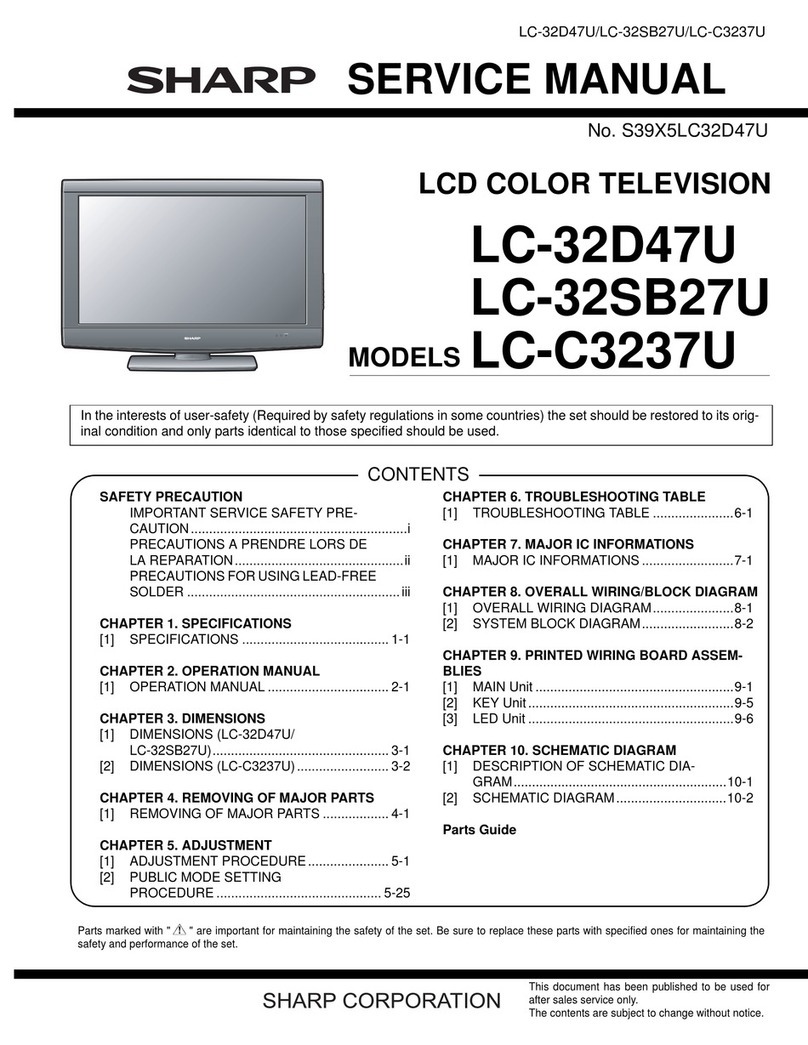

LC-42D43U

v

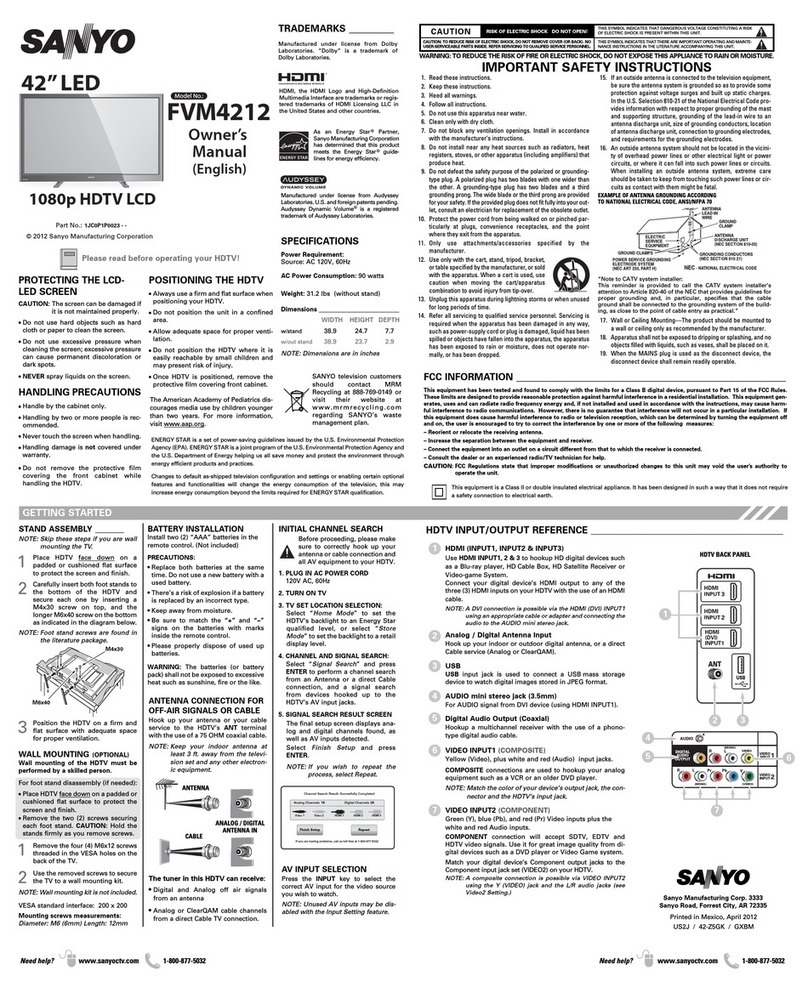

PRECAUTIONS A PRENDRE LORS DE LA REPARATION

De nombreuses pièces, électriques et mécaniques, dans les télévi-

seur ACL présentent des caractéristiques spéciales relatives à la sé-

curité, qui ne sont souvent pas évidentes à vue. Le degré de protec-

tion ne peut pas être nécessairement augmentée en utilisant des

pièces de remplacement étalonnées pour haute tension, puissance,

etc.

Les pièces de remplacement qui présentent ces caractéristiques sont

identifiées dans ce manuel; les pièces électriques qui présentent ces

particularités sont identifiées par la marque " " et hachurées dans la

liste des pièces de remplacement et les diagrammes schématiques.

Pour assurer la protection, ces pièces doivent être identiques à celles

utilisées dans le circuit d'origine. L'utilisation de pièces qui n'ont pas

les mêmes caractéristiques que les pièces recommandées par l'usine,

indiquées dans ce manuel, peut provoquer des électrocutions, incen-

dies, radiations X ou autres accidents.

AVERTISSEMENT

1.

2.

3.

4.

5.

•

•

•

•

/////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

/////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

Ne peut effectuer la réparation qu' un technicien spécialisé qui s'est parfaitement accoutumé à toute vérification de sécurité et aux

conseils suivants.

N'entreprendre aucune modification de tout circuit. C'est danger-

eux.

Débrancher le récepteur avant toute réparation.

Inspecter tous les faisceaux de câbles pour s'assurer que les fils

ne soient pas pincés ou qu'un outil ne soit pas placé entre le châs-

sis et les autres pièces métalliques du récepteur.

Inspecter tous les dispositifs de protection comme les boutons de

commande non-métalliques, les isolants, le dos du coffret, les cou-

vercles ou blindages de réglage et de compartiment, les réseaux

de résistancecapacité, les isolateurs mécaniques, etc.

S'assurer qu'il n'y ait pas de danger d'électrocution en vérifiant la

fuite de courant, de la facon suivante:

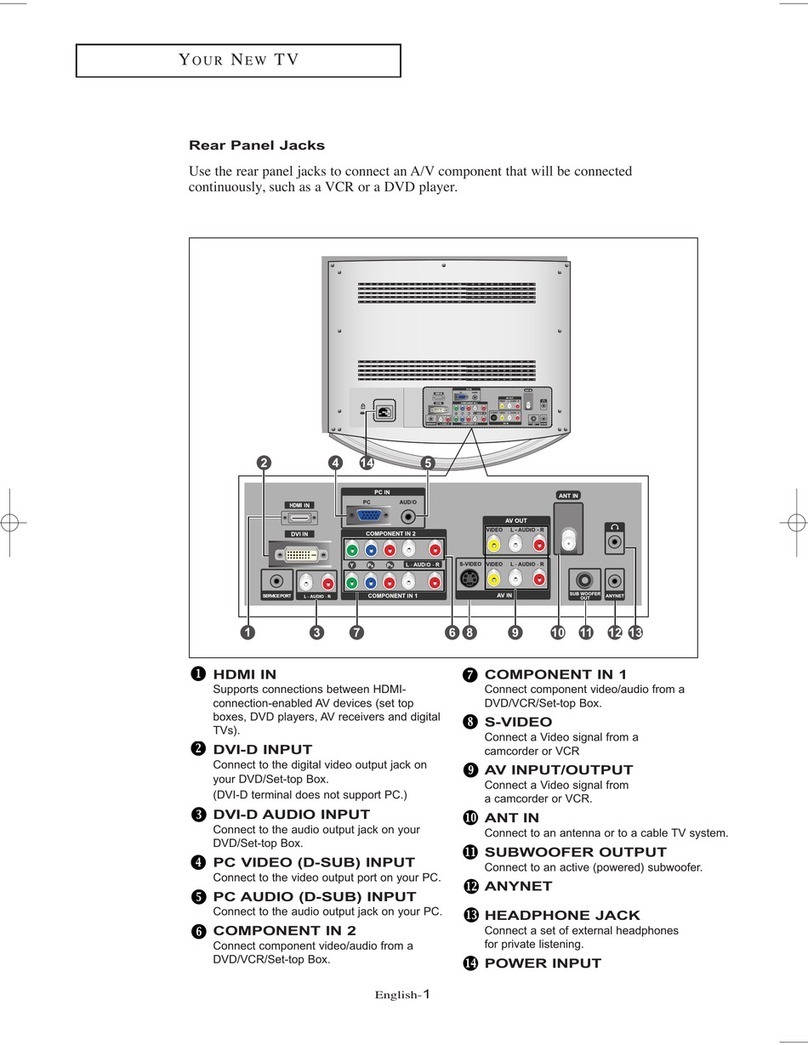

Brancher le cordon d'alimentation directem-ent à une prise de cou-

rant de 120V. (Ne pas utiliser de transformateur d'isolation pour

cet essai).

A l'aide de deux fils à pinces, brancher une résistance de 1.5 kΩ

10 watts en parallèle avec un condensateur de 0.15μF en série

avec toutes les pièces métalliques exposées du coffret et une terre

connue comme une conduite électrique ou une prise de terre

branchée à la terre.

Utiliser un voltmètre CA d'une sensibilité d'au moins 5000Ω/V pour

mesurer la chute de tension en travers de la résistance.

Toucher avec la sonde d'essai les pièces métalliques exposées qui

présentent une voie de retour au châssis (antenne, coffret métalli-

que, tête des vis, arbres de commande et des boutons, écusson,

etc.) et mesurer la chute de tension CA en-travers de la résistance.

Toutes les vérifications doivent être refaites après avoir inversé la

fiche du cordon d'alimentation. (Si nécessaire, une prise

d'adpatation non polarisée peut être utilisée dans le but de termin-

er ces vérifications.)

La tension de pointe mesurèe ne doit pas dépasser 0.75V (corre-

spondante au courant CA de pointe de 0.5mA).

Dans le cas contraire, il y a une possibilité de choc électrique qui

doit être supprimée avant de rendre le récepteur au client.

PRECAUTION: POUR LA PROTECTION CON-

TINUE CONTRE LES RISQUES D'INCENDIE,

REMPLACER LE FUSIBLE

F701 (250V 8A)

VERIFICATIONS CONTRE L'INCEN-DIE ET LE

CHOC ELECTRIQUE

Avant de rendre le récepteur à l'utilisateur, effectuer les vérifica-

tions suivantes.

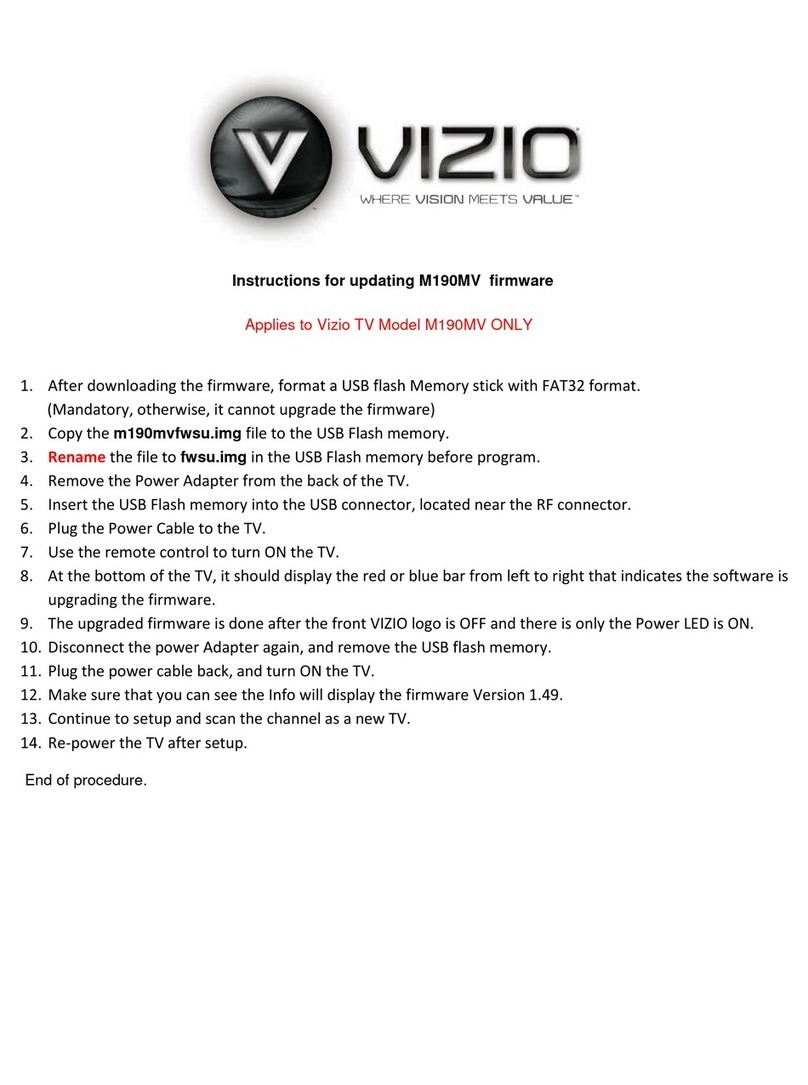

DVM

ECHELLE CA

1.5k ohm

10W

0.15

μ

F

SONDE D'ESSAI

AUX PIECES

METALLIQUES

EXPOSEES

BRANCHER A UNE

TERRE CONNUE

AVIS POUR LA SECURITE