Table of Contents

1. About EtherNet/IPTM ................................................................................................................................................. 6

1.1 Overview................................................................................................................................................................ 6

1.2 G3 EtherNet/IPTM Features.................................................................................................................................. 6

1.3 G3 EtherNet/IPTM Performance Data .................................................................................................................. 6

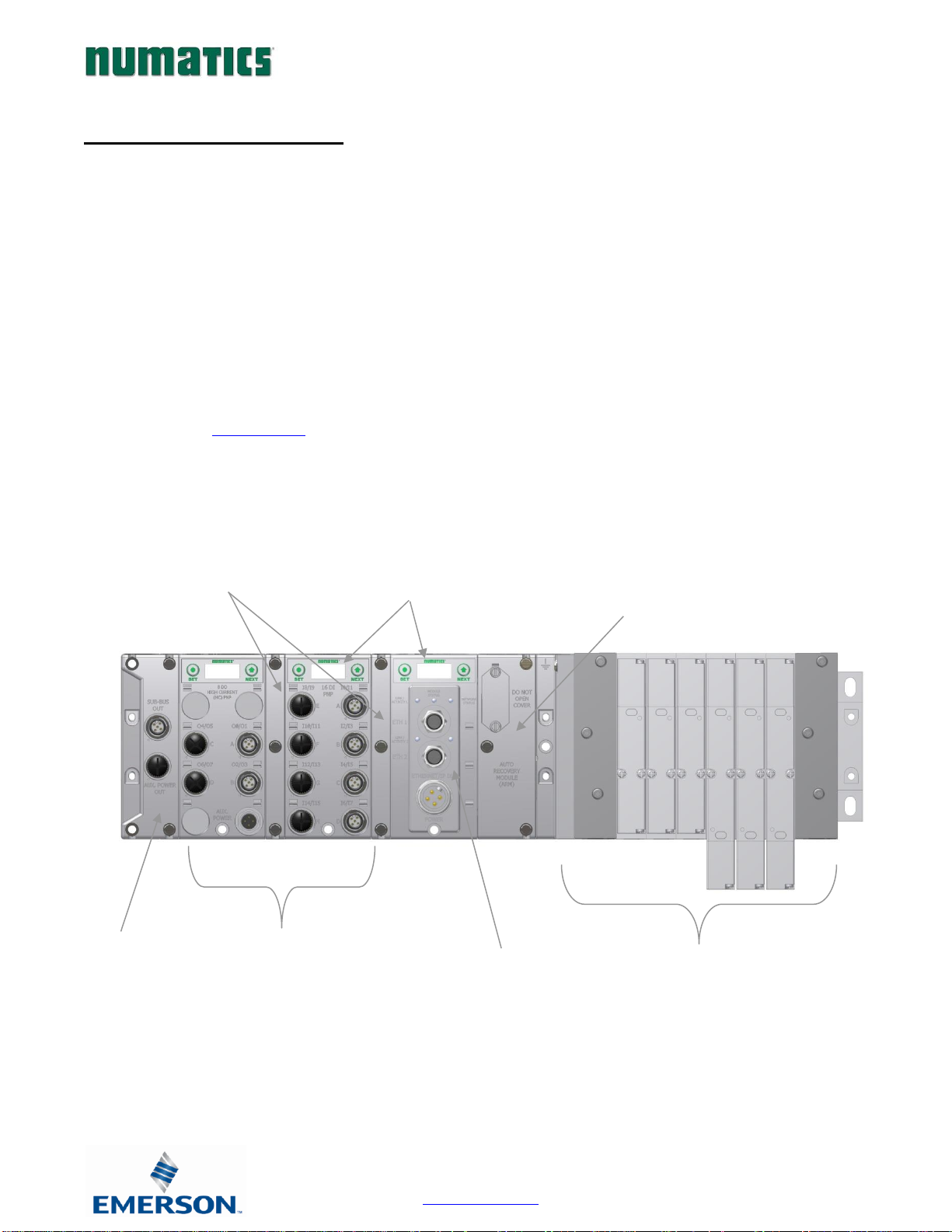

2. G3 Introduction ....................................................................................................................................................... 7

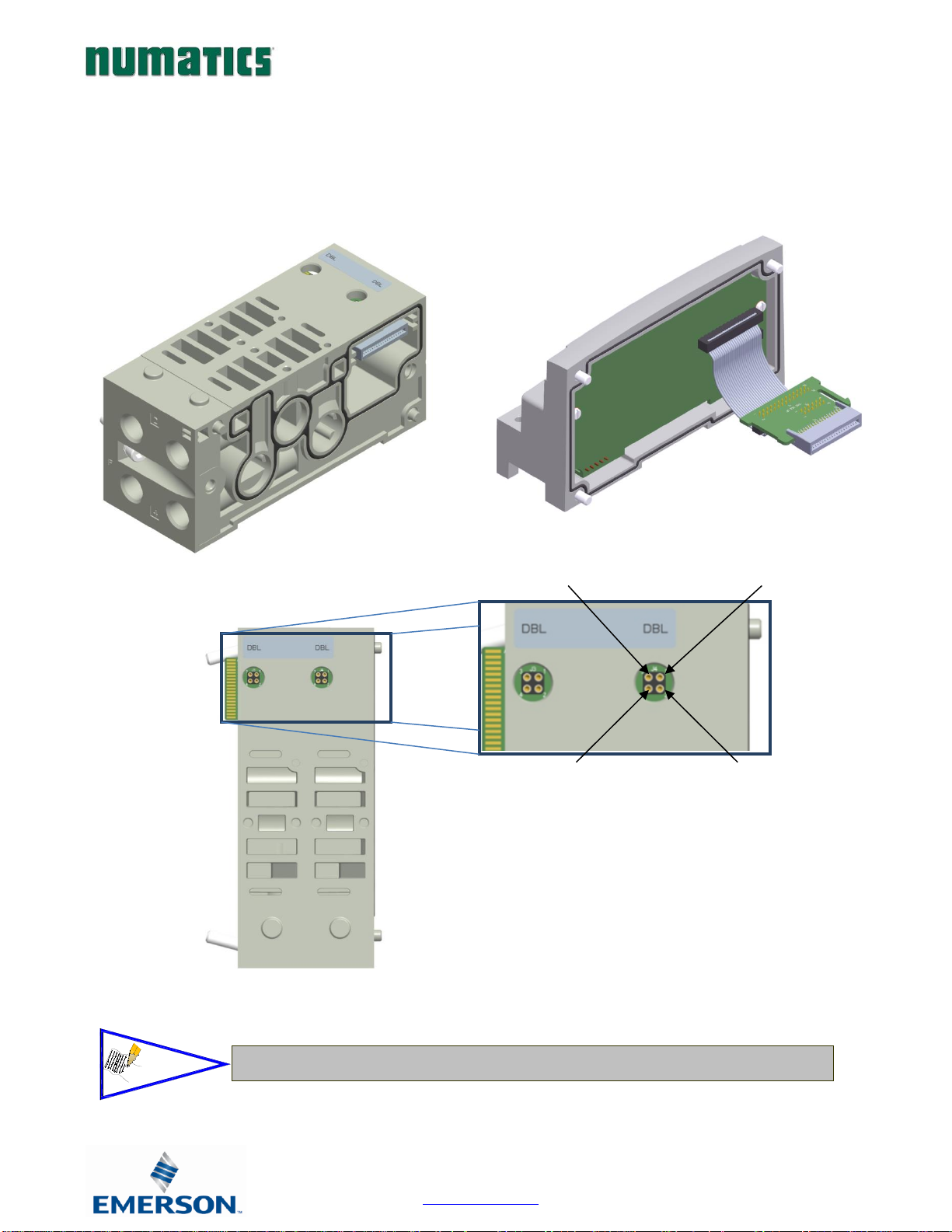

2.1 G3 Electronics Modularity..................................................................................................................................... 8

2.2 500 Series Pneumatic Valve Manifold.................................................................................................................... 9

2.3 500 Series Manifold Stations .................................................................................................................................10

2.4 500 Series Standard Z-Board™ Connectors .........................................................................................................11

2.5 2000 Series Pneumatic Valve Manifold.................................................................................................................12

2.6 2000 Series Z-Board™ Connectors.......................................................................................................................13

2.7 2000 Series Z-Board™ and Ribbon Cable Example............................................................................................14

2.8 2000 Series Z-Board™ with Valve Side Sub-D Example ......................................................................................15

3. Zoned Power......................................................................................................................................................... 16

3.1 503 Series Zoned Power application .....................................................................................................................16

3.2 503 Series Zoned Power example .........................................................................................................................17

4. Communication Module .......................................................................................................................................... 18

4.1 EtherNet/IP DLR Communication Module (Node) ...........................................................................................18

4.2 Communication Module Description...................................................................................................................19

4.3 Connector Pin-Outs............................................................................................................................................. 20

4.4 Electrical Connections .........................................................................................................................................21

4.5 Ground Wiring..................................................................................................................................................... 23

4.6 Power Consumption ............................................................................................................................................ 24

4.7 Diagnostics.......................................................................................................................................................... 26

5. G3 Graphic Display ................................................................................................................................................ 28

5.1 Main Menu Structure .......................................................................................................................................... 29

5.2 IP Address ........................................................................................................................................................... 30

5.3 Subnet Mask .........................................................................................................................................................31

5.4 Gateway IP .......................................................................................................................................................... 32

5.5 DHCP-BOOTP ................................................................................................................................................... 33

5.6 Config. Mode....................................................................................................................................................... 34

5.7 Web-Server........................................................................................................................................................... 35

5.8 MAC Address....................................................................................................................................................... 36

5.9 Advanced Settings –Comm. Fault ...................................................................................................................... 37

5.10 Advanced Settings - Brightness........................................................................................................................... 38

5.11 Advanced Settings –Flip Display........................................................................................................................ 39

5.12 Advanced Settings –Comm. Format................................................................................................................... 40

5.13 Advanced Settings –Parameters Lock .................................................................................................................41

5.14 Advanced Settings –Configuration Lock ............................................................................................................ 42

5.15 Advanced Settings –Quick Connect ................................................................................................................... 43

5.16 Advanced Settings –Compatibility Mode ........................................................................................................... 44

5.17 Factory Defaults .................................................................................................................................................. 45

5.18 Diagnostics.......................................................................................................................................................... 46

5.19 Diagnostics - Self Test Mode .............................................................................................................................. 47

5.20 Error Messages.................................................................................................................................................... 48

6. ARM –Auto Recovery Module (Optional) .................................................................................................................. 49

6.1 ARM process flowchart ....................................................................................................................................... 50

7. Distribution........................................................................................................................................................... 51

7.1 Sub-Bus Distribution Modules............................................................................................................................ 52

7.2 Sub-Bus Cables.................................................................................................................................................... 58

8. Digital I/O Module.................................................................................................................................................. 60

8.1 Digital I/O Module Usage .................................................................................................................................. 60

8.2 I/O Module Technical Data ................................................................................................................................61

8.3 I/O Module Descriptions and Menus................................................................................................................. 62

8.4 Digital Input Modules ......................................................................................................................................... 63

8.5 Digital Output Modules .......................................................................................................................................71