• This forced air furnace is equipped for use with natural gas at altitudes 0 - 10,0001:[ (0 - 3,050m), except 140 size furnaces are only approved for altitudes 0 - 7,000 ft.

(0 - 2,135m).

o An accessory kit, supplied by the manufiacturer, shall be used to convert to propane gas use or may be reduired for some natural gas applications.

e This furnace is for indoor installation in a building constructed on site. This furnace may be installed in a manufactured (nTabile) home when stated on rating plate and

using factory authorized kit..

o Thle furnace may be installed on combustible flooring in alcove or closet at _"ainimum Inches Clearar_ce To Combustible Construction as described below.

® This furnace requires a special venting system. Refer to the installation instructions for parts list and method of installation. This furnace is for use with schedule-40 PVC,

PVC-DV_v', CPVC, or ABS-D_AN pipe, and must not be vented in common with other gas-fired appliances. Construction through which vent!air intake pipes may be

installed is maximum 24 inches (60Omm), minimum 3/4 inches (19 mm) thickness (including roofing materials).

• Cetta foumaise A air pule6 est 6quip@e pour utilisatlen avec gaz natural et altitudes comprises entre 0 - 3,050m (0 - 10,000 pi),except6 queles fournaises de 140 taille

sent pour altitudes comprises entre 0 - 2,135m (0 - 7,000pi).

• Utilleer une trousse de conversion, foumle per le fiabrleant, pour passer au gaz propane ou pour certaines instNlations au gaz naturel.

o Cetta foumaise A air pule6 est pour installation A Hnt6rieur dans un bgtiment construit sur place. Cetta foumaise _ air pulse peut 6tre instalk_e dans une maison

pr6fiabdqu6e (maison mobile) si prescrit par la plaque signal_,tique et si I'on utilise une trousse specifi6e par le fabrleant.

¢ Cette foumaise peut 6tre install6e sur un plancher combustible dans un enfoncement ou un placard en observa!]t los D_gagement Minimum EB Pouces Avec

EI6rnents De Construction Combustibles.

• Cetta fournaise n6cessita un systeme d'6vacuatlen sp6cial. La m6thode d"installation et la Ilete des pi@ces n6cessaires figurent darts los instructions d'installation. Cette

foumalee doit s'utilleer avec la tuyautarie des nomenclatures 40 PVC, PVC-DWV CPVC ou ABS-DWV et ella ne peut pas 6tre ventil6e conjointment avec d'autres

appereils _ gaz. Epeleseur de la construction au travers de laquelle il est possible de faire passer los tuyaux d'a6ratlen (admission/6vacuation): 24 po (600 ram)

maximum, 3/4 po (19mm) minimum (y compris la toiture).

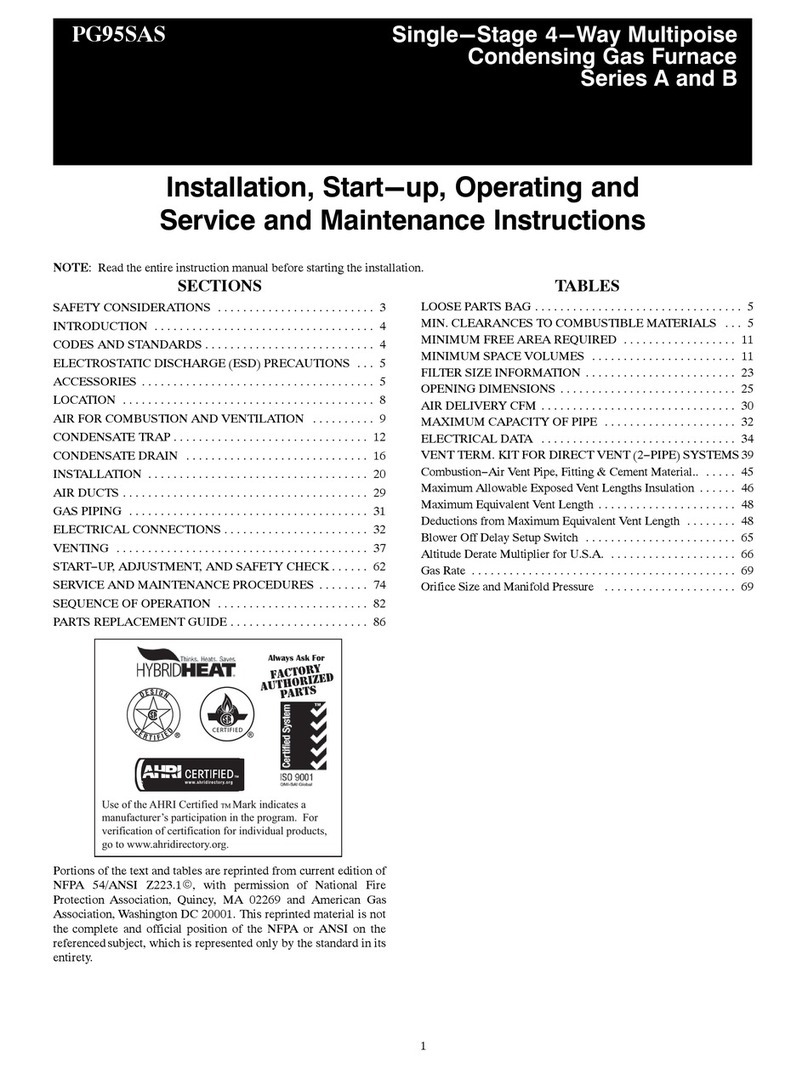

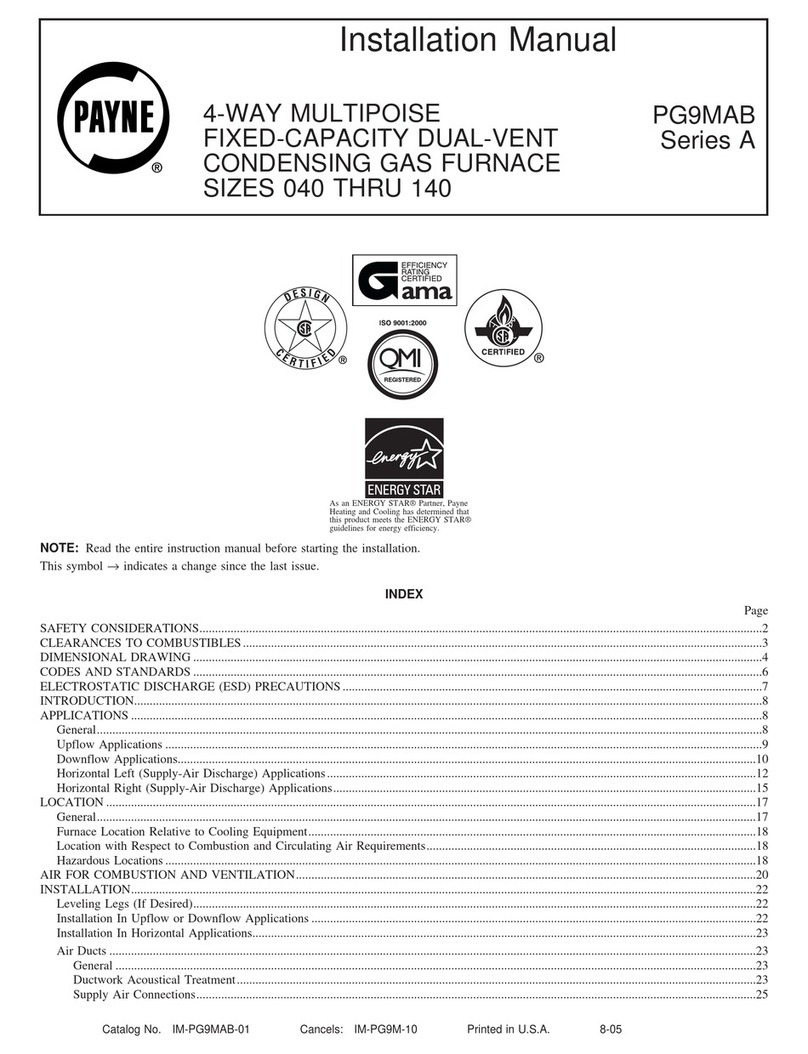

For upflow and dewnflow applications, furnace must be installed level, or pitched within 1/Z' of level. For a MIN 1/4" TO 1/2" MAX

horizontal application, the furnace must be pitched minimum 1/4" to maximum of 1/2" forward for proper

drainage. See Installation Manual for iMPORTANT unit supper[ details on horizontal applications.

Pour des applications de flux ascendant et descendant, le fournalee deit 6b_ install@e de niveau ou inclin6e

pes plus de 1/Z' du niveau. Pour une application horizontale, la foumaise doit _,tre indin6e entre minimum

1/4' et maximum 1/Z' du niveau pour le drainage appropri& En cas d'installation en position horizontale,

censultar lea renseignercents IM PORTANTS sur le support dans le manuel d'installation. HORIZONTAL

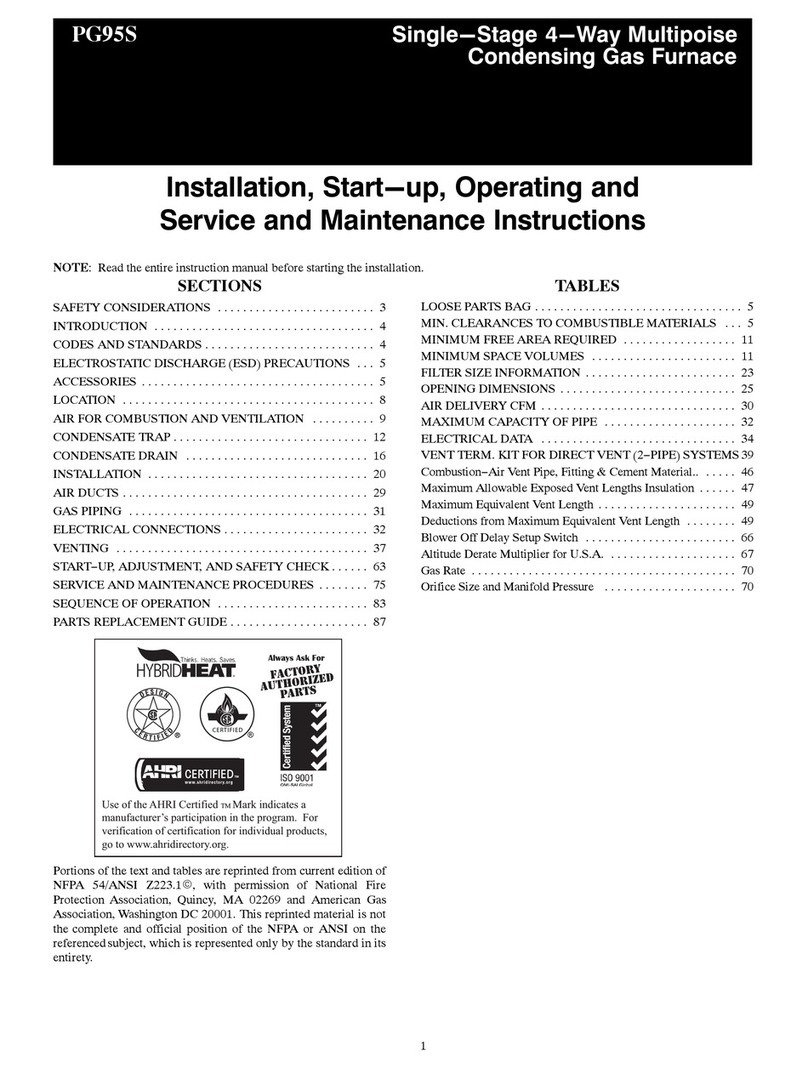

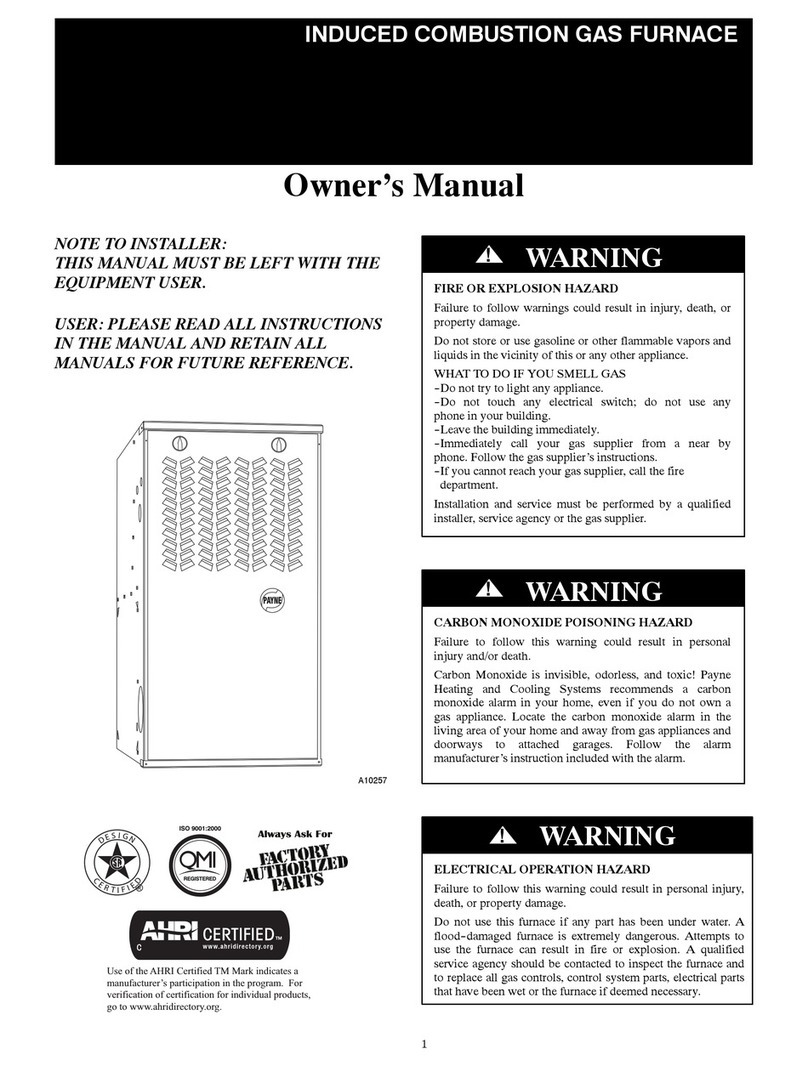

NININUM INCHES CLEARANCE TO COMBUSTIBLE CONSTRUCTION

ALL POSITIONS:

Minimum front clearance for service 24 inches (610ram).

? 1- 140 size furnaces require 1 inch back clearance to combustible materials.

DOWNFLOW POSITIONS:

1- For installatiorl on combustible floors only when installed on spedal base No. KGASB0201ALL

Coil Assembly, Part No. CD5 or CK5, or Coil Casing, Part No. KCAKC.

HORIZONTAL POSITIONS:

Line corRaet is permissible only between lines formed by intersections of top and two sides d

furnace jacket, and building joists, studs, or framing.

§ Clearance shown is for air inlet and air outlet ends.

O 120and 140 size fumaces require 1 inch bottom clearance to combustible materials.

DEGAGEMENT MINIMUM EN POUCES AVEC ELEMENTS DECONSTRUCTION COMBUSTIBLES

POUR TOUS LES POSITIONS:

Degagement avant minimum de 610mm (24 po) pour I'entretien.

1- 1- Pour les fournaises de 140 taille, 1 1_ (25mm) d6gagerT_ent des matedaux combustibles set

requis au-ardere.

POUR LA POSITION COURANT DESCENDANT:

1- Pour Hnstallation sur le plancher combustible seulerT_nt quand on utilise la base sp_ciale, piece

n ° KGASB0201ALL rensemble serpentin, pi6ce n ° CD5 eu CK5, eu le carter de serpentin,

pi6ce n ° KCAKC.

POUR LA POSITION HORIZONTALE:

Le contact n'est permis q0entre les lignes forrnees par les intersections du deseus et des

deuxc6tes de la chemise de la fournaise, et des solives, des montants eu de la charpente du

batiment.

§ La distance indiquee concerne I'extr@mite du tuyau d'arfivee d'air et I'extremite du tuyau de sortie

d'air.

Pour les fournaises de 120 et 140 taille, 1 po (25ram) degagement des materiaux cembusitbles

set requis au_desseus.

This furnace is approved for U PFLOW, DOWN FLOW and

HORIZONTAL installations.

Cette foumaise est approuv¢e pour I'installatlen HORJZONTALE

et la drculation d'atiVERS LE HAUT et VERS LE BAS.

Clearance arrows J_gagement

do not change with ne c.hange pas avec

furnace orientation, I'0rientation de la

g_n@ateur d'air d-_aud,

Vent dearance to

combustibles 0".

Clearance in indqes 0 (po) Dg_Jagement

D@gagement (po). d'@vent avec combustibles.

328066-201 REV. B LIT TOP

J

A04110

Fig. !--Clearances to Combustibles

These instr_ctions cover the minimum requirements and conform to existing national standards and sa_ty codes. In some instances, these

instructions exceed certain local codes and ordinances, especially those that may not have kept up with changing residential cop.strtlction practices.

We require these instructions as a minimum for a safe installation.

Wear safety glasses and work gloves. Have a fire extinguisher available during startoup and adjustment procedures and service calls.

Z_ CAUTION: CUT HAZARD

Failure to follow this caution may result in personal injury.

Sheet metal parts may have sharp edges or burrs, Use care and wear appropriate protective clothing and gloves when handling parts,

Recognize safety in_brmation This is the safety-alert symbol Z_x. When you see this symbol on the unit and in instructions or manuals, be alert

to the potential for personal injury.

Understand these signal words DANGER, WARNING, and (AUTION. These words are used with the sa_Ytyoalert symbol. DANGER identifies

the most serious hazards which wi_]l result in severe personal injury or death. WARNING signifies hazards which could result in personal ir_jury

or death. CAUTION is used to identi_}g unsafc practices which may result in minor personal injury or product and property damage. NOTE is used

to highlight suggestions which wil_ result in enhanced installation, reliability, or operation.

The PGgM Multipoise (ondensing Gas-Fired Furnaces are (SA (fermerly AGA and CGA) designocertified J_br natural and propane gases (see

_imaace rating plate) and for installation in alcoves, attics, basements, closets, utility rooms, crawlspaces, and garages. The ftmaace is

_hctory-shipped f_r use with natural gas. A (SA listed gas conversion kit is required to convert furnace _br use with propane gas.

See Fig. 1 for required clearances to combustibles.

3