Silvan Selecta 042M User manual

Instruction Manual

MANFOAM-2 REV F 05/05/20

14L FOAM MARKER

042M

VICTORIA (HEAD OFFICE)

Telephone: +61 (03) 9215 2700

Fax: +61 (03) 9215 2701

www.silvan.com.au

NEW ZEALAND

Hamilton, New Zealand

Telephone: +64 (07) 8496 033

Fax: +64 (07) 8496070

www.silvannz.co.nz

SILVAN AUSTRALIA PTY. LTD.

ABN 48 099 851 144

PAGE 1

Silvan Warranty

Our goods come with guarantees that cannot be excluded under the Australian Consumer Law.

You are entitled to a replacement or refund for a major failure and for compensation for any other

reasonably foreseeable loss or damage. You are also entitled to have the goods repaired or

replaced if the goods fail to be of acceptable quality and the failure does not amount to a major

failure.

We warrant our goods to be free from defects in materials and workmanship for the warranty

period of 12 months from the date the product is delivered to the consumer.

Silvan warrants its authorised Dealer, who in turn warrants the original purchaser (consumer) of

each new Silvan product that it will repair or replace the product, or, pay the cost of repair or

replacement, as determined by Silvan without charge for labour or any defective or malfunctioning

parts in accordance with the warranty limitations below.

This Warranty is in addition to any other rights and remedies available to consumers under the law

This Warranty Covers

Only conditions resulting directly from defects in workmanship or material under normal use and

service.

Warranty Exclusions

The Warranty does not cover:

•Conditions resulting from misuse, use of incompatible chemicals, exceeding machine

specifications including overloading, impact damage, negligence, accidental damage or failure to

perform recommended maintenance services as specified in the Owner/Operator Manual

applicable to the product.

•Damage caused by continued use of a product after initial failure

•Any product which has been repaired by other than an authorised Silvan service outlet in a way

which, in the sole and absolute judgment of Silvan, adversely affect its performance or reliability.

•The replacement of maintenance items such as diaphragms, batteries, V belts and ground

engaging components, etc.

HOW TO CLAIM WARRANTY

Return the goods to the place of purchase at your cost and within the warranty period along with

evidence of the purchase date. If the original supplier cannot be contacted, then contact Silvan as

below and we can direct you on how to proceed with your warranty claim.

HOW YOUR CLAIM WILL BE MANAGED

The repair of a defective product qualifying under this warranty will be performed by any authorised

Silvan service outlet within a reasonable time following the delivery of the product, at the cost of

the owner, to the service outlet’s place of business. The product will be repaired or replaced

depending on the extent of the problem at the discretion of Silvan and the Silvan dealer.

Warranty

PAGE 2

Whilst each type of Silvan foam marker incorporates all the necessary safety features it is essential

that any person operating them is aware of the safety precautions that should be exercised.

Silvan foam markers are designed and

manufactured solely for the purpose of

dropping foam to define the area sprayed

when agricultural chemicals are being applied

to crops. Under no circumstances should they

be used for any other purpose.

Before using the foam marker carefully read

and ensure you understand the contents of

this manual and any other manual relevant to

the safe operation of any associated tractor

and spraying machinery.

Before operating the foam marker read the

safety warnings carried on the unit and any

associated equipment.

Never allow an inadequately trained person

to operate the foam marker.

Before use of any chemicals including foam

concentrate refer to the chemical

manufacturer’s label and safety instructions

for safe handling procedures and the correct

method of use. Always use the recommended

personal protective clothing and equipment.

Ensure that all operators and associated

personnel are familiar with the legal

regulations and codes of practice that apply

to the safe use and storage of spray chemicals

including foam concentrate.

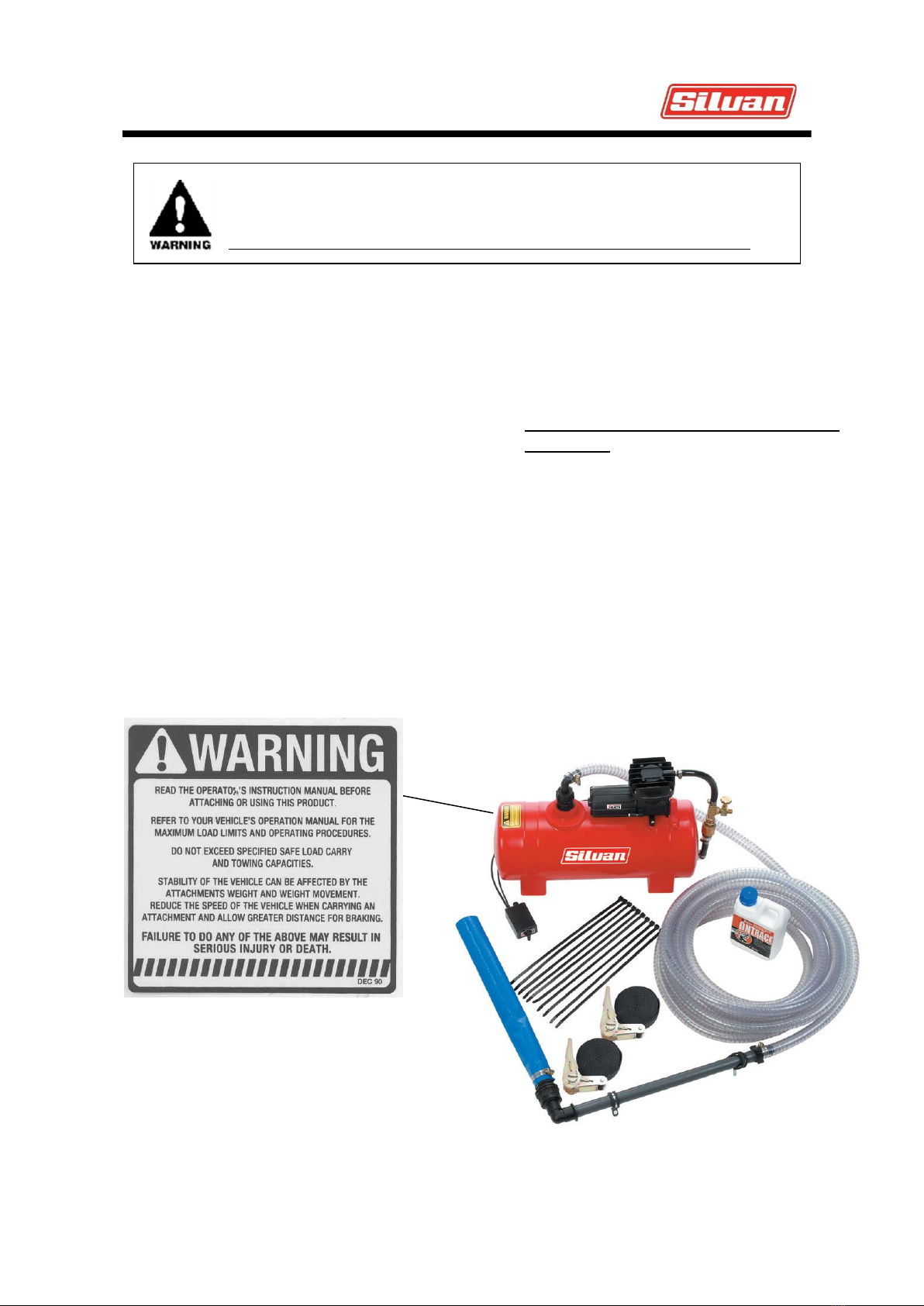

Safety Instructions

Before attempting to operate foam marker carefully read and take note of the

following safety warnings.

Failure to comply with these warnings may result in serious injury or death.

Part Number DEC 48

PAGE 3

Bubbler Standard Foam Marker:

Foam Tank:

Capacity 14L -Impact resistant polyethylene tank.

Air Supply:

12-volt DC diaphragm compressor with in-line non-

return valve and adjustable airflow bleed off valve.

Max 8psi pressure.

Operating Time:

25 to 60 minutes (fitted to 6m boom)

Controls:

Electric control box with single on/off switch.

Foam Delivery:

19 mm diameter reinforced PVC hose, 10metres.

Flexible foam dropper (single side only) with

mounting clamps.

1. Mount the 14L tank to the front or rear of the

vehicle using the 2 tie-down straps supplied with

the unit. Alternatively, it may be supplied fitted to

your new Silvan TPL unit.

2. Attach the electrical leads from the air compressor

to the control box supplied with the marker using

the pin connector supplied. Attach the electrical

leads from the control box to the vehicles 12-volt

battery. Connect the red lead to the positive

terminal of the vehicle battery and the black lead

to the negative terminal. Position the control

on/off switch box in a convenient location for the

operator and attach using the Velcro tape supplied

3. Cut a length of 19 mm wire reinforced hose to

reach from the foam tank to the end of the boom.

Fit one end of the hose to the elbow on top of the

foam tank and secure with a hose clamp. Route

the hose along the vehicle frame, attaching at

convenient points with plastic ties. Ensure that the

hose is not positioned where it can be accidentally

squashed or kinked.

4. Fit the foam dropper to the outer end of wire

reinforced hose and secure with a hose clamp.

5. Attach the rigid tubing section of the foam

dropper to the outer end of the boom with two

saddle clamps. Ensure the dropper is located so

that it does not interfere with the spray pattern of

the end nozzle.

General Considerations

Foam Concentrates

Refer to mixing instructions supplied with foam

concentrate.

Under normal operating conditions it is used in diluted

form at a rate of 1 part of concentrate per 100 parts

of water i.e. 140 ml of concentrate to 14 litres of

water. If this concentration is too thick or slow a rate

of 1 part per 200 parts of water may be necessary.

Water Quality

Foam quality and durability will deteriorate if the

concentrate is diluted with “hard” water. “Soft” water

will give the best foaming result and it is

recommended that rainwater or “soft” town water is

used in preference to bore or dam water.

A reduction in foam volume and durability becomes

noticeable when the calcium carbonate (CaCO3)

content of the water exceeds 300 parts per million

(ppm) and quality can be reduced by up to 40% when

CaCO3 reaches 1500 ppm.

Avoid foam concentrate contact with skin

and eyes and avoid inhaling vapour. Wear overalls,

PVC gloves and face shield or goggles. If product is

on skin immediately wash area with soap and

water. If poisoning occurs, do not induce vomiting.

Give plenty of water or milk to drink and seek

medical assistance. If in eyes, hold eyes open and

flood with water for at least 15 minutes and see a

doctor.

Water Temperature

Foam volume decreases with colder water

temperature. Up to 40% of foam volume can be lost

at 50C compared to 250C. The solution temperature

can be kept above 100C by using hot water if

necessary.

Specifications

Installation

Operation

PAGE 4

Weather Conditions:

Radiant energy from the sun has a far greater

impact on foam life than air temperature. In the

absence of clouds, the surface temperature of bare

ground rises rapidly under direct sunlight,

particularly on dark soils where soil temperature

can approach 550C on a sunny day of 250C air

temperature. Foam blobs falling on bare ground

under these conditions may last less than 20

minutes. Under cloudy conditions the soil

temperature will be like that of the air and foam

blobs will generally last 30 minutes or longer,

depending on the actual temperature. Foam falling

on green vegetation will also last appreciably

longer. Under high temperatures the life of foam

blobs can be extended by increasing the amount of

concentrate added to the tank by approximately

50%.

If the air temperature rapidly falls towards 50C, as

can happen at winter sunset, the volume and

quality of foam may deteriorate noticeably. Under

such conditions it is recommended that the

temperature in the foam tank is raised by adding

concentrate which has been diluted with warm

water.

Dry, windy conditions may require an increased

strength of concentrate to keep the foam on the

ground. The amount of concentrate added can be

increased up to double the normal rate if necessary.

When using increased strength solutions, if the

discharge of foam is slower than required because

it is too thick then dilute the mix by adding water.

Storage of Diluted Solution and Concentrate

Diluted foam solutions tend to deteriorate

considerably if stored in the marker tank for more

than two days, resulting in reduced foam volume

and quality. If the solution has been in the tank for

more than 24 hours, it is recommended that it be

drained and replaced with a fresh mix.

Store concentrate in its original container with the

lid securely closed in a well ventilated, cool area.

Concentrate can tend to age when stored for longer

than 6 months and it is advisable to thoroughly stir

and agitate older concentrate before use.

Principal of Operation

Air is pumped from the electric diaphragm

compressor through a hose fitted with a non-return

valve to the bottom of the foam tank.

As the air bubbles through the mixture of water and

foam concentrate it produces foam. The pressure

produced by the entering air forces the foam out

the top of the tank and along the hose to the foam

dropper at the end of the spray boom.

Operation:

Unscrew the foam hose from the top of the tank.

Take care that any built-up pressure in the tank is

released slowly first. Fill to approximately 3/4

capacity with clean water then add foam

concentrate at the recommended rate. Completely

fill the tank with water and refit the foam hose. To

thoroughly mix the solution and avoid creating

excess foam in the tank whilst adding water, insert

the filling hose below the water surface and use a

gentle flow.

Refer to the General Considerations section for

advice on water quality and foam concentrate

dilution rates.

To start foam generation, turn the compressor on

from the control switch and allow enough time for

foam to reach the boom dropper before

commencing spraying. Once the system has been

primed, foam generation can be stopped and

started by operating the control switch.

An adjustable bleed off tap is fitted and can be used

to reduce the rate of foam production. Operating

the tap reduces airflow to the tank and consequent

foam production.

Sometimes a foam marker may “blow out” due to

excess air escaping through the foam. To correct

this problem, reduce the concentration of foam

concentrate in the mixture by adding more water.

Operation (cont.)

ADJUSTABLE BLEED VALVE

PAGE 5

Flushing the System:

For efficient performance it is important to

remove unused foam and foam solution from

the system after each day’s use.

Remove the top and bottom hose connections

from the foam tank and drain any unused foam

solution, then flush the tank with water.

Electrical Fuses:

If the electrical system fails to operate remove

the fuse and check whether it has blown. If so,

first locate and rectify the fault, then replace

the fuse with a new 15 Amp fuse. A blown fuse

may indicate that an electrical lead has rubbed

through on a sharp surface.

Problem

Solution

Inconsistent Foam quality

Thin Sloppy or Thick Chunky foam

•Incorrect quantity of Foam marker concentrates for

conditions

-If sloppy add more Concentrate or bleed off more

air (less air in tank)

-If chunky, add more water or bleed off less air

(more air to tank)

•Poor water quality –using ‘Hard’ water reduces foam

performance

•Low water temperature –low temp decreases foam

volume

Foam coming out too quickly

•Too much air going thru system –Bleed off more air to

reduce flow

•Adjustments to air flow or concentration can take 5 to

10 min to show at the dropper.

Moisture appears to be entering the

motor. Dye residue is showing on

motor / fan

•Ensure bleed valve is always slightly open to eliminate

possible reverse flow of air back into the compressor

after unit is turned off.

•Ensure fluid does not enter motor while filling tank.

Motor is loading up

Motor is running slow

•Bypass more air to lower compressor pressure

•Check for loose or corroded connections

•Check for moisture damage to moving parts of

compressor & motor

Maintenance

Troubleshoot

Table of contents