3

・WARNINGS AND CAUTIONS FOR SAFETY OPERATION

Proper operation and periodic maintenance are indispensable for long-term use of

this polisher with safety. Carefully read the safety warnings and cautions given in

this instruction manual, and do not start polishing operation and maintenance work

until full understanding of the descriptive contents.

1. GENERAL

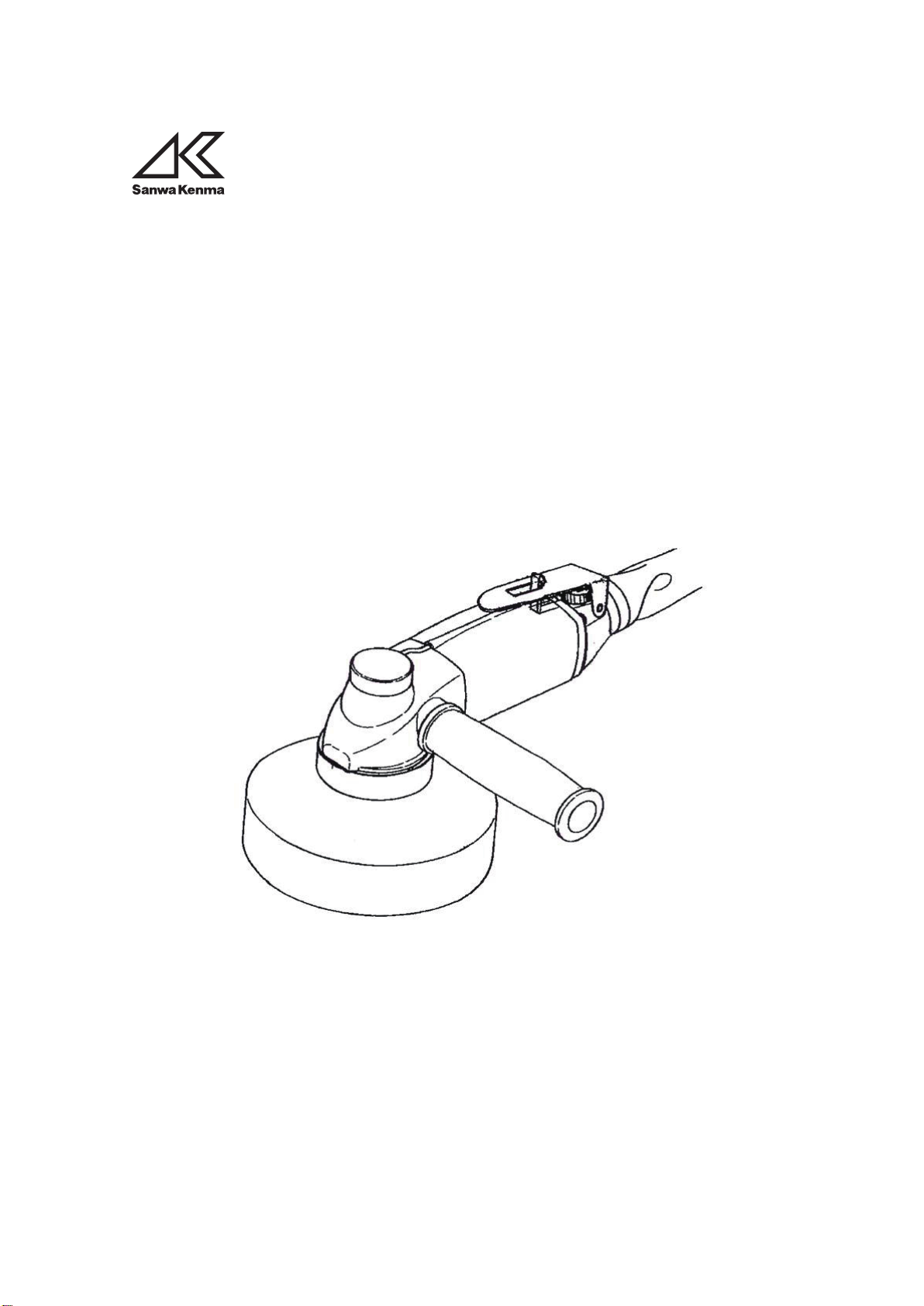

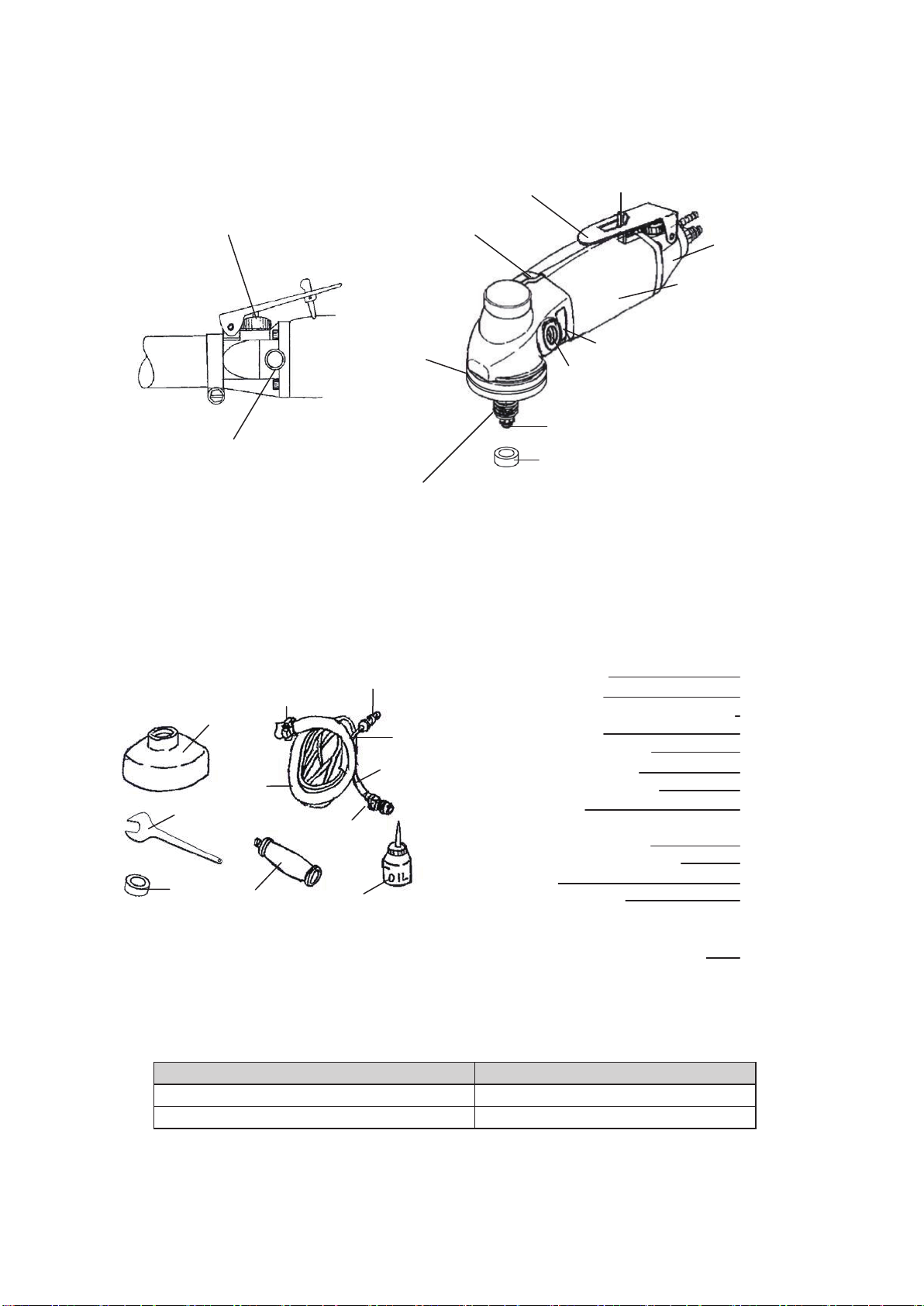

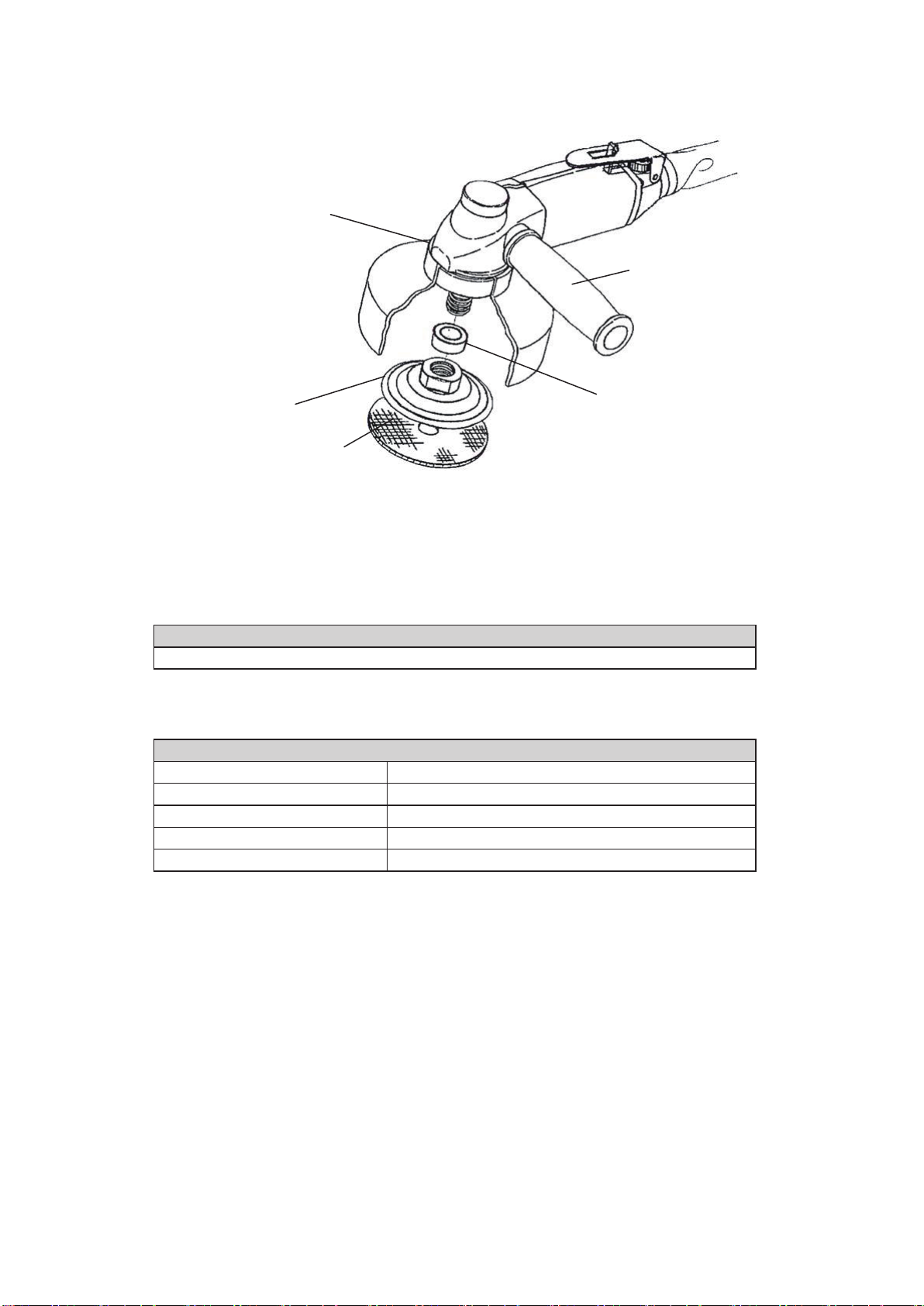

This polisher is equipped with rotating parts. During rotation of the polisher, the operator

shall hold the polisher by both hands; one hand grips the grip bar (see Figure 2, 3 and

4, page 6 and 7), another does the polisher body around the switch lever. In any cases

during rotating, anybody shall not touch the rotating parts of the polisher. Holding by one

hand is prohibited because another hand would have risk to touch the rotating parts.

When controlling airflow or water-flow, one hand shall hold the grip bar and another hand

would adjust the airflow control valve or the water-flow control valve under OFF condition.

WARNING

CAUTION

2. OPERATIONAL ENVIRONMENT

・ DO NOT ALLOW ANY OTHER OPERATORS TO ACCESS TO THE POLISEHR

Do not allow any other operators except specific operators to access to the work

place. Particularly be careful not to allow children to access the working area.

・ CAUTION AGAINST EXPLOSION AND FIRE

Do not use the polisher absolutely in potentially explosive atmospheres to prevent

explosion and fire.

・ KEEP A WORKPLACE IN ORDER

Keeping a worktable and peripheries disordered could cause a drop of the

polisher and the fraction is caught in the polisher. This is very hazardous. Be

careful to keep the workplace and its peripheries in order.

3. WORKING CLOTHING AND PROTECTIVE EQUIPMENT

・ WEAR APPROPRIATE PROTECTIVE EQUIPMENT

Operator engaged in polishing operation shall wear protective glasses, safety

shoes, rubber gloves and protective cap. At a dusty place, inhaling dust and

powder could cause respiratory diseases at throat and lungs. Therefore, when

polishing in such an environment, make sure to put a dust mask on. Furthermore,

when using the polisher, put a pair of earplugs on to prevent ear disease.

WARNING