Snow Performance Diesel Stage 2 Boost Cooler User manual

© V. 0313, Snow Performance, Incorporated

INSTALLATION INSTRUCTIONS

Diesel Stage 2 Boost Cooler™

WATER-METHANOL INJECTION

SYSTEM

© V. 0313, Snow Performance, Inc

CAUTION

You must completely read through these instructions before

installing and operating this product. Failure to do so can

result in damage to this product and the vehicle.

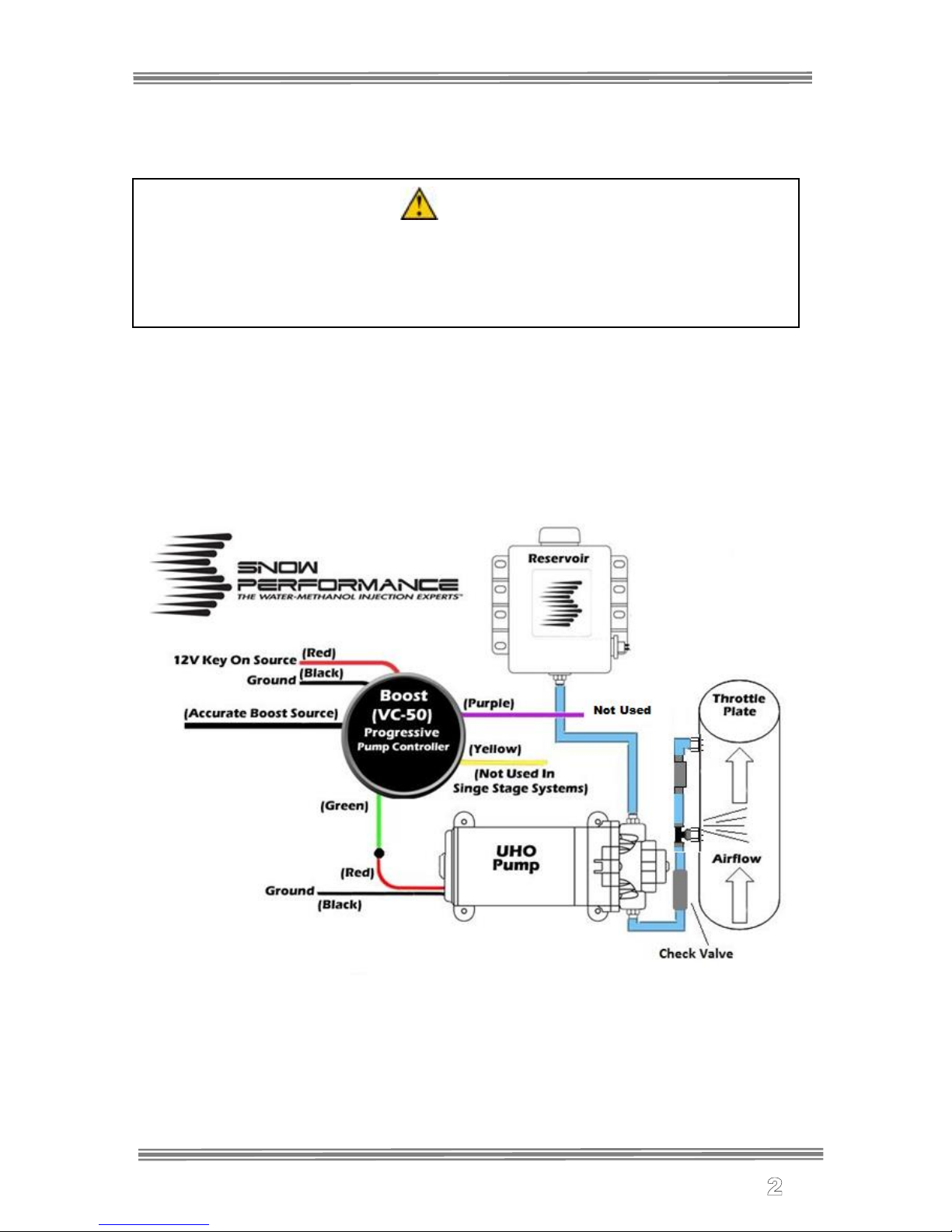

Wiring Diagram

© V. 0313, Snow Performance, Inc

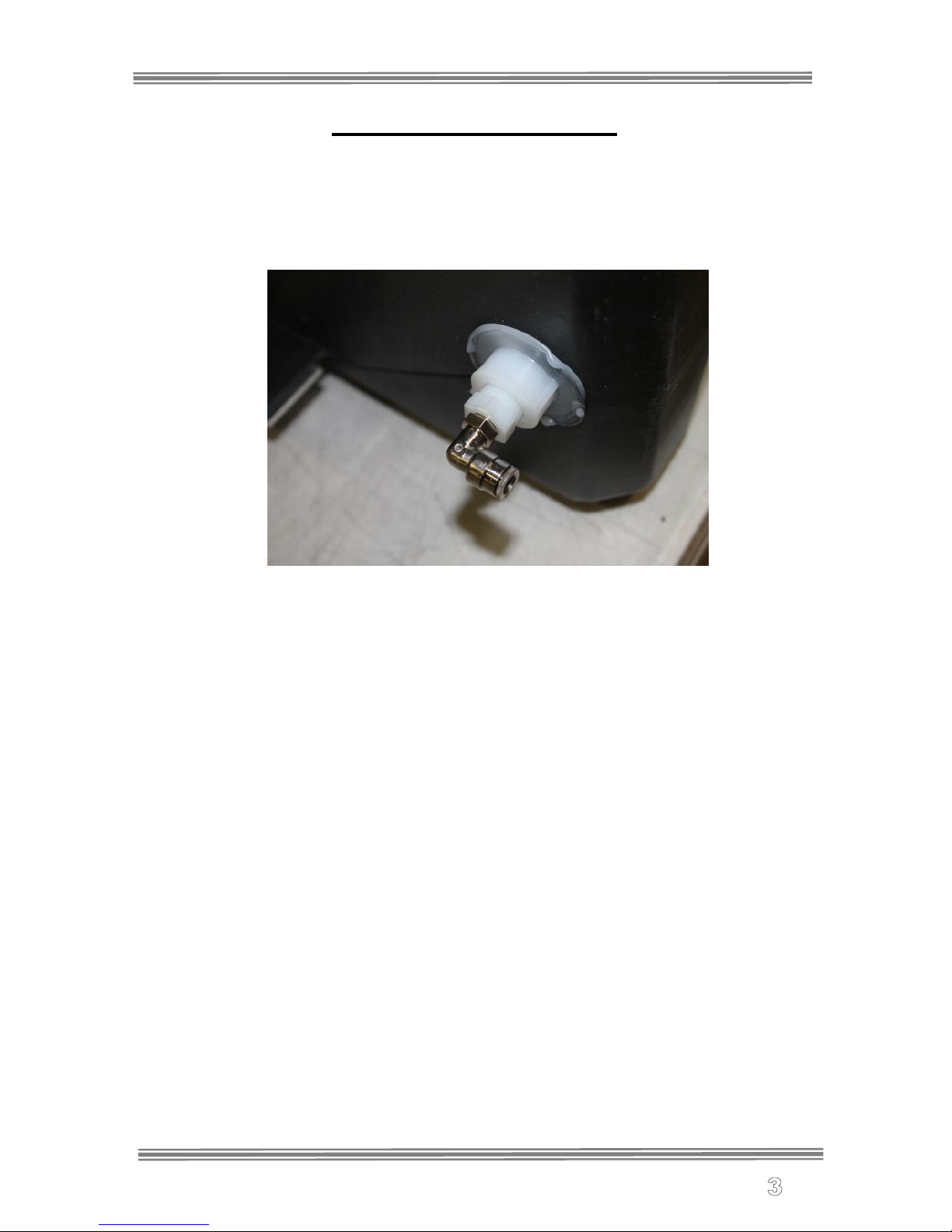

Reservoir Installation

•Install plastic reducer bushing and 90° quick connect fitting or

90° 4AN fitting into reservoir outlet. Use E6000® sealant on

threads.

•Test fit reservoir in desired mounting location. Typical

placement is tucked up along the side of a pickup bed or in a bed

mounted tool box.

•Check the area under the bed near the desired mounting

location. Note the location of fuel tanks, fuel lines, and wiring.

•Mark the location of the four aluminum mounting strap tab bolt

holes.

•Drill through bed with appropriately sized drill bit. USE

CAUTION WHILE DRILLING.

•Mount reservoir with aluminum mounting straps using supplied

hardware.

© V. 0313, Snow Performance, Inc

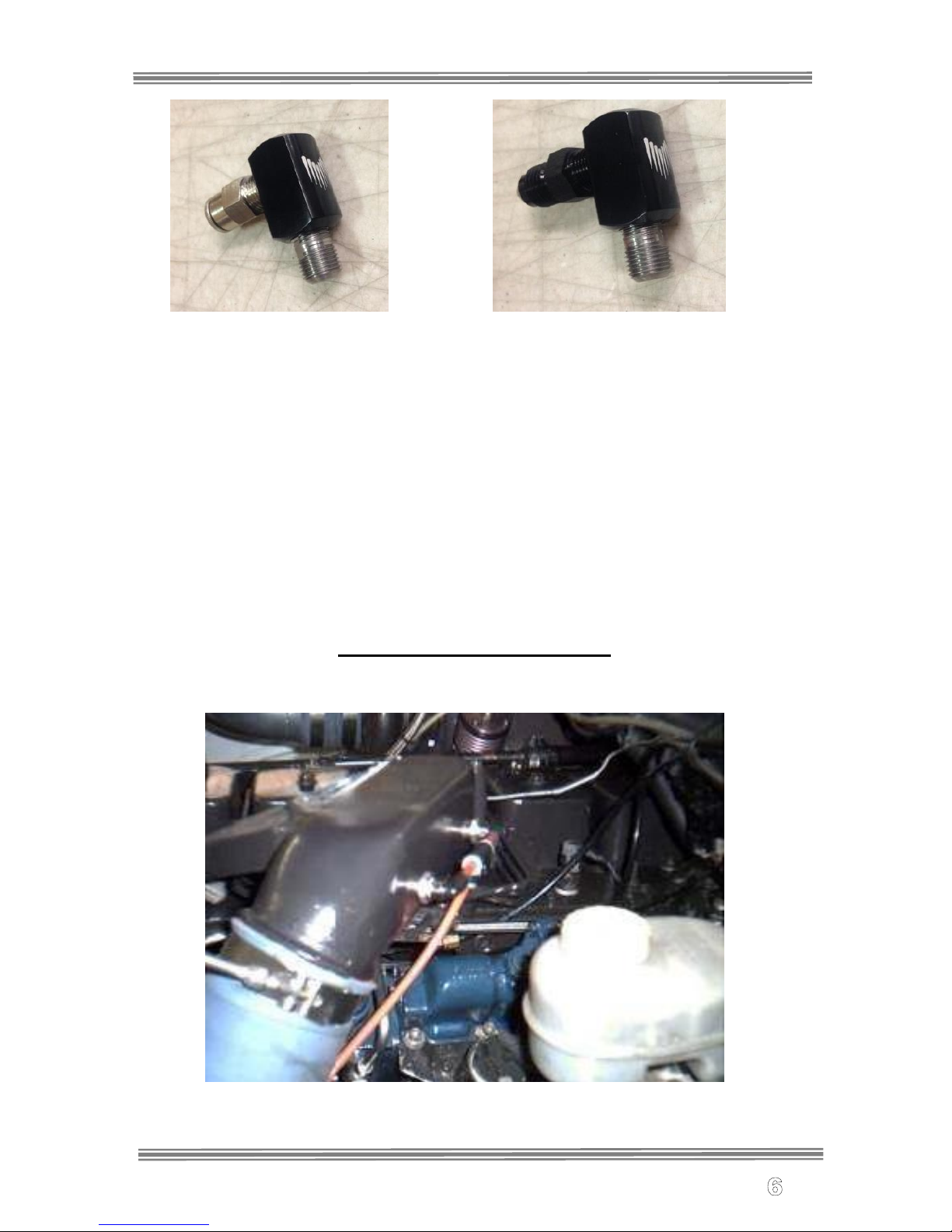

Pump Installation

Braided Line Kits Only- Install

(2) 3/8” NPT to 4AN Straight

fittings into the pump inlet and

outlet using E6000® sealant on

the threads. Do not overtighten

as damage to the pump

housing can occur.

Quick Connect Kits Only-

Remove the blue rubber plugs

from the quick-connect fittings by

first pushing the plug toward the

pump, hold the grey collar

against the pump, and gently pull

the blue plug from the fitting.

Warning: Pulling against the

quick connects with excessive

force may cause fitting damage.

Step 1: Position the fluid pump so

that the inlet is positioned at or

below the lowest point of the reservoir, and within two feet of the

reservoir. (Pump can be installed in any orientation). This will ensure the

pump is primed with fluid for optimal flow and pressure to the nozzles.

**Arrows on the pump inlet and outlet indicate the direction of fluid

flow**

© V. 0313, Snow Performance, Inc

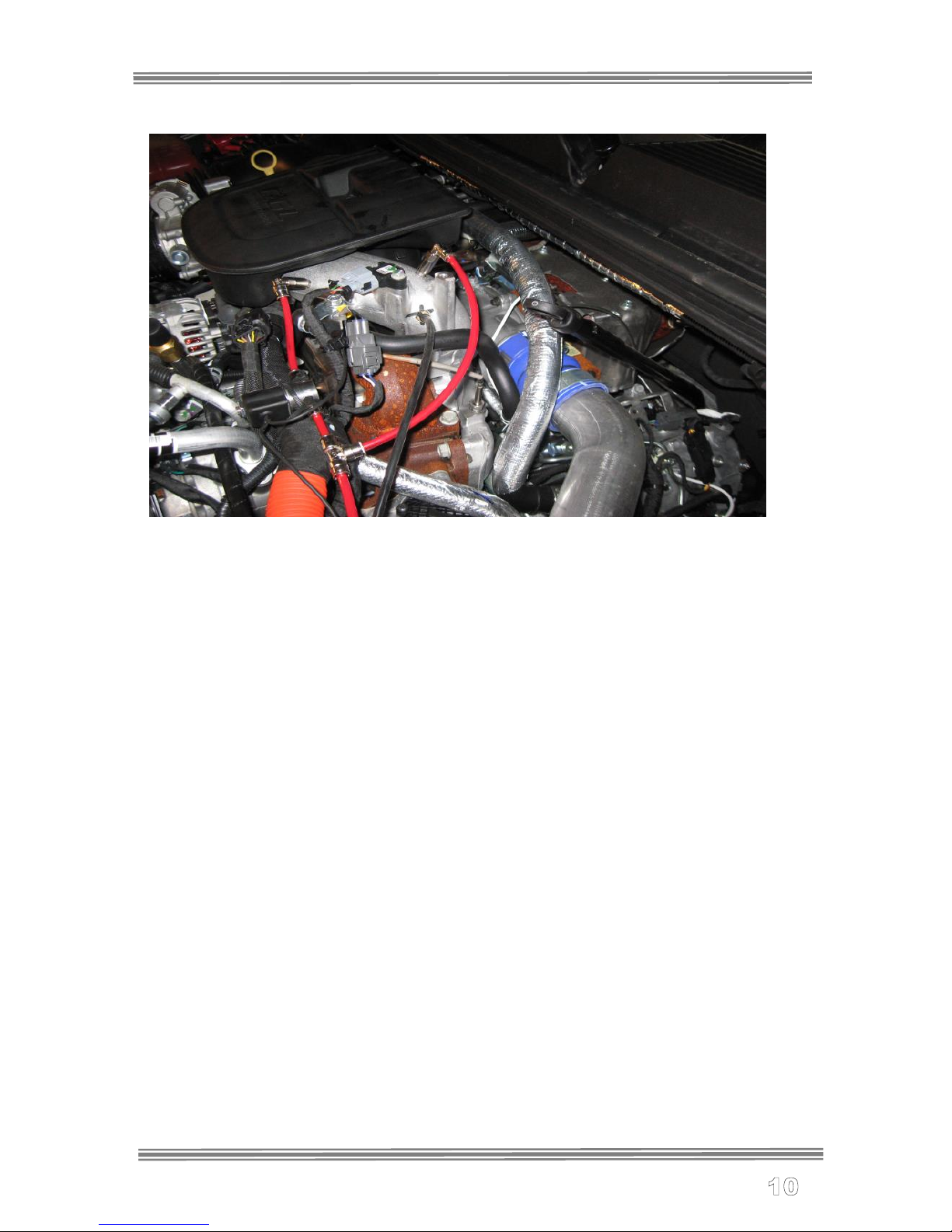

Step 2: Install the fluid pump with four (4) #8x1&1/2” screws and four (4)

#8 washers (supplied) in desired mounting location. Typical locations are

next to the tank in the bed or underneath the bed on frame rail.

Step 3: Fit the high temp nylon tubing or braided line between the tank

outlet fitting and the pump inlet, ensuring there are no kinks in the line

and there is no stress on the fittings. Sharp kinks/bends can cause a leak

in the system.

Braided Line Kits Only- Using the 1’stainless braided line section

supplied in the kit connect the tank outlet to solenoid inlet.

Quick Connect Kits Only- Once high temp nylon is measured from tank

outlet to pump inlet cut tubing using razor blade. Remove any burrs so

that the fluid line properly seals against the internal o-rings inside the

quick connect fittings. Insert tubing into the quick connects until fully

seated, and pull lightly against quick connects to ensure proper

installation between tank outlet to pump inlet

Nozzle Installation

Nozzle sizing is a function of horsepower, which approximates the

engine airflow, and boost, which approximates intake charge heat.

Recommended starting points:

HP

Nozzle 1

Nozzle 2

350 > WHP

175 ml/min

375 ml/min

400 - 500 WHP

175 ml/min

625 m/min

500 < WHP

375 ml/min

625 ml/min

Nozzle Identification:

The nozzles are stamped with the following identification stamps

on the side of the nozzle body:

Nozzle Stamp

Nozzle Size

Nozzle Stamp

Nozzle Size

1

60 ml/min

4

225 ml/min

2

100 ml/min

5

375 ml/min

3

175 ml/min

6

625 ml/min

Assemble desired nozzle into nozzle holder using E6000® sealant. The

end of the nozzle with the fine mesh screen is to be inserted into

the nozzle holder. Torque 1/2 turn past finger tight. Do not use Teflon

sealants on Snow Performance fittings.

© V. 0313, Snow Performance, Inc

Correct Correct

The nozzle is mounted using its external 1/8 NPT threads. Tighten the

nozzle and nozzle holder assembly one half turn past finger tight using

E6000® sealant to seal the threads. Note that the nozzles can be

mounted almost anywhere at or before the inlet to the intake. They must

be located after the turbo and intercooler however. Ideal locations are

usually immediately before the intake itself on the tube coming from the

intercooler outlet. Ensure that the nozzle has a clear spray pattern into

the airflow, and that the tip of the nozzle is flush with the inner wall of the

pipe or protruding slightly into the airflow.

Dodge Applications:

5.9L Cummins:

© V. 0313, Snow Performance, Inc

6.7L Cummins:

Nozzles are mounted in the cast intake elbow located on the

driver’s side of the engine. This elbow houses the EGR

valve, EGR throttle plate, and the MAP sensor.

Recommended location is after the EGR throttle plate –

indicated by arrow in photo.

Tip: It is recommended that the cast elbow be removed

before drilling and tapping.

Tip: Mount nozzles in the middle of the elbow on the front

side approx 3” apart so spray is 90º to airflow.

Tip: To make sure there is no pooling of fluid while injecting,

make sure nozzle tip is at least flush with the inside of the

elbow when tightened.

© V. 0313, Snow Performance, Inc

Ford Applications:

6.0L Powerstroke: 6.4L Powerstroke:

6.7L Powerstroke: 7.3L Powerstroke

© V. 0313, Snow Performance, Inc

GM Applications:

2004-2007 LB7, LLY, LBZ

2007-10 LMM

© V. 0313, Snow Performance, Inc

2011-Up LML

© V. 0313, Snow Performance, Inc

Nozzle/Solenoid/Check Valve (Quick Connect Kits)

Solenoids are flow directional. Be sure to note which port is the

INLET/PRESSURE port (2 or IN) and which is the OUTLET port (1 or

OUT).

The main outlet line coming from the Reservoir connects to the

solenoids inlet. The outlet of this solenoid connects to the inlet of

the pump. The outlet of the pump connects to the Check Valve Inlet.

The Check Valve Outlet connects to the Union “T” and then both

nozzles.

Measure the distance from the pump outlet to the injection location. Cut

the ¼” red tubing using utility knife. Make cuts as square as possible.

Ensure there are no kinks in the tubing and insert tubing into quick

disconnects until fully seated. Gently pull on tubing to ensure a good

connection. Use tie wraps to help route tubing and to ensure it doesn't

contact moving or hot parts in the engine compartment.

The check valve assembly will ensure that boost pressure does not

back-feed air into the system or siphon due to engine vacuum. Ensure

the check valve is installed with the arrow pointing in the direction of flow.

The Check valve will be installed between the pump outlet and T fitting.

Install check valve as close to T fitting as possible.

Quick Connect

Kits Only- Fit the

NPT thread to push

connect adapters in

both sides of the

check valve using

E-6000 sealant on

the threads. Press

the high pressure

tubing in each fitting, ensuring the check valve is oriented properly in the

direction of flow.

© V. 0313, Snow Performance, Inc

Nozzle and Solenoid Connection (Braided Line Kits)

Solenoid is flow directional. The solenoid is designed to be installed

between the 7 gallon and pump inlet. Before installing on vehicle remove

all NPT threaded fittings and install E6000 sealant on threads / re install.

Use supplied self-tapping screws/washers to install in desired location.

The solenoid outlet connects to the pump inlet via a 1’ section. The

pump outlet connects to the 20’ section of braided line and then to

the check valve inlet. The rest of the system will be plumbed using

the 1’ sections.

Installation- Electrical

Step 1 Variable Controller Installation

•Mount controller in desired location using a 52mm gauge

pod.

•Connect vacuum/boost hose (black silicon hose included in

kit) to tubing coming from the controller to an accurate

boost source using included brass hose barb fitting and

supplied 1/8” boost line. Secure connections with tie wraps.

CAUTION: Disconnect the negative battery terminal while

connecting wires to prevent electrical fire or damage to controller.

•Connect BLACK wire to good ground location.

•Connect GREEN wire to Pump RED power wire.

•Connect RED wire to 12Volt key on source.

•YELLOW wire is not used.

•Purple wire is not used

***Caution***

Do not route wires near hot or moving parts. Use corrugated wire

loom and tie wraps to protect and route wires.

© V. 0313, Snow Performance, Inc

Always have a good electrical ground connection.

Poor ground will result in erratic operation of

controller.

Variable Controller Settings/Screens/Functions

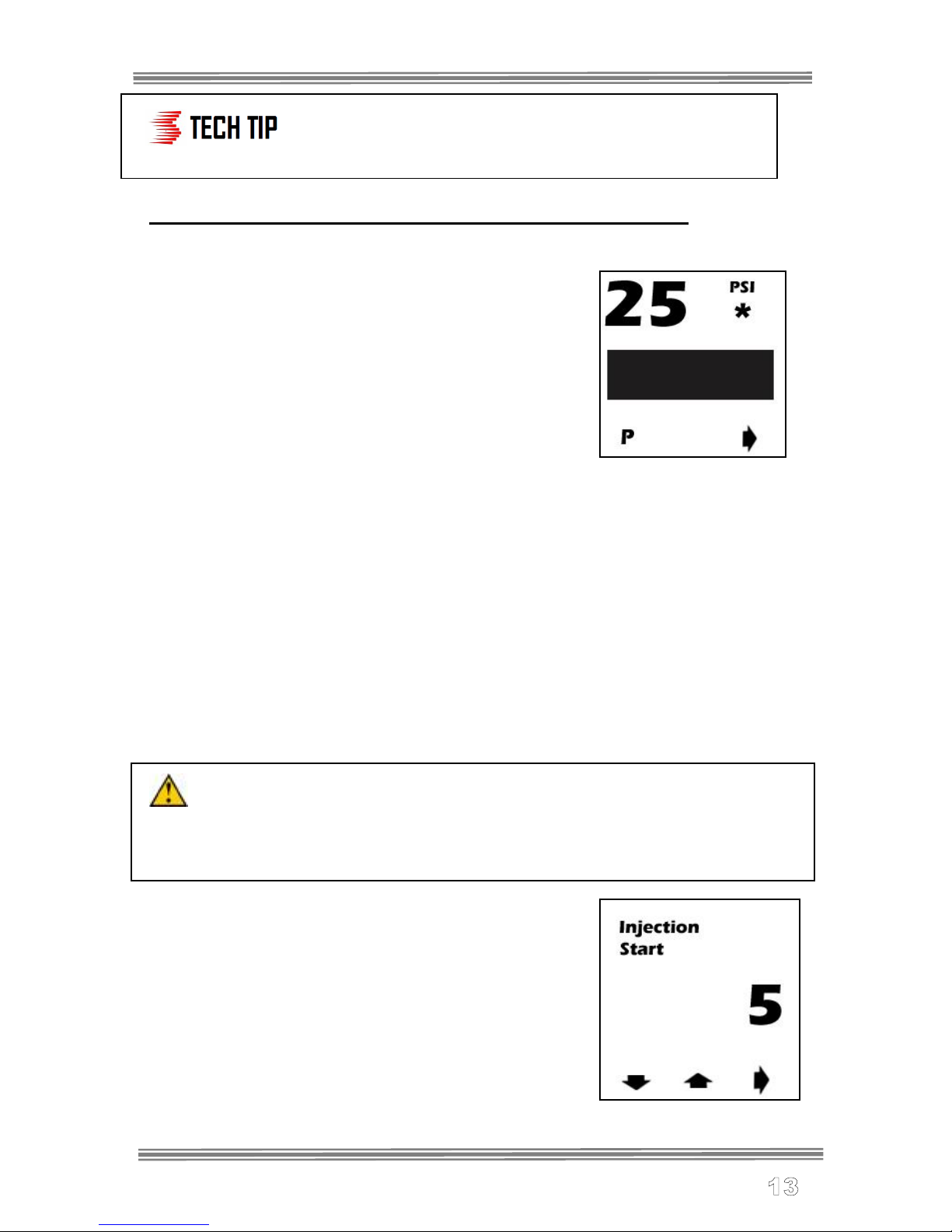

Main Screen

•Main Screen (see right) is used to monitor

boost pressure, injection, second stage

activation, and to prime the system.

•To prime the system press the red

button underneath “P”. This will

command 100% injection briefly to fully

prime the system. ONLY ENGAGE

PRIME WHEN ENGINE IS RUNNING!

•Boost pressure is displayed in PSI on the upper left of the screen

•Percentage of Injection is displayed using the graph in the

middle of the screen. When injection is turned “Off” the graph will

display the text “Off”.

•(Dual Stage Systems Only) When a second stage of water-

methanol is activated a asterisk will appear where “PSI” is

located alerting the user or both stages injecting.

•To enter the setting screens press the red button directly

under the arrow on the bottom right.

CAUTION: Do not operate the prime button when the engine is

not running. Only engage priming of the system when the engine is

on.

Injection Start

•Setting screen 1 (see right) is used to select

what boost pressure will start injection. This

should be set 3psi above your vehicle’s

unloaded flat land cruising boost using the

red buttons below the up and down arrows

to adjust the PSI to desired setting. Press

the red button underneath the arrow

pointing right to move to setting screen 2.

© V. 0313, Snow Performance, Inc

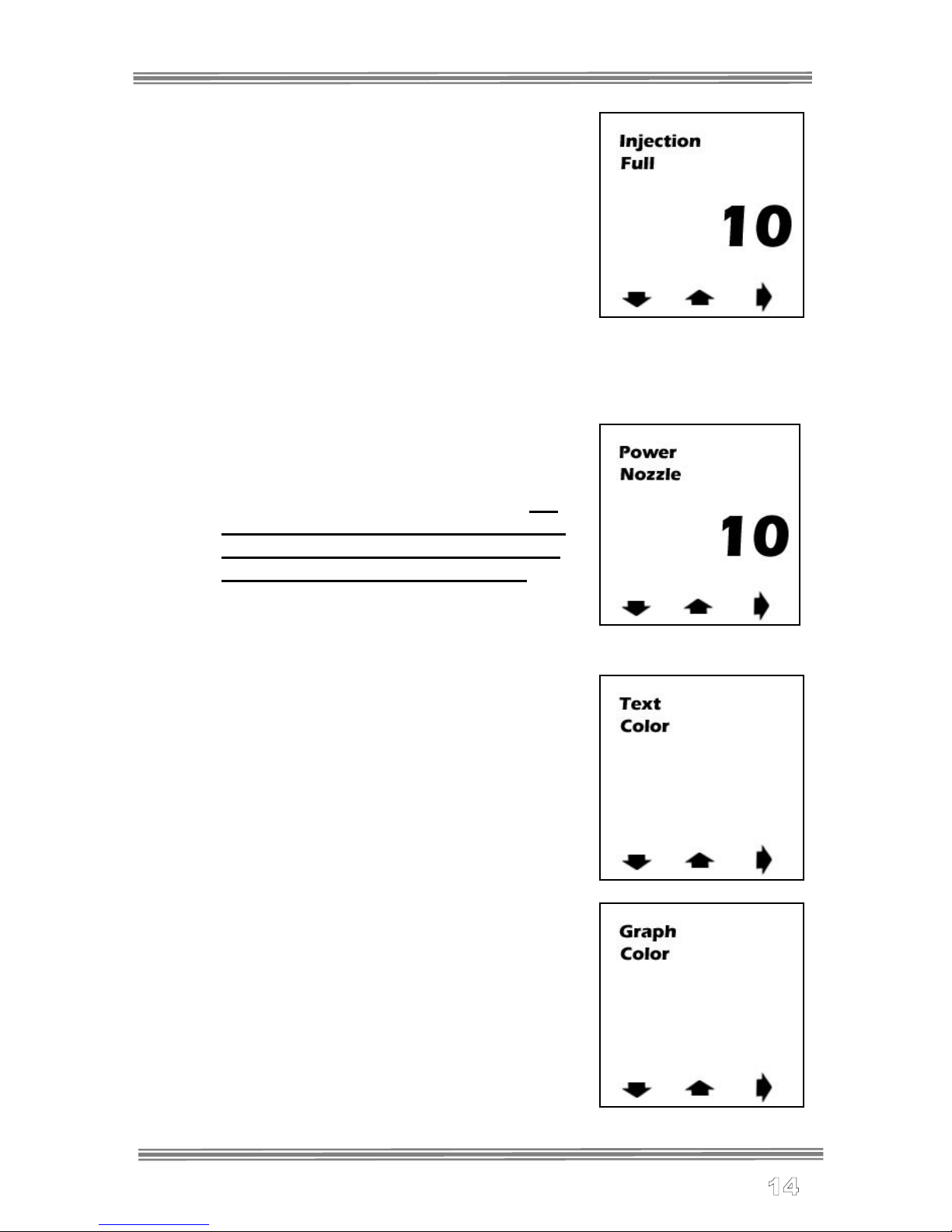

Max Injection

•Setting screen 2 (see right) is used to select

what boost pressure will correlate to max

injection. This should be set the vehicles

maximum boost level using the red buttons

below the up and down arrows to adjust the

psi to desired setting. Press the red button

underneath the arrow pointing right to move

to setting screen 3.

Power Nozzle

•Setting screen 3 (see right) is used to

select what boost pressure a second

stage of injection will be triggered. If a

dual stage system is not being used

this must be set above 50 psi to the

“off” setting to avoid fault code.

Press the red button underneath the

arrow pointing right to move to setting

screen 4.

Text Color

•Setting screen 4 (see right) is used to select

what text color will be displayed on screen.

Using the red buttons below the up and

down arrows adjust the color to the desired

setting (Red, Blue, Green, Yellow, Orange,

Purple, White) available. Press the red

button underneath the arrow pointing right to

move to setting screen 5.

Graph Color

•Setting screen 5 (see right) is used to

select what Graph color will be

displayed on screen. Using the red

buttons below the up and down arrows

adjust the color to the desired setting

(Red, Blue, Green, Yellow, Orange,

Purple, White) available. Press the red

button underneath the arrow pointing

right to move to setting screen 6.

© V. 0313, Snow Performance, Inc

Injection On/Off

•Setting screen 6 (see right) is used to toggle

between on/off mode. In on mode injection

will take place based off the boost settings

in the unit. In off mode no injection will take

place and the “off” icon will be shown on the

main screen. In this mode the controller will

only function as a boost gauge.

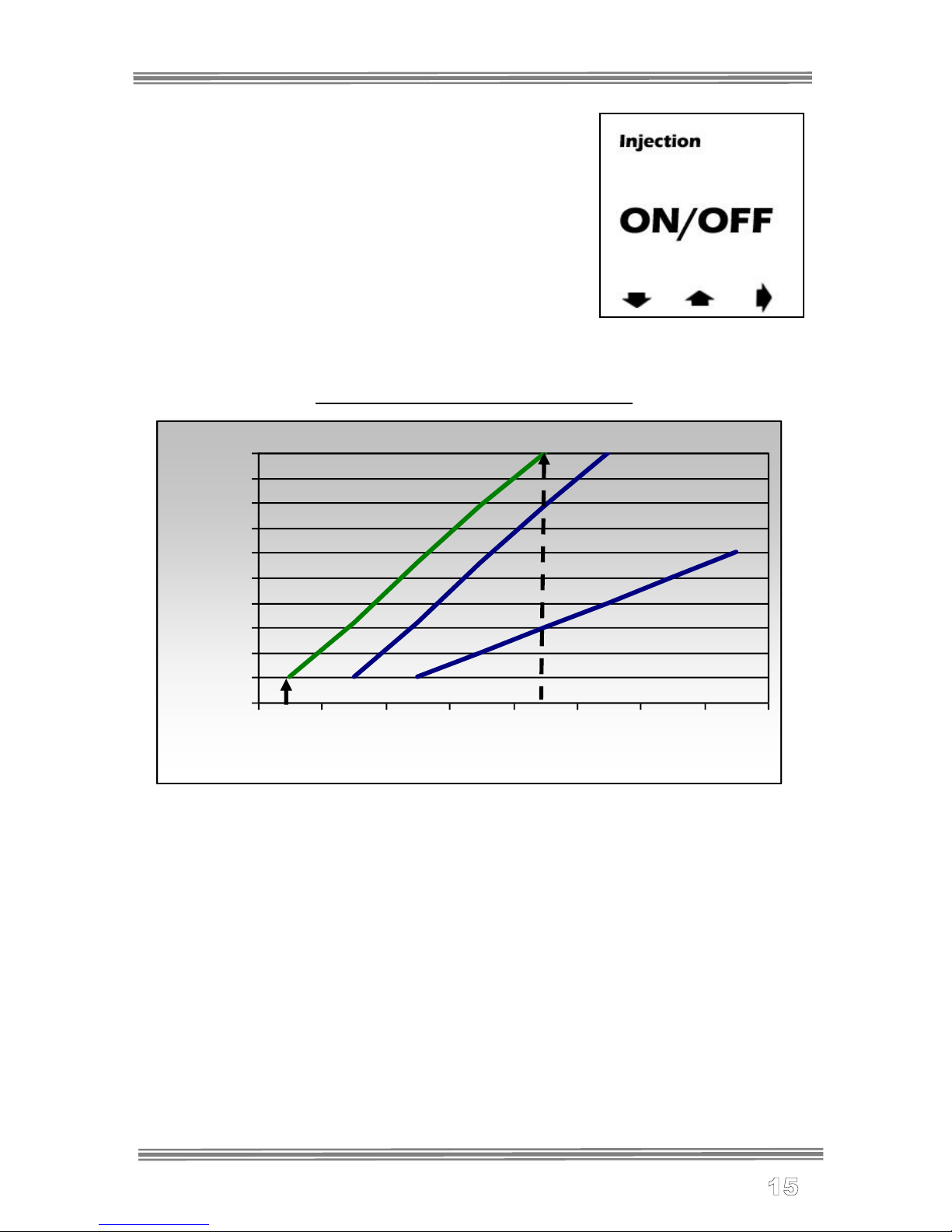

Controller Operation Example

For the middle line, the chart shows the Start dial at 6 psi and the

Full dial at 13 psi. At 6 psig of boost pressure the pump will

operate at 10%. At 13 psig of boost pressure, the pump will

deliver 100% of injection pressure. For boost pressure readings

between the Start and Full settings, the controller will linearly

adjust the pump pressure as shown on the graph.

0

10

20

30

40

50

60

70

80

90

100

4 6 8 10 12 14 16 18

Boost Pressure psi

Start

Pump Output %

Full

© V. 0313, Snow Performance, Inc

Other Controller Functions

Fail Safe Alerts

Clogged Line

•In the event of a clogged line the psi reading on the main screen

will turn to stars and begin flashing. If this occurs, fix the problem

and press the middle red button to clear the code.

Broken Line

•In the event of a broken line the psi reading on the main screen

will turn to stars and begin flashing. If this occurs, fix the problem

and press the middle red button to clear the code.

Solenoid Not Engaging (Dual Stage Systems Only)

•In the event of a solenoid not opening to engage a second stage

of water-methanol the psi reading on the main screen will turn to

stars and begin flashing. If this occurs, fix the problem and press

the middle red button to clear the code.

Testing the System

Step 1 Priming The System

**Before operating the system, it is recommended that the lines are

first primed with fluid and the spray pattern checked**

•Fill reservoir with water

•Remove the nozzle from the

intake tube.

•With the nozzle temporarily

placed inside an empty container,

purge the system by pushing the

“prime” button (left hand button)

on the controller until fluid flows

consistently through the nozzle.

**If pump goes on and fluid level doesn't go down, there is an

obstruction in the tube or nozzle.**

© V. 0313, Snow Performance, Inc

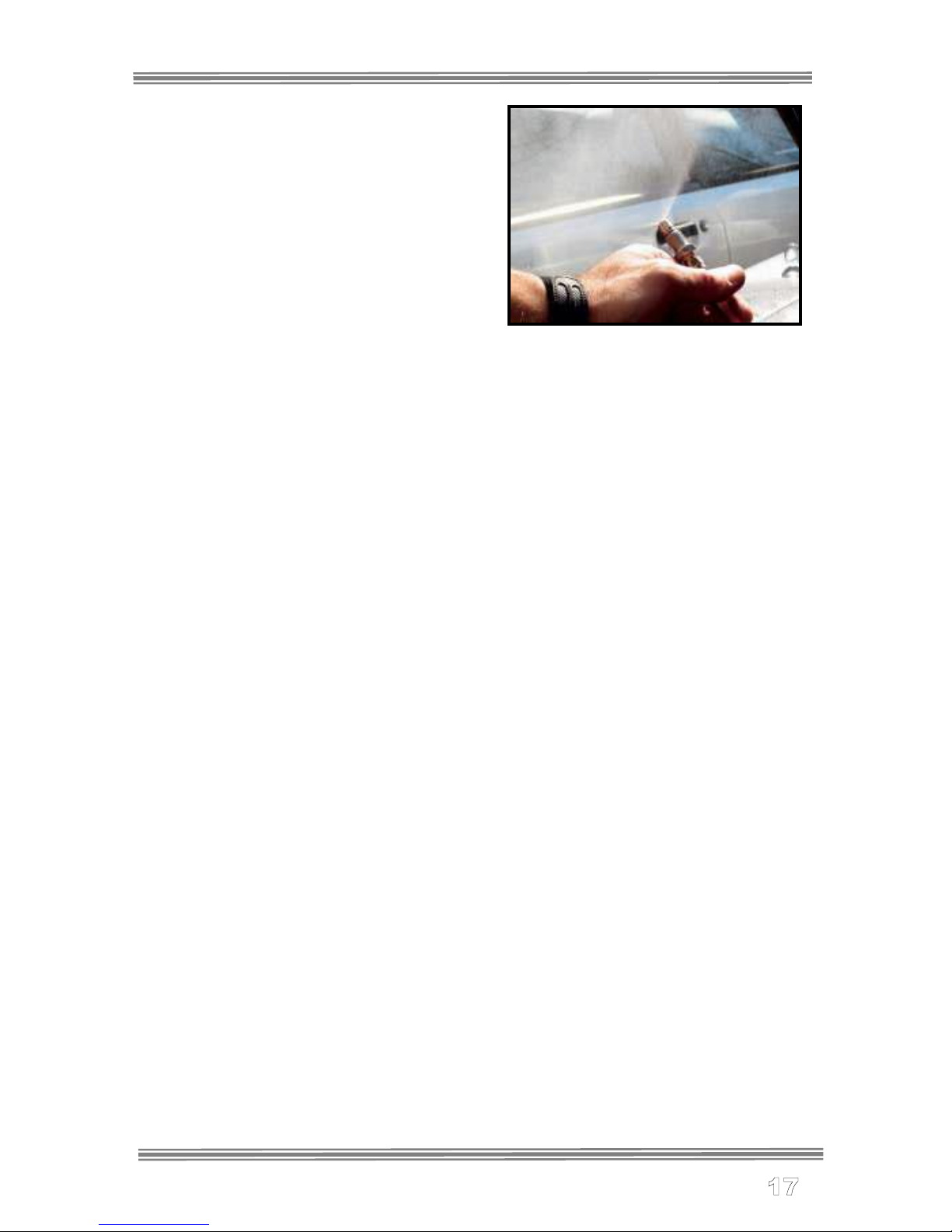

** Spray pattern should be 120º and

a fine mist. See photo.

**If the pump fails to activate,

check power and ground wiring**

Maintenance

Remove nozzle(s) and clean screen filters once per year using a

calcium removing formula such as CLR®

The Boost Cooler® has been designed to operate with high

concentrations of methanol. Oil or other additives are not required

for system lubrication, and can cause damage to the system.

Contaminants in the fluid such as dirt can damage the system.

Ensure that dirt and debris do not fall into the tank.

Do not use Teflon tape or paste to seal connections. These sealers

are not as effective as the Goop sealant provided and can break

down over time, clogging components.

© V. 0313, Snow Performance, Inc

Disclaimer

Do not use this product until you have carefully read the following agreement.

This sets forth the terms and conditions for the use of this product. The installation of this

product indicates that the BUYER has read

and understands this agreement and accepts its terms and conditions.

Performance products by their nature are designed to increase horsepower and

performance not engineered in the original vehicle and the increased stress could result in

damage to related systems. This is a high performance product –use at your own risk.

Snow Performance Inc., Its agents, employees or owners shall not be under any liability

whether in contract or otherwise whether or not resulting from our negligence or contents of

information supplied for any damage or loss resulting from such information.

The BUYER is responsible to fully understand the capability and limitations of his/her

vehicle according to manufacturer specifications

and agrees to hold the SELLER harmless from any damage resulting from failure to adhere

to such specifications.

The SELLER disclaims any warranty and expressly disclaims any liability for personal

injury or damages. The BUYER acknowledges

and agrees that the disclaimer of any liability for personal injury is a material term for this

agreement and the BUYER agrees to

indemnify the SELLER and to hold the SELLER harmless from any claim related to the

item of the equipment purchased. Under no

circumstances will the SELLER be liable for any damages or expenses by reason of use or

sale of any such equipment.

The BUYER is responsible to obey all applicable federal, state, and local laws, statutes,

and ordinances when operating his/her

vehicle, and the BUYER agrees to hold SELLER harmless from any violation thereof.

The SELLER assumes no liability regarding the improper installation or misapplication of its

products.

It is the installer's responsibility to check for proper installation and if in doubt, contact the

manufacturer.

Warranty

Snow Performance 1-Year Warranty Policy:

Snow Performance, Inc. warrants that the Product shall conform to and perform in

accordance with published technical specifications and shall be free of defects in materials

and workmanship for 1-year providing:

1. You are the original purchaser and provide proof of purchase.

2. The system was purchased from a Snow Performance Authorized Dealer at MRP pricing

set by Snow Performance.*

*No warranty will be offered for any Snow Performance products if purchased below

MRP. For MRP pricing of your product check www.snowperformance.net.

3. An RMA # has been attained and is displayed on package containing returned part.

4. Parts Warranty ~ 90 day warranty on parts purchased separately if used in conjunction

with a Snow System. No warranty implied if used with a non-Snow part/system. Subject to

Snow’s inspection of the product, Snow will remedy defects in materials and/or

workmanship by repairing or replacing, at Snow’s option, the defective product without

charge for parts or labor, subject to the limitations and exclusions described in this

warranty.

This warranty does not cover problems caused by normal wear and tear including aesthetic

oxidation of surfaces, accidents, unlawful vehicle operation, or modifications or repairs to

© V. 0313, Snow Performance, Inc

product not performed or authorized by Snow. This includes any product that is

disassembled or taken apart for any reason.

In addition, this warranty does not cover problems resulting from conditions beyond Snow’s

control including, but not limited to, theft, misuse, overloading, or failure to assemble,

mount or use the product in accordance with Snow’s written instructions or guidelines

included with the product or made available to the original retail purchaser. In the event of

failure, Snow will repair or replace the part at Snow's sole discretion. Failures resulting from

misapplication or misuse of the Product, failure to adhere to any specifications or

instructions, or failure resulting from neglect, abuse, accidents, or act of nature are not

covered under this warranty.

Warranty service may be obtained by emailing tech@snowperformance.net with a copy of

your purchase invoice for the product, getting an RMA (Return Merchandise Authorization)

number, and delivering the part to Snow. Customer agrees to insure the Product or assume

the risk of loss or damage in transit, to prepay shipping charges to Snow, and to use the

original shipping container or equivalent. Shipping for Warranty replacement parts shipped

outside the continental US will be charged to customer.

Non-Warranty Repair/Retest

Products returned due to damage or misuse and Products retested with no problem found

are subject to repair/retest charges. Product will be returned to customer at customer’s

expense. A credit card number must be provided in order to obtain an RMA (Return

Merchandise Authorization) number prior to returning Product.

Distributor/Dealer Warranty:

All customers/dealers must deal directly with Snow Performance to receive warranty. No

warranty will be issued through a distributor for any reason.

Return Policy:

All returns must be called in for RMA #. Snow Performance will not take used kits or parts

for refund. If you are returning an unused kit there is a 15% restocking fee minus

shipping/handling. All returns must be made within 30 days of purchase date. No

exceptions.

LIMITATION OF LIABILITY: REPAIR OR REPLACEMENT OF A DEFECTIVE PRODUCT

IS THE ORIGINAL RETAIL PURCHASER’S EXCLUSIVE REMEDY UNDER THIS

WARRANTY. DAMAGE OR INJURY TO THE ORIGINAL RETAIL PURCHASER, TO HIS

OR HER VEHICLE, CARGO, OR PROPERTY, AND/OR TO ANY OTHER PERSON OR

PROPERTY IS NOT COVERED BY THIS WARRANTY. THIS WARRANTY IS

EXPRESSLY MADE IN LIEU OF ANY AND ALL OTHER EXPRESS WA RRANTIES,

WHETHER ORAL OR WRITTEN. SNOW’S SOLE LIABILITY IS LIMITED TO THE

REMEDY SET FORTH ABOVE. IN NO EVENT WILL SNOW BE LIABLE FOR ANY

DIRECT, INDIRECT, CONSEQUENTIAL, INCIDENTAL, SPECIAL, EXEMPLARY, OR

PUNITIVE DAMAGES OR FOR ANY OTHER DAMAGES OF ANY KIND OR NATURE

(INCLUDING, BUT NOT LIMITED TO, LOST PROFITS OR LOST SALES). SOME

STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATIONS MAY NOT APPLY TO

YOU.

Non-Warranty Repair/Retest

Products returned due to damage or misuse and Products retested with no problem found

are subject to repair/retest charges. Product will be returned to customer at customer’s

expense. A credit card number must be provided in order to obtain an RMA (Return

Merchandise Authorization) number prior to returning Product.

© V. 0313, Snow Performance, Inc

Notes

The contents of this document are subject to change without prior notice.

No part of or this entire document may be reproduced in any form

without prior written permission of Snow Performance, Inc under the

copyright except for private use.

Table of contents

Popular Engine manuals by other brands

Hiwin

Hiwin TMRW13 Assembly instruction

Lenze

Lenze M Series Mounting instructions

Interroll

Interroll RollerDrive BT100 user manual

GEIGER

GEIGER SOLIDline GJ56 Series Original installation and operating instructions

Tecumseh

Tecumseh OHV140 Operator's manual

O.S. engine

O.S. engine FS-30S Owner's instruction manual