Page 2 / 28

Contents

Contents.................................................................................................................................2

1Safety information............................................................................................................3

1.1 Information symbols in the repair guidelines..............................................................3

1.2 Qualification and training...........................................................................................4

1.3Repair works safety instruction..................................................................................4

1.4 Modifications without approval from the manufacturer...............................................5

1.5 Disclaimer ............................................................................................................5

2Contact and Service address...........................................................................................6

3Needed tools and utilities.................................................................................................6

3.1 Test equipment.....................................................................................................6

4General Overview............................................................................................................7

4.1 Description / Application area....................................................................................8

4.2 Technical Data..........................................................................................................8

5Repair Works...................................................................................................................9

5.1 Door removal/mounting, Change of door firebrick......................................................9

5.1.1 Replacing of the handle ........................................................................................9

5.1.2 Door removing ......................................................................................................9

5.1.3 Replace door firebrick.........................................................................................10

5.1.4 Door sensor replacement....................................................................................11

5.1.5 Door mounting. ...................................................................................................11

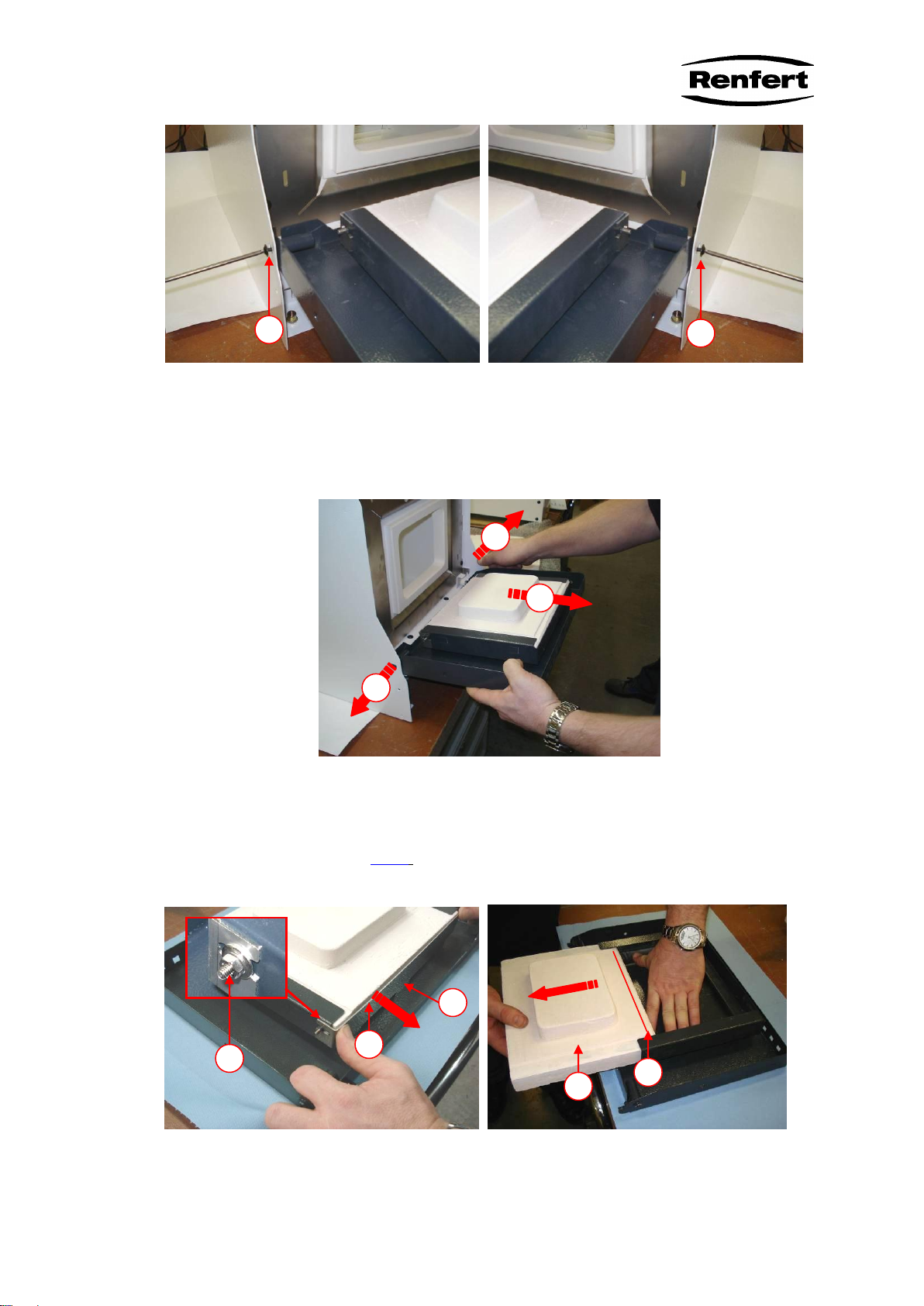

5.2 Rim stone replacement............................................................................................12

5.2.1 Remove the ledge...............................................................................................12

5.2.2 Removing front panel and replacement of rim stone ...........................................12

5.2.3 Install front panel and ledge................................................................................13

5.3 Control unit and backup battery...............................................................................14

5.3.1 Operating unit board ...........................................................................................14

5.3.2 Replace the processor circuit board....................................................................14

5.3.3 Backup battery replacement................................................................................15

5.3.4 Installing control unit ...........................................................................................15

5.4 Thermocouple replacement.....................................................................................16

5.5 Replacing power electronics....................................................................................16

5.6 Compensating wire replacement.............................................................................18

5.7 Remove the heating cable.......................................................................................18

5.8 Ribbon cable replacement.......................................................................................19

5.9 ON/OFF switch replacement ...................................................................................20

5.10 Power cord replacement..........................................................................................20

5.11 Unit feet replacement ..............................................................................................21

5.12 Muffle replacement..................................................................................................21

5.12.1Removing the muffle ...............................................................................................21

5.12.2Installing the new muffle..........................................................................................22

6Adjustment.....................................................................................................................24

7Function check after repair.............................................................................................24

8Maintenance..................................................................................................................24

9Spare part......................................................................................................................24

9.1 Spar part drawing –Version A and B.......................................................................25

9.2 Spare part list - version A and B..............................................................................26

10 Troubleshooting.............................................................................................................27

10.1 General errors.........................................................................................................27

10.2 Controller errors ......................................................................................................28