Mower

CAT DISC 33

( Type PTM 372 : + . . 01001 )

GB Excerpt from

operating manual Nr. 0372B00C.pdf

Table of contents

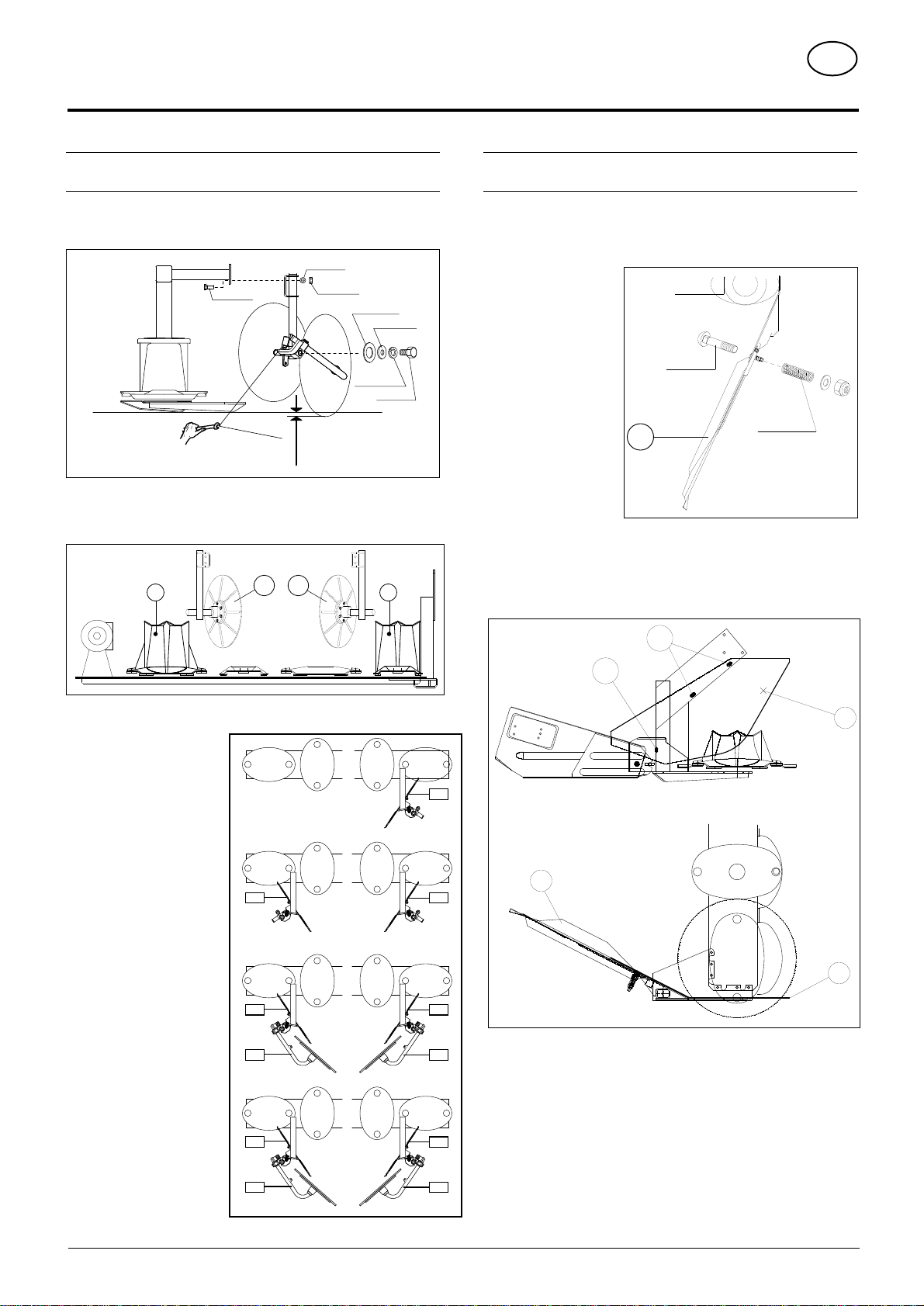

Swath Discs ......................................................................................................... 13

Swath Boards....................................................................................................... 13

Safety points......................................................................................................... 14

General maintenance hints .................................................................................. 14

Cleaning of machine parts ................................................................................... 14

Parking in the open .............................................................................................. 14

Winter storage...................................................................................................... 14

Drive shafts .......................................................................................................... 14

Angular gear......................................................................................................... 14

Quantity: ............................................................................................................... 14

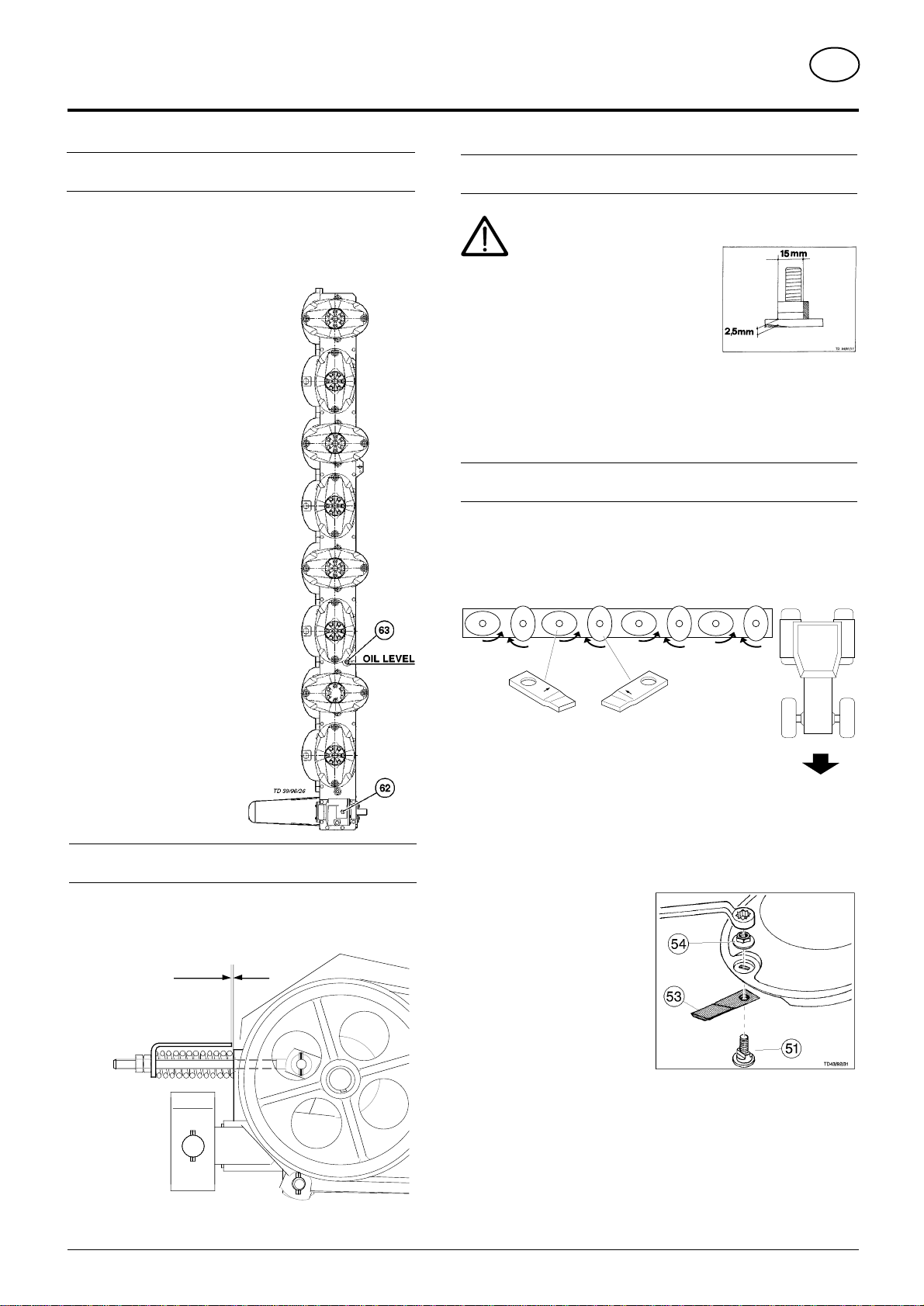

Cutter bar ............................................................................................................. 15

Oil level check ...................................................................................................... 15

Topping up (replenishing) oil ................................................................................ 15

Changing oil ......................................................................................................... 15

Quantity: ............................................................................................................... 15

V-belt Drive........................................................................................................... 15

Cutter blades and blade bolts............................................................................... 15

Installing cutter blades ......................................................................................... 15

Technical data ...................................................................................................... 16

The defined use of the mower unit....................................................................... 16

Position of Vehicle Identification Plate.................................................................. 16

Optional equipment: ............................................................................................. 16

Repairs on the cutter bar.................................................................................... R-1