Ningbo R2DH2080-01 User manual

1/15

2-door Refrigerator and Freezer

Installation &

Operation Manual

PLEASE READ THIS MANUAL BEFORE USING THE PRODUCT AND

KEEP IT FOR FUTURE REFERENCE

Ningbo Wanquan Electrical appliance Company

195#,Beixing road, Mazhu town,Yuyao county,

Ningbo city ,Zhejiang province, China.

Table of Contents

SHIPPING DAMAGE

General . . . . . . . . . . . . . . . . . . . . . . . . 3

Apparent Loss or Damage . . . . . . . . . .3

Concealed Loss or Damage . . . . . . . . . 3

Location . . . . . . . . . . . . . . . . . . . . . . . . .3

PREPARATION OF CABINET FOR

OPERATION

2/15

Removing Cabinet from Skid . . . . . . . .4

Leveling Cabinet . . . . . . . . . . . . . . . . .4

Shelf lnstallation . . . . . . . . . . . . . . . . . 4

Door seal . . . . . . . . . . . . . . . . . . . . . .5

Fan Cycle Switch . . . . . . . . . . . . . . . .5

Lamps . . . . . . . . . . . . . . . . . . . . . . . . . . .5

EXTERIOR DIMENSION

Exterior Dimensions . . . . . . . . . . . . . . . . 6

Case specification . . . . . . . . . . . . . . . . 7

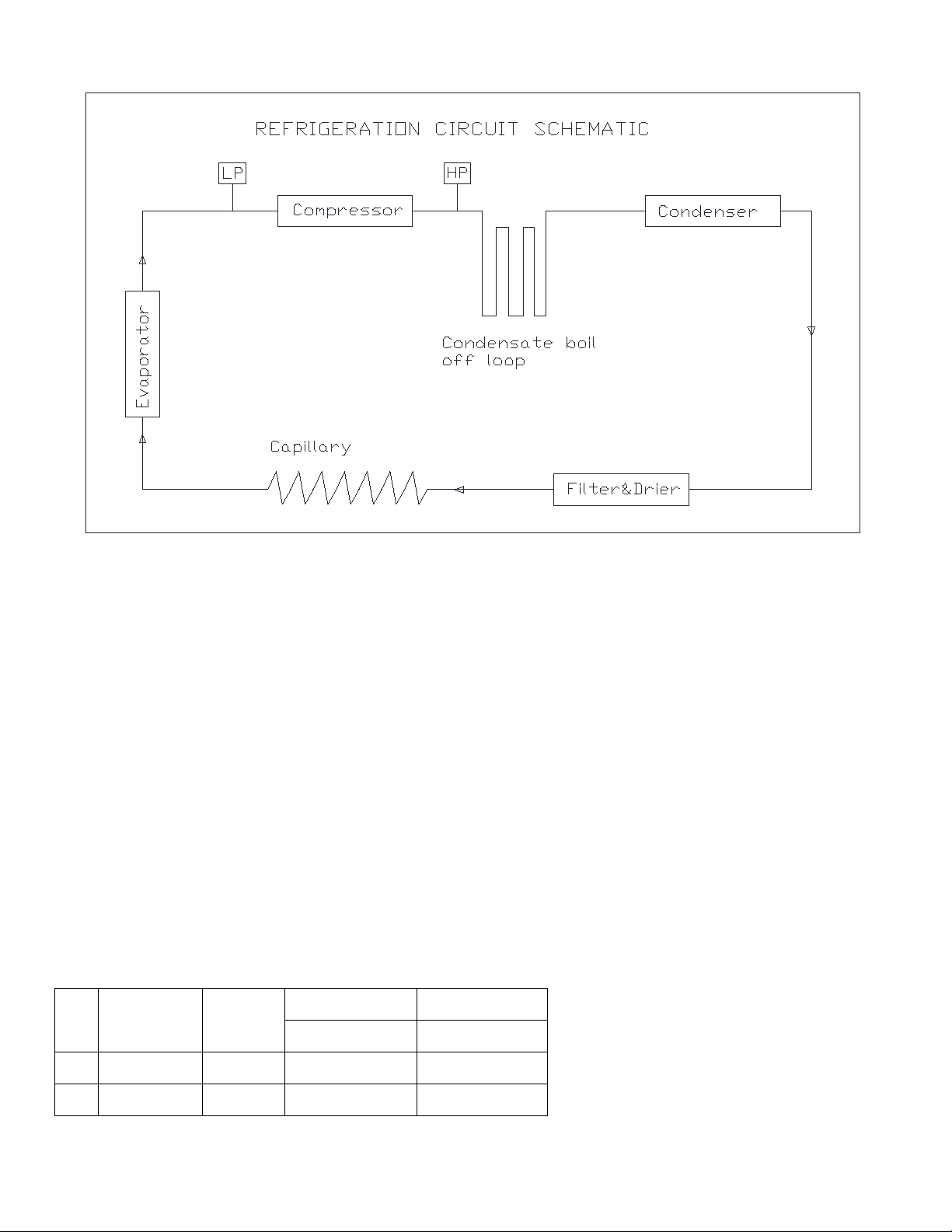

REFRIGERATION SYSTEM

Refrigeration circuit schematic. . . . . . .8

Defrost Cycle . . . . . . . . . . . . . . . . . .8

START UP / OPERATION

Electrical Supply . . . . . . . . . . . . . . . . . .8

Controller setting. . . . . . . . . . . . . . .8

Lighting . . . . . . . . . . . . . . . . . . . . . . .9

Defrost Water Evaporation . . . . . . . . . . 9

MAINTENANCE

Maintenance . . . . . . . . . . . . . . . . . . . .9

Cabinet Surfaces . . . . . . . . . . . . . . . . . . .10

Condenser . . . . . . . . . . . . . . . . . . . . . . . .10

Evaporator Housing .

. . . . . . . . . . . . .10

Merchandiser Electrical Data . . . . . . . . 11

WARRANTY ………………………. .14

1. SHIPPING DAMAGE

1.1 General

All equipment should be thoroughly examined for shipping damage before and during unloading.

This equipment has been carefully inspected at factory and the carrier has assumed

responsibility for safe arrival.

If

damaged, either apparent or concealed, claim must be made to

the carrier.

1.2 Apparent Loss or Damage

If

there is an obvious loss or damage, it must be noted on the freight bill or express receipt and

signed

by

the

carrier’

s

agent; otherwise,

carrier may refuse claim. The carrier will supply

necessary forms.

1.3 Concealed Loss or Damage

When loss or damage is not apparent until after equipment is uncrated, a claim for concealed

damage is made. Upon discovering damage, make request in writing to carrier for inspection

within 15 days and retain all packing. The carrier will supply inspection report and required claim

forms.

1.4 Location

3/15

These merchandisers are designed for indoor operation with a recommended operating room

ambient temperature of 75° F (24° C)/55% rh. Their performance is affected by store air currents

when the doors are open. Do NOT allow air conditioning, electric fans, or open doors and

windows to create air currents around these merchandisers nor should they be exposed to direct

sunlight or other heat sources.

NOTE: The condensing unit draws ambient air through the front of the unit and discharges hot air

out the rear of the unit. In order to maintain proper refrigerator performance and compressor

life,

a

mini

mum

space

of

4

” (

10

cm)

must

be

maintained between the refrigerator and

surrounding surfaces.

2.

PREPARATION OF CABINET FOR OPERATION

Removing Cabinet From the wooden Pallet

Move the merchandiser as close as possible to its permanent location. Check refrigeration

lines to see that they are “free” and no damage has occurred during shipping. Check fan

blades for free operation.

2.1 Leveling Cabinet

These merchandisers must be installed level

(front to back and end to end) to permit maximum draining of the condensate water as well as

proper door alignment and operation.

The merchandiser has been shipped with 6 adjustable foot bolts installed. Level the unit by

placing a level on the merchandiser and make it to level by adjusting the foot bolts.

2.2 Shelf Installation

After the cabinet has been leveled and is in its final position, the shelves may be installed.

Shelf spacing is adjustable by positioning the shelf supports according to your loading

requirements.

WARNING

(Freezer. Models) Do NOT place product directly on floor of merchandiser. Locate

bottom shelf in the lowest position to the floor of the merchandiser (approximately 3” [7.5

cm] off bottom) before loading. Failure to comply may result in product loss.

4/15

Light box

Serial plate

Shelves

Door

Front grill

Adjustable foot bolt

Resr spacer

2.3 Door seal (closing mechanisms).

Hinged Doors. Check to ensure the door torque is capable of closing the door

automatically. Open the door 30 degrees and release it, the door should close and seal.

2.4 Fan Cycle Switch (Hinged doors, freezer only )

The evaporator fan is cycled off upon a door opening by a switch located above each door.

This reduces the amount of warm moist air introduced to the evaporator coil during door

openings

With the door open, depress the switch to ensure the evaporator fan is working.

2.5 Lamps.

Turn the lighting switch on to ensure the lamps are operating correctly. Check to ensure the

lamps are in their place.

3.

Exterior Dimensions

5/15

84.7" [2151]

31.9" [809]

52.8" [1340]

Specification

Model

R2DH2080-01

F2DH2080-01

Classification

Refrigerator

Freezer

Overall size (W x D x H,

inch)

52 8/64 x 31 9/64 x 84 7/64

(1340 x 809 x 2151 mm)

52 8/64 x 31 9/64 x 84 7/64

(1340 x 809 x 2151 mm)

6/15

Capacity(cuft)

44.2

44.2

Product Temperature,F

≤38

≤0

Doors

2

2

Qty of shelf

10

10

Refrigerant

R290, 4.23oz

R290, 4.94oz

Compressor (hp)

1/4 hp

3/4 hp

Cooling Type

Forced air

Defrost

Off cycle

Electric heater

Insulation

Polyurethane) / Cyclopentane + CFC Free

Temperature control type

Auto

Power supply

115V,60Hz,1phase

115V,60Hz,1phase

Rated Power (hp)

1/2

2

Rated Amps(A)

3.2

12.82

Weight (lb)

547

585

4. REFRIGERATION SYSTEM

7/15

Defrost Cycle (Low Temperature Models)

The evaporator fin coil is defrosted by an electric defrost heater located on the underside of the coil.

The defrost cycle is initiated and terminated by the controller fitted on the electrical box. This control

not only terminates the defrost cycle, but delays the fan start-up after the defrost cycle to prevent the

residual heat of heater from being blown into the product area.

5.

START UP / OPERATION

5.1 Electrical Supply

WARNING: Equipment MUST be GROUNDED!

Wiring of the unit is complete when it is shipped from the factory. The unit is supplied with a three

conductor electrical cord which extends from the rear of cabinet. Plug the cabinet into correct

grounded outlet. It is recommended that a separate circuit be run for each cabinet to prevent the

possibility of another appliance blowing a fuse, causing subsequent loss of product.

Control setting, please see the appendices at the last page. The pre-set parameters in factory as

below:

5.2 Controller parameter

No.

Parameter

unit

R2DH2080-01

F2DH2080-01

Value

Value

1

Set

℉

33

-2.2

2

Hy

℉

4

4

8/15

3

De

℉

54

59

4

dt

℉

0

0

5

id

hour

24

12

6

Md

minute

45

30

7

od

minute

3

3

8

Ac

minute

3

3

9

P2

minute

Y

Y

10

Fd

minute

5

5.3 Lighting

Interior light and light box are controlled by a manually operated switch. The switch is located near the

controller.

5.4 Defrost Water Evaporation

External drain plumbing is not required. Behind the case, there is a plastic soft pipe

directing

defrost water from the evaporator coil to water tray on condensing unit. The water tray in the

condensing unit area serves as a reservoir for the storage of the water until it is evaporated by a hot

gas loop from the compressor.

6. MAINTENANCE

Maintenance

Long life and satisfactory performance of any equipment is dependent upon the care given to it.

To ensure efficient operation, proper sanitation and minimum maintenance, the cabinet should be

thoroughly cleaned, debris removed and the interior cleaned regularly.

CAUTION

TO AVOID PERSONAL INJURY OR DAMAGE TO ELECTRICAL COMPONENTS ALWTAYS

DISCONNECT UNIT FROM MAIN POWTER SOURCE BEFORE SERVICING OR CLEANING

6.1 Cabinet Surfaces (Interior and Exterior)

To preserve finish, the cabinet should be cleaned with a mild solution of soap and warm water

only, using a soft cloth or sponge. DO NOT use any type of caustic soap, abrasive cleaner, or

steel wool scouring pads which can mar the cabinet finish.

6.2 Condenser

The air cooled condenser should be cleaned regularly. A dirty condenser restricts air flow,

causing decreased refrigeration efficiency. (Clean every month or as required).

I ) With main power supply disconnected, remove the front grill from front of lower cabinet. Most

dirt will collect on the air intake side of the condenser. This is opposite the fan motor.

2) Use a bristle brush to loosen the dust and dirt and remove with a vacuum cleaner. When

cleaning condenser line beware of fin edges as they are sharp

3) If the merchandiser is located in an area susceptible to grease collecting on the condenser,

9/15

scrub with a solution of warm water and detergent. Care should be taken to keep solution away

from wiring and electrical components.

Check for loose items before replacing panel.

6.3 Evaporator Housing

The thermostat “OFF” position disconnects the condensing unit only. The evaporator fan

motor will be energized until the unit is disconnected from the main power source. Remove the

fasteners to lower the evaporator housing for cleaning and/or service.

NOTE: Evaporator fan will cycle “ OFF ” during defrost cycle. Evaporator fan will delay

approximately 5 minutes after each defrost cycle and initial start-up on freezer model.

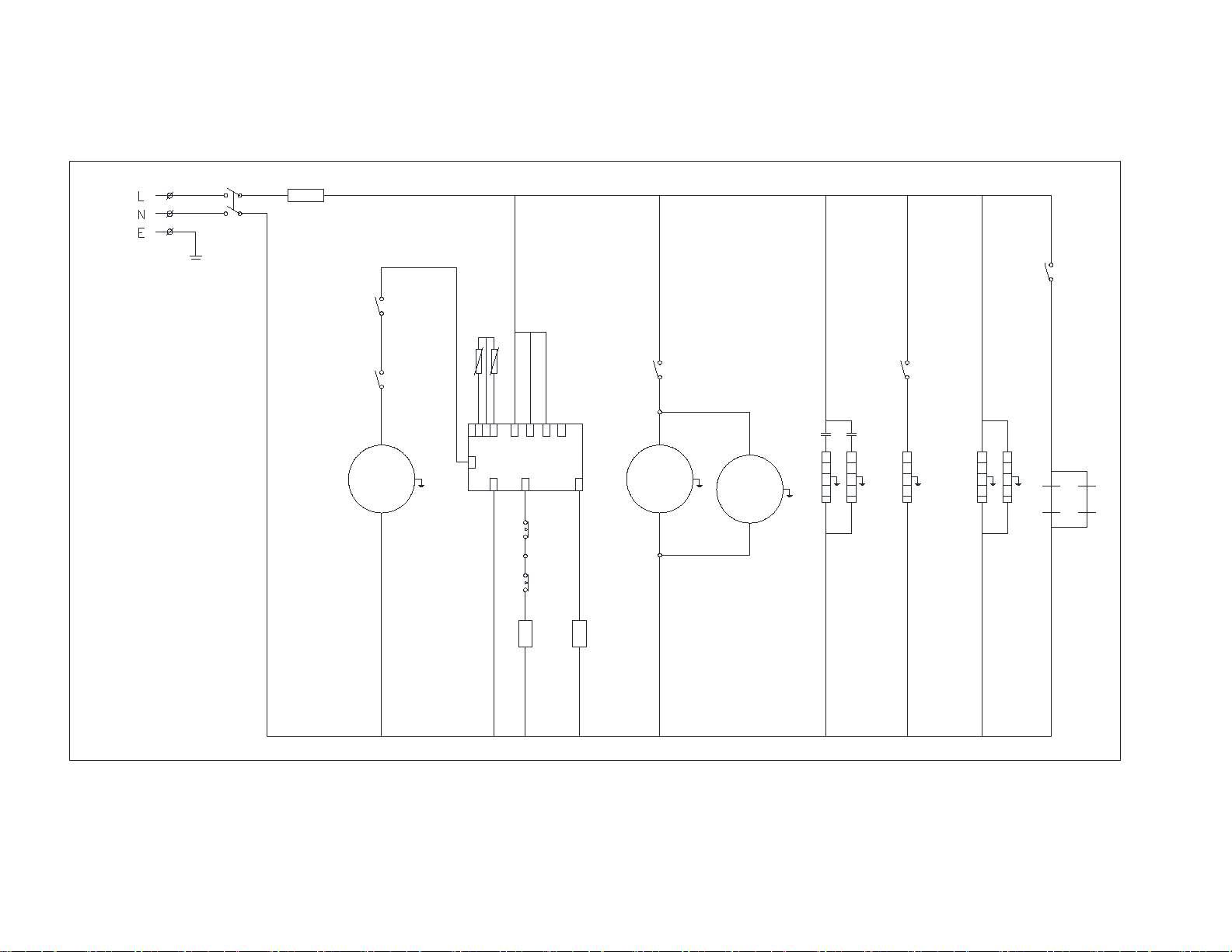

6.4 Merchandiser Electrical Data

10 /15

6.4.1 Electrical Schematic for Freezer F2DH2080-01

Electrical schematic with controller XR06CX

4

6

4

6

AOP

DP

LPHP X1

2

1

2

1

0

1

0

1

M

6419 10 11 12

5 3 7

Dixell-XR06CX

Relay1 Relay2

Relay1 Relay2

Compressor

Door frame

Heater

MM

R1R5

Blown13

Blown15

Blown17

Blown19

Blown21

Blown23

Blown49

Blue16

Blue18

Blue20

Blue24

Blue50

2

1

2

1

Defrosting Heater

Door

Switch1

Door

Switch2

Blown31

Blown33Blown35

R2

Blown37

Blue36

Door Heater

R3

Blown39

Blue38

R4

Blown41

Blue40

Capacitor

2

1

Light

Switch

Blown27

Blown29

Blue34

LED1 LED2

Blown01

Blue02

Blown03

Blue04

115V 60Hz Fuse

20A

Blown05

Load Switch

Evaporator Fan

M2/3

Blown07

Blown09

Blue11

Blue06

Blue08 Blue12

Condenser Fan

2

5

4

Electrical schematic with controller IR33

11 /15

4

6

4

6

M

Relay1 Relay2

Compressor

Door frame

Heater

MM

R1R5

Blown13

Blown15

Blown17

Blown19

Blown21

Blown23

Blue16

Blue18

Blue20

Blue24

5

4

2

1

2

1

Defrosting Heater

Door

Switch1

Door

Switch2

Blown33Blown35

R2

Blown37

Blue36

Door Heater

R3

Blown39

Blue38

R4

Blown41

Blue40

Capacitor

2

1

Light

Switch

Blown27

Blown29

Blue34

LED1 LED2

Blown01

Blue02

Blown03

Blue04

115V 60Hz Fuse

20A

Blown05

Load Switch

Condenser Fan

Blown07

12

15

5

611 8 103 9

7

4 2

1

14

13

16

17

18

2

Black

Black

Black

Carel Electronic

Controller IR33

AOP

DP LPHP X1

2

1

2

1

0

1

0

1

Relay1

Relay2

Blown49

Blue50

Blown31

Blown09

Blue11

Blue06

Blue08 Blue12

6.4.2 Electrical Schematic for Refrigerator R2DH2080-01

12 /15

Blown01

Blue02

Blown03

Blue04

115V 60Hz

4

6

2

1

AOP

DP

LP

HP

X1

2

1

2

1

0

1

M

684 3 2 1

7 9

Dixell-XR04CX

Fuse

15A

Relay

Relay

Evaporator Fan

M2/3/4

Light Switch

M M

Blown05

Blown07

Blown09

Blown13

Blown15

Blown27

Blown29

Blue11

Blue06

Blue08 Blue12

Blue16

Blue24

Blue34

10

14

Blown25

LED1 LED2

Condenser Fan

Load Switch

Compressor

13 /15

7. Warranty

This warranty is made to the original user at the original installation site and is not transferable.

Wanquan merchandisers are warranted to be free from defect in material and workmanship

under normal use and service for a period of one (1) year from the date of original installation

(not to exceed fifteen (15) months from the date of shipment for the factory). Wanquan

evaporators and condensers are warranted for a total of five (5) years based upon the above

criteria. Wanquan’s obligation under this warranty shall be limited to repairing or exchanging any

part or parts, without charge F.O.B. factory or nearest authorized parts depot within said period

and which is proven to the satisfaction of the original manufacturing

plant warranty group to be thus defective.

Wanquan covers the entire case or refrigeration product and all its components (except for

lamps, driers, fuses, and other maintenance type replacement parts) for the one (1) year

warranty period.

Additionally, Wanquan warrants for a total period of three (3) years all sealed, multi-glass

assemblies. If within three (3) years from the date of installation (not to exceed thirty-nine (39)

months from the date of shipment from factory), it shall be proven to the satisfaction of the

originating factory warranty group that there is impaired visibility through the multi-glass

assemblies thereof caused by moisture between the glasses, the multi-glass assembly will be

replaced free of charge, F.O.B. factory. This additional warranty excludes accident, misuse, or

glass breakage.

On Wanquan manufactured self-contained display cases, Wanquan agrees to repair or

exchange, at its option, the original motor/compressor unit only with a motor/compressor of like

or of similar design and capacity if it is shown to the satisfaction of Wanquan` that the

motor/compressor is inoperative due to defects in factory workmanship or material under normal

use and service as outlined in Wanquan’s “Installation Instructions” which are shipped inside

new Wanquan equipment. Wanquan’s sole obligation under this warranty shall be limited to a

period not to exceed five years from date of factory shipment.

On Wanquan refrigeration systems, an additional (4) year extended warranty for the

motor/compressor assembly is available, but must be purchased prior to shipment to be in

effect. Wanquan reserves the right to inspect the job site, installation and reason for failure.

The motor/compressor warranties listed above do not include replacement or repair of controls,

relays, capacitors, overload protectors, valve plates, oil pumps, gaskets or any external part on

the motor/compressor replaceable in the field, or any other part of the refrigeration system or

self-contained display case.

THE WARRANTIES TO REPAIR OR REPLACE ABOVE RECITED ARE THE ONLY

WARRANTIES, EXPRESS, IMPLIED OR STATUTORY, MADE BY WANQUAN WITH

RESPECT TO THE ABOVE MENTIONED EQUIPMENT, INCLUDING ANY IMPLIED

WARRANTY OF MERCHANTABILITY OR FITNESS, AND WANQUAN NEITHER ASSUMES

NOR AUTHO- RIZES ANY PERSON TO ASSUME FOR IT, ANY OTHER OBLIGATION OR

LIABILITY IN CONNECTION WITH THE SALE OF SAIDEQUIPMENT OR ANY PART

THEREOF.

THIS WARRANTY SHALL NOT APPLY TO LOSS OF FOOD OR CONTENTS OF THE

EQUIPMENT DUE TO FAILURE FOR ANY REASON. WANQUAN SHALL NOT BE LIABLE:

1. For payment of labor for any removal or installation of warranted parts;

14 /15

2. For any repair or replacements made without the written consent of Wanquan, or

when the equipment is installed or operated in a manner contrary to the printed

instructions covering installation and service which accompanied such

equipment;

3. For any damages, delays, or losses, direct or consequential which may arise in

connection with such equipment or part thereof;

For damages caused by fire, flood, strikes, acts of God or circumstances beyond its control;

4. When the equipment is subject to negligence, abuse, misuse or when the serial

number of the equipment has been removed, defaced, or altered;

5. When the equipment is operated on low or improper voltages

6. When the equipment is put to a use other than normally recommended by

Wanquan (i.e. deli case used for fresh meat);

7. When operation of this equipment is impaired due to improper drain installation;

8. For payment of refrigerant loss for any reason;

9. For costs related to shipping or handling of replacement parts.

1. If the supply cord is damaged, it must be replaced by a special cord or assembly available from the

manufacturer or its service agent.

2. Do not store explosive substances such as aerosol cans with a flammable propellant inside the appliance.

3. Please according to local regulations regarding disposal of the appliance for its flammable blowing gas.

Before you scrap the appliance, please take off the doors to prevent children trapped.

4. WARNING: Keep clear of obstruction all ventilation openings in the appliance enclosure or in the structure

for building-in.

5. WARNING: Do not use mechanical devices or other means to accelerate the defrosting process, other than

those recommended by the manufacturer.

6. WARNING: Do not damage the refrigerant circuit.

7. WARNING: Do not use electrical appliances inside the food storage compartments of the appliance, unless

they are of the type recommended by the manufacturer.

8. Warning: Risk of fire / flammable materials, taking care to avoid causing a fire by igniting flammable

material.

15 /15

9. The appliance shall be disconnected from its power source during cleaning or maintenance and when

replacing parts.

10. The A-weighted emission sound pressure level is below 70Db(A).

11. Max. loading of shelves: 195.3kg/m²,the deformation <1.04cm/m.

12. Inspections and maintenance are required once a year.

13. The ambient temperature and humidity conditions of the show case climate class following the tab below:

Test room

climate class

Dry bulb

temperature

(⁰C)

Relative

humidity (%)

Dew point

(⁰C)

Water vapour

mass in dry air

(g/kg)

0

20

50

9.3

7.3

1

16

80

12.6

9.1

8

23.9

55

14.3

10.2

2

22

65

15.2

10.8

3

25

60

16.7

12.0

4

30

55

20.0

14.8

6

27

70

21.1

15.8

5

40

40

23.9

18.8

7

35

75

30.0

27.3

NOTE: the water vapour mass dry air is one of the main points influencing the performance

and the energy consumption of the cabinets. Therefore, the order of the climate class in the

table is based on the water vapour mass column. See also Annex B to compare lab and store

conditions.

14.Food should be placed within the load line.

This manual suits for next models

1

Table of contents