8

9.

14.

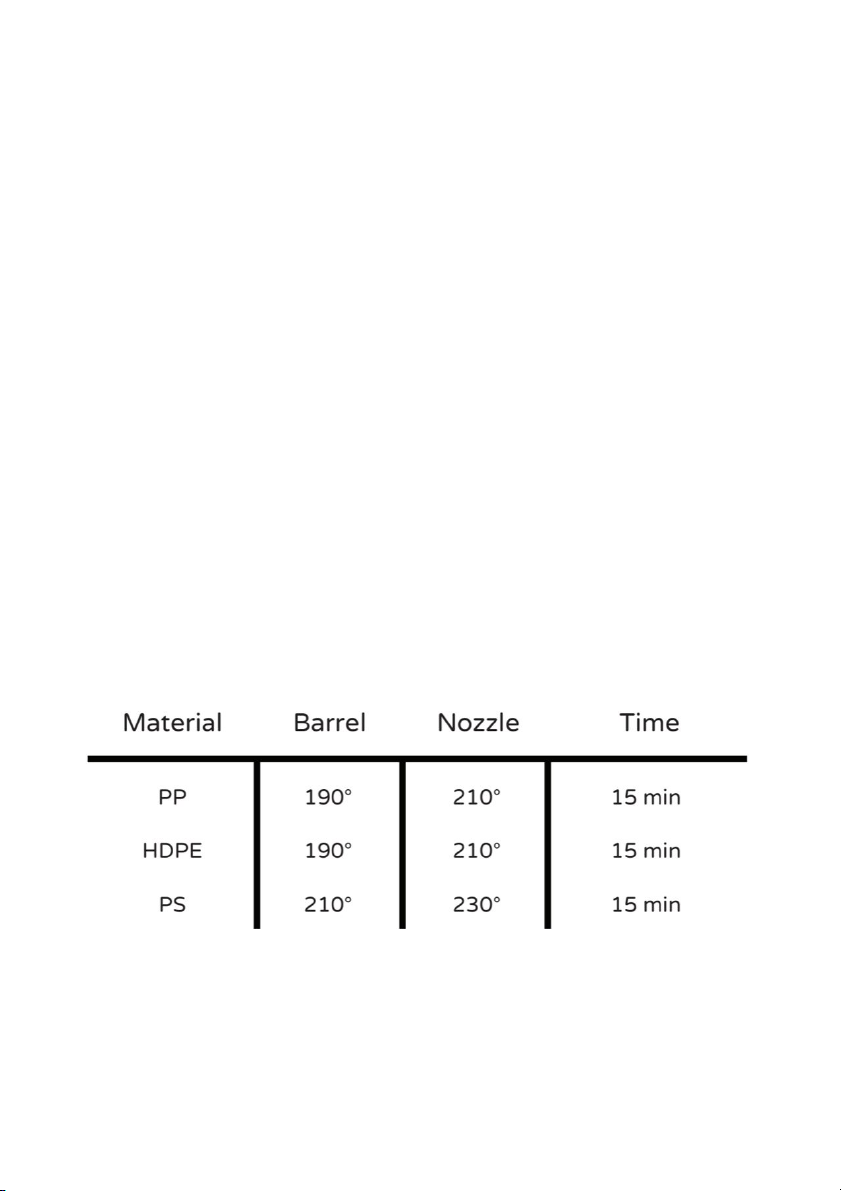

Tip: Depending on the plastic type, you’ll need one or sometimes two

people to pull down the lever. Before injecting into the mould, make sure

the plastic in the barrel is completely melted in order to fill all areas of the

mould. To ensure this you can remove the nozzle cap and gently push the

lever down to let a little bit of plastic come out to check the consistency. If

it's not the desired consistency, increase 5 degrees at the time until you

achieve the desired consistency (*Warning*: Plastic should never be in a

liquid state, this means plastic is burning and can be very dangerous for the

operator and can cause very serious burns).

Cooldown