SINNOWA W600 User manual

W600

Auto Washer

(

V1.0

)

User’s Manual

Sinnowa Medical Science &Technology Co.,Ltd

INDEX

1. INTRODUCTION........................................................................................................................1

1.1 FEATURES..............................................................................................1

1.2 WORKING ENVIRONMENT REQUIREMENTS..................................................1

1.3 PERFORMANCE .......................................................................................1

1.4 INSTRUMENT STRUCTURE ........................................................................2

2. INSTALLATION...........................................................................................................................2

2.1 UNPACKING ............................................................................................2

2.2 CONNECT THE OUTER PIPE.......................................................................2

2.3 CONNECT THE POWER .............................................................................2

3. OPERATIONS .............................................................................................................................3

3.1SYSTEM SETUP .......................................................................................3

3.2 PROGRAM SETUP ....................................................................................7

3.3 WASH ..................................................................................................11

3.4 WASH PIPE ...........................................................................................14

4. WASH PROCESS OPERATION SUMMARY.............................................................15

5. ROUTINE MAINTENANCE .................................................................................................15

6. TROUBLESHOOTING...........................................................................................................16

7. TRANSPORTATION AND STORAGE...........................................................................17

7.1 TRANSPORTATION .................................................................................17

W600 Auto Washer User’s Manual

1 Introduction

W600 automatic washer is a microprocessor-controlled washer. It

can be fitted with either an 8 or 12 channel manifold which are

fitted with one aspirating and one dispensing needle per well. Up

to 50 user-defined programs can stored in the memory and recalled

by user.

This manual gives the installation and operations for the W600

Automatic Washer, it shouldbe read carefµlly in its entirety prior

to any attempt to operate the washer.

1.1 Features

Washer has the feature of simple structure, stable working

condition, and low maintenance cost. Chinese / English version is

free to switch for users.

1.2 Working environment requirements

Power requirements

110/220 V ± 10

%

,50/60Hz ± 2

%

Fuse

T1AL250V

Power consumption

100VA

Operation temperature

10°C to 40°C

Relative humidity

No more than 75 percent

Atmospheric pressure

86.0kPa ~ 106.0kPa

Other requirement

Avoid dust, strong

electromagnetic interference and

corrosive gases

Avoid mechanical vibration

Good grounding of network power

supply

1.3 Performance

Washing strips

1-12

Washing cycle

1-99

Washing scope of application

96-well plate, 48-well plate and

single plate

Residual volume

< 2uL per well

programs storage

50 stored programs

Washing capacity

50-500µl, optional setting(step

length is 50µl)

Soake time:

0-3600 seconds

plate-type options

U plate, flat plate, V plate

Shake time

1-99 seconds

1

W600 Auto Washer User’s Manual

1.4 Instrument structure

Washer is content of control system, movement system, pump,valve,

washing manifold and carrier home.

2 Installation

2.1 Unpacking

(1) Lift the unit from the box by holding the unit.

(2) Remove the accessories from the unit.

(3) Verify that all items on the packing list have been received.

(4) Inspect all components for shipneedleg damage. In case of

damage, contact the shipper who delivered your equipment.

(5)Save all packing material in case it becomes necessary to return

the unit.

(6)Put the instrument on a flat level platform.

2.2 Connect the outer pipe

Six pieces of silicon rubber tubes is used to connect the unit with

the outer bottles,please connect them according to apellation. Cut

off the belts on the washing manifold after the outer pipe has been

well connected.

2.3 Connect the power

Connect the power cable to the unit, switch on the power, the washer

begins self-initialize, after a few minutes the LCD will display:

Then the washer is ready to use. Press Enter key to come into main

menu :

W600Auto Washer

Wash

Program setup

System setup

Wash pipe

W600Auto Washer

SINNOWA

2

W600 Auto Washer User’s Manual

3. Operations

3.1 System setup

It is recommendable that you should check and adjust the position

parameter before you begin to use the washer in order to get the

good washing effect.

Press

to choose “System setup”.

Press Enter key to come into “System setup”.

Input six “

”.

Press Enter to confirm.

W600Auto Washer

Wash

Program setup

System setup

Clean pipe

System setup

Please input password:

System setup

Please input password:

*******

System setup

Language setup

Position setting

Title setup

3

W600 Auto Washer User’s Manual

Press Enter key to come into “Language setting”.

Press

to choose language.

Press

to choose language.

Press

to choose “Position Setting”.

Press Enter key to come into “Position Setting”.

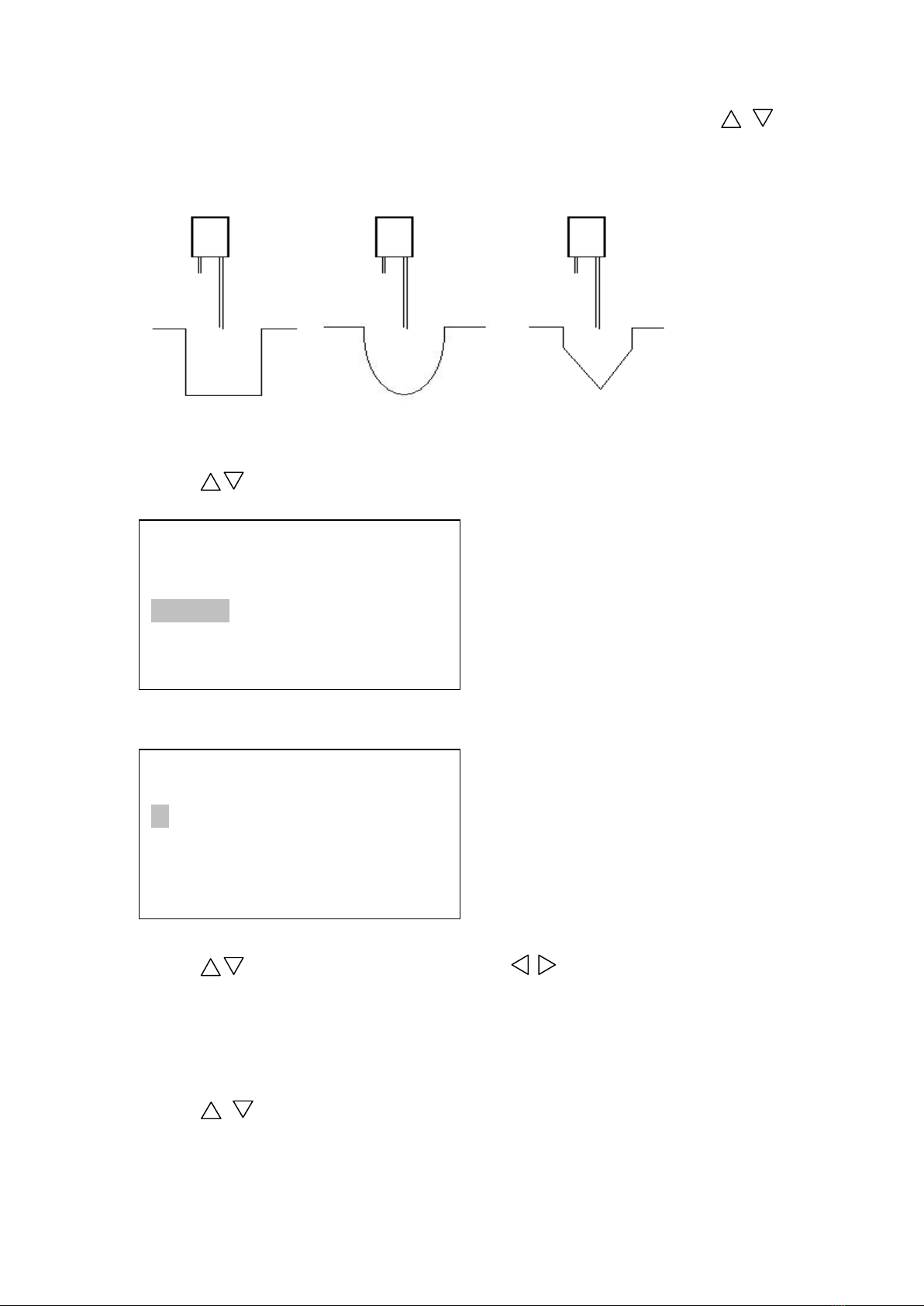

Press

key to adjust long needle to reach the bottom of

trough.

Press

to move the carrier to the left or right to adjust

long needle to the center of first strip micro-wells ,and as

following shown:

Language setup

中文

English

System setup

Language setup

Position setting

Title setup

Position setting

Long pin in the center of first

strip micro-well

micro-well left

right

Please press “Entre” to sure

Position setting

Long needle to

the bottom of

trough

needle up

down

Please press “Entre” to sure

4

W600 Auto Washer User’s Manual

Press Enter key to confirm.

For flat micro-well, this is the first point of the manifold

aspiration needle when use two-point aspiration. Press

to

move the carrier to the left or right, the best position should

be close to the left wall of the micro-well.Adjusted position is

as shown below.

Press Enter key to confirm.

Position setting

Long needle on the left

of

micro-well

micro-well left

right

Please press “Entre” to sure

Position setting

Long needle on the right

of

micro-well

micro-well left

right

Please press “Entre” to sure

5

W600 Auto Washer User’s Manual

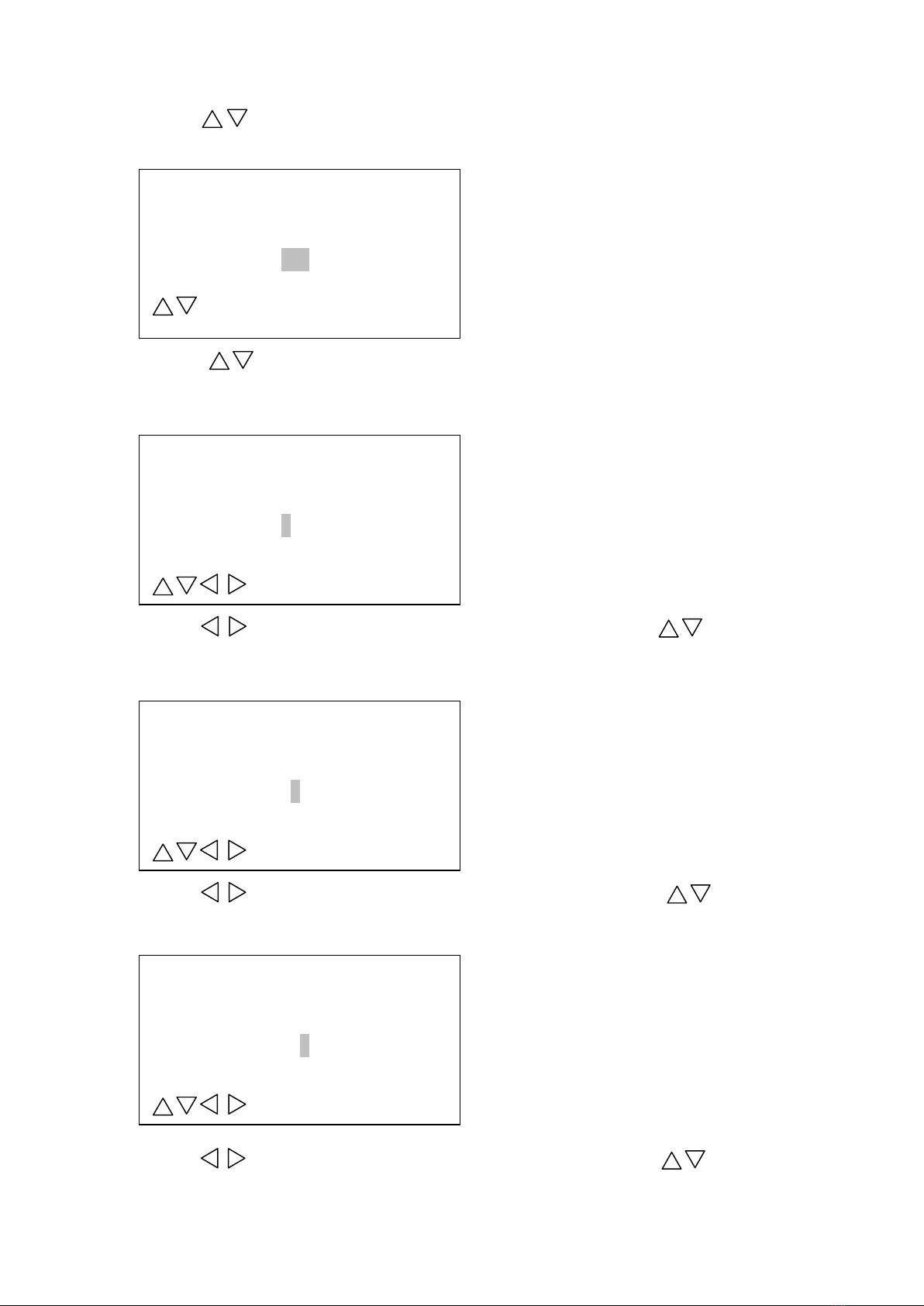

For flat micro-well, this is the second aspirating point in

two-point aspiration process. Press

to tune up long probe

position. Adjusted position is as shown below.

Attention: When adjust long needle to the left or right of first

strip micro-wells, the position should not too close to or too far

away with wall according to washing effect.

Press Enter key to confirm.

Press

to move the washing manifold so that long needle to

reach the bottom of micro-well, the best position is the position

that the long needle be closest to the bottom of the

micro-well.Adjusted position is as shown below.

Press Enter key to confirm.

Position setting

Long needle to the

bottom of

micro-well

needle up ,

down

Please press “Entre” to sure

Position setting

Long needle at the upside of

micro-well

needle up ,

down

Please press “Entre” to sure

6

W600 Auto Washer User’s Manual

This is edit the overflow position of the micro-well,Press

key to move the washing manifold so that the long needle r is just

above the top of the wells,and adjusted position is as shown below.

Press key Enter to get in to main menu.

Press

to choose “Title setup”

Press “Enter”to come into “Title setup”

Press

to choose character,press

to move cursor.

Press “Enter”to choose “SINNOWA” to setup company information.

3.2 Program setup

Press to choose program setup.

System setup

Languang setup

Position setting

Title setup

W600 Auto Washer

SINNOWA

7

W600 Auto Washer User’s Manual

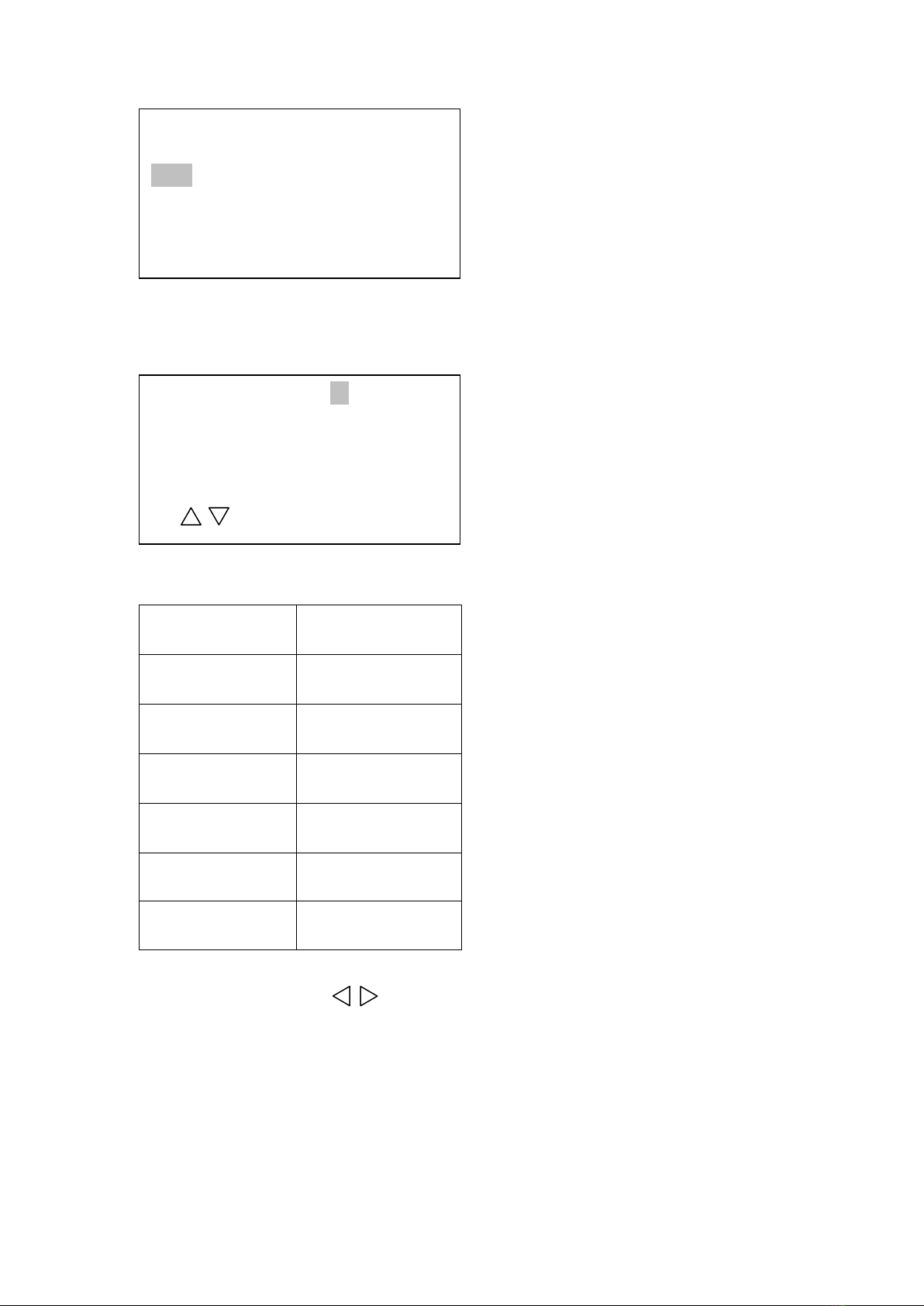

Press Enter key to come into “Program setup”.

Press Enter key to add new program.

Press

to choose plate model,and press Enter key to confirm.

Press

key to choose micro-well number on single plate, and

press Enter key to confirm.

W600 Washer

Wash

Program setup

System setup

Wash pipe

Program setup

Program add

Program modify

Delete one program

Delete all program

Program Setup

Program

No. 02

Plate model

Flat U V

Select “ Enter”Sure

Program setup

Program No. 02

Micro-wells

812

Select “Enter”Sure

Program Setup

Program No. 02

Strips(1-12)12

Date alter “ Enter”Sure

8

W600 Auto Washer User’s Manual

Press

key to setup wash strips , and press Enter key to

confirm.

Press

key to setup washing volume, and press Enter key to

confirm.

Press

key to choose program number and press

key to

adjust washing times.

Press

key to choose program number and press

key to

adjust shaking time, and press Enter key to confirm.

Press

key to choose program number, then press

key to

adjust soaking time, and press Enter key to confirm.

Program setup

Program No. 02

Volume (50-500,50µl/step)

400 µl

Date alter “ Enter”Sure

Program setup

Program

No. 02

Wash times (1-99)

10

Date alter“ Enter”Sure

Program setup

Program

No. 02

Shake time (0-99)

05 Sec

Date alter“ Enter”Sure

Program setup

Program No. 02

Soak time (0-3600)

0020 Sec

Date alter“ Enter”Sure

9

W600 Auto Washer User’s Manual

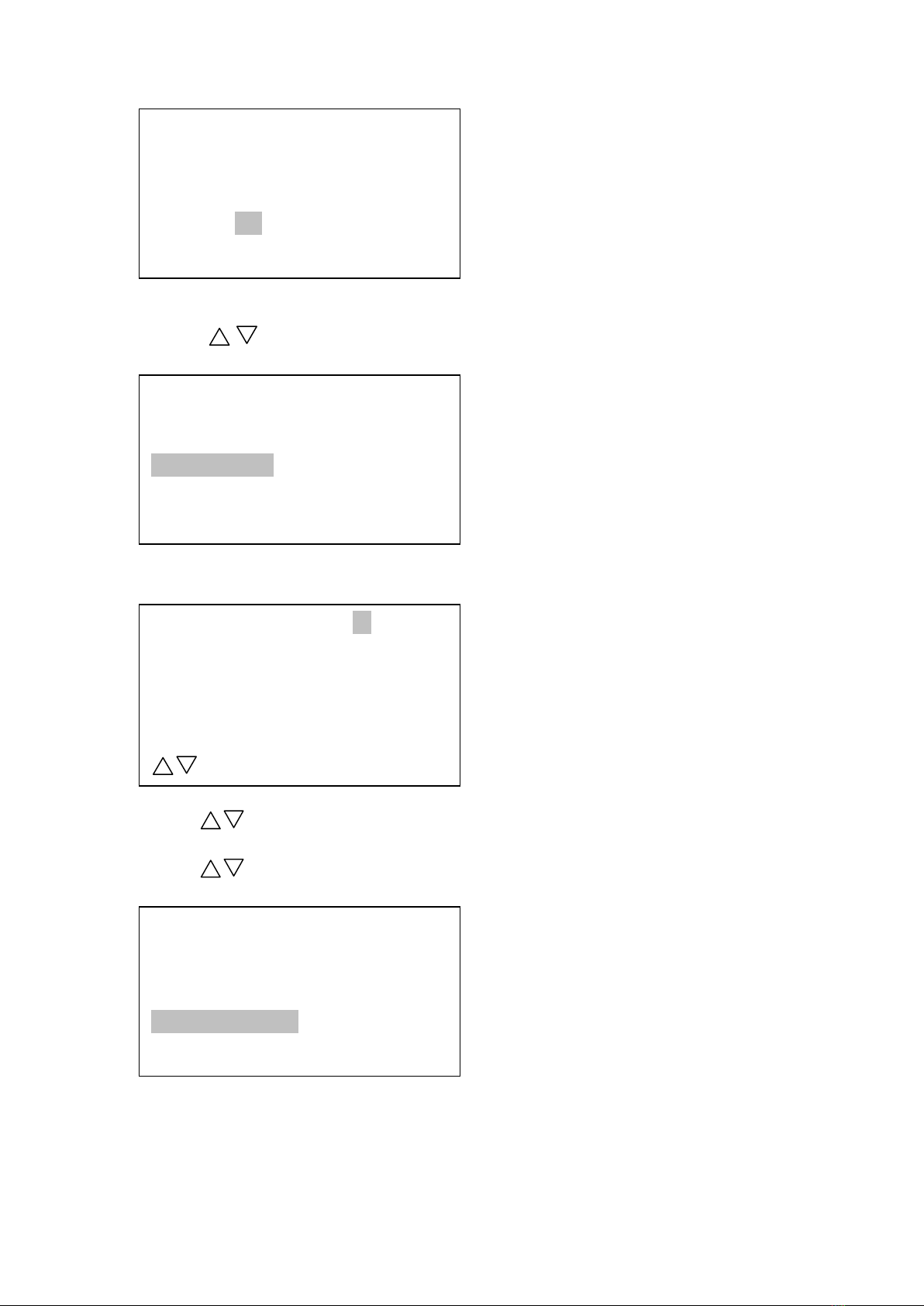

Press “YES” to confirm , and press “NO” to quit.

Press

to choose “Program modify”.

Press Enter key to come into “Program modify”.

Press

key to choose program to edit.

Press

key to choose to “Delete one program”.

Press Enter key to come into “Delete a program”.

Program setup

Sure to add?

Yes No

Modify program No. 01

Plate Modle :Flat

08micro-wells

12strips

Volum 450µl Wash 03times

Shake 05 Sec Soak 0010Sec

Date alter “ Enter”Sure

Program setup

Program add

Program modify

Delete one program

Delete all program

Program setup

Program add

Program modify

Delete one program

Deleteall program

10

W600 Auto Washer User’s Manual

Press

to choose program to delete.

Press

to choose to “Delete all the programs”.

Press Enter key to come into “Delete All Program”.

Press “Yes” to confirm delete, and press “No” to quit.

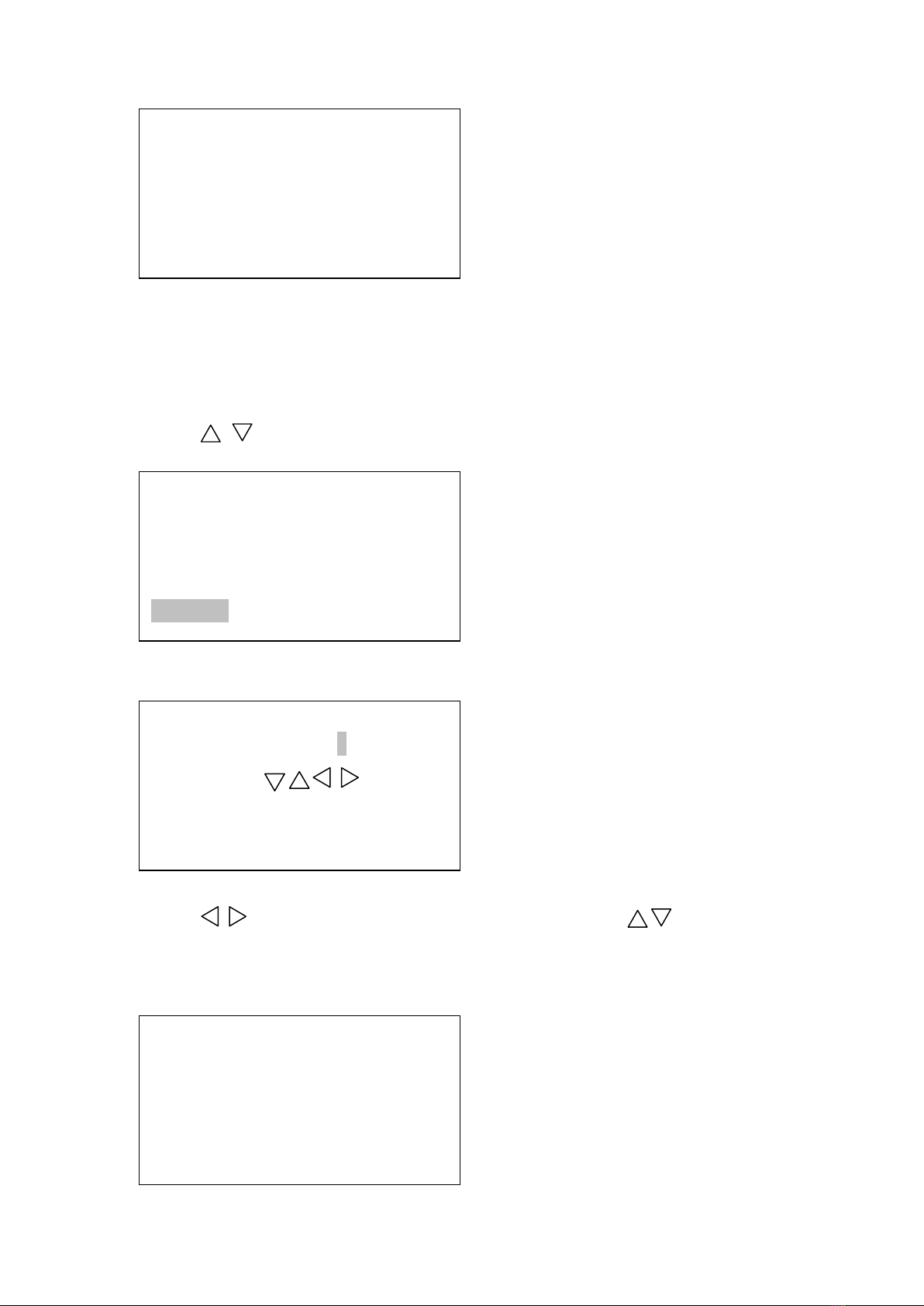

3.3 Wash

Press

to choose “Wash”.

Del Program No. 01

Plate Modle :Flat

08 micro-wells

12strips

Volum 450µl Wash 03times

Shake 05 Sec Soak 0010Sec

Date alter “ Enter”Sure

Program setup

Program add

Program modify

Delete one program

Delete all program

Delete all program

No Yes

Delete all program

Sure to delete?

No Yes

11

W600 Auto Washer User’s Manual

Press “Enter” to get into wash process.

At this moment, it needs to call the programs stored in the

instrument.

This code program is 01 that means No.01 program is been stored.

Plate type

Flat

Washing manifold

8 micro-wells

Washing strips

12strips

Washing volume

450µl

Washing times

3 times

Shaking time

5 seconds

Soaking time

10 seconds

You also can press

key to choose other programs, or press

ENTER to choose to implementation of the washing procedure. (If

there are no pre-storage programs, the possibility is they not

being set up when leave factory, or have been deleted at all.)

Press ENTER key into operate program 01.

W600 Washer

Wash

Program setup

System setup

Wash pipe

Run Program No. 01

Plate Mode:Flat

08micro-wells

12strips

Volume 450µl Wash 03times

Shake 05Sec Soak 0010Sec

Select “ENTER”Sure

12

W600 Auto Washer User’s Manual

After 3 washes, the display below will show.

Run Program No. 01

Adding pression

Run Program No. 01

Wash

Remain 02 times

Running Program No. 01

Shake

Remain 04 Sec

Run Program No. 01

Soak

Remain 0009 Sec

Run Program No. 01

Sucking

13

W600 Auto Washer User’s Manual

Attention:If liquid surface is raised or overflow happens in the

process of washing , adjust air-pressure adjuster on the back of

the instrument.

3.4Wash pipe

Press

to choose “Wash pipe”.

Press Enter key to come into wash pipe.

Press

to choose program number, and press

to adjust

washing time.

Press “Cancel” to quit.

Running Program No. 01

Wash complete

Press any key to return!

W600 Washer

Wash

Program setup

System setup

Wash pipe

Wash pipe

Wash Time:04 Sec

Input date press

Cancel to return, Enter to sure

Reset please press Reset

Wash pipe

Remain time 04 Sec

14

W600 Auto Washer User’s Manual

4. Wash process Operation Summary

1. Before power on the washer, check the washer, be sure that:

The pipe is well connected;

The waste bottle is empty;

These are distilled water in the distilled water

bottle.

These are regent in the washing bottle.

2. Switch on the washer, wait a moment until main menu has been

displayed, then washer is ready to use.

3. Place a microplate to be washed in the carrier.

4. Use “System setup” to check and set the position of the

microplate.

5. Get into “Program setup” to edit washing parameter.

6. Used “wash pipe”to washing pipe.

7. Come into “Wash” to wash a microplate.

8. Wait until wash process finished.

9. Used “wash pipe”to washing pipe before power off the washer

everyday.

10.Power off the washer.

5. Routine maintenance

1.Rinse pipe and manifold using distilled water after finishing

assay

The salt deposits left by the dried wash solution can easily

clog the system. So it is recommended to wash pipe and manifold

using distilled water everyday beore power off the washer.

2.Ensure that the waste bottle is emptied

Ensure that the waste bottle is emptied regulated and at least

every time that lotion and distilled water bottle is loaded.

3.Cleaning manifold needles

A needle cleaning wire is supplied with each manifold, and

may be used to unclog aspirate or dispense needles, which have

been plugged by dirt or dried salt deposits.

It is possible that the dispense/aspirate tips of the wash

manifold may become clogged with salt deposits. To clear them,

lift up the manifold and unclog the tips using the small

declogging tool provided.

4. Clean the instrument as necessary

It is recommended that the instrument is wiped with a soft

cloth moistened with a mild detergent solution. Spillage

of liquid on the carrier should be wiped off promptly as this

may cause the plate carrier to drag during operation.

5.Check and adjust the position of microplate when it is

necessary .

6.Switch off the unit after washing.

15

W600 Auto Washer User’s Manual

6. Troubleshooting

SYMPTOM PROBABLE CAUSE REMEDY

The instrument does

not work, no message

display on the LCD.

1.AC

power not getting to

the unit.

check AC line

cord.

2.Blown fuse.

C

onnect to AC

line.

Replace fuse with

proper type.

N

eedle of manifold

can not extend into

the micro-well

1.The locatio

n of first

strip of the micro-

plate

is not correct.

2.S

omething may be put on

the working platform or

micro-well carrier.

A

djust the

location of the

first strip of

micro-well.

Remove things put

on the carrier ,

try again.

N

eedle of the

manifold can not

aspirate

waste

liquid

1.Aspirating

liquid

nozzle of washing manifold

has not been well

connected with inlet

nozzle of waste bottle.

2.C

over of the waste

bottle is not tightly

closed.

3.Extracting air nozzle of

waste bottle has not been

well connected

with the

vacuum pump.

4.S

ilicon pipe is broken

or creased.

5.A

spirating needle of

manifold has been blocked.

6.Vacuum pump

does not

C

heck and well

connect the pipe.

T

ight the cover

of waste bottle.

C

heck and well

connect the pipe.

Replace th

e

silicon pipe.

Use needle of dim

1.0mm to delicate

the black of long

needle hole.

Contact

with

manufacture.

16

Table of contents