7

Installation and Operation

Blood Bank Refrigerators

9 Alarm Systems

9.1 Operating the Alarm

The alarm system is designed to provide visual and audible

warning signals for both power failure and rise in temperature.

The alarm is equipped with a battery backup.

The factory default warm alarm setpoint is 5.5ºC; the default cold

alarm setpoint is 1.5ºC.

The alarm system is activated only when the key switch is turned

to the Alarm On position. The audible warning signal sounds

when there is a power failure or temperature alarm condition, or

when the door is ajar for more than 2 minutes.

The Mute function (pressing the button) allows you to turn off

the audio warning without turning off the visual indicators.

9.2 Local and Remote Alarms

Blood bank units can have either a factory-installed local alarm

or an optional user-installed remote alarm. Operating and testing

procedures are the same for both types of alarm.

The maximum distance between a blood bank and a remote

alarm depends on the wire gauge used. Refer to Table 5 below.

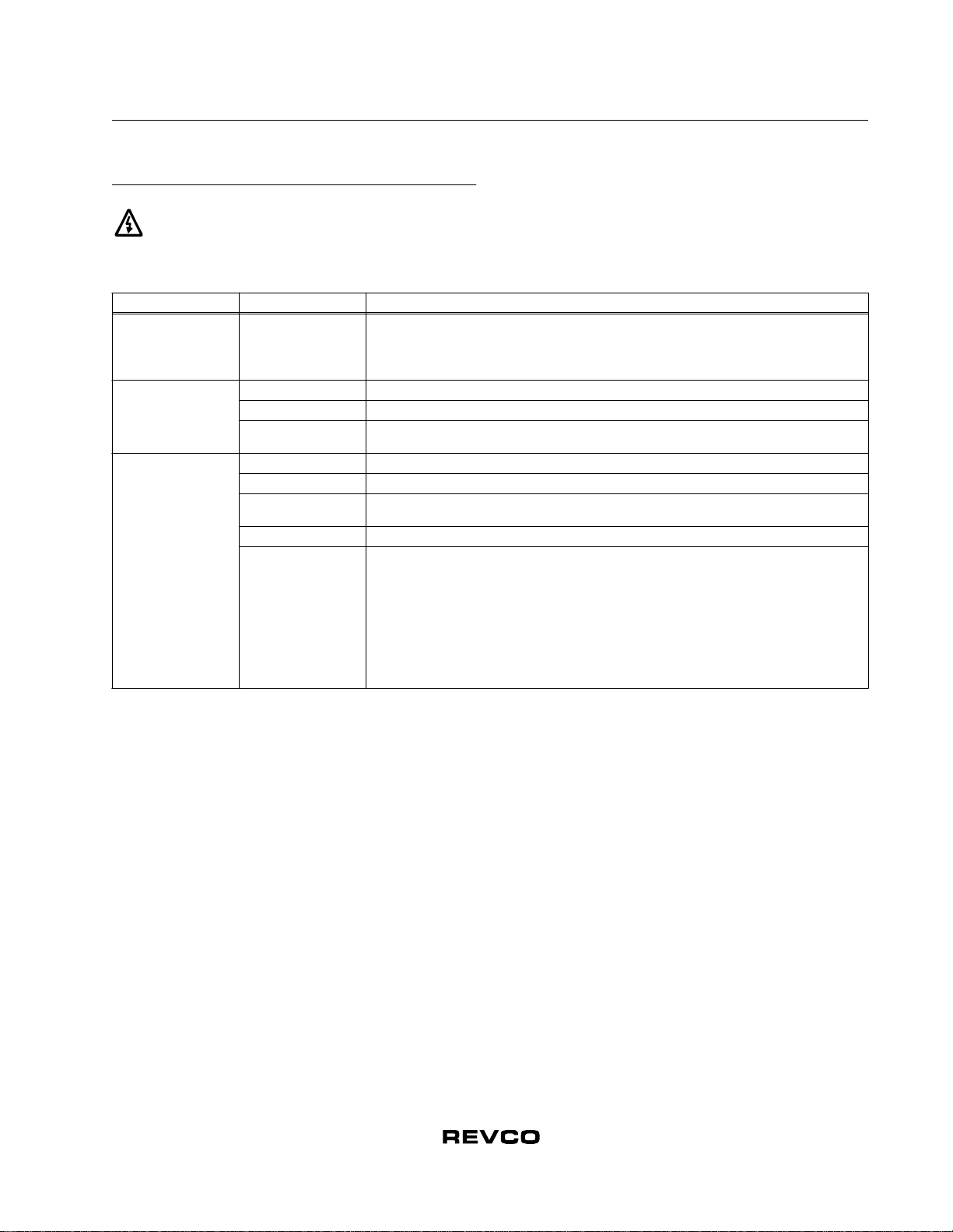

Table 5. Wire Gauges and Distance to Remote Alarm

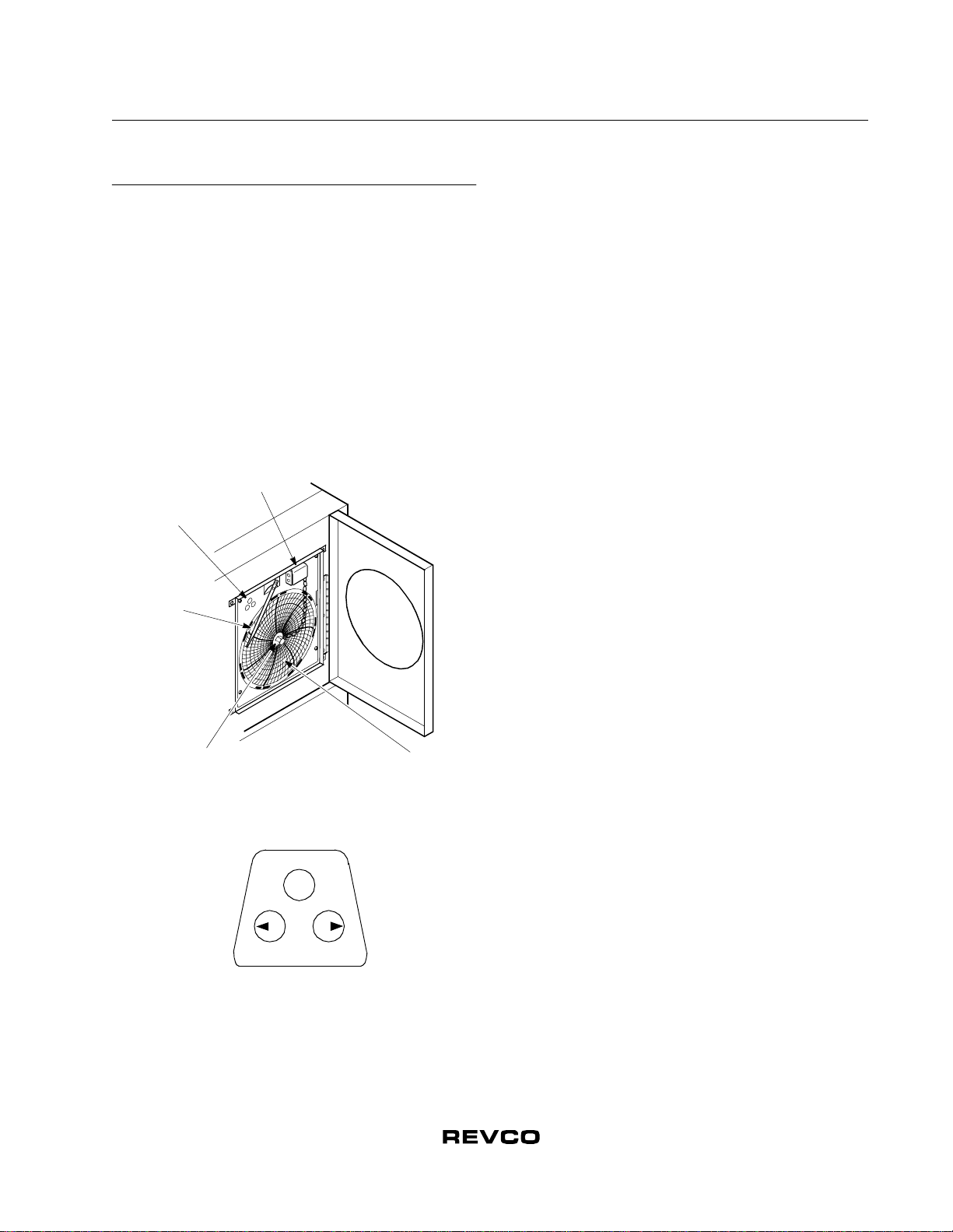

9.3 Installing a Remote Alarm (Optional)

Remote alarm terminals are located at the rear of the machine

compartment. The terminals are: Common, Open on Fail

(Normally Closed), and Close on Fail (Normally Open).

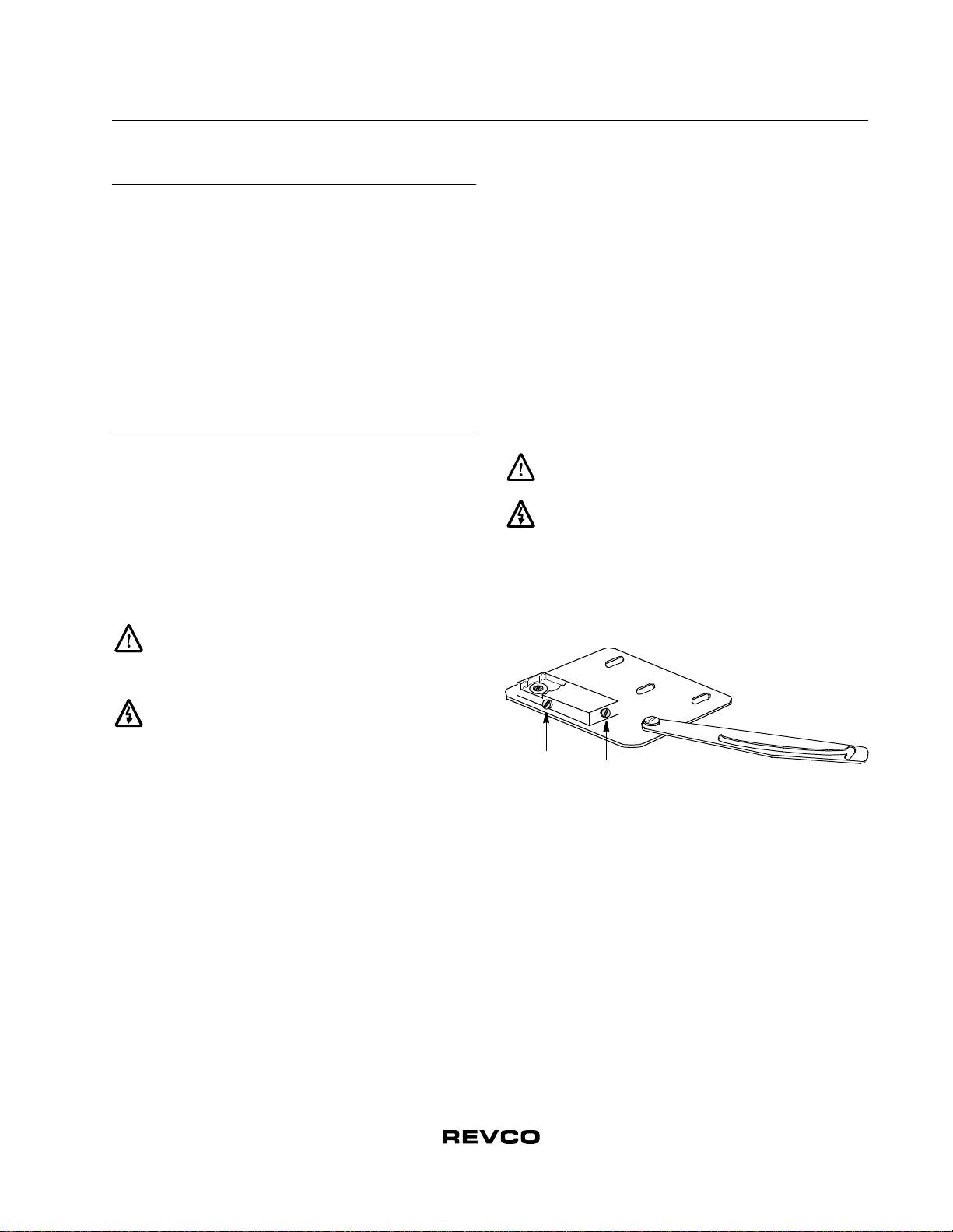

1. The remote alarm system has two keyhole slots on the back

to hang the alarm system on the wall. Insert two screws, no

longer than a #12 truss-head type and spaced two inches

apart, into a wall and mount the alarm.

2. Make the following connections:

a. Connect the common terminal on the cabinet switch to

the purple wire on the alarm.

b. Connect the normally closed terminal on the cabinet to

the black (“open on fail”) wire on the alarm. This

connection gives an alarm when the switch contacts open.

3. Plug the alarm system service cord into an electrical outlet.

This alarm is designed for 115V/60 Hz, 115V/50 Hz, or

100V/50 Hz operation.

Note: If you want the alarm signal to sound when the switch

contacts close, connect the normally open terminal on

the cabinet to the red/white (“close on fail”) wire on the

alarm. The purple and red/white wires must be tied

together in this application.

The wiring diagram is attached to the inside of the alarm back

cover.

9.4 Alarm Test

Note: It is important to test your alarm system after any

maintenance operation or temperature control

adjustment.

9.4.1 Theory of Operation

This test procedure applies to both factory-installed built-in

alarms and optional field-installed remote alarms.

During the alarm test, the temperature sensor is artificially heated

and cooled by a tiny, built-in thermoelectric heating and cooling

unit which simulates both warm and cold conditions. The

electronic control module notes the sensor temperature changes

and the control panel displays these changes.

While this alarm testing procedure is very accurate and reliable,

the temperature of the refrigerated space does not change during

the alarm test.

9.4.2 Alarm Test Procedure

Note: This test automatically advances through all steps and

stops.

1. Verify that the current warm and cold alarm setpoints are

within normal ranges (the warm and cold simulations may

not work if the setpoints are set to extreme values).

2. To start the alarm test, press and simultaneously and

hold for five seconds. During the test the main display and

thermometer bulb will indicate simulated (not actual) cabinet

temperature.

3. When simulated temperature exceeds the warm alarm

setpoint, the alarm sounds and the alarm icon on the control

panel illuminates (#10 in Figure 3 on page 4).

4. The temperature display begins to drop. After a few seconds,

the temperature in the display is back in the operating range.

5. The alarm stops. The temperature on the display drops until

the cold alarm sounds.

6. The test is now complete but the alarm continues to sound

until the temperature on the display is back in the operating

range.

If the simulated alarm conditions do not occur during the first 10

minutes of the alarm test, the service (wrench) icon illuminates

and the test is terminated. When during the alarm test, the

temperature display does not change or the service icon

illuminates, check the sensor connections.

You can terminate the alarm test at any point by pressing the

button.

Wire Gauge Total Wire Length

(feet)

Distance to Alarm

1/2 Wire Length

(feet)

20 530 265

18 840 420

16 1,330 665

14 2,120 1,060

12 3,370 1,685