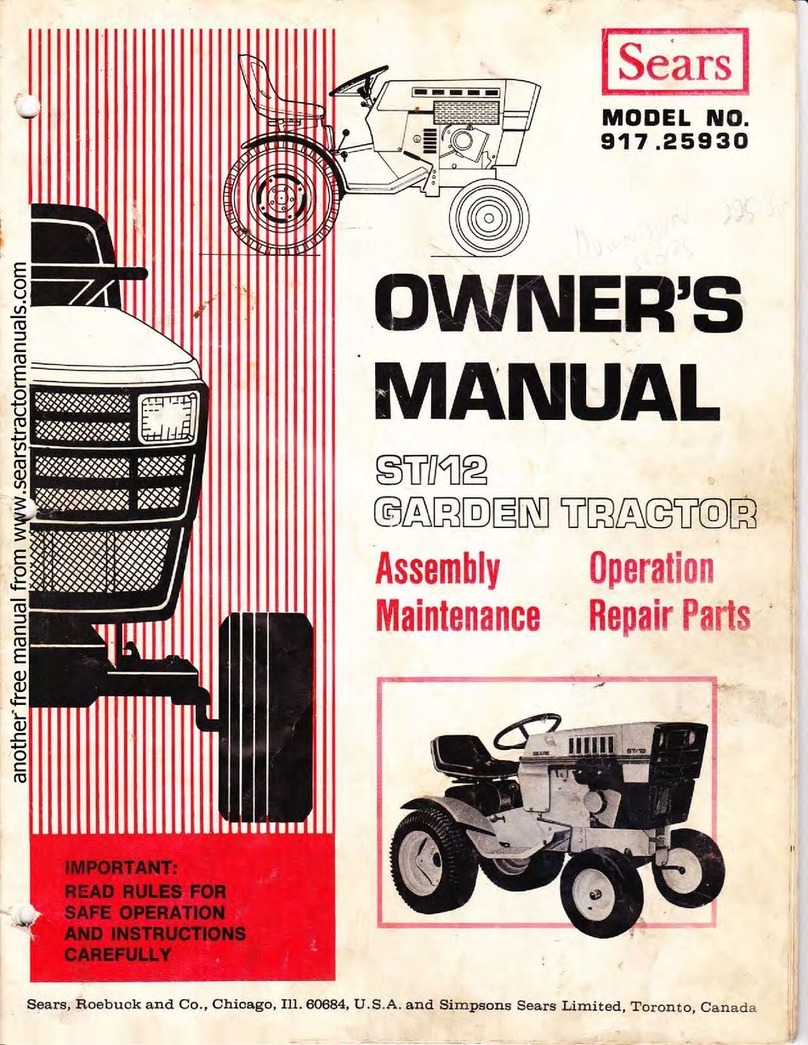

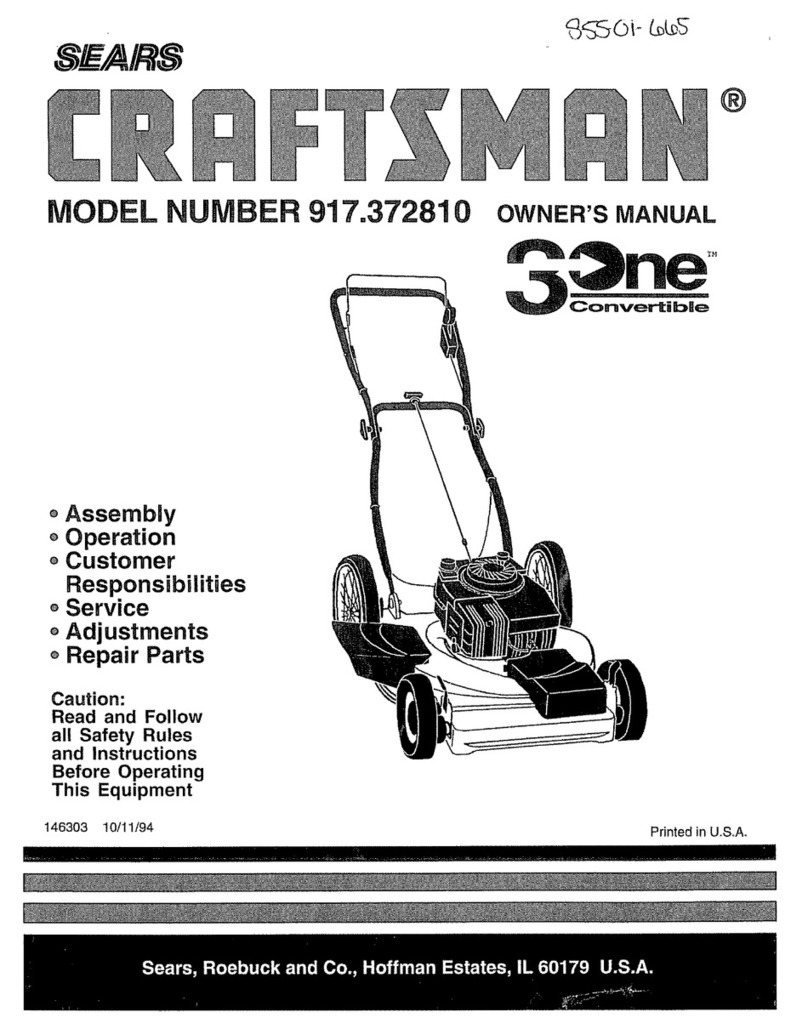

SEARS SICKLE BAR MOWER

MODEL

842.26002

Your Sears Sickle Bar Mowerhas been designed speci-

fically for your tractor with all controls convenient to

the operator,its rugged construction assures

YQU

long

lifeand highest performance.The mower cuts an ef-

fective48" swath.

Keepthis manual available for ready reference. It has

been carefully prepared to instruct you in operating,

maintainingand lubricating your Sears Sickle Bar

Mower.Emphasis has been placed on safetyand oper-

ator protection. However,careless and negligent

operation can stillresult in serious injury to persons

and property.It is very important that each operator

fully understands the contents of this manual for safe,

.dependable operation and to prolong the life ofthe

equipment.

OPERATING TRACTORS WITH GEAR TYPE

TRANSMISSIONS

Best cutting results will be obtained by operating trac-

tor at 314to full engine speed.

The tractor should beequipped with a wheel weight

on the left rear wheel of the tractor.These can

be obtained from your Sears store

Performance of the sickle knife depends on the follow-

ing points, all of which are important:

(1)

sharpness

of sickle knife;(2) wear plate adjustment; (3) straight-

ness of knife bar; (4) hold-down clip clearance; (5)

speedof sickle knife.

When mowing in extremely rough areas,tractor

~hould beoperated in 1st Gear(Low Range).D~pend-

Ing on ground and grassconditions. In other areas,

2nd Gea~(Low Range) or 1st Gear (High Range) will

usually give you the best results. When cutting brush

larger than 1/2"diameter,it may be necessary to

stop tractor movementwhen sickle bar makescontact

and allow the sickle knife tocut through the brush

material.It is not recommended to attempt to cut

through material exceedingan inch in diameter.

Thesickle barmower can be transported from one

location to another bv raising the unitand locking it

Into position as illustrated on page 11Fig.15

Always install knife guard on mower bar when trans-

porting.Fig.15

Always operate at careful speeds in transporting and

avoid making sudden orsharp turns with the mower

in raised position .

Cutting Width Mows48" Swath

LJrive Belt Uriven from tractor P.T.O.

Clutch Manual

Suspension Free-Floating, Spring Suspended

Mounting Swivel, Vibration-Dampening

Cutting Speed 900-11 00 Strokes per Minute

Stroke FuIl3 "Width

Shear Knives High Carbon Steel

Guards Non-clogging

Vertical Adjustment 45° below to 45°above

horizontal

Transport Position Pin-Locked forTransport

........................................Automatic Spring-Loaded

"Swing Back"device protects against

damage from solid objects

Construction AII Steel, with Anti-Friction bear-

ings

Table of Contents

SAFETY'••••.••••.•

0 •••••••••

$ ••••••••••••

III•• • • • • • • ••

2-3

SET UP ••••.•.•••••••••.•.••.•..••••.

0 •••••••••••••••

5-9

OPERATION••••••••••••..•..•••.•••

ea. • • • • • • • • • • • • • ••

10 -15

MAINTENANC E ••••••.• •••• '••••••••••••

0• • • • •• • • • • •• • • •

16

OPERATING MOWER •••••••••••••••••••••••••••••••••••••

10

V-BELTS ••••••.•.•••••••••••••••••.•••••.•••••••••••••

12-13

SICKLEKNIFE ••••••••••••••••••••••••••••••••: • • • • • •••

14

TRANSPORTINGMOWER. • • • • ••• • •• • • • • • • ••• • • • ••• • •••••••

11

ADJUSTMENTS ••••••• \.. • • • • • • • • • • • • • • • • • • • • • • • • • • • • • ••

12..14

SERVICE TIPS

It ••••••••••••••••••••••••••••••••••••• 0 • GO.

15

PARTS LISTING •••••••••••••••••.••.•.•••••••••...••.••••17-23