Form I-XE/CRGB/RPB, Page 2

1. Approval and Installation Codes

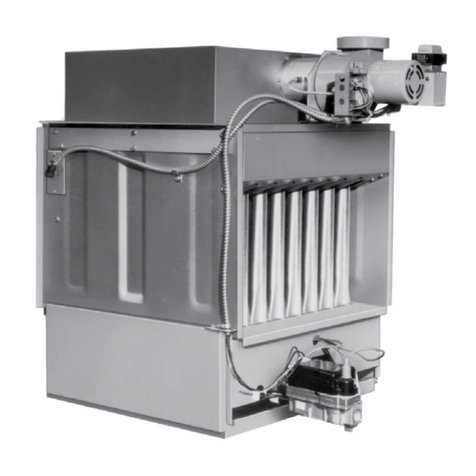

The models covered in this manual are design certified or approved duct

furnaces that are factory assembled with air handing components, creat-

ing a unified packaged furnace/blower system. The packaged system

models listed on page 1 are design-certified toANSI and CSAStandards

by the Canadian Standards Association. All models are approved for

installation in the United States. All models except Model CRGB and

Model HCRGB are approved for installation in Canada.All furnaces are

approved for use with either natural gas or propane. The type of fuel for

which the furnace is equipped and the correct firing rate are shown on

the rating plate attached to the unit. Electrical characteristics are shown

on both the motor nameplate and the unit rating plate.

These units must be installed in accordance with local building codes. In

the absence of local codes, in the United States, the unit must be in-

stalled in accordance with the National Fuel Gas Code NFPA54/ANSI

Z223.1 (latest edition). A Canadian installation must be in accordance

with the CSA B149.1 Natural Gas and Propane Installation Code. These

codes are available from CSA Information Services, 1-800-463-6727.

Localauthoritieshavingjurisdictionshould be consulted before installa-

tion is made to verify local codes and installation procedure require-

ments.

Special Installations (Aircraft Hangars/Garages)

Installations in aircraft hangars should be in accordance with NFPANo.

409 (latest edition), Standard forAircraft Hangars; in public garages in

accordance with NFPA No. 88A (latest edition), Standard for Parking

Structures; and for repair garages in accordance with NFPA No. 88B

(latest edition), Standard for Repair Garages. In Canada, installations in

aircraft hangars should be in accordance with the requirements of the

enforcing authorities, and in public garages in accordance with CSA

B149.1 codes.

WARNING: To ensure safety, follow the lighting

instructions located on the outlet box cover plate

in the heater section of the packaged furnace

assembly.

HAZARDINTENSITYLEVELS

usedforWarningsinthisManual

1. DANGER:Failuretocomplywillresultin

severepersonalinjuryordeathand/or

propertydamage.

2. WARNING:Failuretocomplycouldresultin

severepersonalinjuryordeathand/or

propertydamage.

3. CAUTION:Failuretocomplycouldresultin

minorpersonalinjuryand/orpropertydam-

age.

WARRANTY:Warranty is void if......

a. Packaged furnacesareusedinatmospheres containing

flammablevaporsoratmospherescontaining

chlorinatedorhalogenatedhydrocarbonsorany

contaminant(silicone,aluminiumoxide,etc.)that

adherestothe sparkignitionflamesensing probe.

b. Wiringisnotin accordance withthediagramfurnished

withtheheater.

c. Unitisinstalledwithoutproperclearancesto

combustiblematerialsorwithoutproperventilationand

airforcombustion.(See Paragraphs 5and 6.)

d. Furnaceairthroughputisnotadjustedwithintherange

specifiedontheratingplate.

3. Uncrating and Preparation

This furnace was test operated and inspected at the factory prior to

crating and was in operating condition. If the equipment has incurred

any damage in shipment, document the damage with the carrier and

contact your Reznor distributor.

Check the rating plate for the gas specifications and electrical character-

istics of the furnace to be sure that they are compatible with the gas and

electric at the installation site. Read this booklet and become familiar

with the installation requirements of your particular model. If you do

not have knowledge of local requirements, check with the local gas

company or any other local agencies who might have requirements

concerning this installation. Before beginning, make preparations for

necessary supplies, tools, and manpower.

Check to see if there are any field-installed options that need to be

assembled to the furnace prior to installation.

Option Parts - Some gas control options will have parts either shipped

loose with the heater or shipped separately. If your unit is equipped

with any of the following gas control options, be sure these parts are

available at the job site.

Other shipped-separate options could include a roof curb, a cooling coil

cabinet, a screened outside air hood, a gas shutoff valve, a condensate

drain fitting, a thermostat, a different control switch, a power venter, a

remote console, a manual fan switch, a vertical vent terminal, a gas

supply regulator, and/or a disconnect switch. Or, if equipped with an

optionalevaporative cooling module, awater hammer arrestor orfill and

drain or freeze kit could be shipped separately.

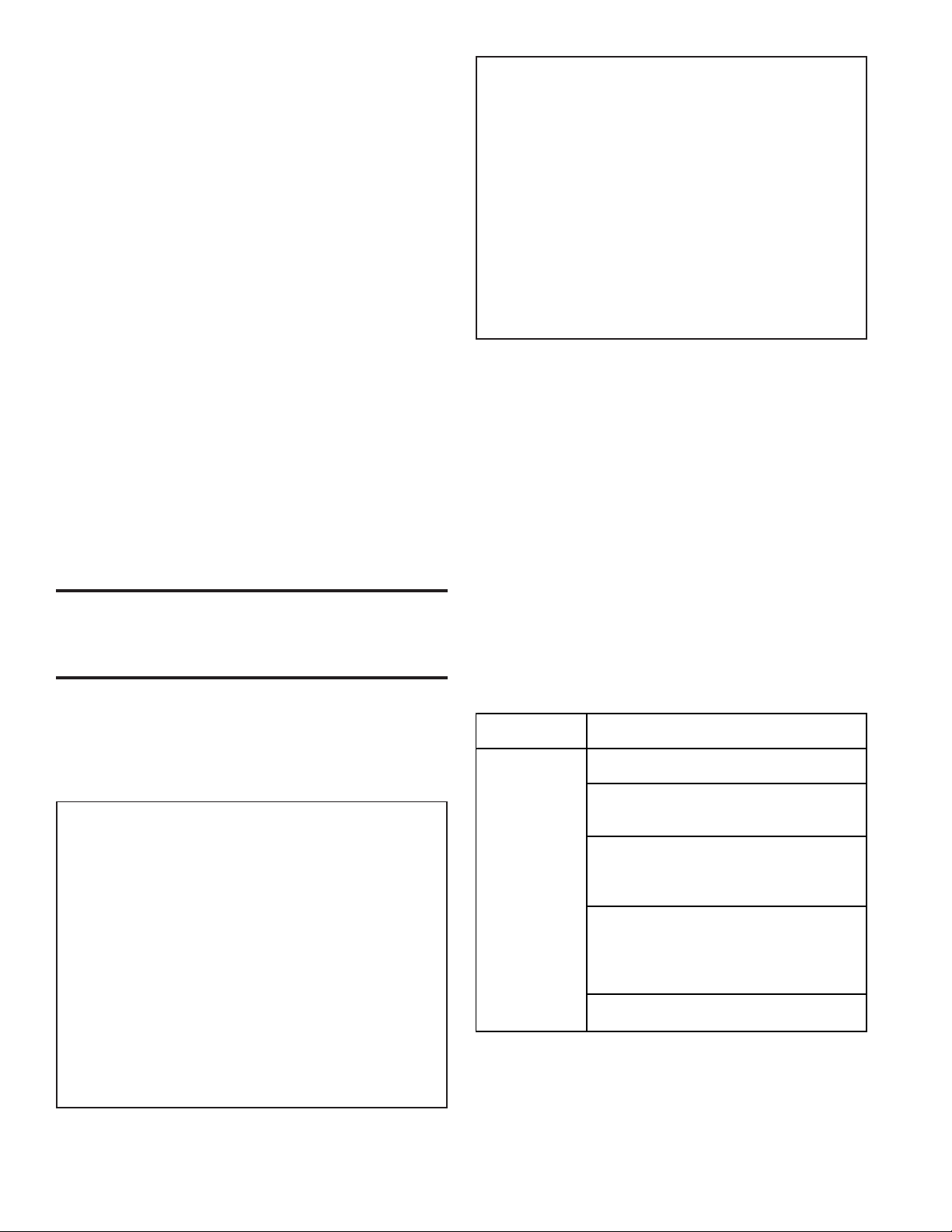

Heatin

-- Gas O

tion AG7

Control O

tion Thermostat, P/N 48033

Makeu

Air -- O

tion AG3, AG6, AG8 or AG13

Gas Control Control Switch, P/N 29054

O

tions O

tion AG9

Remote Temperature Selector, P/N 48042

(If an o

tional Control Switch, P/N 29054

remote console O

tion AG15

is ordered, the Remote Temperature Selector, P/N 115848

control switch Stage Adder Module, P/N 115849

is mountedon Control Switch, P/N 29054

the console.) O

tion AG16

Remote Temperature Selector, P/N 115848

Stage Adder Module, P/N 115849

Remote Display Module, P/N 115852

Control Switch, P/N 29054

Option AG39

Remote Temperature Selector, P/N 174849

2. Warranty

Refer to limited warranty information on the warranty card in the

"Owner's Envelope".