Shimadzu CTO-40C CL User manual

228-97203A

Jun. 2022

Column Oven

For Shimadzu Liquid Chromatograph

CTO-40C CL

Instruction Manual

Read this manual thoroughly before you use the product.

Keep this manual for future reference.

This page is intentionally left blank.

Read this Instruction Manual thoroughly before using

the product.

Thank you for purchasing this product.

This instruction manual describes the basic operation, and accessories and options for this

product. Read this manual thoroughly before using the product and operate the product

in accordance with the instructions in this manual.

The following instruction manuals are included with the product.

Document Name Document

No. Description

Instruction Manual (PDF) 228-97203 This instruction manual.

System Guide (PDF) 228-97194

This manual provides details on how to use

the system:

system performance optimization, analysis

procedure, troubleshooting, validation,

installation, etc.

Safety Guideline

(Booklet/PDF) 228-97195 This manual describes the precaution

instructions to ensure safe operation.

Read "Safety Guideline" thoroughly before using the product.

"Safety Guideline" describes the information about the warranty, after-sales service,

safety instructions and precautions to ensure safe operation of the instrument.

Keep this manual for future reference.

IMPORTANT

• If the user or usage location changes, ensure that the manual is always kept

together with the product.

•If any manual or a product warning label is lost or damaged, immediately contact

your Shimadzu representative to request a replacement.

•To ensure safe operation, read the accompanying booklet "Safety Guideline"

before using the product.

•To ensure safe operation, contact your Shimadzu representative if product

installation, adjustment, re-installation (after the product is moved), or repair is

required.

ã 2019-2022 Shimadzu Corporation. All rights reserved.

Original version is approved in English.

Introduction

CTO-40C CL i

Notice

• Information in this manual is subject to change without notice and does not represent

a commitment on the part of the vendor.

• Any errors or omissions which may have occurred in this manual despite the utmost

care taken in its production will be corrected as soon as possible, although not

necessarily immediately after detection.

• All rights are reserved, including those to reproduce this manual or parts thereof in

any form without permission from Shimadzu Corporation.

•Prominence, Nexera, and LabSolutions are trademarks of Shimadzu Corporation.

Windows is a registered trademark of Microsoft Corporation in the United States and/or

other countries.

Third-party trademarks and trade names may be used in this publication to refer to

either the entities or their products/services, whether or not they are used with

trademark symbol "TM" or "®".

Indications Used in This Manual

Precaution symbols are indicated using the following conventions:

Indication Meaning

Indicates a potentially hazardous situation which, if not

avoided, could result in serious injury or possibly death.

Indicates a potentially hazardous situation which, if not

avoided, may result in minor to moderate injury or equipment

damage.

Emphasizes additional information that is provided to ensure

the proper use of this product.

The following symbols are used in this manual:

Indication Meaning

Indicates an action that must not be performed.

Indicates an action that must be performed.

Indicates information provided to improve product performance.

Indicates the location of related reference information.

ii CTO-40C CL

Introduction

Operating Nexera CL System

nIntended Use

This system is designed to perform qualitative and quantitative analysis of target

compounds in a sample matrix and can be used as a column oven of the liquid

chromatograph for general in vitro diagnostic applications. However, only personnel who

have received appropriate training on use of the system can use it for these purposes.

nCalibration

A calibration curve should be generated for each analyte in appropriate methods. At

least four out of six non-zero standards should meet the appropriate criteria, including

the calibration standard lower than the assumed LOQ and the calibration standard at

the highest concentration.

nQuality Control

Implement quality control of the instrument by routinely measuring at least one each of

four types of quality-control samples (a sample with a normal concentration level, a

sample with a concentration level higher than normal as well as a sample lower than

normal, and a blank sample). Check the selectivity/specificity in the matrix used for the

actual sample, the accuracy, correctness, recovery rate, dynamic range, linearity, and lower

limit of quantitation.

Based on these assessment results, check that the results are within the permissible range.

If the assessment results are out of range, the measured data may be invalid, so do not

use analysis results obtained from the instrument in question until it can be confirmed

that it is functioning normally. When, for example, analyzing samples that contain

complex sample matrices such as serum, plasma or urine, it may be possible to obtain

stabilized data by using an appropriate pre-treatment or an internal standard.

Electromagnetic Compatibility

Descriptions in this section apply only to the following model:

• 228-65202-55 CTO-40C CL

This product complies with European standard EN61326, class B for electromagnetic

interference (Emissions) and industrial electromagnetic environment (Immunity).

nEN55011 Emissions (Electromagnetic Interference)

This is a class B product. When this product causes an electromagnetic disturbance to

devices being used near this product, create an appropriate distance between those

devices and this product in order to eliminate the disturbance.

CTO-40C CL iii

Operating Nexera CL System

Contents

Introduction Indications Used in This Manual ......................... ii

Operating Nexera CL System .............................. iii

Electromagnetic Compatibility ............................ iii

1Overview 1.1 Features ............................................................. 1

1.2 Component Parts ................................................. 2

1.3 Optional Parts ..................................................... 2

2Parts Identification

and Function

2.1 Front .................................................................. 6

2.2 Interior ............................................................... 8

2.3 Back ................................................................... 9

2.4 Name and Functions of the Operation Panel ....... 10

2.4.1 Display Area ................................................... 12

2.4.2 Operation Area ................................................ 13

3Operation 3.1 Settings for the Basic Operation ......................... 15

3.1.1 Prior to Key Operation ........................................ 15

3.1.2 Temperature Control Operation ............................... 15

3.2 Types of Screens ................................................ 18

3.3 Monitoring Screens ............................................ 19

3.4 Auxiliary Functions Screen (FUNCTION) ................ 20

3.4.1 Auxiliary Functions (FUNCTION) List .......................... 20

3.4.2 [PARAMETER] Setting Group .................................. 23

3.4.3 [SYSTEM] Setting Group ...................................... 24

3.4.4 [UTILITY] Setting Group ....................................... 29

3.5 VP Functions Screen ........................................... 31

3.5.1 List of VP Functions .......................................... 31

3.5.2 Product Information Group (PRODUCT INFO) ................ 32

3.5.3 Maintenance Information Group (MAINTENANCE) ........... 33

3.5.4 Validation Support Information Group (VALIDATION) ........ 35

3.5.5 Calibration Support Information Group (CALIBRATION) ...... 38

iv CTO-40C CL

3.6 Creating Time Program ...................................... 43

3.6.1 Time Program Command List ................................. 43

3.6.2 Time Program Setting Screen ................................. 44

3.6.3 Creating a Time Program ..................................... 45

3.6.4 Deleting a Step ............................................... 47

3.6.5 Starting and Stopping a Time Program ...................... 48

3.6.6 Special Commands Used in Time Programs .................. 49

3.7 Connection with the System Controller ............... 50

3.7.1 Setting the Instrument ........................................ 50

3.7.2 Basic Parameters .............................................. 50

3.8 Connection to External Input/Output Terminals

......................................................................... 51

3.8.1 External Input/Output Terminals .............................. 51

3.8.2 Connection of Remote Cable ................................. 53

4Maintenance 4.1 Periodic Inspection and Maintenance .................. 54

4.1.1 Prior to Inspection and Maintenance ......................... 55

4.1.2 List of Periodic Inspection and Maintenance ................. 55

4.1.3 Check After Inspection and Maintenance .................... 56

4.2 Temperature Accuracy Calibration ....................... 56

4.3 Gas Sensor Calibration ....................................... 57

4.4 Leak Sensor Calibration ...................................... 57

4.5 Cleaning the Leak Tray ...................................... 58

4.6 Replacing the Air Filter ...................................... 58

4.7 Cleaning the Exterior ....................................... 59

4.7.1 Usual cleaning ............................................... 59

4.7.2 Decontamination cleaning ..................................... 60

5Technical

Information

5.1 Specifications .................................................... 61

5.2 Maintenance Parts ............................................. 62

5.2.1 Consumable Parts ............................................. 62

5.2.2 Replacement Parts ............................................. 62

CTO-40C CL v

Contents

The Shimadzu CTO-40C CL column oven was developed to maintain the temperature of

the LC system column and flow lines at a constant temperature, in order to provide

heightened analysis reproducibility and separation performance. The oven is an

air-circulated thermostatic chamber for the Shimadzu Liquid Chromatography system. In

this instrument, the temperature is controlled by a heater for heating and a Peltier

element for cooling, and the temperature around the column is kept uniform by agitating

the inside of the thermostatic chamber with an air circulation fan.

Excluding the thermostatic chamber, the other instruments necessary for liquid

chromatography such as a solvent delivery unit, autosampler, detector, and system

controller are sold separately.

For instruments that suit your purpose of use, contact your Shimadzu representative.

1.1 Features

nIn addition to columns, the thermostatic chamber allows installation of flow line parts

in it including a mixer and automatic column switch valves.

The main purpose of this column oven is to keep the column temperature constant. The

thermostatic chamber can store flow line parts in it including a mixer and automatic

column switch valves as well as columns. Installing these in the oven isolates them from

the influence of ambient temperature and makes for more stable analysis. Shorter

plumbing distances also reduce dead volume in the flow lines.

nTime program functions are available for setting the temperature even in standalone

use.

Use of a system controller (CBM-40 CL) permits finer control, like starting analysis when

temperature stabilizes and stopping analysis when leaks or problems are detected.

nThe automatic speed control of the air circulation fan provides a stable temperature

control.

The speed of the air circulation fan is automatically controlled based on the temperature

setting. At high temperatures, the air circulation ratio is increased to keep the

temperature constant, and at temperatures close to the ambient temperature, the air

circulation ratio is decreased to suppress heat generation due to the air circulation. The

fan speed is controlled so as to remain constant even when there are fluctuations in the

power supply. This enables stable temperature control.

nThe built-in thermal fuse and leak sensor ensure safety.

To ensure safe use, the thermal fuse cuts off the power to the heater if the temperature

rises abnormally. In addition, if some liquid leaks inside, the gas sensor (flammable

organic solvent) or liquid leak sensor (aqueous solvent) issues an error to automatically

stop temperature control.

1Overview

CTO-40C CL 1

1

1.2 Component Parts

This instrument consists of the standard parts listed below. Check the parts against this

list after unpacking.

No. Part Name Part No. Q'ty Remark

- Main Unit CTO-40C CL - 1 -

-Safety Guideline

(Booklet) 228-97195 1 Contains cautions for use

regarding the instrument.

-

Instruction Manual/

System Guide

(CD-ROM)

228-97193-41 1

1 Filter holder 228-72234 1

System Guide "7

Installation"

2 Air filter 228-72570-01 1

3 Drain Tube 228-25162-03 1

4 Rubber column clamp 228-72586 2

5 Clamp CKN-10-R 072-60330-53 1

6 Clamp DKN-10GSP 072-60319-01 1

1.3 Optional Parts

Optional parts which can be added to the column oven are listed below.

For information about other optional units listed below, contact your Shimadzu

representative.

For optional parts for the whole LC system, refer to System Guide. For columns, refer to

Shimadzu's column catalog.

nParts for the oven

Option Part No. Features

Active preheater 228-72084-41

The preheating unit heats the mobile phase

before it enters columns by independent

heating control. The unit controls the

temperature gradient in columns so that sharp

peaks are obtained.

Column clamp B5 228-15617-41 Can fix one column with an outer diameter of

6.5 mm to 9.5 mm. (Metal)

Column clamp B8 228-15617-42 Can fix one column with an outer diameter of

9.5 mm to 12.7 mm. (Metal)

Column catch 228-28637-91 Can fix two columns with an outer diameter of

6.5 mm to 12.7 mm. (Metal)

Remote Cable 228-28253-91 Used for connection of an external device.

2CTO-40C CL

1 Overview

nCMD (Column Management Device)

The device stores information on a column and is capable of managing the column in

combination with the database of a PC workstation. One CMD chip is required for each

column. For details, refer to the instruction manual of LabSolutions chromatography data

system.

System Guide "3.9 Column Management"

Option Part No. Features

CMD (Column

Management Device) 228-37281-41 The device is stored colmun-related infomation.

One CMD chip is required for each column.

CMD cable (150 mm) 228-39991 The cable connects a CMD chip with the

instrument.

CMD cable (400 mm) 228-39991-01

nAutomatic column switch valve

Two valves can be installed with one on the lower-left part and the other on the

lower-right part.

Option Part No. Features

FCV-0206H 228-65607-58

The valve with two positions and six ports

automatically switches between two columns.

The withstand pressure is 80 MPa.

FCV-0206H3 228-65624-58

The valve with two positions and six ports

automatically switches between two columns.

The withstand pressure is 130 MPa.

FCV-0607H 228-65608-58

The valve with six positions and seven ports

automatically switches between six columns.

The withstand pressure is 80 MPa.

FCV-0607H3 228-65625-58

The valve with six positions and seven ports

automatically switches between six columns.

The withstand pressure is 130 MPa.

FCV-DR 228-65602-58 The unit drives the previously listed valves. (One

unit is required for each valve.)

FCV-36AH 228-45206-58

The valve with two positions and ten ports

automatically switches between two columns.

The withstand pressure is 100 MPa. (Including

the driving unit)

Manifold 228-72436-41

The part joins tubes of column outlets to

enable one valve to switch between columns.

PEEK resin is used for a wetted part.

Safety GuidelineSystem Guide "5.

Precautions for Mobile Phase Selection

and Use"

FCV installation kit

(CTO-40C) 228-72589-41

The common installation kit is required for

installing the previously listed valves in the

instrument. (Only one unit is required for this

instrument.)

FCV tubing two-piece kit

(ID 0.3) 228-72437-41 The tubing kit is required for installing two

columns.

CTO-40C CL 3

1.3 Optional Parts

1

Option Part No. Features

FCV tubing two-piece kit

(ID 0.1) 228-72437-42 The tubing kit is required for installing two

columns.

FCV tubing two-piece kit

(ID 0.1 300 mm Nexlock) 228-72437-49

The tubing kit is required for installing two

columns. (This Nexlock tubing comes with finger

tight fittings.)

FCV tubing six-piece kit

(ID 0.3) 228-72437-43 The tubing kit is required for installing two to

six columns.

FCV tubing six-piece kit

(ID 0.1) 228-72437-44 The tubing kit is required for installing two to

six columns.

FCV tubing six-piece kit

(ID 0.1 300 mm Nexlock) 228-72437-50

The tubing kit is required for installing two to

six columns. (This Nexlock tubing comes with

finger tight fittings.)

4CTO-40C CL

1 Overview

nGradient mixer

The instrument can store one of the following mixers coming with a mixer detection

device.

For how to select a mixer, refer to System Guide.

Connecting a mixer detection device to the instrument requires a separate CMD cable

(150 mm).

Option Part No. Features

MIXER SUS316L ASSY

(With a mixer detection

device)

228-72654-41

The general-purpose mixer, where stainless steel

is used for the wetted part material, is intended

for both high and low pressure gradient

analysis. The capacity can switch between three

settings of 0.5 mL, 1.7 mL, and 2.6 mL.

MIXER PEEK

(With a mixer detection

device)

228-72654-42

The non-metal gradient mixer does not contain

any metal as a material in its parts that come

in contact with liquid. The capacity can switch

between two settings of 0.4 mL and 1.6 mL.

The mixer can be used for both high and low

pressure gradient analysis.

MIXER MR 20 µL

(With a mixer detection

device)

228-72652-41

The mixer is intended exclusively for high

pressure gradient analysis with high

performance and a small internal capacity of 20

μL, where stainless steel is used for the wetted

part material.

MIXER MR 40 µL

(With a mixer detection

device)

228-72652-42

The mixer is intended exclusively for high

pressure gradient analysis with high

performance and a small internal capacity of 40

μL, where stainless steel is used for the wetted

part material.

MIXER MR 100 µL

(With a mixer detection

device)

228-72652-43

The mixer is intended exclusively for high

pressure gradient analysis with high

performance and a small internal capacity of

100 μL, where stainless steel is used for the

wetted part material.

MIXER MR 180 µL II

(With a mixer detection

device)

228-72652-44

The mixer is intended exclusively for high

pressure gradient analysis with high

performance and a small internal capacity of

180 μL, where stainless steel is used for the

wetted part material.

MIXER MR 300 LPGE

(With a mixer detection

device)

228-72653-42

The high performance mixer is intended

exclusively for low pressure gradient analysis

with an internal capacity of 300 μL, where

stainless steel is used for the wetted part

material.

CTO-40C CL 5

1.3 Optional Parts

1

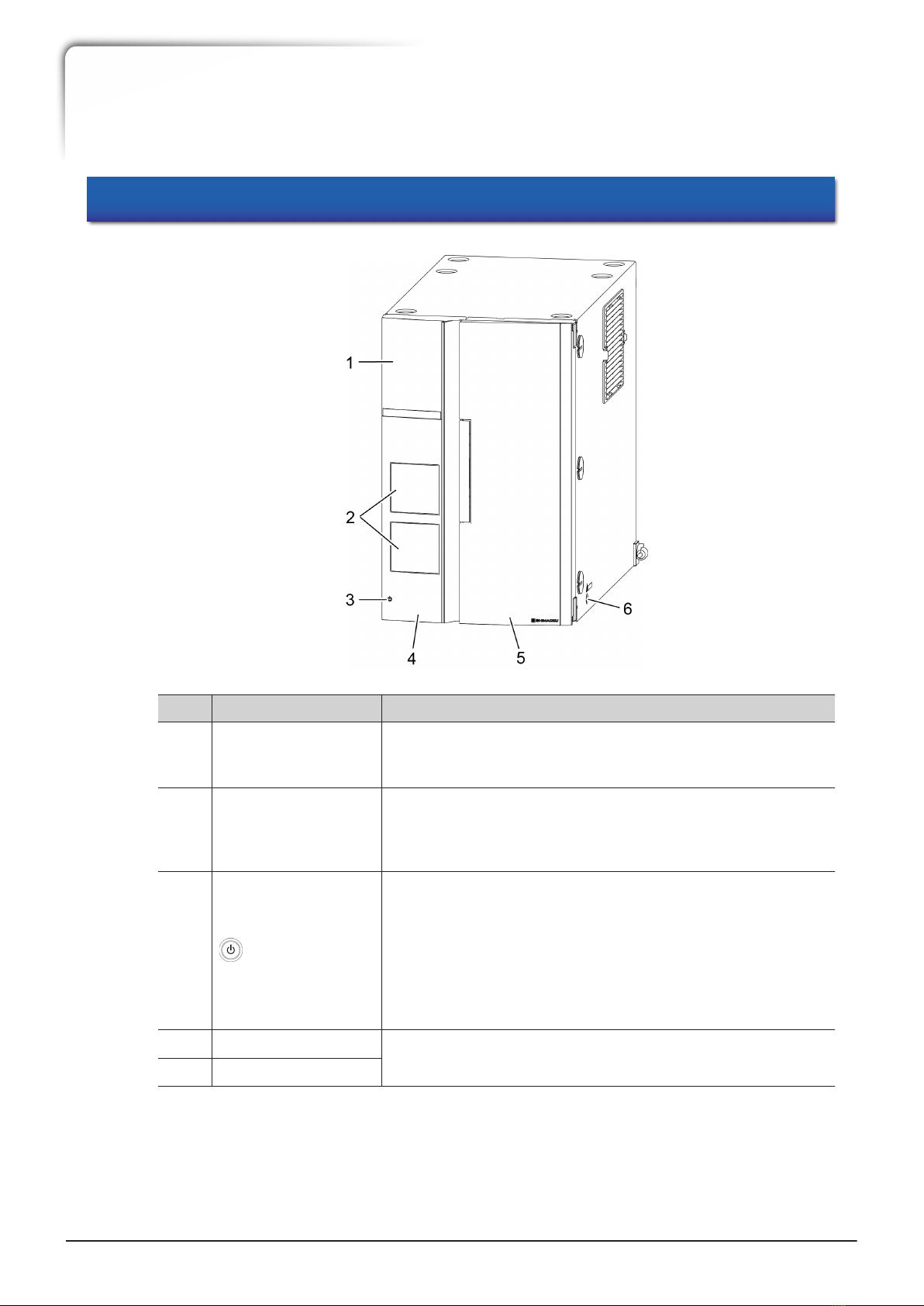

2.1 Front

No. Name Function

1 Operation panel

Configure or operate the instrument with the operation keys.

Touching any other point than the display area on the

operation panel displays the operation keys.

2

Manual injector

(optional) positions

(Not used in CL

model)

Manual injectors (optional) can be installed here after

removing the covers.

3 (Power button)

Switches ON/OFF the power. When the power is ON, the

switch illuminates in white, and when the power is OFF, the

switch illuminates in orange. Even when the power is OFF,

the standby current is fed to the instrument. For the main

power, see "2.3 Back" P.9.

Note that, with a system controller CBM-40 CL connected,

the switch does not illuminate and the operation to the

switch is ignored.

4 Left door The door of the column temperature control part. Open the

door when setting a column.

5 Right door

2

Parts Identification and Function

6CTO-40C CL

No. Name Function

6 Drain hole The hole on the right of the instrument drains dew water

and mobile phase leaking inside.

The right and left doors have a built-in sensor. Opening the door during

temperature control causes the control to be stopped and the [DOOR] indicator

on the display area to blink. Closing the door causes the temperature control to

be resumed.

CTO-40C CL 7

2.1 Front

2

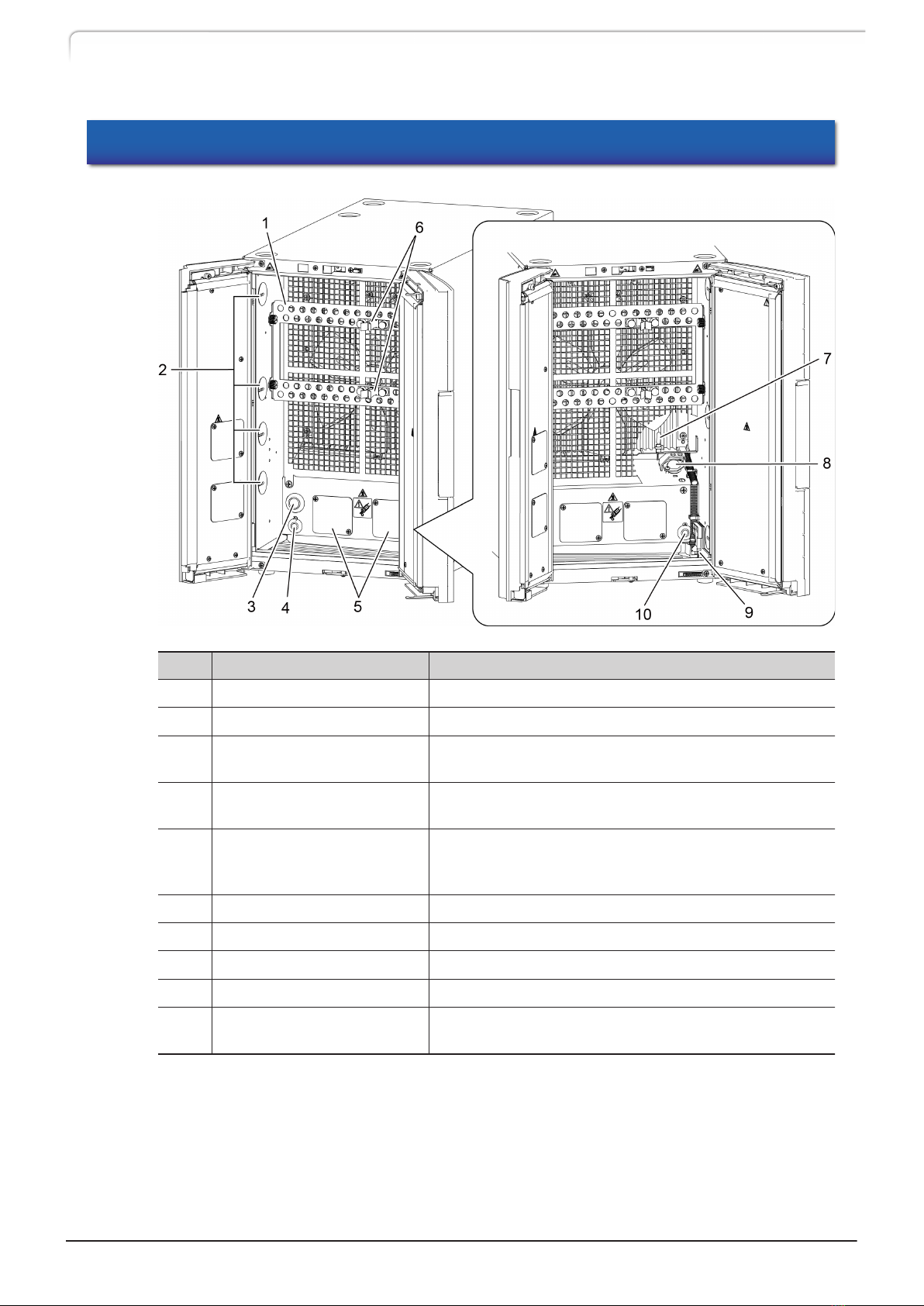

2.2 Interior

No. Name Function

1 Column bracket Used for fixing columns.

2 Tube cap Removing the caps allows inserting tubes.

3 Optional hole cap Used for installation of an optional active preheater

and multi-column rack.

4 [CMD4/Mixer] connector The connector is for a mixer detection device

(optional). ([CMD4] is a future expanded function.)

5

Automatic column switch

valve (optional) installation

part

Allows installation of the optional automatic column

switch valves.

6 Column clamp Used for fixing tubes.

7 Thermosensor The sensor is for temperature measurement.

8 Gas sensor The sensor detects organic solvent vapors.

9 Liquid leak sensor The sensor detects leakage of aqueous solvent.

10 [CMD1] connector The connector is for a column management device

(CMD) (optional).

8CTO-40C CL

2 Parts Identification and Function

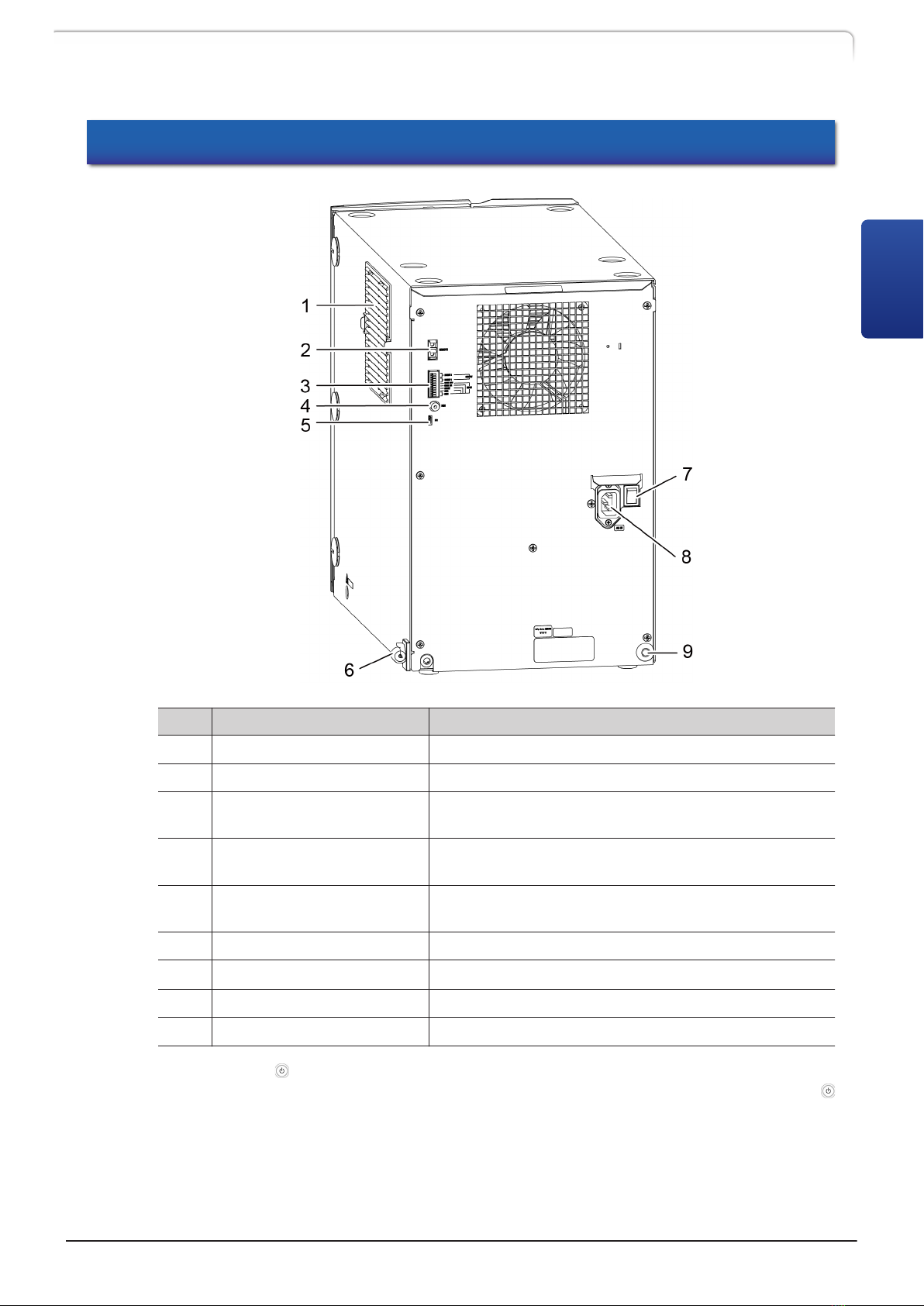

2.3 Back

No. Name Function

1 Air filter Prevents dust from entering the instrument.

2 [REMOTE] connector Connect to the system controller.

3External input/output

terminals Connect to external equipment.

4 [REC] connector The connector outputs the signal of column oven

temperature (100 °C/mV).

5 [PC] connector Connector for service personnel. Normally, this is not

used.

6 Room temperature sensor Monitors the room temperature.

7 Main power switch It turns on/off the power to the instrument.*1

8 Power cord connector Connect the power cord.

9 External-device hole cap Used for attaching an external device.

*1 Normally use (power button) of the operation panel or system controller to turn ON/OFF the

power. If the system controller is connected and the main power switch is on, the user can use

(power button) of the system controller to turn ON/OFF the power from the front of the instrument.

If the instrument is not used for a long time, turn off the main power switch. Before turning off

the main power switch, be sure to turn OFF the power using the power button.

CTO-40C CL 9

2.3 Back

2

2.4 Name and Functions of the Operation Panel

This instrument is controlled through the keypad of the operation area. The display area

allows verification of the instrument status.

The operation area has two input modes: [Arrow key input mode] to enable screen

transfer, and [Numerical key input mode] to enable value input.

In a screen where the numeric keys are available, pressing [Enter] switches the operation

area between the modes.

When turning off the main power switch on the back of the instrument after

changing the parameters via panel operation, be sure to turn OFF the power

with the power button at the front of the instrument, and turn off the main

power switch. Otherwise, some of the changed parameters may return to their

original values.

No. Name Description

1 Display area Displays various screens and settings.

"2.4.1 Display Area" P.12

2 Link LED Illuminates when controlled by the system controller.

3 Status LED

• Blue: analysis in progress

• Green: analysis ready (Temperature control stabilized)

•Yellow: preparation for analysis in progress (Temperature

control yet to be stabilized)

• Red: error

• Orange: sleep mode

10 CTO-40C CL

2 Parts Identification and Function

No. Name Description

4 (Power

button) *1

Switches ON/OFF the power.

• To turn the power ON:

Press and hold the power button for at least 3 seconds.

•To turn the power OFF:

Holding down the power button 3 seconds or more displays

the confirmation screen. Holding it down again 1 second turns

off the power.

The button cannot be used if the instrument is connected

with the system controller CBM-40 CL.

When a CBM-40 CL is used, pressing the power button of

the solvent delivery unit connecting CBM-40 CL in it turns

off the power to the whole system.

5 Direct key

Temperature control start/stop, and time program start/stop can

be performed directly.

"2.4.2 Operation Area" P.13

*1 There is the power button in the lower left in the front of this instrument, not on the operation

panel.

CTO-40C CL 11

2.4 Name and Functions of the Operation Panel

2

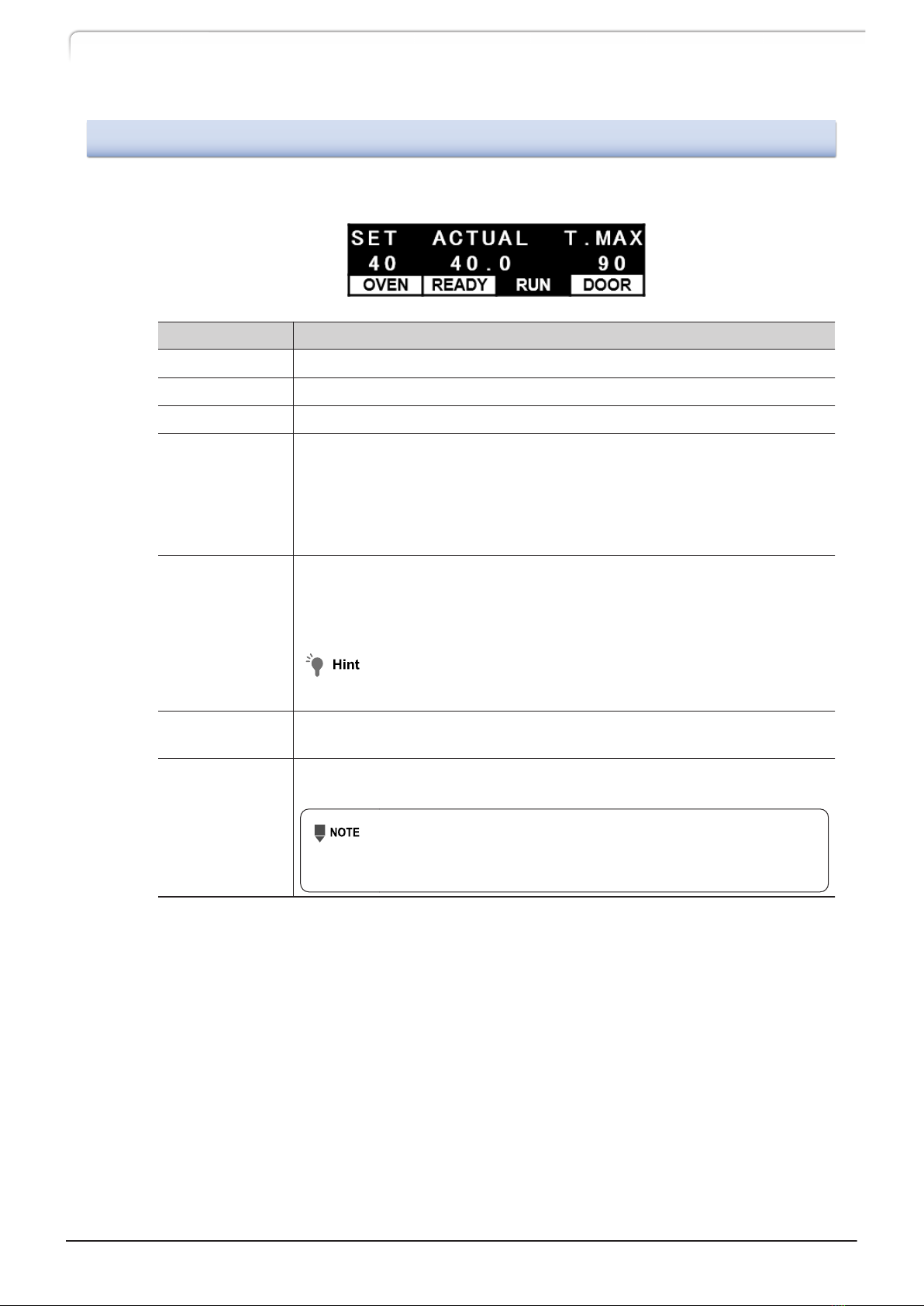

2.4.1

Display Area

In this section the display on the initial screen is described.

Display Function

SET Displays the setting temperature.

ACTUAL Displays the current operation temperature in the oven.

T.MAX Displays the upper limit value of the temperature.

OVEN

When the oven temperature is in adjustment, the word [OVEN] is

highlighted.

The direct key under the display enables to start or stop the temperature

control, thus pressing it while the temperature control is stopped starts

the adjustment, and pressing it while the adjustment is activated stops

the adjustment.

READY / WAIT

Once the temperature control is completed and stabilized, the word

[READY] is highlighted.

While the temperature control is in preparation, [WAIT] blinks.

While the temperature control is stopped, nothing is displayed.

Users can change the condition to display [READY].

"Setting the temperature ready check《READY CHECK》" P.26

RUN Highlighted during execution of a time program.

The direct key under the indicator starts or stops a time program.

DOOR

Blinks when the front door of the oven unit is opened. When the door

is open, the temperature control is paused.

When the oven temperature is 60 °C or higher, a warning

message is displayed. Closing the door clears the warning

message and resumes the temperature control.

12 CTO-40C CL

2 Parts Identification and Function

Table of contents