Panasonic Omnivision PV-C2540-K User manual

Other Panasonic TV VCR Combo manuals

Panasonic

Panasonic Omnivision VHS PV-M2046 User manual

Panasonic

Panasonic OmniVision PV-QM2508 User manual

Panasonic

Panasonic PVQ-1312W User manual

Panasonic

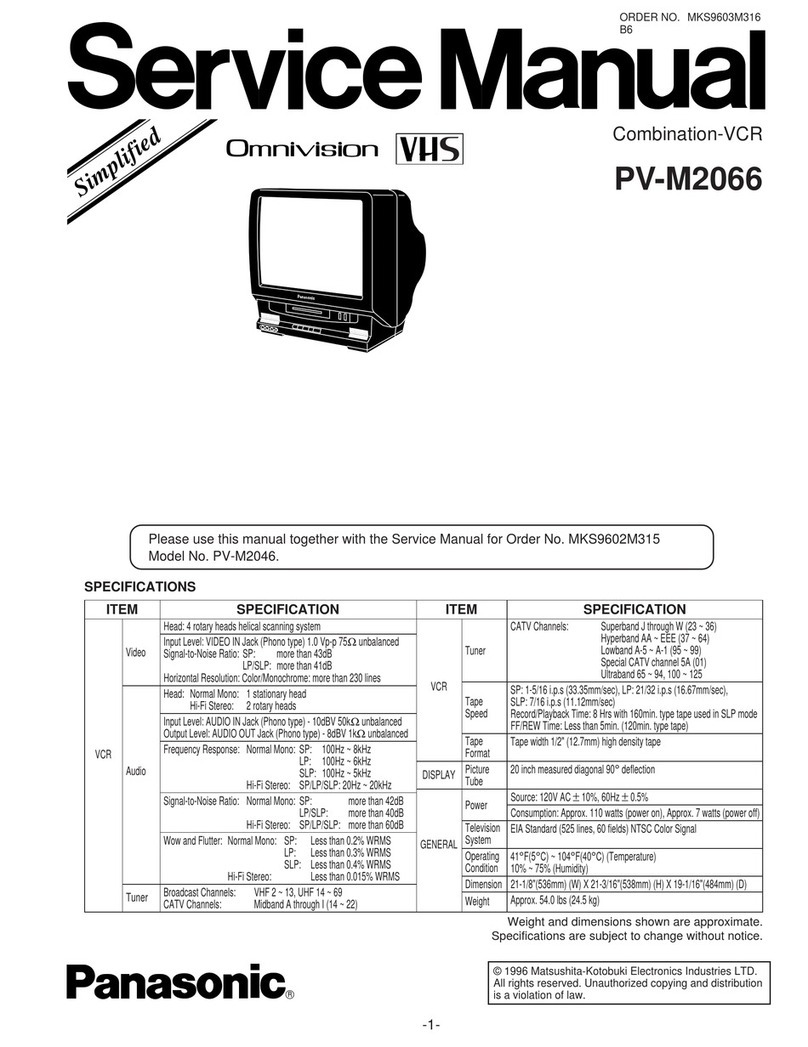

Panasonic OmniVision PV-M2066 User manual

Panasonic

Panasonic PV C2062 User manual

Panasonic

Panasonic AG527D - COMBINATION VCR User manual

Panasonic

Panasonic OmniVision PV-M2776 User manual

Panasonic

Panasonic PV-C2022 User manual

Panasonic

Panasonic PV C2023 User manual

Panasonic

Panasonic PV-C2541 User manual

Panasonic

Panasonic OmniVision PV-M1347 User manual

Panasonic

Panasonic PV-C2031W User manual

Panasonic

Panasonic OmniVision PV-Q1310 User manual

Panasonic

Panasonic Omnivision PV-M1378W User manual

Panasonic

Panasonic Omnivision VHS PV-C2780 User manual

Panasonic

Panasonic TX-29GV10 Series User manual

Panasonic

Panasonic Omnivision VHS PV-C1324 User manual

Panasonic

Panasonic Omnivision PV-C1320W User manual

Panasonic

Panasonic PV-M1367AD Operating User manual

Panasonic

Panasonic OmniVision PV-M2767 User manual