Project 2000 EuroLoft User manual

EuroLoft™ Bed Lift

(Overhead Cab)

OEM INSTALLATION MANUAL

Rev: 05.21.18 Page 2 EuroLoft™ Bed Lift (Overhead) OEM

Safety Information

Important Information

• Safety devices shall not be tampered with for any reason.

• It is strictly forbidden to be on the bed lifting system while it is being operated.

• Do not interfere with the bed lifting system while operated, neither with any objects or with hands.

• Before starting the vehicle engine and driving, always make sure the bed lifting system is in its highest

position and the safety belts are fastened (excluding garage bed).

• Do not operate the system improperly (e.g. with people on it).

• The bed lifting system shall only be used by adults and responsible staff.

• It is forbidden to use the bed lifting system while the vehicle is running.

• Do not move the bed lifting system if people or animals or items are around, under or on it.

• The bed lifting system must never be used while the vehicle is running.

• It is forbidden to start the bed lift system manually with disconnected wires from motor unit to control unit.

• Should the mechanism not work, do not use the bed and ask for assistance at the next service center.

TABLE OF CONTENTS

Safety Information 2

Important Information 2

Resources Required 3

Prior to Installation 3

Unpacking the Bed Frame 3

Motor and Motor Bracket 4

Power Controller 5

ACS Module Holder and Bracket 5

Stabilizer Guide Track Bracket and Roller Assembly 6

Installation 6

Belt Mounting Brackets 6

Stabilizer Channel Guides 8

Euroloft Switch 8

Wiring Harness Connections 9

Wire Harness to Components 9

Wiring Diagram 10

Setting the ACS Stop Procedure 11

Operation 12

Prior to Operating the EuroLoft Bed Lift System 12

Lowering the Bed Lift 12

Raising the Bed Lift 12

Manual Override 13

Maintenance 13

Failure to act in accordance with the following may result in death, serious injury or property

damage.

Moving parts can pinch, crush or cut. Keep clear and use caution during assembly.

Rev: 05.21.18 Page 3 EuroLoft™ Bed Lift (Overhead) OEM

• Cordless or Electric Drill or Screw Gun

• Appropriate Drive Bits

• Appropriate Drill Bits

• Pneumatic Rivet Gun

• Level

• Saw Horses

• Hex Key (4 mm)

• Socket Wrench (8 mm)

• Pencil

NOTE: Always install the bed lifting system taking into account the system maximum load. THE BED UNIT,

AS A WHOLE-INCLUDING BED LIFTING SYSTEM, MATTRESS, PILLOW, BLANKETS, ETC. - MUST NOT

WEIGH MORE THAN 132 lbs.

NOTE: The bed lifting system can bear a total maximum weight of 800 lbs.

Resources Required

Prior to Installation

All installation operations shall be carried out by skilled and authorized staff. Remove the product from

packaging.

Unpacking the Bed Frame

1. Make sure the bottom of the bed is facing up, the motor should be easily accessible.

2. Remove and set aside the subassembly component kit (Fig.1) packaged with the bed frame.

3. Remove and set aside the two stabilizer channel guides (Fig. 2) packaged with the bed frame.

Fig. 1 Fig. 2

Rev: 05.21.18 Page 4 EuroLoft™ Bed Lift (Overhead) OEM

Motor and Motor Bracket

1. Rotate the motor up from the bed frame (Fig. 3C).

2. Align the motor bolt holes with the holes in the motor bracket (Fig. 4A).

3. Install the two M8-1.25 X 22mm hex head DIN 6921 steel serrated flange bolts through the motor

bracket into the motor (Fig. 5A).

A

Fig. 4 Fig. 5

A

A

A

E

E

C

D

A

Fig. 3

B

4. Remove the tape around the power controller (Fig. 3A) attached to the center support rail of the bed

frame and set aside.

NOTE: In some cases the power controller may already be installed to the motor bracket.

5. Remove the tape around the two M8-1.25 X 22mm hex head DIN 6921 steel serrated flange bolts

(Fig. 3B) attached to the center support rail of the bed frame and set aside.

6. Remove the tape holding the long drive shaft and the short drive shaft belts together in the middle of

the bed frame (Fig. 3E).

Rev: 05.21.18 Page 5 EuroLoft™ Bed Lift (Overhead) OEM

Power Controller

NOTE: The power controller may already be installed to the motor bracket.

If the power controller is not attached, do as follows.

1. Remove the two #4 x 1/4" Phillips, Type A, sheet metal screws from the power controller (Fig. 6B).

2. Align the power controller screw holes with the motor bracket (Fig. 7A) screw holes.

3. Make sure the power controller interface (Fig. 6A) is facing towards the motor, then install the two

previously removed screws through the motor bracket and into the power controller (Fig. 7B).

B

Fig. 6 Fig. 7

B

B

B

A

A

ACS Module Holder and Bracket

1. Rotate the ACS module holder up from the bed frame (Fig. 3D).

2. Remove the two #6 - 18 x 3/8" Phillips, Type A, sheet metal screws inserted halfway into the ACS

module holder (Fig. 8A).

3. Align the ACS module holder with the ACS support bracket, then install the two previously removed

screws (Fig. 9A) through the bracket and into the ACS module holder.

A

A

Fig. 8 Fig. 9

A

A

Rev: 05.21.18 Page 6 EuroLoft™ Bed Lift (Overhead) OEM

Stabilizer Guide Track Bracket and Roller Assembly

1. Make sure the guide track roller assembly screw (Fig. 10A) is secured tightly to the wheel bracket

(Fig. 10B).

2. Place the stabilizer guide track bracket (Fig. 11A) on the corner of the side of the bed frame that will

support the bed.

NOTE: The stabilizer guide track bracket locations may vary per bed.

3. If the frame is not already pre-drilled, use the pre-drilled holes in the stabilizer guide track bracket as a

guide. Pre-drill 5/32" holes into the top and sides of the end and side rails (Fig. 10B).

4. Secure the bracket to the bed frame holes using three of the subassembly kit's #10 -12 x 1/2" hex. head

screws.

5. Repeat steps 1- 4 for the opposite stabilizer guide track bracket.

Fig. 10

A

A

B

B

B

Fig. 11

B

C

A

Installation

Belt Mounting Brackets

1. Remove the belt mounting assembly (Fig. 12) from the subassembly kit. Unscrew the nuts (Fig. 13C)

and slide the belt plates (Fig. 13B) off the belt bracket (Fig. 13A) and set aside. Do this for all four belt

brackets.

Fig. 12 Fig. 13

B

Rev: 05.21.18 Page 7 EuroLoft™ Bed Lift (Overhead) OEM

NOTE: A prefabricated jig may be used for a faster installation of the belt brackets.

NOTE: If installing on a unit with aluminum backing in the wall, use a minimum size of #10 x 1" self-drilling

screws. If installing on a unit with wood backing in the wall, use a minimum size of #10 x 1" wood

screws.

2. Starting on the passengers side at the desired height, install a belt mounting bracket (Fig. 13A). The left

edge of the belt mounting bracket should be approximately 10 1/4" away from the top roll bar of the

unit.

3. Install seven #10 x 1" screws at the top and seven #10 x 1" screws at the bottom of the belt mounting

bracket into wall of the unit.

4. On the passenger's side, place the second belt mounting bracket's left edge approximately 47 1/2"

away from the top roll bar of the unit.

5. Install seven #10 x 1" screws at the top and seven #10 x 1" screws at the bottom of the belt mounting

bracket into wall of the unit.

6. On the driver's side at the desired height, install the third belt mounting bracket's right edge of the

bracket, approximately 12 3/4" away from the top roll bar of the unit.

7. Install seven #10 x 1" screws at the top and seven #10 x 1" screws at the bottom of the belt mounting

bracket into wall of the unit.

8. Place the fourth belt bracket's right edge approximately 46 1/2" away from the top roll bar of the unit.

9. Install seven #10 x 1" screws at the top and seven #10 x 1" screws at the bottom of the belt mounting

bracket into wall of the unit.

10. Place the bottom side of the bed frame down on level supporting saw horses at the approximate fully

extended position. Make sure the bed frame is level.

11. Extend one belt up from the bed frame, making sure the belt is not twisted and there is no slack in the

belt.

12. Wrap the belt (Fig. 14C) over the top of the first belt plate (Fig. 14B). The belt extending up from the

bed frame should be in between the belt mounting bracket and the belt plate.

13. Place the belt plate and the belt onto the posts (Fig. 14A) of the belt mounting bracket.

14. Slide the second belt plate (Fig. 15A) onto the posts (Fig. 15B) of the belt mounting plate, against the

belt.

15. Install the four previously removed M6 - 1.0mm hex flange nuts (Fig. 16A) onto the belt mounting

bracket posts. Tighten the nuts to 25 ft-lbs.

16. Repeat steps 11-15 for the other three belts.

Fig. 14 Fig. 15 Fig. 16

A

B

CA

BA

Rev: 05.21.18 Page 8 EuroLoft™ Bed Lift (Overhead) OEM

Stabilizer Channel Guides

NOTE: Prior to installing the stabilizer channel guides, the excess length of the stabilizer channel guides

can be removed by measuring the length starting from the top of the roller guide assembly at the

fully retracted position to the bottom of the roller guide assembly at the fully extended position.

NOTE: If installing on a unit with aluminum backing in the wall, use a minimum size of #10 x 1" self-tapping

screws. If installing on a unit with wood backing in the wall, use a minimum size of #10 x 1" self-

drilling screws.

1. Make sure the bed frame is in the fully extended position.

2. Take the top end of the stabilizer channel guide (Fig. 17B) and place under the roller track assembly

(Fig. 17A).

3. Guide the roller track assembly into the stabilizer channel guide. Raise the stabilizer channel guide up

to the desired height.

4. Install three #10 x 1" screws through the stabilizer channel guide; top, middle and bottom, inside the

middle of the stabilizer channel guide (Fig. 18A) and into the wall of the unit.

5. Repeat steps 1-4 for the opposite side.

Fig. 17 Fig. 18

B

A

A

Euroloft Switch

NOTE: If installing on a unit with aluminum backing in the wall, use a minimum size of #10 x 1" self-drilling

screws. If installing on a unit with wood backing in the wall, use a minimum size of #10 x 1" wood

screws.

The Euroloft switch can be installed in the wall of the unit next to the bed frame or if installing padded rails

to the bed frame, in the padded rails.

1. Cut into the wall or the side panel of the bed an area 3" X 2" X 1" for the switch plate to be installed.

2. Install two #10 x 1/2" screws one screw on each side of the switch plate (Fig 19A).

Fig. 19

A A

Rev: 05.21.18 Page 9 EuroLoft™ Bed Lift (Overhead) OEM

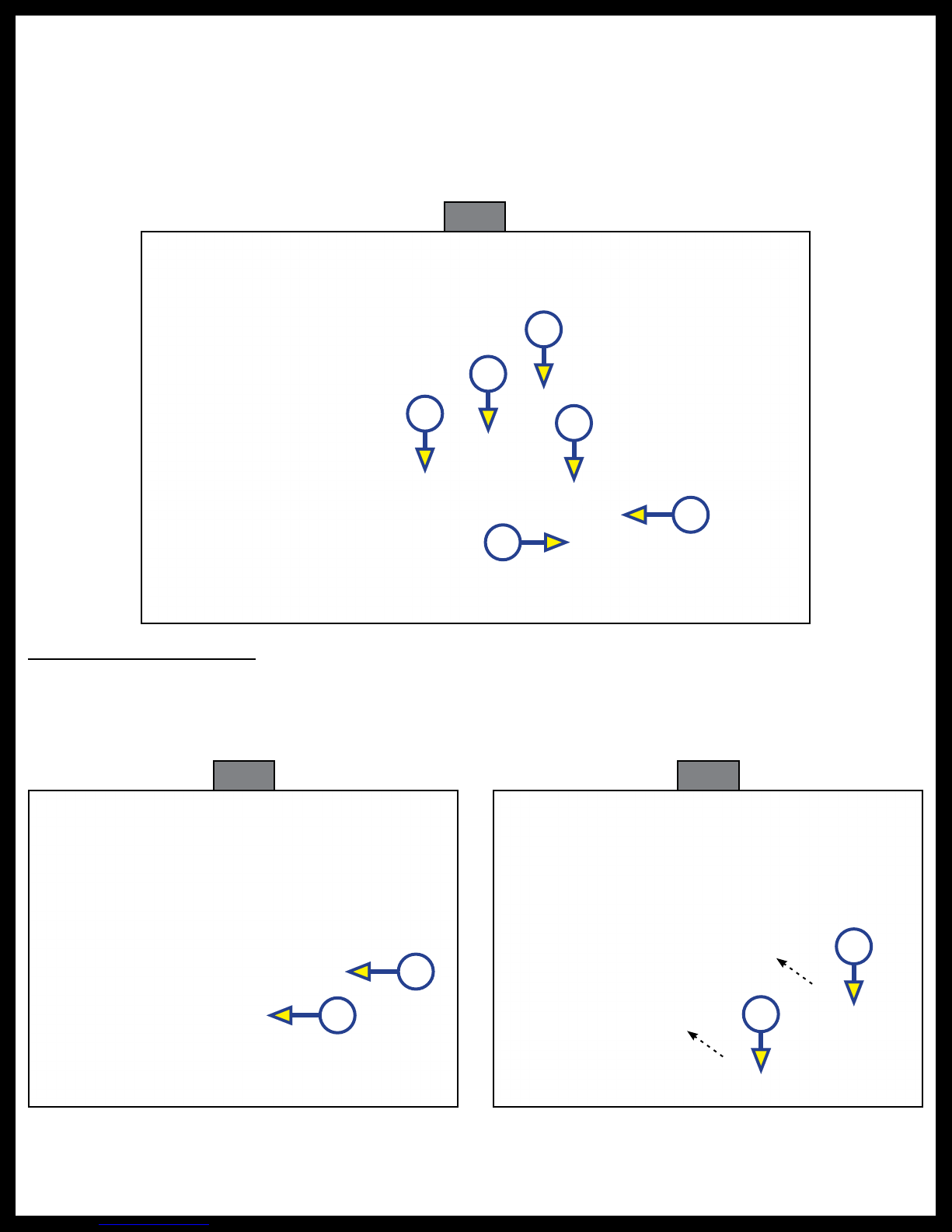

Wiring Harness Connections

Wire Harness to Components

1. Install the main wire harness power controller's connector (Fig. 20B) to the power controller's male

connector (Fig. 20A).

2. Install the main wire harness ACS (Advanced Control System) connector (Fig. 20E) to the ACS module

connector (Fig. 20C). The connecting wire colors are white, yellow, orange and green.

NOTE: The ACS module blue and purple wires (Fig. 20D) are only used to set the ACS module when

assembling the components. Disregard these wires for OEM installation.

3. Remove the connector plug (Fig. 20J) from the main wire harness power and directional wires. This

plug is only used when testing the system.

4. Splice the yellow and orange wires (Fig. 20H) to the corresponding yellow and orange wires of the

switch harness non-connector end (Fig. 20G).

5. Splice the red and black wires (Fig. 20I) to the corresponding red and black wires of the switch harness

non-connector end (Fig. 20G) and to unit's main power source or battery (Fig. 20L).

6. Install the switch harness connector end (Fig. 20F) to the back of the switch (Fig. 20K).

7. Install the main wire harness motor connector (Fig. 20M) to the motor's female connector (Fig. 20N).

Rev: 05.21.18 Page 10 EuroLoft™ Bed Lift (Overhead) OEM

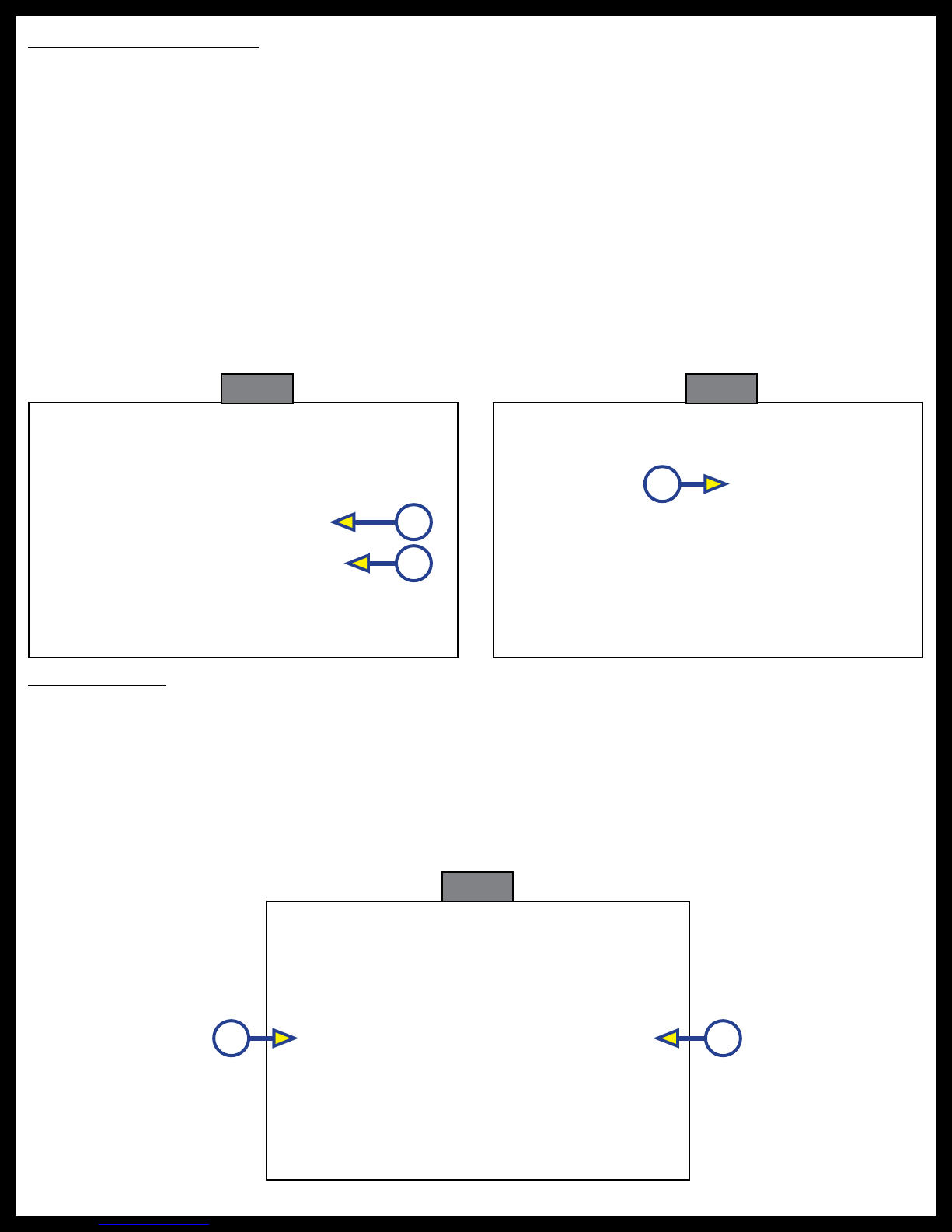

Wiring Diagram

Fig. 20

B

A

E

M

H

K

C

D

N

L

Power Controller ACS Module

MotorBattery

Back of Switch

Main Wire Harness

Switch Harness

J

I

F

G

Rev: 05.21.18 Page 11 EuroLoft™ Bed Lift (Overhead) OEM

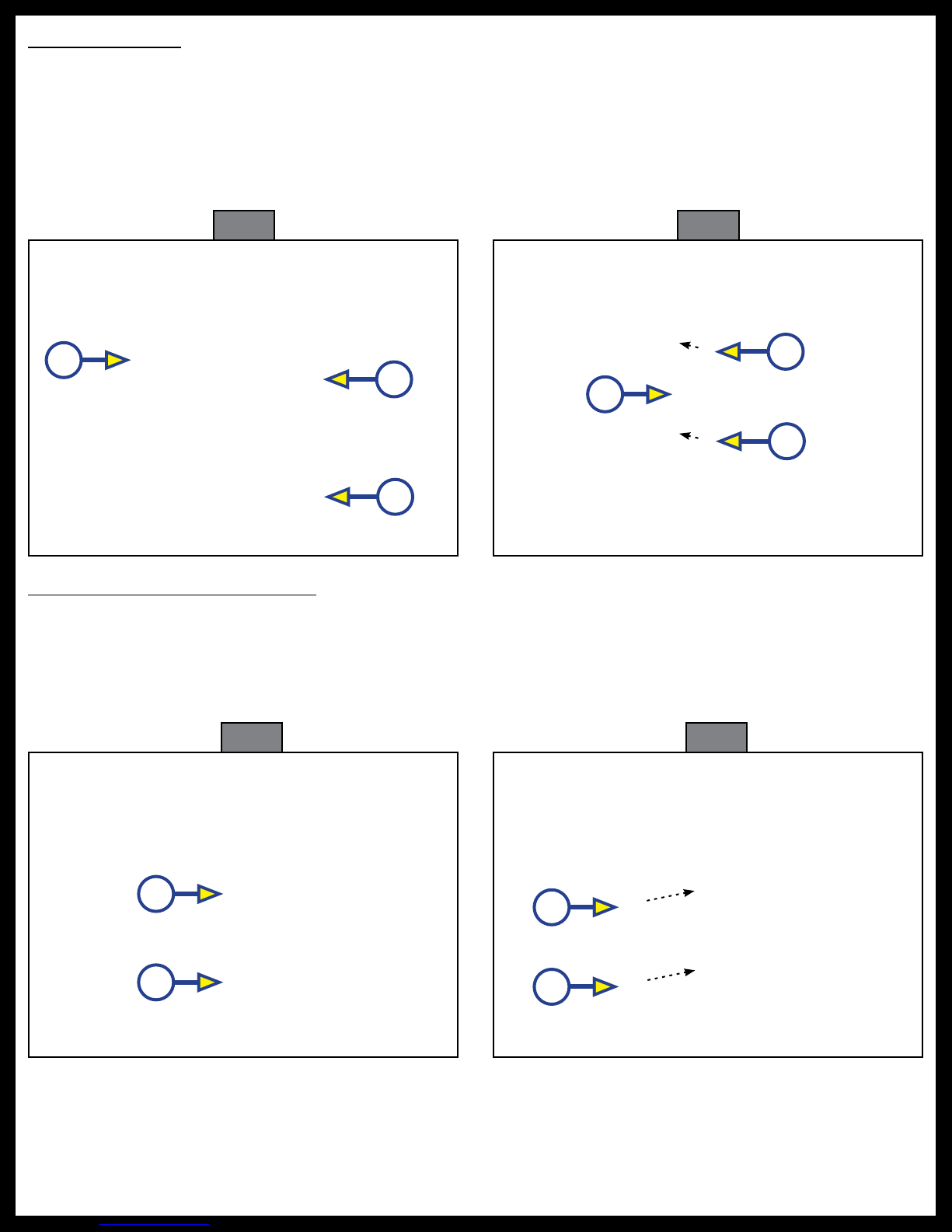

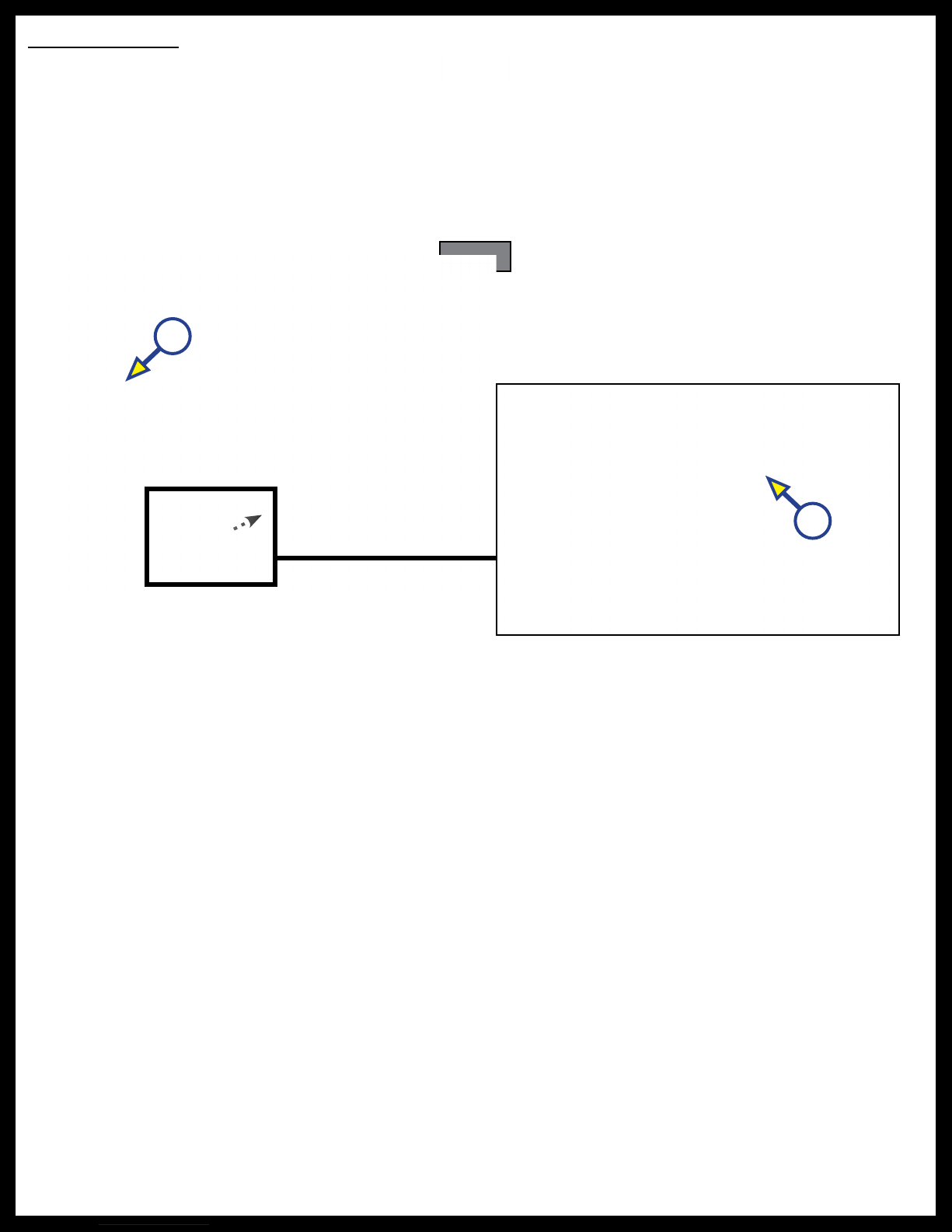

Setting the ACS Stop Procedure

Setting the UP Position

1. Make sure the safety belts are unfastened.

2. Turn the key switch to the ON position (Fig. 22D) located on the key pad.

3. Press and hold the UP arrow-shaped button (Fig. 22A) on the key pad. A green LED light (Fig. 22C) on

the key pad will turn on in the direction the bed is moving. The bed will keep moving until you reach

the pre-set stop position.

4. If the bed lift stops too low, turn the white screw (Fig. 21A) in the ACS module counterclockwise. This

will allow the bed lift to move higher. If the bed lift stops too high, turn the white screw (Fig. 21A)

clockwise until the bed lift stops lower.

NOTE: One full rotation of the screw is approximately one inch of movement up or down.

5. Press the UP arrow (Fig. 22A) and DOWN arrow (Fig. 22B) to run the bed lift system after each

adjustment of the screw. If necessary, repeat this procedure until desired stop location is obtained.

Setting the DOWN Position

1. Make sure the safety belts are unfastened.

2. Turn the key switch to the ON position (Fig. 22D) located on the key pad.

3. Press and hold the DOWN arrow-shaped button (Fig. 22B) on the key pad. A green LED light (Fig. 16C)

on the key pad will turn on in the direction the bed is moving. The bed will keep moving until you

reach the pre-set stop position.

4. If the bed lift stops too high, turn the yellow screw (Fig. 21B) counterclockwise. This will allow the bed

lift to move lower. If the bed lift stops too low, turn the yellow screw (Fig. 21B) clockwise until the bed

lift stops higher.

NOTE: One full rotation of the screw is approximately one inch of movement up or down.

5. Press the UP arrow (Fig. 22A) and DOWN arrow (Fig. 22B) to run the bed lift system after each

adjustment of the screw. If necessary, repeat this procedure until desired stop location is obtained.

A

B

Fig. 21

Rev: 05.21.18 Page 12 EuroLoft™ Bed Lift (Overhead) OEM

Operation

Prior to Operating the EuroLoft Bed Lift System

The bed lifting system must never be used while the vehicle is in motion.

1. Make sure the vehicle is parked, secured and stabilized before starting operations.

2. Set the parking brake, if applicable.

Lowering the Bed Lift

1. If installed, make sure the safety belts are unfastened.

2. Turn the key switch to the ON position (Fig. 22D) located on the key pad.

3. Press and hold the DOWN arrow-shaped button (Fig. 22B) on the key pad. A green LED light (Fig.

22C) on the key pad will turn on in the direction the bed is moving. The bed will keep moving until it

reaches the pre-set stop position.

NOTE: The bed will stop moving when the button is released. Continue to press and hold the button until

the stop position has been reached.

4. Release the DOWN arrow-shaped button.

5. Turn the key switch to the OFF position.

Fig. 22

D

Key

A

B

C

C

Raising the Bed Lift

1. Turn the key switch to the ON position (Fig. 22D) located on the key pad.

2. Press and hold the UP arrow-shaped button (Fig. 22A) on the key pad. A green LED light (Fig. 22C)

on the key pad will turn on in the direction the bed is moving. The bed lift will keep moving until it

reaches the pre-set stop position.

NOTE: The bed will stop moving when the button is released. Continue to press and hold the button until

the stop position has been reached.

3. Release the UP arrow-shaped button.

4. If installed, make sure the safety belts are fastened.

5. Turn the key switch to the OFF position.

Always make sure that the EuroLoft Bed Lift path is clear of people, pets and objects before and

during operation. Always keep away from the slide rails when the bed is being operated. Do not

allow people or pets on bed while bed is in motion.

Rev: 05.21.18 Page 13 EuroLoft™ Bed Lift (Overhead) OEM

Maintenance

The EuroLoft Bed Lift system has been designed to require very little maintenance. To ensure the long life

of your EuroLoft Bed Lift system, read and follow these few simple procedures:

1. When the bed is raised, visually inspect the slide rail assemblies.

A. Check for excess buildup of dirt or other foreign material.

B. Remove any debris that may be present.

2. If the system squeaks or makes any noises, blow out any debris from the drive shaft and apply a dry

lubricant to prevent and/or stop squeaking.

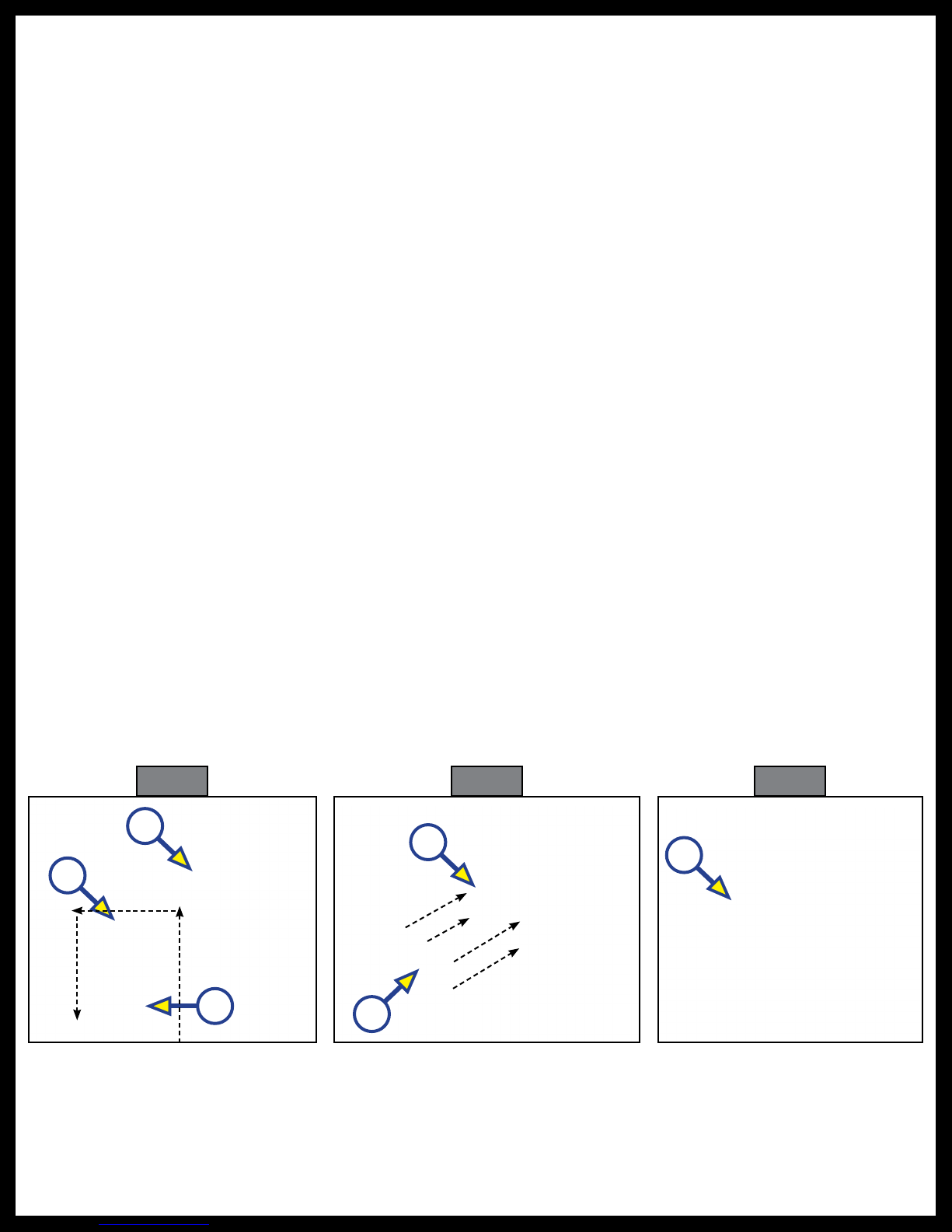

Manual Override

Always disconnect from power source before performing any operation on the bed lifting system.

To raise or lower the bed lift in case of emergency, it is possible to operate the system manually.

1. Insert the provided crank device (Fig. 23A) into the motor (Fig. 23B).

2. Turn clockwise to raise or counterclockwise to lower the bed.

3. Have the bed lift serviced by an OEM-authorized dealer as soon as possible. Do not operate the bed lift

until service is complete, as damage to the bed lift system may result.

Fig. 23

A

B

The contents of this manual are proprietary and copyright protected by Lippert Components, Inc. (“LCI”).

LCI prohibits the copying or dissemination of portions of this manual unless prior written consent from an

authorized LCI representative has been provided. Any unauthorized use shall void any applicable warranty.

The information contained in this manual is subject to change without notice and at the sole discretion of LCI.

Revised editions are available for free download from lci1.com.

Please recycle all obsolete materials.

For all concerns or questions, please contact

Lippert Components, Inc.

Table of contents

Popular Motorhome manuals by other brands

Fleetwood Folding Trailers

Fleetwood Folding Trailers 1995 Four Season Yosemite owner's manual

Winnebago

Winnebago Minnie owner's manual

Auto-Trail

Auto-Trail Excel Owner's handbook

elddis

elddis XPLORE Owner's handbook

Alpine Coach

Alpine Coach 2006 Limited owner's manual

Fleetwood

Fleetwood 1997 vision PaceArrow owner's manual