws

M4 hexagon socket

head cap screws

Washing tank holder

Left/Right

direction

Instruction Manual: Sample Changer SC-5 NIC-TD-0000008-04

12 Nippon Instruments Corporation

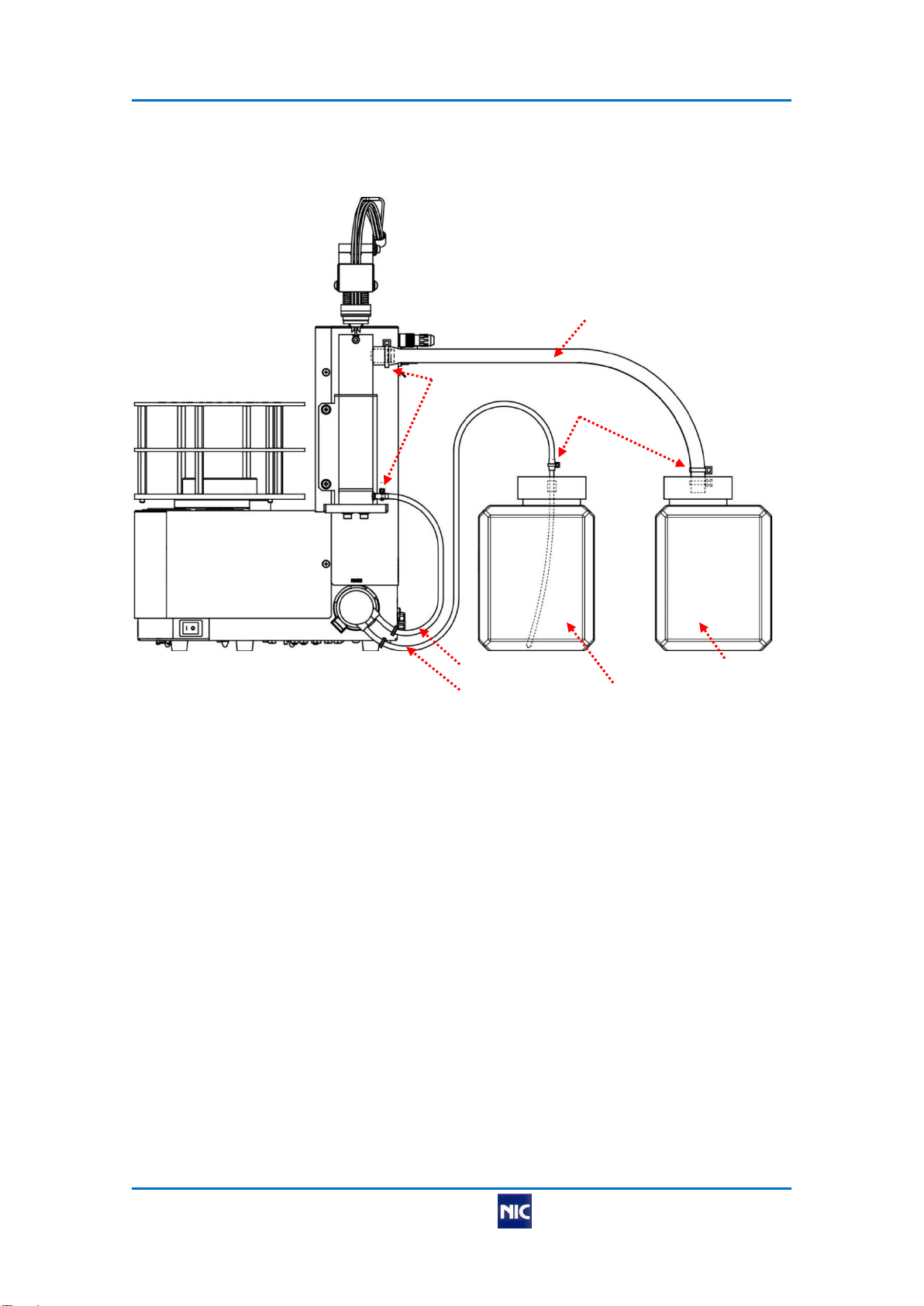

3.7. Connection of pure water tank and effluent tank

1) Pour the necessary quantity of pure water for washing into the pure water tank,

and close the lid.

2) Connect the pure water inlet tube to the washing pump inlet side.

3) Connect the pure water outlet tube to the washing pump outlet side, connect the

other side to the pure water joint of the washing tank, and fix them using supplied

cable ties.

4) Connect the drain tube to the washing tank effluent joint, and fix it using a supplied

cable tie. Insert the other side in the hole in the lid of the effluent tank, and attach

two supplied cable ties to prevent the tube from coming out.

*Effluent is drained to the effluent tank from the washing tank by the natural fall.

Because effluent will not be drained if the tip of the drain tube is soaked in effluent,

fix the tip of the drain tube in the position immediately below the lid of the effluent

tank, as shown in the figure.

3.8. Connection to main detector and RD-5

See each instruction manual and carry out connection job.

Cable ties

Cable ties

Pure water outlet tube

Pure water inlet tube

Pure water tank

Effluent tank

Effluent tube

Instruction Manual: Sample Changer SC-5 NIC-TD-0000008-04

Nippon Instruments Corporation 13

4. Startup and shutdown

1) Check that the supplied AC adapter has been connected to the outlet with the

ground, and turn on the power switch of the SC-5.

2) The initialization (return to origin) and various control operations are carried out

through communication with the main detector.

For details, see the instruction manual of the upper instrument.

3) After the termination process commanded by the main detector is completed, turn

off the power switch of the SC-5.

5. Maintenance

5.1. Daily inspection

Item

Inspection standard

Communication

cable

1) Should be connected to the main detector and RD-5.

2) Should be fixed to the connectors using the screws of the

communication cable.

Power supply

1) The output plug of the AC adapter should be connected to the DC

jack.

2) The AC adapter should be connected to an outlet with the ground.

Reagent tubes

1) Any connection should not be disconnected.

2) Any tube should not be bent or clogged.

3) The tubes should be filled with reagents.

4) The protrusion of the tube should be right length.

Washing tank

1) Tubes should be connected to the pure water joint and effluent

joint.

2) Tubes should be fixed using cable ties.

3) When the standard cap (5 mL) is used, the rinse sleeve should be

installed in the washing tank.

4) When the large cap is used, the rinse sleeve should be removed.

Pure water

tank

1) The pure water tank should have the necessary quantity of pure

water.

2) Any tube should not be bent or clogged.

Effluent tank

The effluent tank should be empty.

Table holder

Should be installed in the predetermined position.

Shaft cap

The shaft cap should be attached to the unused shaft.

Table

1) The table suitable for the sample container should be installed.

2) Should not be dirty or shaky.

Instrument

startup

The initialization (return to origin) should be carried out normally when

the instrument is started.

* The initialization is carried out by the command of the main detector.

Instruction Manual: Sample Changer SC-5 NIC-TD-0000008-04

14 Nippon Instruments Corporation

5.2. Time-change components

We recommend that the following components be replaced periodically to use the

product stably, though their lifetimes vary depending on the usage condition:

Item

Exchange period and replacement procedure

Rinse pump tube

Replace a tube approximately one year or 2,000 hours after the

start of use.

If any abnormality in a tube such as a crack is found, replace it

even before the above period expires.

Replacement procedure

1) After carrying out the washing operation and draining pure

water in the flow path, disconnect the pure water inlet and outlet

tubes according to “3.6. Connection of pure water tank and

effluent tank”.

2) Turn the pump cassette counterclockwise and pull it toward you

to remove it.

3) Pull the hook of the tube holder in the direction of the arrow,

and remove the tube holder.

4) Pull out the rotor and tube from the cassette.

5) Apply silicone grease on the illustrated range of the new tube

and the shaft of the cassette.

6) Attach to the cassette the tube and rotor on which silicone

grease has been applied. Check that the tube has been caught

in the gap between the rollers and the cassette.

7) Attach the tube holder.

8) Insert the cassette and turn it clockwise until it is locked.

9) Attach the pure water inlet and outlet tubes as before.

Rinse pump

Replace the rinse pump approximately three years or 3,000 hours

after the start of use.

If there is an abnormality such as an abnormal sound during

rotation, replace the rinse pump even before the above period

expires.

Replacement procedure

1) After carrying out the washing operation and draining pure

water in the flow path, disconnect the pure water inlet and outlet

tubes.

2) Catch the hook with your finger, pull it out toward you and

remove the connector.

3) Connect the connector of the new pump to that of the main unit,

catch the hook in the notch in the main unit, and push it in.

4) Insert the pure water inlet and outlet tubes as before.

Effluent tank

Replace the effluent tank approximately one year after the start of

use.

* The recommended exchange period is not the guaranteed lifetime.

Instruction Manual: Sample Changer SC-5 NIC-TD-0000008-04

Nippon Instruments Corporation 15

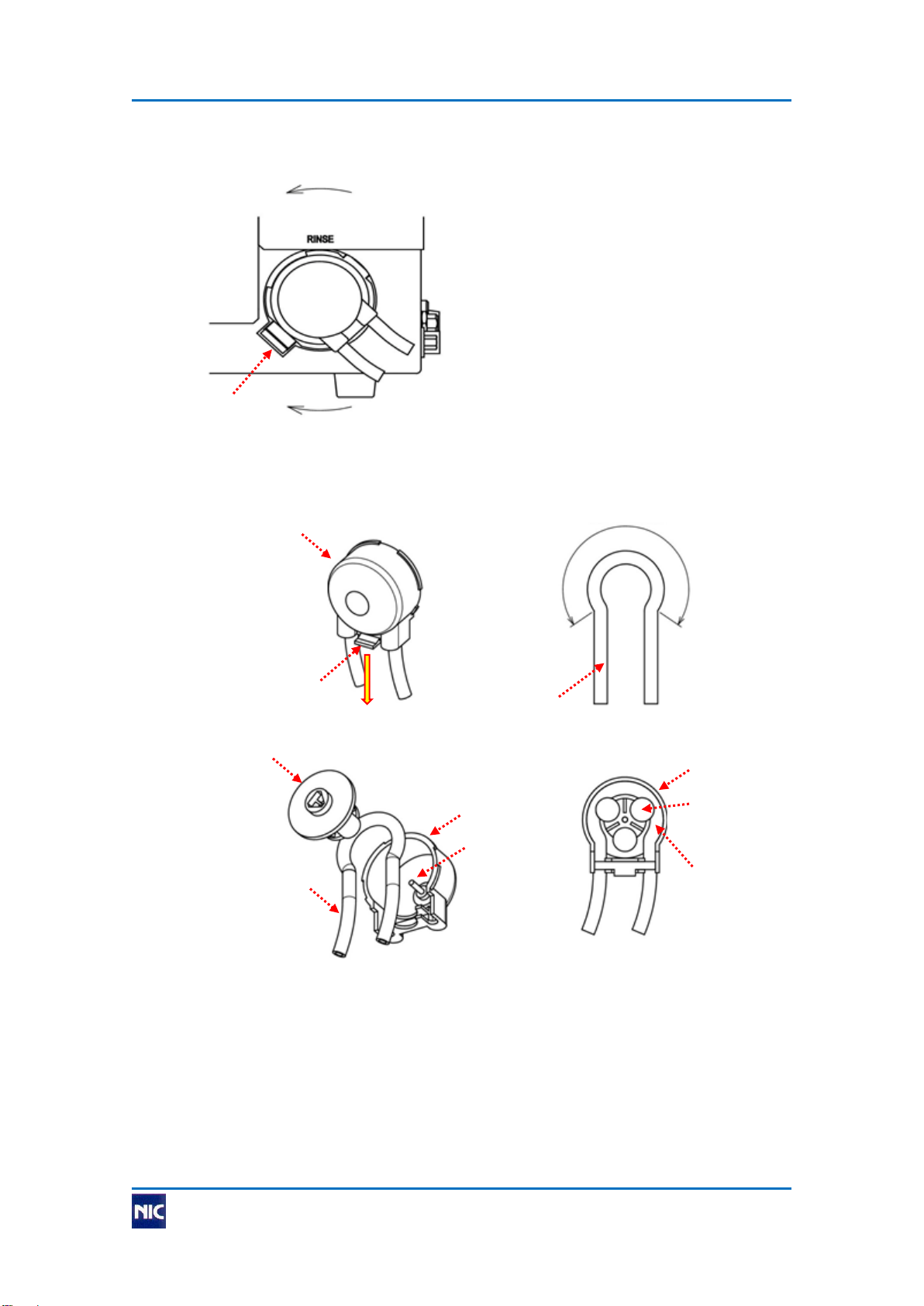

●Removal and attachment of pump cassette

●Removal and attachment of pump tube

5.3. Yearly inspection

To use the product stably for a long period of time, we recommend that the instrument

be sent back for annual maintenance.

In the sending back maintenance, the replacement of time-change components, repair,

adjustment and performance check are carried out.

When pump cassette is removed

When pump cassette is attached

Hook

Pump cassette

Tube holder

hook

Pull.

Rotor

Tube

Cassette

Shaft

Tube

Range for application of grease

Cassette

Roller

The tube should be

caught in the gap

between the rollers

and the cassette.

Instruction Manual: Sample Changer SC-5 NIC-TD-0000008-04

16 Nippon Instruments Corporation

5.4. Replacement of components

Bubbler (standard: 5 mL)

1) Referring to "3.2. Fixing of cap unit", remove the screws fixing the cover and

remove the arm covers F and R.

2) Hold the PharMed tube for the bubbler tube, and pull it up with the bubbler.

3) Pull the PharMed tube out of the bubbler.

4) Pull the bubbler out of the cap unit.

5) Insert the new bubbler in the cap unit, and make the bubbler inserted in the

PharMed tube for the bubbler tube (insertion depth: 10 mm).

6) As shown in the figure, adjust the position of the bubbler so that it is set at 108+/-1

mm from the tip of the cap.

7) Attach the arm covers F and R as before.

Seal packing (standard: 5 mL)

Pull out the packing downward and attach a new one. The packing has a smooth

surface and a sponge surface. Attach it with the smooth surface placed downward.

PharMed tube

Cap unit

Bubbler

Seal Packing

(Place the smooth

surface downward.)

Bubbler tube

Instruction Manual: Sample Changer SC-5 NIC-TD-0000008-04

Nippon Instruments Corporation 17

Cap unit tubes and seal sensor (standard: 5 mL)

1) Carry out the reagent collection using the main detector.

2) Turn off the main detector and sample changer.

3) Loosen the two resin screws and remove the cap unit cover.

4) When replacing the seal sensor, remove the two resin screws fixing the sensor, and

remove it from the arm block.

Loosen the three resin screws and separate the arm block and the cap unit.

5) Loosen the three resin screws of the cap unit.

Cap unit cover

Resin screw

(also on opposite side)

Cap unit

Resin screw (3 places)

Seal sensor

Resin screw for fixing sensor

(2 places)

Arm block

Resin screw

(3 places)