primatech SECOR d User manual

METHANE GAS AND CARBON

MONOXIDE DETECTOR

USER’S MANUAL

Methane Gas (CH4) and

Carbon monoxide (CO)

Dual Detector

by

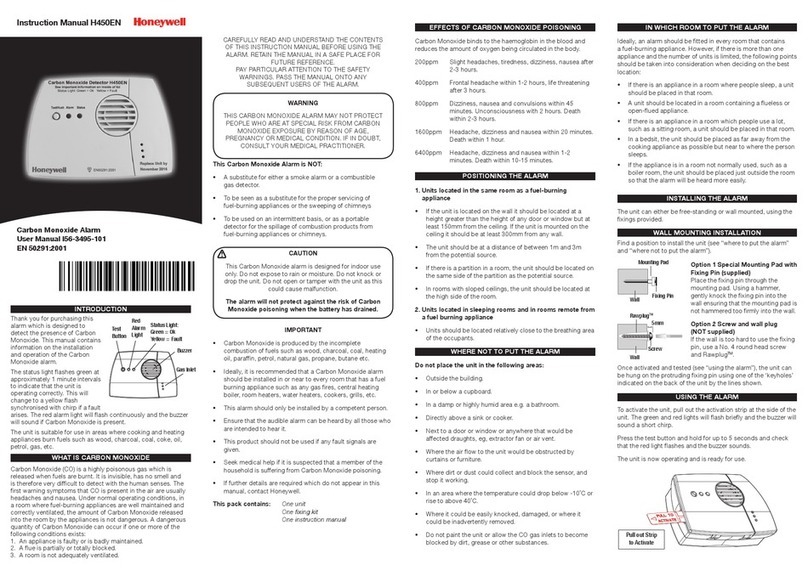

WARNING! Please read the manual carefully

before installation of the detector.Failure to

follow instructions will lead to loss of warranty.

Dual Detector for Methane (CH )

4

and Carbon Monoxide (CO)

TABLE OF CONTENTS

TECHNICAL SPECIFICATIONS............................................2

WHAT YOUR METHANE GAS AND CO DETECTOR CAN

AND CANNOT DO..............................................................3

WHERE TO INSTALL YOUR METHANE GAS AND CO

DETECTOR..........................................................................5

WHERE NOT TO INSTALL YOUR METHANE GAS AND CO

DETECTOR..........................................................................6

CONNECTION METHODS.................................................9

OPERATION......................................................................12

TESTING THE DETECTOR................................................13

MAINTENANCE................................................................13

DETECTOR LIFETIME.......................................................15

TECHNICAL SPECIFICATIONS:

Sensor: Semiconductor SnO2

Power supply: 230 V AC (-15% +10%) 50/60 Hz

Detected gas: methane and carbon monoxide

Methane Gas sensitivity: 3% - 20% LEL

Alarm before 3 min: 300 ppm Carbon monoxide

concentration

Initial delay time: 2 min 30 sec

Indicators:

Green LED: Power supply

Red LED: Carbon Monoxide Visual alarm

Red LED: continuous – Methane gas visual alarm

flashing – normal operation

BUZZER: acoustic alarm – min. 85 dB at 1 m

Sensor lifetime: 5 years

Contact ratings:

8(2) A @ 250 V AC SPDT

3A @ 250 V AC SPST (optional)

Operating temperature: -10° C ÷ +40° C

Storage temperature: -20° C ÷ +50° C

Humidity limits (non-condensing): 20% - 90% RH

Protection Grade: IP 42

Case:

Material: ABS V0

Color: white

Size: 115 x 75 x 43 mm (W x H x D)

Weight: 300 g

2

WARNING! The installation of the detector in an area

where it is not recommended for it to be installed can

affect sensor operation.

WARNING! Do not tamper with the detector, since

this may stop the detector working or cause an

electric shock hazard.

WHAT YOUR METHANE GAS AND CO

DETECTOR CAN AND CANNOT DO

This unit is designed to sense unacceptable levels of gas

from malfunctioning furnaces, appliances or other

sources. This unit will provide early warning of the

presence of gas, usually before a healthy adult would

experience symptoms.

It will provide warning of a gas condition when a

concentration between 3% and 20% LEL for methane is

detected, before the gas concentration reaches a

dangerous level for triggering an explosion.

In the case of an apartment with several rooms with open

doors on the same floor or different floors, the gas

concentration will be higher in the room where the leak

occurs and will decrease in the other rooms further away

from the origin of the leak. The detector cannot detect a

gas leak which has been produced on another level of the

building. The gas detector will indicate the presence of gas

only in the proximity of the sensor, but the gas can be

located in other areas too. The detectors have limitations.

Like any other electronic device, gas detectors are not

foolproof. 3

You must test your gas detector monthly.

If your Gas Detector fails to test properly, or if its self-

diagnostic test reveals a malfunction, have the unit

replaced immediately. It's important to safeguard your life

from carbon monoxide(CO) gas because it is impossible to

see, taste, or smell the toxic fumes of CO. CO accidentally

kills people each year.

Most confuse the symptoms of CO exposure with the flu

or food poisoning as the symptoms are similar. Exposure

to CO can impede coordination, worsen cardiovascular

conditions, and produce fatigue, headache, weakness,

confusion, disorientation, nausea, and dizziness. High

levels of CO exposure can result in death. Homeowners

should be aware of the risks of CO exposure.

CO is produced as a result of incomplete burning of

carbon-containing fuels including coal, wood,charcoal,

natural gas, propane, and fuel oil. CO can be emitted by

combustion sources such as unvented kerosene and gas

space heaters, leaking chimneys and furnaces, back-

drafting from furnaces, gas water heaters, wood stoves,

and fireplaces, gas stoves, generators and other gasoline

powered equipment, automobile exhaust from attached

garages, and tobacco smoke.

4

WHERE TO INSTALL YOUR METHANE GAS AND CO

DETECTOR

The gas detector should be installed in the room where

a gas leak is most likely to occur. This may be the kitchen

because of the presence of a gas cooker and other gas

appliances.

The gas , lighter than air, tends to rise and fill all the

volume above the level of the leak. Also several factors

may modify this behavior, such as heat sources and

ventilation. In general the concentration above the level

of a leak will be equal to or greater than the

concentration below.

It should be possible to view all the light indicators and

hear the alarm,in case of a leak, when you are in the

vecinity of the chosen location of the detector.

The gas detector should be installed above the level of a

possible gas leak and near the ceiling (typically 30 cm from

the ceiling), in a place where air movements are not

impeded by furniture and furnishings.

5

The detector should be at horizontal distance of between

1 m and 3 m from the potential source.

If there is a partition in a room, the detector should be

located on the same side of the partition as the potential

source.

The detector in room with sloped ceiling should be

located at the highest side of the room.

The detector located in sleeping room or in room remote

from the fuel-burning appliance should be located

relatively close to the breathing zone of the occupants.

WHERE NOT TO INSTALL YOUR METHANE

GAS AND CO DETECTOR

The detector should not be installed:

- in an enclosed space (for example in a cupboard or

behind a curtain);

- where it can be obstructed (for example by furniture);

- directly above a sink;

- next to a door or window;

- next to an extractor fan;

- next to an air vent or other similar ventilation

openings;

- in an area where the temperature may drop below -

10°C or exceed +40°C;

- where dirt and dust may block the sensor;

- in a damp or humid location;

- in the immediate vicinity of the cooking appliance.

6

The detector should not be installed above or next to gas

appliances because small gas releases may occur at start

up and they may generate unwanted alarms. It should be

noticed that installation near cookers may lead to alarms

produced by cooking vapors and not gas leaks.

It should also be noticed that contamination by grease

may impede the correct operation of the apparatus.

The detector should not be painted during the cleaning,

decorating or painting activities.

In order to avoid situations in which the safety of the

apparatus could be affected on short and long term, the

detector should not be installed in areas where emissions

of the paint solvents can appear, or near the heating

systems, stoves or fireplaces, or near the exhausted

gases.

Vapors of cleaning liquid gases, varnishes, paints, vapors

from the kitchen activities can affect the detector

operating and can cause false alarms and malfunctions of

the detector.

Avoid the expo sure of the detector in humid

environments or subjecting it to shocks

(e.g. the cleaning operations in the house).

According to the EN 50244 and EN 50292 standards,

ideally, a detector should be installed in every room

containing a fuel burning appliance. For added protection,

install additional detectors in remote rooms, in which the

occupants spend considerable time whilst

awake and from which they may not be able to hear an

7

alarm from the detector in another part of the premises,

and in every sleeping room.

WARNING! The installation of the detector in an area

where it is not recommended for it to be installed,

can affect sensor operation.

NOTE: The installation of the gas detector does not

eliminate the obligation to use all gas appliances in

safety conditions and to maintain the gas installations

in very good operating conditions and also all the

apparatus that operate based on combustible gases

must be periodically checked by authorized

personnel.

8

CONNECTION METHODS

WARNING! The apparatus should be installed only by

qualified personnel. Before any intervention, switch

off the power supply and make sure the device is not

powered.

For maximum protection, the recommendation is to

use the external signal, to control a solenoid valve, or an

air vent which in case of an alarm, will shut off the gas

supply, or will ventilate.

For electrical connection to the solenoid valve carefully

check the following instructions.

It is necessary to first remove

the cover of the detector.

Remove the screw from the

back of the case. Insert a flat

screwdriver in places specified

by arrows (see the drawing) to

be able to free the securing flaps

from inside.

Follow these steps:

-inside the detector, make a bridge between the COM

position of the three terminals connector and position R

of the two terminals connector;

-make a connection between NO position of the three

terminals connector and terminal 1 of solenoid

connector;

9

-make a connection

between 0 position of the

two terminals connector

and terminal 2 of solenoid

connector;

-make a ground connection

to terminal 3 of solenoid

connector;

-after you have ensured that

all connections are properly

made, power the detector

from the main 230 V AC.

In the situation of more than one detector, you can

make a parallel conection of the detectors to a

solenoid valve, like in the following instructions:

10

Follow these steps:

-inside the nearest detector from the valve, make a bridge

between the COM position of the three terminals

connector and position R of two terminals connector;

-make a connection between NO position of the nearest

detector from the valve to the terminal 1 of the solenoid

connector;

-make a connection between 0 position of the nearest

detector from the valve to the terminal 2 of the solenoid

connector;

-make a ground connection to terminal 3 of solenoid

connector;

-link between them all the NO positions of the detectors;

-link between them all the COM positions of the detectors;

-after you have ensured that all connections are properly

made, power the detectors from the mains 230 V AC.

WARNING! The user should take into consideration

that the gas detector does not function without a

power supply, that could be caused by a malfunction

of the power supply net, a burned fuse, a break

disjuncture, a shortcircuit or any other cause that

could cause the damage of the power supply.

NOTE! The gas installation and shutt-off valve must

comply with the national regulations in force

in the country where it is being installed.

11

OPERATION

This version of the detector is both a methane gas and

carbon monoxide detecting device for domestic

installations. To ensure the prevention of gas leakage the

detector is installed along with a solenoid valve, which has

the purpose to shut-off the gas supply in case of an alarm

or start a ventilator which will air the room.

NORMAL OPERATION

When there is no gas in the room, the Green LED is ON,

which indicates the unit is powered, the Red LEDs are OFF

and the Buzzer does not sound. The Red LED lights up

intermittently ,which indicates the checking of the sensor

state while the detector is in stand by.

ALARM CONDITION

When the methane gas or carbon monoxide level in

the room in which the detector is installed exceeds the

safety level the detector generates an acoustic signal (the

Buzzer sounds) and a visual signal

(Red LED is ON for carbon monoxide or for methane gas)

and the relay generates the output signal. The acoustic

and visual signal remain until the gas concentration

returns below safety limits.

IMPORTANT! The detector needs 2 min 30 sec of

warm-up time, at every power up, to stabilize and

start operating normally!.

12

TESTING THE DETECTOR

Simply press the Test/Reset button any time while in

normal operation. The Red LEDs should flash, the alarm

should sound and the relay switches while the solenoid

valve will cut off the gas flow. Release the button and

manually rearm the solenoid valve.

THIS IS THE ONLY WAY YOU SHOULD TEST THE

DETECTOR.

WARNING! Do not try to test the detector using a

cigarette lighter!

Do not test the detector by starting the gas appliance

without a flame!.

MAINTENANCE INSTRUCTIONS

In order to be sure that the detector is operating the

Green LED should be ON.

At least once a month it is recommended to verify that the

detector is functional by pressing the TEST/RESET button

for a few seconds.

For an efficient operation the detector should be cleaned

up every six months. Easily and carefully

vacuum the detector. Do not touch the apparatus with the

hose of the vacuum cleaner. Use the soft brush

attachment of your vacuum cleaner, and unplug the

detector from the electrical outlet before vacuuming.

Hand wash using a damp cloth or paper towel. Dry with a

soft cloth.

13

DO NOT SPRAY CLEANING AGENTS OR WAXES directly

onto the front panel. This action may damage the sensors,

cause an alarm or cause a detection malfunction.

Instruct children never to touch, unplug or otherwise

interfere with the detector.

Never use detergents or solvents to clean the detector.

Chemicals can permanently damage or temporarily

contaminate the sensors.

Avoid spraying air fresheners, hair spray, paint or other

aerosols near the detector.

DO NOT PAINT THE DETECTOR. Paint will seal the vents

and interfere with proper sensor operation.

NOTE: If you will be staining or stripping wood floors or

furniture, painting, wall-papering, or using aerosols or

adhesives for a do-it-yourself project or hobby, before you

begin: Remove the apparatus to a remote location to

prevent possible damage to or contamination of the

sensors. You may wish to unplug the gas detector and

store in a plastic bag during the project.

The following is a list of substances that at high levels can

affect the sensors and cause an alarm:

methane, ethylene, ethanol, alcohol, iso-propanol,

benzene, toluene, ethyl acetate, hydrogen, hydrogen

sulfide, sulfur dioxide also most aerosols sprays, alcohol

based products, paints, thinners, solvents, adhesives, hair

sprays, aftershaves, perfumes, auto exhaust (cold start)

and some cleaning agents.

14

DETECTOR LIFETIME

The lifetime of the detector is 5 years from the date of

installation.

Replace the detector after 5 years of operation.

15

ENVIRONMENTAL PROTECTION

Please dispose of packaging materials in appropriate

container at your local recycling center.

Waste electrical products should not be disposed of

with household waste. At the end of detector working life

please take the device to the recycling/disposal center or

inform about the regular collection actions organised by

the local authorities.

In the view of a constant development of their products,

the manufacturer reserves the right to change technical

data and features without prior notice.

For more information,

please visit us at:

M-DD-SED 0822 (EN)

Table of contents

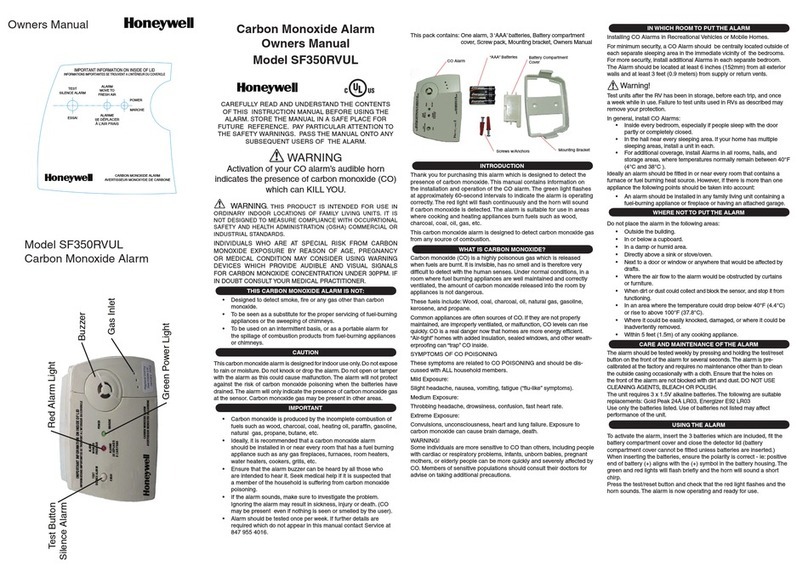

Popular Carbon Monoxide Alarm manuals by other brands

Kidde

Kidde Fyrnetics 423/9HIR Installer's guide

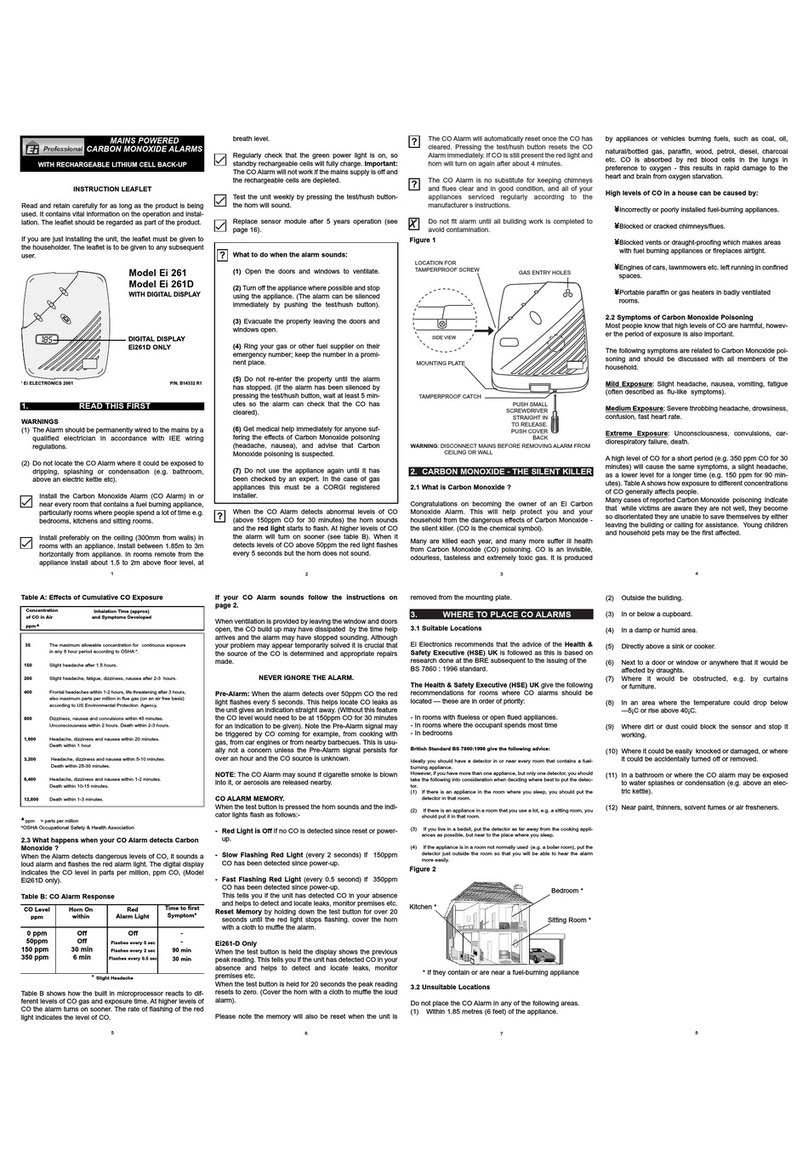

Ei Electronics

Ei Electronics Ei 220E User instructions

Sierra Monitor Corporation

Sierra Monitor Corporation 2-Wire Series instruction manual

x-sense

x-sense XP04 user manual

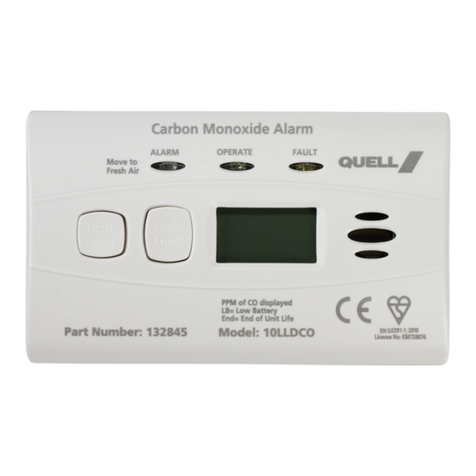

Quell

Quell 10LLDCO user guide

Sierra Monitor Corporation

Sierra Monitor Corporation Modbus Communications Interface Specifications