Sierra Monitor Corporation 1991 Tarob Court Milpitas, CA 95035 USA (408) 262-6611 (800) 727-4377 Fax: (408) 262-9042

Visit our website: www.sierramonitor.com E-mail: sierra@sierramonitor.com

You really have to have back-

bone to survive in the safety

monitoring world today. No,

there is no heavy lifting re-

quired. I am referring to the

data backbone of the facility,

plant or process to which the

monitoring system is applied.

In times past, gas monitor-

ing systems were free-stand-

ing, and any data they gen-

erated was collected and used

on a local basis. Today, plants

and other facilities most likely

require that all data be cen-

tralized so monitoring sys-

tems can perform their func-

tions and provide data to

higher-level systems. Data must be accessible

on plant-wide backbones, which come in many

flavors.

In addition to various proprietary data busses,

some plant backbones are serial-based

(Modbus RTU, DF1, Metasys), many are based

on Ethernet architecture (Modbus TCP,

EtherNet/IP, BACnet/IP) and others are based

on fieldbusses such as Profibus, DH+ and

ControlNet. This discussion is confined to se-

rial data busses and Ethernet networks, but

the principals and issues are universal.

A strong backbone

The challenge for industrial hygiene profes-

sionals is to determine which backbone inter-

face is required and then ensure that the se-

lected equipment meets that requirement.

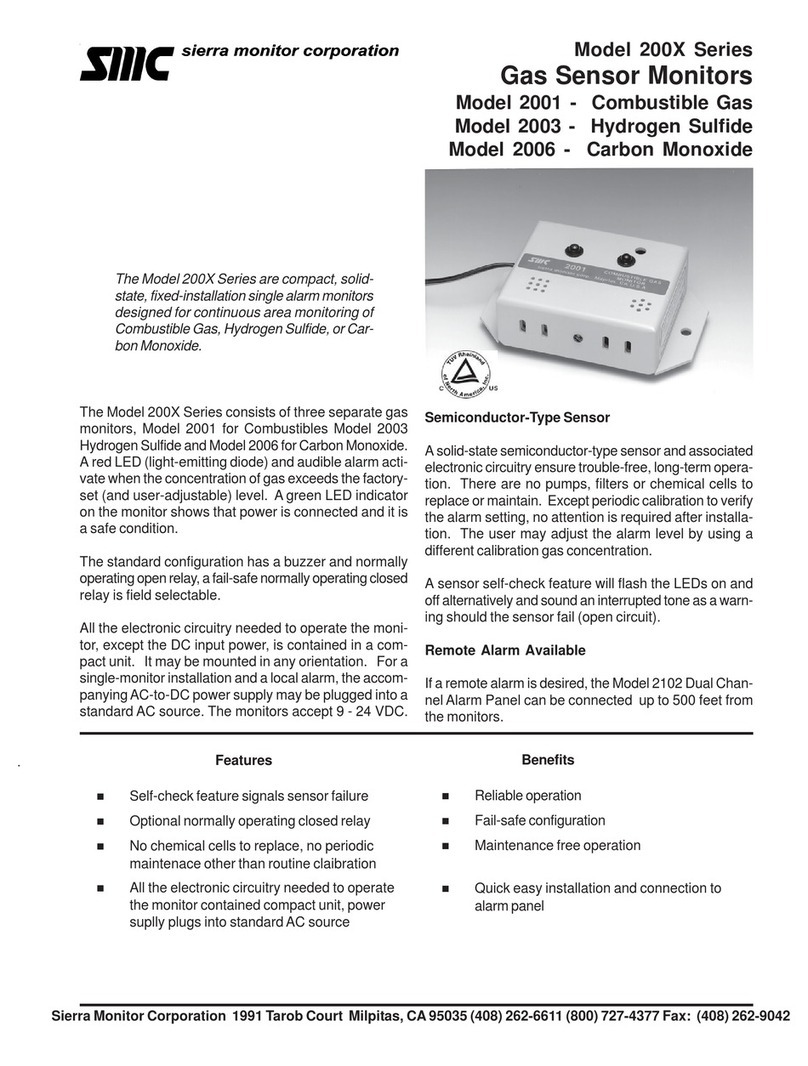

Figure 1 represents the minimum requirements

for a gas detection system that are generally

well understood. The system must include gas

detection modules, a method to communicate

to a controller, flexible alarm handling with relay

outputs, and a method for communicating data

to higher-level systems. In this case, serial

communications are used to provide data to a

dedicated computer.

Technical Reprint TR-005

Gas Detection Systems

How to make your facility's monitoring data accessible

by Gordon Arnold

For purposes of meeting future requirements

to integrate data to a facility backbone, this

minimum system with serial communications

is now well on the way to plant-wide integra-

tion. At the Control level the system provides

sensor monitoring and also controls the alarm

activities. At the Information level data can be

retrieved from the controller via the serial con-

nection. The facility IT group, plant process

control team or the building automation con-

sultants are now free to investigate opportu-

nities to interface to the gas detection system

via the plant backbone.

The terms “serial communication” or “Ethernet”

describe only the electrical hardware charac-

teristics of the backbone, such as the type of

wires and the methods of connection. Com-

paring to an office equipment environment, a

serial connection would interface a computer

to a modem, while an Ethernet connection

would network the computer and allow it to

communicate with a server, a network printer

or many other devices. The aspect that is not

yet described is the protocol, which is the data

format and handling instructions that travel

on the backbone.