Pelsis CURTIS DYNA-FOG HURRICANE ES HESUK User manual

230V electrostatic fogger

USER MANUAL

CURTIS DYNA-FOG warrants to the original purchaser for

two years after the date of purchase that its products

are free from manufacturing defects. Should any defect

appear and be the subject of a written notice from

purchaser, received by CURTIS DYNA-FOG within the

two-year period, CURTIS DYNA-FOG at its option will

repair, replace or send replacement parts for the defective

product at its expense. If repair parts are necessary, these

could be either new or remanufactured, but all shall be of

new quality.

The foregoing is the sole and exclusive remedy for any

breach of warranty by CURTIS DYNA-FOG. This warranty

does not cover cosmetic damage or damage due to

the Acts of God, accident, misuse, abuse, normal wear

or negligence to the product. THE IMPLIED WARRANTIES

OF MERCHANTABILITY AND FITNESS FOR PARTICULAR

PURPOSE ARE EXCLUDED AND CURTIS DYNA-FOG SHALL

HAVE NO LIABILITY FOR ANY CONSEQUENTIAL, INCIDENTAL

OR SPECIAL DAMAGES EVEN IF CURTIS DYNA-FOG WAS

APPRISED OF THE POSSIBILITY THEREOF. In no event shall

CURTIS DYNA-FOG’s liability hereunder exceed the amount

of the purchase price paid for the product. Any warranty

claim must be accompanied by proof of purchase such

as a sales receipt, serial number or receipted invoice to

establish that the product is within the warranty period.

WARRANTY

Limited Warranty

1.0 MAIN COMPONENTS DIAGRAM - HURRICANE ES

CARRYING HANDLE

AIR INTAKE AREA

ON/OFF SWITCH

WITH LIGHT

HIGH CAPACITY

CHARGING SYSTEM

REMOVABLE FILLING

CAP WITH TETHER

ADJUSTABLE

LOCKING DEVICE

STAINLESS STEEL

PRECISION METERING

VALVE WITH FILTER

THREE (3) PRECISION

NOZZLES FOR GREATER

OUTPUT CAPACITY

TRANSLUCENT

CORROSION

AND IMPACT

RESISTANT

HDPE TANK

2.0 SAFETY PRECAUTIONS

(It is the Operator’s responsibility to read and understand the Cautions and Warnings in this manual before attempting to

operate the machine.)

CAUTION

Important: The Hurricane ES has been designed and engineered to be very safe during normal operation. As with all AC

powered equipment, certain safety precautions should be taken. Please read the following WARNINGS before operating the

machine.

.

UNDERSTAND THESE SAFETY PRECAUTIONS BEFORE OPERATING THIS MACHINE. FAILURE TO PROPERLY FOLLOW

THESE PRECAUTIONS MAY LEAD TO A FIRE, EXPLOSION, OR ELECTRICAL SHOCK HAZARD.

MODEL

HESUK 10001

SERIAL

UNITED STATES PATENT: 4,177,949

CANADIAN PATENT: 1,101,381

230V – 50Hz – 4.15A - POWER 930W

DISCONNECT THE POWER SUPPLY BEFORE SERVICING

Pelsis Ltd, HG5 8PJ, UK | Pelsis Belgium NV, Bornem 2880

WARNING

Read and understand

operator’s manual and all

other safety instructions

before using this equipment.

WARNING

Always have the machine serviced by a professional, qualified representative. Never attempt to service

the machine or access its internal components while it is plugged into an electrical outlet.

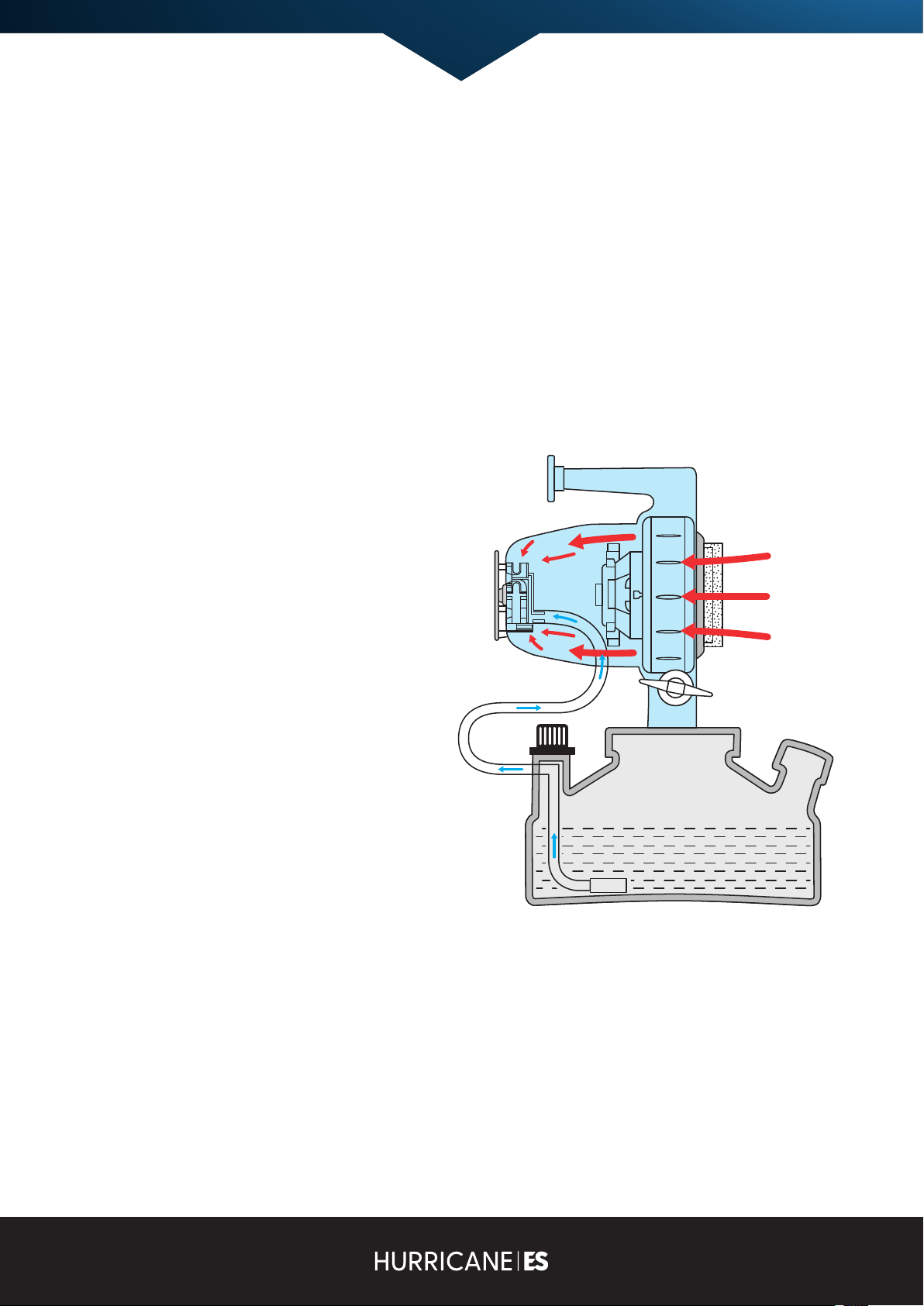

CAUTION

To avoid electrostatic shock, do not

touch the metal charging ring or

3-prong electrode located at the

nozzle while the machine is operating.

Charging Ring

3-Prong Electrode

This machine contains an electrostatic device that may interfere with sensitive medical devices such as pacemakers and

defibrillators, etc. DO NOT operate this machine or stand within 3 metres if you use any such medical devices. Contact your

physician prior to operation if you are unsure if this machine will interfere with your medical device.

This machine contains an electrostatic device that may cause an electrical shock if not properly grounded. Always use a

three (3) prong grounded extension lead at the ratings shown in the table when using an extension lead.

Hold the appliance when operating so that your hand remains in contact with the grounding strip located underneath the

carrying handle. Leaving the appliance unattended while in operation can cause a build-up of electrostatic charge that can

cause a static shock. Note: Objects in the vicinity of the machine may develop an electrostatic charge during operation.

WARNING

Please read and understand these safety precautions before operating this appliance. Failure to properly follow

these precautions may lead to a serious incident, such as a fire, explosion, or electrical shock hazard.

1. Electric Power.

Precautions:

This machine uses electrical power at common commercially available voltages. When directly contacted, such voltages

are hazardous to human life. All precautions commonly applicable to the use of the electric power are generally applicable

to the use of this appliance. This appliance is designed to operate from three wire power systems where one of the wires is

a safety ground. Use a GFCI (Ground Fault Circuit Interrupter) power outlet whenever possible. Do not disconnect the safety

ground or use extension leads or “cheater” plugs to connect this machine to a two-wire system. This machine must be used

with a 3-prong grounded extension lead plugged into a grounded electrical supply.

Extension Leads:

Extension leads must be properly sized and rated for the voltage, current, and length of an individual lead. Consult the

nameplate current and voltage rating of your machine and the marked rating of the extension lead. A single extension lead

only should be used. When two or more extension leads are placed in a series, the rated current carrying capacities of the

leads may no longer be valid. If an extension lead becomes warm to touch, discontinue its use and obtain a lead with a

higher current rating. Improper extension leads are not only hazardous, but may result in poor machine performance due to

excessive voltage drop.

2. Formulations.

This machine is designed for water formulations only. Do not use flammable formulations with this machine and do not spray

it near sources of admission. Oil based formulations must not be used.

3. Aerosol Concentration.

An acceptable level of liquid in the atmosphere is 2.7 litres per 1,000 cubic metres. There is a safety margin of at least 5 to 1

in this figure.

4. Aerosol Ignition.

If a combustible atmosphere is established or a combustible deposit is laid down, a source of ignition may cause a fire. It is

Carrying Handle

Grounding Strip

strongly recommended that all such sources be eliminated in the appropriate manner. To avoid danger of fire or explosion in

an enclosed space, the enclosed volume fogging time and required formulation volume should be carefully calculated. While

operating the machine, always carry the machine by the carrying handle to ensure that you are properly grounded.

5. Proper and Improper Use.

The following rules apply to the operation of this machine:

DO read the entire manual before operating the machine and pay particular attention to all

CAUTIONS AND WARNINGS

•Only use water-base formulations with this machine

•Store formulation in its original labelled container.

•Only use a 3-prong grounded extension lead which is properly rated for voltage, current, and length and which is

free from nicks, cracks, and other signs of prior abuse. For lengths up to 30.5 metres. Leads with No. 12 AWG wire are

adequate.

•Turn off the appliance before unplugging. Unplug by grasping the plug. Do not pull on the lead to unplug. Do not unplug

machine with wet hands.

•Replace damaged or worn electric lead immediately.

•Turn the flow valve CLOCKWISE to the OFF position after each fogging application while the motor is still operating to

allow clearing of the lines.

•Always comply with any requirements for protective clothing, goggles, facial masks, or respiratory equipment required

by the formulation label.

•Ensure that formulation is applied only in strict compliance with the formulation label.

DO NOT

•Do not use oil-based or flammable formulations with this machine.

•Do not use a machine that is broken or damaged in any way.

•Do not alter the machine by adding or removing parts.

•Do not restrict the motor blower air intake area.

•Do not tamper with the output nozzle or 3-prong electrode and charging ring (collector).

•Do not allow the machine to operate unattended.

•Do not stand in water or hold over water while operating machine.

•Do not allow the power lead or extension lead to be submersed in water.

•Do not use outdoors when it’s raining.

•Do not apply more than 2.7 litres per 1,000 cubic metres in an enclosed space. Exceeding this concentration is both

hazardous and wasteful.

•Do not touch the 3-prong electrode while the machine is operating.

3.0 SPECIFICATIONS

Description

The Hurricane ES™ machine is an electrostatic “Cold Fog” ULV/Mister that utilises a 3-nozzle air-assist design. This device

is intended for applications of Water-Base formulations. The body and tank are made of high-density chemical resistant

polyethylene. The applicator is useful for dispensing most chemicals which are labelled for aerosol or mist applications such

as disinfectants, deodorizers, germicides, insecticides, etc., in locations such as hospitals, schools, nursing homes, greenhouses,

stables, warehouses, homes, and farm buildings. The particle sizes generated range from 10 to 50 microns VMD, obtained

using water. Machine output and particle size are dependent upon the viscosity of the liquid being dispensed. See table 2 for

particle size vs. valve setting (flow rate).

Hurricane™ ES HESUK

Hurricane™ ES HESEU

Motorized Blower:

High efficiency Motor/Blower

Brush Life: Approximately 1000 hours

Electrostatic Power Supply:

230V

Current Draw:

230V

3.40 A

50Hz

Nozzle Type:

Professional grade electrostatic, 3 nozzle,

air assist (vortical type)

Droplet Size:

10-50 Microns VMD (adjustable)

Flow Rate:

0-120 ml/min using water

Droplet throw distance*:

4.5 metres

*Distance is based on indoor use and will vary

depending on droplet size and formulation type.

Smaller droplets (i.e. 20 Microns) can carry much

greater distances than larger droplets.

Tank Capacity:

3.8 litres

Tank Material:

High Density Polyethylene

Weight Empty:

3.4 kg

Shipping Information:

42 cm L X 32 cm W X 47 cm H

Weight:

4.3 kg

Figure 3

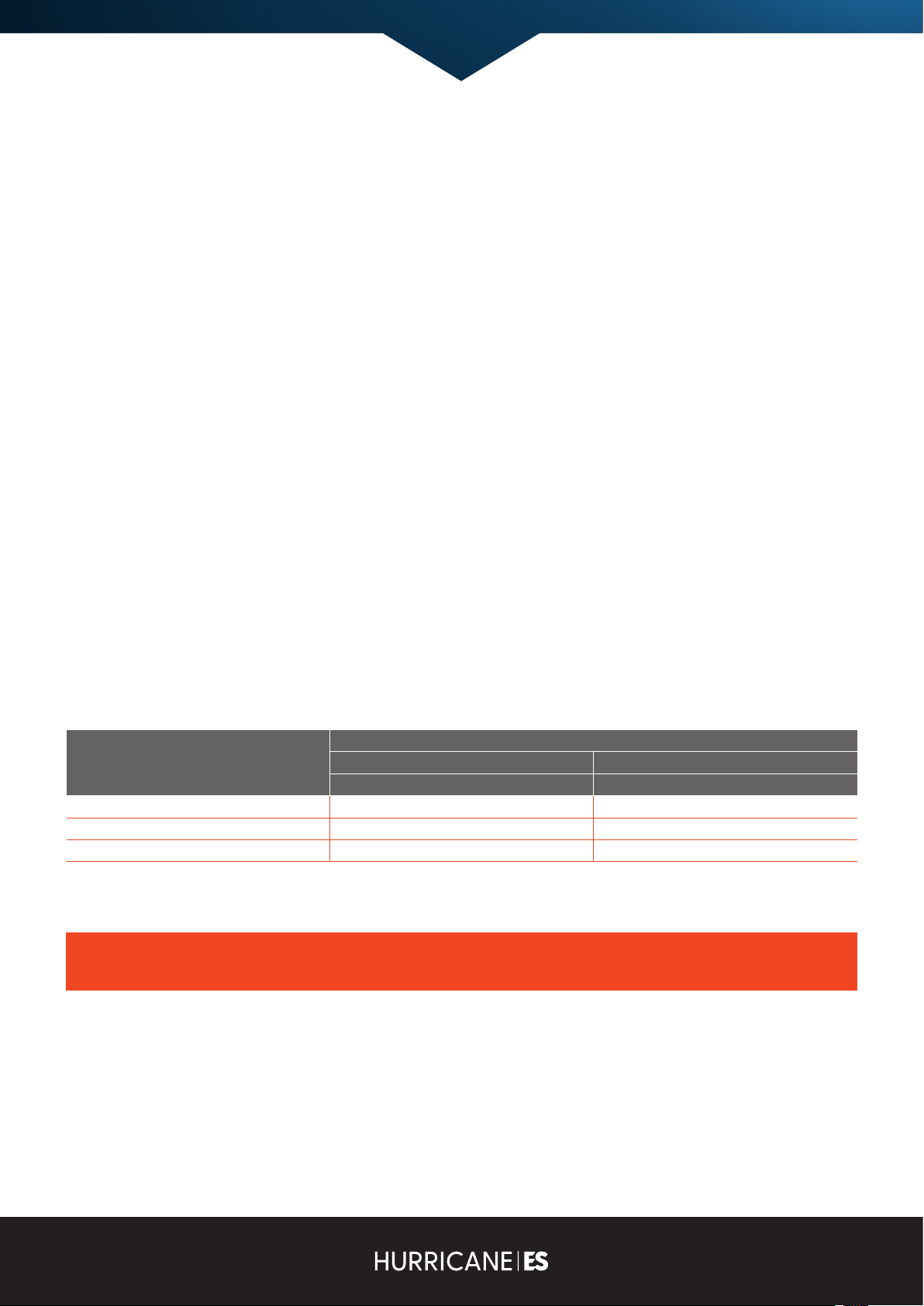

4.0 Principles of Operation - Hurricane ES

•This machine consists of a motor/blower assembly, high voltage power supply, charging ring and electrode, blower

housing, a nozzle, formulation tank and metering valve.

•The blower is a two-stage centrifugal compressor driven by a universal motor operating at a speed of 20,000 rpm.

•The blower moves a large amount of air through the nozzle system.

•The nozzle has six (6) stationary fins, which direct the air to create a swirling effect of the air mass as it leaves the nozzle.

•In the centre of this exiting swirling air, a liquid supply spout tube injects formulation.

•The liquid is delivered to the nozzle by a negative pressure at the nozzle caused by the exiting air mass.

•The flow rate is controlled by a one turn precision metering valve located at the formulation tank.

•Generally, the sizes of the output droplets increase with increasing flow rates and with increasing viscosity of the liquid

being dispensed.

•After the nozzles shear the formulation into billions of droplets, the droplets are dispersed into the atmosphere. As the

droplets exit the nozzles they pass through an “electrostatic ion field”.

•This field is created using the combination of a high voltage power supply, an emitting electrode and charging ring (Collector).

The result is billions of electrostatically charged droplets that gravitate to neutral objects to form a uniform coverage.

5.0 Flow Rates, Droplet Sizes and Applications

Liquid flow rate of the Hurricane ES is created by the suction caused by the design of the 3 nozzles. The Flow rate

is regulated by adjusting the metering valve. The liquid flow rate can be increased by rotating the metering valve

anticlockwise and decreased by rotating it clockwise.

There are three flow indicator marks on the side of the tank that designate position 1, position 2 and position 3. All flow rate

information is based on using water with a temperature of 21 C. Increasing the viscosity will decrease flow rate and can

increase droplet size.

Refer to the table below for approximate flow rates and droplet sizes at the various valve settings. Droplet sizes are shown

in microns VMD (Volume Median Diameter). The VMD is an industry standard and represents the “middle point” of the spray

droplet spectrum of the liquid being applied.

Metering Valve Setting

Hurricane ES Flow Rate And Droplet Size

Flow Rate Droplet Size

mL/Min Microns - Volume Median Diameter

#1 60 10 - 20 MICRONS

#2 90 20 - 30 MICRONS

#3 120 30 - 50 MICRONS

IMPORTANT

To maximise electrostatic efficiency, only use Water-Based formulations with the Hurricane ES.

Warning: To prevent damage to sensitive objects or surfaces such as wood finishes, carpeting, and upholstery.

Do not over apply the formulation being sprayed. If in doubt, always perform a spray test on a small area to check

the effects prior to doing the actual spray treatment.

5.1 Insect Control

Depending on the target insect, droplets are generated in the 10-30 Micron range so that even with some evaporation and

settling time, the droplets remain in the correct range for optimal air born suspension and insect impaction. In dry climates

evaporation will tend to cause droplets to “shrink”. Therefore, it may be necessary to increase flow rate to get adequate

coverage. The smaller the droplet size the greater the number of droplets that are created. For example: If 1 millilitre of spray

is dispersed as 20 Micron droplets, there will be 239 million droplets produced. For the same spray mixture using 100 micron

droplets, only 1.91 million will be produced. The large quantity of droplets greatly increases the chances of contact being

made with the insect.

Droplet Size (Microns) Time to fall 10 metres Droplet Density (no/cm3)

1 93.7 hours 19120.0

5 3.7 hours 152.0

10 56 minutes 19.2

20 14 minutes 2.38

50 135 seconds 0.150

100 36 seconds 0.0192

The recommended droplet for Mosquito control is 10-20 Microns. For Fly control approximately 30 Microns. For Bedbugs,

spiders and other crawling insects where a slight residual is desired, 20-40 Microns droplets are effective depending on

insect type and type of formulation being used.

5.2 Odour Control

Depending on the type of environment and odour source, droplets for controlling odours can be in the 20-30 Micron range

and even larger if a “residual affect” can be tolerated.

5.3 Disinfecting

Disinfectants are designed to be applied to non-living objects to destroy microorganisms. Typically, a disinfectant for objects

or surfaces is more affective when applied in the 30-50 micron range. However, smaller size droplets in the 10-20 micron

range can be effective when targeting microorganisms suspended in the air.

Formulation Tube

Metering Valve

Approximate flow rates for the valve

position settings are as follows:

Position Flow rate* Droplet Size (Microns)

1 60 ml/min 10-20

2 90 ml/min 20-30

3 120ml/min 30-50

*Flow rates shown are approximate and will vary depending on liquid viscosity and temperature.

Important: Always spray responsibly. This device is designed to dispense

formulations in a SPRAY (Cold Fog). Always calibrate your machine

to the proper flow rate in accordance with the formulation labels

recommended rate prior to doing any spray application.

POSITION APPLICATION

1 INSECTICIDE

2 DEODORISER

3 DISINFECTANT

CAUTION

READ AND FOLLOW THE INSTRUCTIONS ON THE

FORMULATION MANUFACTURER’S LABEL AND IN THE

OPERATION MANUAL!

THIS DEVICE DISPENSES FORMULATIONS IN ASPRAY (COLD

FOG) OR MIST. MANY FORMULATIONS WHICH MAY BE

DISPENSED WITH THIS DEVICE REQUIRE FEDERAL AND/OR

STATE REGISTRATION. ALWAYS USE THE APPROPRIATE SAFETY

EQUIPMENT AS SPECIFIED ON THE FORMULATION LABEL.

6.0 Maintenance

1. Periodically clean the formulation tank using a hot water/detergent solution. Fully open the machine valve and operate

the machine for 3 to 5 minutes, flushing the solution through the valve, lines and nozzle.

2. Examine the electrical lead for evidence of damage and replace any damaged lead immediately.

3. Clean the Air Intake Filter after every application. If the filter gets saturated (wet and dripping) while the machine is

working, stop the machine and clean the filter.

7.0 Noise Level

The Hurricane ES noise levels do not require hearing protection, however, we would still recommend it, especially when using

it for prolonged periods or in enclosed spaces.

This manual suits for next models

1

Table of contents