Southworth PalletPal User manual

OWNER’S MANUAL

PalletPal™ Stretch Wrapper

Model # _______________________________

Serial # _______________________________

Placed in Service _______________________

July 2015

SOUTHWORTH PRODUCTS CORP

PO Box 1380, Portland, ME 04104-1380

Telephone: 1-800-743-1000 or 207-878-0700

Fax: 207-797-4734

www.SouthworthProducts.com

Please note: This manual was current at the time of printing.

To obtain the latest, most updated version, please contact

Southworth’s Customer Service Department or go to our website:

www.SouthworthProducts.com > Parts & Service > Online Manuals, you

will nd a complete list of current owner’s manuals to print.

SOUTHWORTH

PALLETPAL STRETCH WRAPPER OWNER’S MANUAL 3

TABLE OF CONTENTS

INTRODUCTION.............................................................................................................. 4

RESPONSIBILITY OF OWNERS AND USERS ...............................................................5

SAFETY ALERT SYMBOLS AND SIGNAL WORDS.........................................................6

SAFETY .........................................................................................................................7

IMPORTANT INSTALLATION NOTES ..............................................................................7

Specications ..................................................................................................8

Unpacking the Lift ............................................................................................8

Assembly ........................................................................................................9

Anchoring the Unit ..........................................................................................9

Electric Connections ........................................................................................9

Testing ............................................................................................................9

OPERATING INSTRUCTIONS .......................................................................................10

Loading Film .................................................................................................10

Wrapping Film................................................................................................10

Stopping the Machine .................................................................................... 11

Operation Notes............................................................................................. 11

Safety Labels ................................................................................................12

MAINTENANCE .............................................................................................................12

Routine Periodic Maintenance ......................................................................12

Adjusting the Belt Tension .............................................................................12

Removing the Turntable.................................................................................13

Inspecting and Lubricating the Turntable.......................................................13

Changing the Drive Belt.................................................................................14

Troubleshooting Check List ...........................................................................14

ORDERING REPLACEMENT PARTS ............................................................................15

WARRANTY STATEMENT .............................................................................................19

LIST OF FIGURES

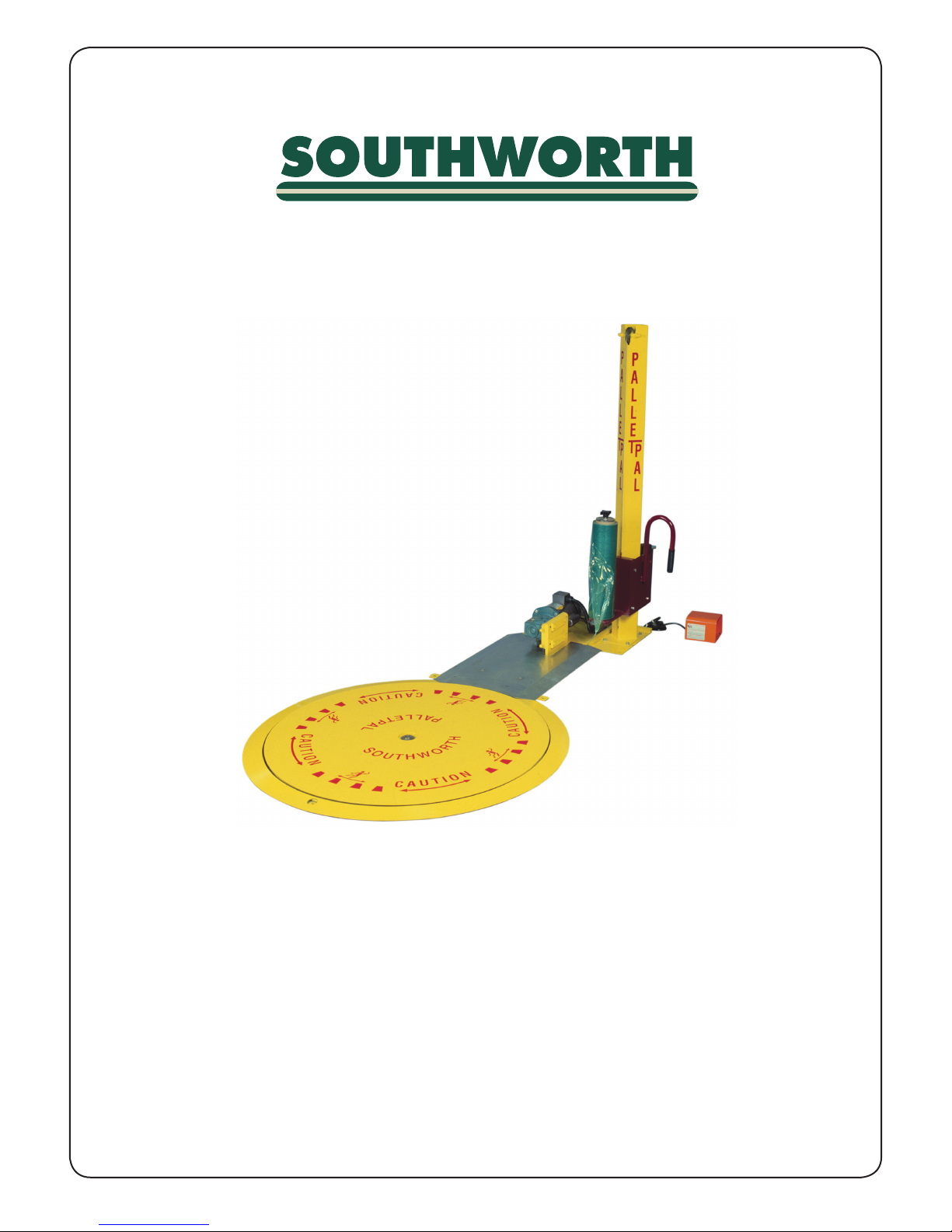

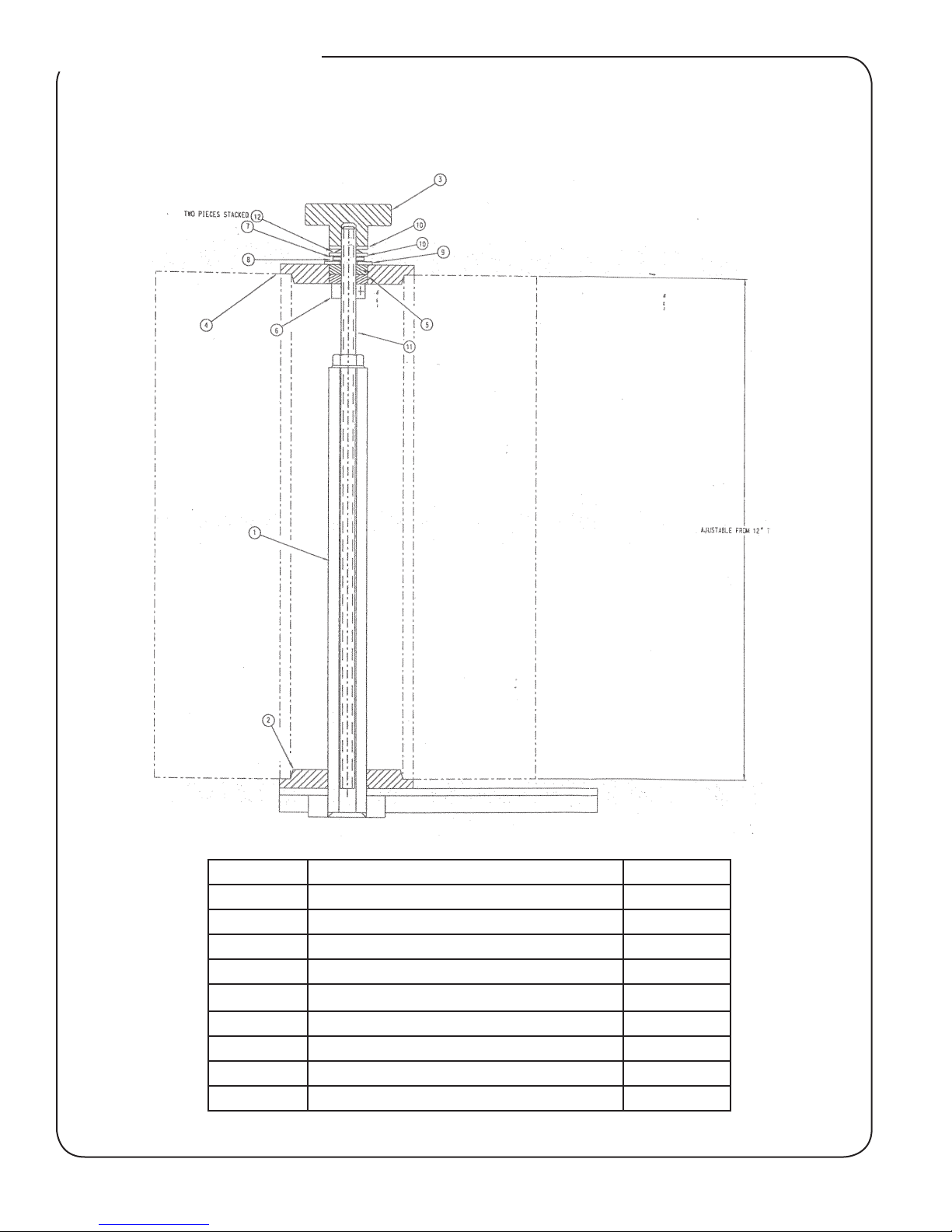

Figure 1: PalletPal Stretch Wrapper..................................................................................8

Figure 2: Film Roll Tensioning Parts ...............................................................................16

Figure 3: Wiring Diagram.................................................................................................18

PalletPal Stretch Wrapper

4 PALLETPAL STRETCH WRAPPER OWNER’S MANUAL

INTRODUCTION

The PalletPal™ Stretch Wrapper is an industrial grade powered turntable stretch wrapper. The

unit improves productivity and reduces worker fatigue and injury. It also produces tighter, more

secure wraps. The PalletPal™ Stretch Wrapper unit saves lm, and uses less expensive lm than

hand wrappers.

This manual contains information to help you to learn about the safe and proper installation, use

and upkeep of your PalletPal™ Stretch Wrapper. Please be sure that this manual is available to

anyone who uses or services the stretch wrapper. Be sure that everyone who uses the stretch

wrapper has read this manual.

The PalletPal™ Stretch Wrapper units may be used in a wide variety of industrial settings. The

instructions included in this manual are not necessarily all-inclusive, because Southworth cannot

anticipate all conceivable or unique situations.

In the interest of safety, please read this whole manual carefully. Please understand the material in

the manual before you install, use, or service the Stretch Wrapper unit. If you have any questions

about the instructions in this manual, please contact your dealer or Southworth Products Corp.

Southworth’s product warranty is shown on the rear cover of this manual. This instruction manual is

not intended to be or to create any other warranty, express or implied, including any implied warranty

of merchantability or tness for a particular purpose, all of which are hereby expressly excluded.

As set forth more specically in the product warranty, Southworth’s obligation under that warranty

is limited to the repair or replacement of defective components, which shall be the buyer’s sole

remedy, and Southworth shall not be liable for any loss, injury, or damage to persons or property,

nor for any direct, indirect, or consequential damage of any kind resulting from the PalletPal™

Stretch Wrapper unit.

SOUTHWORTH

PALLETPAL STRETCH WRAPPER OWNER’S MANUAL 5

Responsibility of Owners and Users

Inspection and Maintenance

The device shall be inspected and maintained in proper working order in accordance with

Southworth’s owner’s manual.

Removal from Service

Any device not in safe operating condition such as, but not limited to, excessive leakage,

missing rollers, pins, or fasteners, any bent or cracked structural members, cut or frayed

electric, hydraulic, or pneumatic lines, damaged or malfunctioning controls or safety de-

vices, etc. shall be removed from service until it is repaired to the original manufacturer’s

standards.

Deection

It is the responsibility of the user/purchaser to advise the manufacturer where deection

may be critical to the application.

Repairs

All repairs shall be made by qualied personnel in conformance with Southworth’s instruc-

tions.

Operators

Only trained personnel and authorized personnel shall be permitted to operate the lift.

Before Operation

Before using the device, the operator shall have:

• Read and/or had explained, and understood, the manufacturer’s operating instruc-

tions and safety rules.

• Inspected the device for proper operation and condition. Any suspect item shall be

carefully examined and a determination made by a qualied person as to whether

it constitutes a hazard. All items not in conformance with Southworth’s specication

shall be corrected before further use of the equipment.

During Operation

The device shall only be used in accordance with this owner’s manual.

• Do not overload.

• Ensure that all safety devices are operational and in place.

Modications or Alterations

Modications or alterations to any Southworth industrial positioning equipment shall be

made only with written permission from Southworth.

PalletPal Stretch Wrapper

6 PALLETPAL STRETCH WRAPPER OWNER’S MANUAL

SAFETY ALERT SYMBOLS AND SIGNAL WORDS

The safety of all persons operating, maintaining, repairing, or in the vicinity of this equipment is of

paramount concern. This is a powerful machine with moving parts, and is capable of causing personal

injury if proper precautions are not taken. Therefore, throughout this manual, certain hazards have been

identied which may occur in the use of the machine, and there are appropriate instructions or precautions

which should be taken to avoid these hazards. In some cases, there are consequences which may occur

if instructions or precautions are not followed. Below are the symbols and signal words along with their

denitions referenced from ANSI Z535.4 - Product Safety Signs and Labels.

Safety Alert Symbols

These are the safety alert symbols. They are used to alert you to potential physical injury

hazards. Obey all safety messages that follow this symbol to avoid possible injury or

death.

For use with DANGER signal word

(Red Background)

For use with WARNING signal word

(Orange Background)

For use with CAUTION signal word

(Yellow Background)

Signal Words

The meaning of different signal words as dened by ANSI Standard Z535.4 indicates the

relative seriousness of the hazardous situation.

DANGER indicates a hazardous situation which, if not

avoided, will result in death or serious injury.

WARNING indicates a hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION, used with the safety alert symbol, indicates a

hazardous situation which, if not avoided, could result in

minor or moderate injury.

NOTICE is used to address practices not related to per-

sonal injury.

(Red Background)

(Orange Background)

(Yellow Background)

(Blue Background)

SAFETY

INSTRUCTIONS

SAFETY INSTRUCTIONS (or equivalent) signs indicate

safety-related instructions or procedures.

(Green Background)

SOUTHWORTH

PALLETPAL STRETCH WRAPPER OWNER’S MANUAL 7

SAFETY

The Stretch Wrapper unit has been carefully designed to

be as safe as possible for operators and service workers.

If you take a few common sense precautions, you will

be able to use the machine safely. However, the Stretch

Wrapper unit is a powerful machine with moving parts, and

is capable of causing personal injury if proper precautions

are not taken.

Therefore, throughout this manual, Southworth has iden-

tied certain hazards, which may occur in the use and

servicing of the Stretch Wrapper unit, and has provided

appropriate instructions or precautions, which should be

taken to avoid these hazards. In some cases, Southworth

has also pointed out the consequences which may occur if

Southworth’s instructions or precautions are not followed.

Southworth uses the following system of identifying the

severity of the hazards associated with its products:

Danger!

Immediate hazard which will result in severe

personal injury or death.

Warning!

Hazard or unsafe practice which could result

in severe personal injury or death.

Caution!

Hazard or unsafe practices, which could result

in minor personal injury or property damage.

Please read and follow this instruction

manual, including all safety Instructions and

precautions, carefully and completely.

IMPORTANT

INSTALLATION NOTES

Danger!

The electric motor used in the unit can create sparks.

Don’t use the unit in an area where ammable gases

may be present.

Warning!

The unit is attached to the skid using metal bands. These

bands are under high tension. The edges are sharp.

Wear safety glasses and gloves when you handle or cut

the banding.

Warning!

Do not use the machine without tightening the bolts, which

hold the tower and lm carriage assembly. See Fig. 1. If

you do not do this, the tower may fall when you try to raise

the lm carriage. You may be injured, or the machine may

be damaged.

Caution!

When removing the unit from the shipping pallet, be very

careful to support the section of the machine where the

drive belt housing meets the turntable disk. This is the

weakest point, yet it is very important to the function of

the machine.

Caution!

During installation, do not tilt the unit more than 30 degrees

or drop it. This can cause the balls in the carrier plate to

become unseated. The machine may be damaged when

you start the unit.

Caution!

The unit must be installed on a smooth at surface. If the

oor is not at, this can create stresses in the base of the

machine. The machine may not work properly, or parts of

the machine may wear more quickly than they should.

Caution!

Do not use the machine unless it has been rmly anchored

to the oor. If you do not do this, the machine may move

as it operates. This can create stresses, which may dam-

age the machine.

Caution!

Be sure the lm carriage is latched in position at the bot-

tom of the tower before you remove the tower from the

pallet. If you do not do this, the carriage may slide as you

remove the pallet.

Caution!

Do not move the machine once you have attached the

tower. If you must move the machine, disassemble the

tower rst. If you strike the tower while moving the ma-

chine, it is very easy to damage the machine.

PalletPal Stretch Wrapper

8 PALLETPAL STRETCH WRAPPER OWNER’S MANUAL

SPECIFICATIONS

Load capacity: 2500 lbs. uniform load

Load size: 50” wide x 50” long x 65” high

Power: 115V AC, 10, 60Hz, 6 amp

Film capacity: 10” dia. x 12”

to 20” long 90-1/2” long

Length overall: 90-1/2”

Height of mast: 60-3/8”

Height

(lm carriage

raised, 20” lm): 66-3/4”

Turntable ramp dia: 49-7/16”

Turntable

diameter: 43 3/8’’

Turntable height: 1’’

Speed: 8.25 rpm

Controls: Footswitch, momentary contact

Net weight: Approximately 600 lbs.

Unpacking the Lift

The PalletPal Stretch Wrapper unit has been pre-wired

and pre-assembled. It was tested to factory specications

before shipment.

1. Before you start to install the unit, check for local

codes and ordinances, which may apply. It is your

responsibility to obtain any necessary permits.

2. Please read all of these instructions carefully. Be sure

to read and understand all of the warnings.

3. Inspect the shipping crate carefully for any damage

that may have affected the machine. If you see signs

of damage, tell the trucker.Also make a note of this on

the shipping papers which you are asked to sign.

4. Choose the place where you want to mount the unit.

It is extremely important that the PalletPal Stretch

Wrapper be set up on a smooth and at surface.

Check the oor surface carefully and make sure that

it is free of all loose debris and dirt.

Danger!

The electric motor used in the unit can create

sparks. Don’t use the unit in an area where am-

mable gases may be present.

INSTALLATION

INSTRUCTIONS

Turntable

Belt guard

Tension adjustment

Mast for lm

carriage

Film carriage

Lag bolts

SOUTHWORTH

PALLETPAL STRETCH WRAPPER OWNER’S MANUAL 9

5. Position the crate beside the point where the machine

will be set up.

Warning!

The unit is attached to the skid using metal bands.

These bands are under high tension. The edges

are sharp. Wear safety glasses and gloves when

you handle or cut the banding.

6. Remove the metal banding which secures the ma-

chine to the pallet. Remove all packing material.

7. Remove the tower and set it aside.

Caution!

Be sure the lm carriage is latched in position at the

bottom of the tower before you remove the tower

from the pallet. If you do not do this, the carriage

may slide as you remove the pallet.

8. Carefully remove the turntable assembly and place

it in the center of the setup area. Slide the disk and

drive belt assembly onto the oor. The best way to

do this is to make a ramp to the oor, using steel or

wood lengths. Slowly slide the disk and drive belt to

the oor using this ramp.

Caution!

When removing the unit from the shipping pallet, be very

careful to support the section of the machine where the

drive belt housing meets the turntable disk. This is the

weakest point, yet it is very important to the function of

the machine.

Caution!

During installation, do not tilt the unit more than 30 degrees

or drop it. This can cause the balls in the carrier plate to

become unseated. The machine may be damaged when

you start the unit.

Caution!

The unit must be installed on a smooth at surface. If the

oor is not at, this can create stresses in the base of the

machine. The machine may not work properly, or parts of

the machine may wear more quickly than they should.

9. Remove the remaining components and lay them out

on the oor.

10. If you have any questions about the steps in the in-

stallation process, please call Southworth Customer

Service at 1-800-743-1000.

Assembly

1. Install the tower and carriage assembly. Remove the

nuts and washers from the four studs on the tower

mounting plate.

2. Lift the tower and carriage assembly and position it

above the motor and tower mounting plate.

Warning!

The tower and carriage assembly weighs about 120

lbs. To prevent back injury, get a helper to assist with

this assembly. Bend your knees, and keep your back

straight as you lift.

3. Align the four holes in the tower base plate with the

studs on the mounting plate. Lower the tower and

carriage assembly onto the mounting plate.

4. Install and tighten the washers and nuts.

Warning!

Do not use the machine without tightening the bolts that

hold the tower and lm carriage assembly. If you do not

do this, the tower may fall when you try to raise the lm

carriage. You may be injured, or the machine may be

damaged.

Caution!

Do not move the machine once you have attached the

tower. If you must move the machine, disassemble the

tower rst. If you strike the tower while moving the ma-

chine, it is very easy to damage the machine.

Anchoring the Unit

Once the tower has been attached, the machine must be

anchored before you use it. The machine has holes for 7

lag bolts. See Fig. 1.

Caution!

Do not use the machine unless it has been rmly anchored

to the oor. If you do not do this, the machine may move

as it operates. This can create stresses, which may dam-

age the machine.

Electrical Connections

Plug the power cord directly into a 115V AC outlet. Do not

use an extension cord. When possible, use a dedicated

service to provide power to the machine. This eliminates

voltage drops, which may cause the machine to work

erratically. The power source should have a 15-amp fuse

or circuit breaker.

PalletPal Stretch Wrapper

10 PALLETPAL STRETCH WRAPPER OWNER’S MANUAL

Testing

1. Press the footswitch. The turntable should begin to

rotate in a clockwise direction.

2. Grip the handle on the lm carriage. Raise and lower

the carriage. It should travel up and down the tower

with little resistance.

OPERATING

INSTRUCTIONS

Do not use this unit with a load greater than 2500 lbs. This

includes the weight of the payload and the weight of the

pallet. If you overload the machine, it may be damaged.

This machine is designed for light commercial duty. Do

not use the unit to process more than 20 pallets per day.

If you try to use the machine more often, or try to use the

machine continuously, the machine may be damaged. The

motor may overheat, and other parts may wear quickly.

Do not use the machine with a pallet which is larger than

50” x 50”. If you try to use a larger pallet, a corner of the

pallet may hit one of the xed parts of the machine. This

can cause the pallet or the load to shift. You may be injured,

and the machine may be damaged.

Do not try to use this machine with damaged or broken

pallets. Broken pallets may have boards or nails that

hang down below the main part of the pallet. As the pal-

let is turned, these boards or nails may catch on the belt

guard. See Fig. 1. This can cause the pallet to stop turning

suddenly, and this can cause the load to shift. You may

be injured, and the machine may be damaged. Boards

or nails may extend up to 1/8 inch below the bottom of

the pallet. If necessary, you can raise the bottom of the

pallet by placing spacers on the turntable. Use pieces of

2” x 4” lumber, about 36” long. Don’t use small blocks to

support the pallets - these may not be stable when the

load begins turning.

The power cord can be damaged or cut by sharp objects.

Keep all sharp objects away from the power cord. Don’t

step on the power cord or drop anything on it. If the

power cord is damaged, you may be exposed to 120V

AC electricity. Do not use the machine if the power cord

is damaged in any way.

Never use this machine if it is wet or under water. This can

create a serious electrical shock. Protect the unit from rain

and moisture. The machine is not intended to be used in

a washdown environment.

Do not drop the load on the turntable. If you do this while

the turntable is moving, the load may shift. You may be

injured, or the machine may be damaged. If you drop the

load while the turntable is stopped, the machine may be

damaged.

Keep the area around machine clean. Do not allow any

dirt, debris, spilled oil, or excess grease to collect. These

materials may cause you to slip while the machine is

operating, and you may be injured.

Stay clear of the turntable when it is moving. As the pallet

turns, a part of the load may rotate around and hit you.

Never operate the unit when anyone is standing on the

turntable. The person on the turntable may be thrown off

and injured.

Keep the lm carriage in the latched (lower) position when

the machine is unattended or not in use.

Loading Film

1. Loosen the hand knob near the top of the lm carriage.

Remove the upper saddle core from the shaft in the

center of the carriage.

2. Place the roll of lm over the shaft. The new roll may

be up to 20 inches wide. As you look down on the roll

of lm, the loose end of the lm should be on the left.

When you pull lm off of the roll, the roll should turn

in a clockwise direction.

3. Replace the upper saddle core. Tighten the hand knob

to provide the desired lm tension.

Wrapping Film

1. Place a pallet on the turntable. The unit is designed

with a low clearance so it can be loaded by a pallet

jack. Place the center of the load over the center of

the turntable.

Warning!

Never operate the unit if the load is off-center. As the turn-

table moves, the load may shift, and you may be injured.

This can also damage the machine.

Warning!

Do not drop the load on the turntable. If you do this while

the turntable is moving, the load may shift. You may be

SOUTHWORTH

PALLETPAL STRETCH WRAPPER OWNER’S MANUAL 11

injured, or the machine may be damaged. If you drop the

load while the turntable is stopped, the machine may be

damaged.

2. Walk halfway around the load and attach one end of

the lm to the side of the load.

3. Press the footswitch to start the turntable rotation.

Some pallets tend to sag a bit at the corners. The

comers may hit the sides of the belt cover. See Fig. 1.

If the corners hit, stop the machine and place blocks

under the pallet to raise it.

Warning!

Stay clear of the turntable while it is moving. As the pallet

turns, a part of the load may rotate around and hit you.

Never operate the unit when anyone is standing on the

turntable. The person on the turntable may be thrown off

and injured.

4. Grasp the handle on the lm carriage. As the turntable

turns, raise and lower the lm carriage to wrap differ-

ent parts of the load. The amount of overlap between

pieces of lm is determined by how fast you raise and

lower the carriage.

5. The knob on top of the lm carriage is used to adjust

the lm tension. If the lm breaks or stretches, the

tension is too high. Reduce the tension by turning

the knob counterclockwise.

Warning!

If the load is very light and there is too much tension on

the lm, the load can be pulled off of the pallet. The load

may be damaged, and you may be injured.

6. When the load has been wrapped, lower the lm

carriage. Be sure the latch is engaged to hold the

carriage in position.

7. Cut the lm. Attach the trailing edge of the lm to the

load.

8. Remove the pallet with the wrapped load.

Stopping the Machine

1. To stop the machine, remove your foot from the

footswitch.

2. When the machine is unattended or not in use, lower

the lm carriage into the latched position.

Operation Notes

Danger!

The power cord can be damaged or cut by sharp objects.

Keep all sharp objects away from the power cord. Don’t

step on the power cord or drop anything on it. If the

power cord is damaged, you may be exposed to 120V

AC electricity. Do not use the machine if the power cord

is damaged in any way.

Danger!

Never use this machine if it is wet or under water. This can

create a serious electrical shock. Protect the unit from rain

and moisture. The machine is not intended to be used in

a washdown environment.

Warning!

Never operate the unit if the load is off-center. The load

may shift, and you may be injured. This can also damage

the machine.

Warning!

Do not try to use this machine with damaged or broken

pallets. Broken pallets may have boards or nails, which

hang down below the main part of the pallet. As the pal-

let is turned, these boards or nails may catch on the belt

guard. See Fig. 1. This can cause the pallet to stop turning

suddenly, and this can cause the load to shift. You may

be injured, and the machine may be damaged. Boards

or nails may extend up to 1/8 inch below the bottom of

the pallet. If necessary, you can raise the bottom of the

pallet by placing spacers on the turntable. Use pieces of

2” x 4” lumber, about 36” long. Don’t use small blocks to

support the pallets - these may not be stable when the

load begins turning.

Warning!

Do not use the machine with a pallet which is larger than

50” x 50”. If you try to use a larger pallet, a corner of the

pallet may hit one of the xed parts of the machine. This

can cause the pallet or the load to shift. You may be injured,

and the machine may be damaged.

Warning!

Do not drop the load on the turntable. If you do this while

the turntable is moving, the load may shift. You may be

injured, or the machine may be damaged. If you drop the

load while the turntable is stopped, the machine may be

damaged.

PalletPal Stretch Wrapper

12 PALLETPAL STRETCH WRAPPER OWNER’S MANUAL

Warning!

Keep the area around machine clean. Do not allow any

dirt, debris, spilled oil, or excess grease to collect. These

materials may cause you to slip while the machine is

operating, and you may be injured.

Warning!

Stay clear of the turntable when it is moving. As the pallet

turns, a part of the load may rotate around and hit you.

Never operate the unit when anyone is standing on the

turntable. The person on the turntable may be thrown off

and injured.

Caution!

Keep the lm carriage in the latched (lower) position when

the machine is unattended or not in use.

Caution!

Do not use this unit with a load greater than 2500 lbs. This

includes the weight of the payload and the weight of the

pallet. If you overload the machine, it may be damaged.

Caution!

This machine is designed for light commercial duty. Do

not use the unit to process more than 20 pallets per day.

If you try to use the machine more often, or try to use the

machine continuously, the machine may be damaged. The

motor may overheat, and other parts may wear quickly.

Safety Labels

When it is shipped from the factory, the machine includes

the following safety labels. Be sure all of these labels are

in place. Never paint over the labels. Replacements are

available from Southworth.

• A series of labels around the turntable indicating that

workers should not stand on the turntable.

• A label on the belt guard: “Maximum capacity 2500 lbs.”

• Two labels on the sides of the belt guard: “Warning -

Machine must be lagged down to a at surface.”

Maintenance

Danger!

This machine contains electrical parts which carry 120V

AC. If you touch an exposed part while it is charged, you

may be killed or injured. Do not work on the machine unless

you are a trained electrician or electrical technician.Always

disconnect the power before you service the machine.

(Remember to do this if you lubricate the machine.)

Routine Periodic Maintenance

After the rst 100 hours of operation –

• Inspect the machine carefully. Tighten any loose nuts,

screws, set screws, sprocket keys, etc. Do not change the

oil in the gear drive.

• It is normal to see some wear on the plates under the

turntable. After a short “break-in” period, this wear should

be reduced.

At the start of each shift –

• Make a general walk-around inspection. Remove any

dirt and debris from the machine.

• Check for loose or damaged components and wiring.

• Check the condition of the power cord. Don’t use the unit

if the power cord is damaged.

Every month –

• Remove the belt cover and check the condition of the

belt. The driving surfaces of the belt should be smooth,

but not hard and shiny or cracked. If the belt is worn or

damaged, replace it.

• Check the belt tension. Press on one section of the belt

in the middle of its run. If you can deect the belt more

than 1/2 inch, tighten the belt.

Once ayear –

Change the oil in the reducer. Use SAE 90 gear oil.

Adjusting the Belt Tension

1. Unplug the machine.

2. Remove the two sheet metal screws that hold the belt

cover in place.

3. Loosen the four bolts that hold the motor mounting

bracket.

4. The belt adjustment mechanism includes two adjust-

ing bolts with locking nuts. Back off the locking nuts.

Turn the adjusting bolts until you have the correct belt

tension. Press on one section of belt in the middle of

its run. You should be able to deect the belt about

1/4 inch. Adjust both bolts by the same amount.

5. Re-tighten the locking nuts.

6. Replace the belt cover and re-tighten the sheet metal

screws.

7. Plug in the machine.

SOUTHWORTH

PALLETPAL STRETCH WRAPPER OWNER’S MANUAL 13

Removing the Turntable

1. Unplug the machine.

2. Remove the belt guard. Use the two adjusting bolts

to release the tension on the drive belt. Remove the

belt from the drive pulley under the motor.

3. Use a pair of snap-ring pliers to remove the snap ring

in the center of the turntable.

4. Use a lever to lift one edge of the turntable. Start by

lifting the edge that is nearest the belt guard.

Warning!

The turntable is very heavy. You will need at least three

people to lift this part safely. Be sure to wear heavy gloves

when performing this job.

5. Lift the edge of the turntable just a bit so that you can

reach the belt. Pull the belt away from the turntable.

Caution!

Be careful to keep the belt away from the grease. If the belt

does touch the grease, you must remove the grease before

you re- assemble the machine. Use the smallest possible

amount of spray degreaser. Degreaser tends to dry out the

rubber material in the belt, so use it sparingly.

6. Once the belt is free, you can lift the turntable away

from the machine.

7. If necessary, you can now remove the carrier plate.

The steel balls used in the machine will remain in

the lower part of the machine. Don’t do this unless

you want to degrease the bearings - it can be time-

consuming to reassemble this part of the machine.

8. There are 72 balls, 5/8 inch in diameter, in the car-

rier plate. These are standard chrome-plated steel

balls.

9. If you have removed the carrier plate, put it back in

position. Place each of the balls in one of the bearings.

Be sure that every bearing has a ball. The machine

uses the large number of bearings to spread out the

weight of the load. If some of the balls are missing,

the machine may not work properly, and may wear

more quickly.

10. To reassemble the machine, reverse the remaining

steps listed above.

Inspecting and Lubricating

the Turntable

1. Unplug the machine.

2. Remove the belt guard and release the tension on

the drive belt. Remove the belt from the drive pulley

under the motor.

3. Remove the turntable as described in the last sec-

tion.

4. Lift out the carrier plate. Collect the 72 steel balls.

5. Degrease the carrier plate and the steel balls.

6. Inspect the steel balls for signs of wear. Check several

balls for discoloration or breakdown of the chrome

layer.

7. Set the carrier plate back in position. Place each of the

balls in one of the bearings. Be sure that every bear-

ing has a ball. The machine uses the large number of

bearings to spread out the weight of the load. If some

of the balls are missing, the machine may not work

properly, and may wear more quickly.

8. Place a bit of grease inside the opening of each bear-

ing.

9. Work some grease into the bearing at the center of

the turntable. The bearings for the V-belt idler rolls

are sealed and do not need lubrication.

10. To reassemble the machine, reverse the remaining

steps listed above. Guide the belt over the idler wheels

on either side of the belt guard. Be careful not to let

the drive belt touch the grease.

Caution!

Be careful to keep the belt away from the grease. If the

belt does touch the grease, you must remove the grease

before you reassemble the machine. Use the smallest

possible amount of spray degreaser. Degreaser tends to

dry out the rubber material in the belt, so use it sparingly.

PalletPal Stretch Wrapper

14 PALLETPAL STRETCH WRAPPER OWNER’S MANUAL

Changing the Drive Belt

Change the belt if it is cracked or dried out, or if the sides of the belt become very shiny. The belt is an A-size V-belt,

183 inches long.

1. Unplug the machine.

2. Remove the belt guard and release the tension on the drive belt. Remove the old belt from the drive pulley under the

motor.

3. Remove the turntable as described earlier. Leave the carrier plate in position - do not remove it.

4. Replace the turntable, running the new belt around the base of the part. Be careful not to let the new belt touch the

grease here.

Caution!

Be careful to keep the belt away from the grease. If the belt does touch the grease, you must remove the

grease before you reassemble the machine. Use the smallest possible amount of spray degreaser. Degreaser

tends to dry out the rubber material in the belt, so use it sparingly.

5. Guide the belt around the two idler pulleys at the end of the belt guard.

6. Guide the belt around the drive pulley under the motor. Tighten the two bolts that set the belt tension. The free play in

the center of the belt’s run should be about 1/4 inch.

7. Replace the belt guard and plug in the machine.

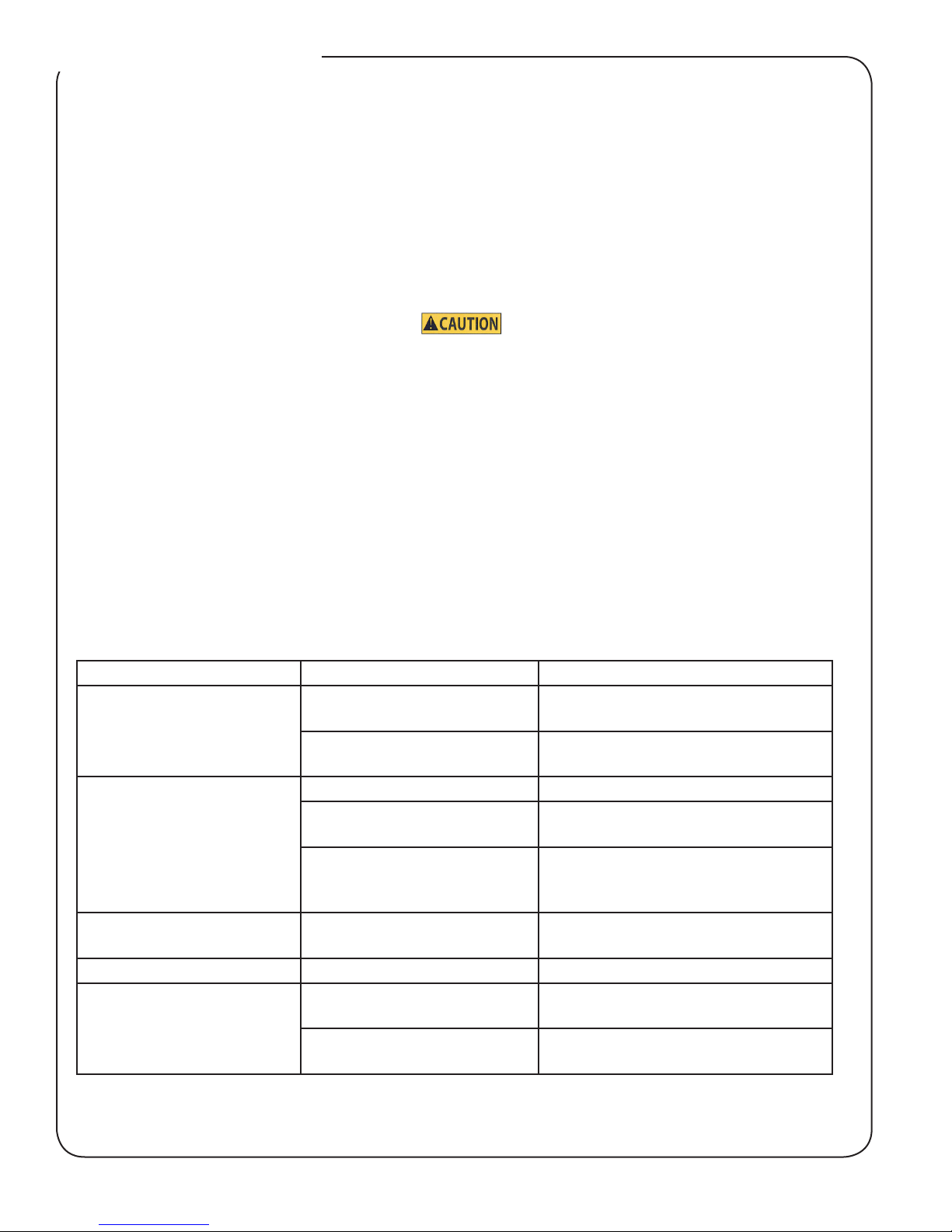

TROUBLESHOOTING

Troubleshooting Check List

Problem Possible Cause Check This

Turntable does not start, motor is

dead.

No power to motor. Check power source, power cord, start

switch.

Drive belt broken or slipping. Remove belt cover. Check belt condition.

Check for correct tension.

Turntable starts slowly.

Drive belt is loose. Check belt tension and adjust if necessary.

Drive belt is worn. Check for shiny surface and cracks. Replace

if necessary.

Grease on drive belt. Remove belt guard and inspect belt. If belt is

contaminated, remove turntable. Degrease

turntable and belt.

Excessive “rumble” when unit

operates

Wear or lack of lubrication to bearings

under turntable.

Remove turntable, inspect, lubricate.

Drive belt wears quickly. Mounting surface is not at. Check for atness using a level.

Drive motor overheats.

Exceeding duty cycle. Unit is designed for 20 pallets per day maxi-

mum.

Unit is overloaded. Unit is designed for 2500 lb. load including the

weight of pallet.

SOUTHWORTH

PALLETPAL STRETCH WRAPPER OWNER’S MANUAL 15

ORDERING REPLACEMENT PARTS

Southworth has carefully chosen the components in your lift to be the

best available for the purpose. Replacement parts should be identical to

the original equipment. Southworth will not be responsible for equipment

failures resulting from the use of incorrect replacement parts or from

unauthorized modications of the machine.

Southworth will gladly supply you with replacement parts for your

Southworth lift. With your order, please include the model number and the

serial number of the lift. You may nd these numbers on the nameplate,

which is located on the crossbar at the base of the cylinder(s). When

you are ordering parts for a cylinder, also include the cylinder number.

This is stamped on the base of the cylinder housing.

To order replacement parts, please call the Parts Department at (207)

878-0700 or (800)743-1000. Parts are shipped subject to the following

terms:

• FOB factory

• Returns only with the approval of our parts department

• Payment net 30 days (except parts covered by warranty)

• Freight collect (except parts covered by warranty)

• The warranty for repair parts is 30 days from date of shipment

Parts replaced under warranty are on a “charge-credit” basis. We will

invoice you when we ship the replacement part, then credit you when

you return the worn or damaged part, and we verify that it is covered

by our warranty. Labor is not covered under warranty for Parts orders.

SOUTHWORTH PRODUCTS CORP

Parts Department

Telephone: (207) 878-0700

(800) 743-1000

Fax: (207) 797-4734

PalletPal Stretch Wrapper

16 PALLETPAL STRETCH WRAPPER OWNER’S MANUAL

Stretch Wrapper

Film Roll Tensioning Parts

ITEM NO. PART DESCRIPTION PART NO.

3 KNOB 2980126

4 CORE MOUNT PIVOT 2980127

5 BEARING 2980128

6 THREADED COLLAR, 3/8-16 2612321

7WASHER, .375 ID X .812 OD X .030 THICK 2340599

8 THRUST BEARING 2340700

9WASHER, 7/16 ID X 1 1/4 OD X 5/64 THICK 2340217

10 WASHER, 3/8 ID X 13/16 OD X 1/16 THICK 2340701

12 CURVED SPRING WASHER 2760065

SOUTHWORTH

PALLETPAL STRETCH WRAPPER OWNER’S MANUAL 17

PARTS LISTING

PART LOCATION PART NO. QTY

Axle Top of lm carriage A-2980222 4

Ball bearing 5/8” dia. Under turntable, outer ring 6521304 72

Bearing Center of turntable 6521306 1

Bearing V-belt idler roller 2332296 2

Bearing Center of core mount A-2980128 2

Bearing holder (both size balls) Under turntable A-2980213 72

Cable assembly Film carriage A-2980072 1

Carrier plate Under turntable B-2980212 1

Collar Below core mount 2612321 1

Core mount Center of lm carriage A-2980127 1

Drive belt Around turntable 2612320 1

Drive pulley Under reducer A-298015B 1

Gear reducer End of motor 2281126 1

Handle grip Film carriage 2381046 1

Idler roller for V-belt Under belt guard A-2980113 2

Motor 1/3 HP Near lm carriage 2265491 1

Retaining ring Center of turntable 2881155 1

Roller Top of lm carriage A-2980221 1

Seal brush Under turntable A-2980774 1

Seal brush holder Under turntable A-2980074 1

Sheave Film carriage cable 2660093 1

Spacing washer Under turntable bearing 2820199 1

Tab washer Above turntable bearing 2341453 1

Tensioning knob Film carriage A-2980126 1

Thrust bearing Below lm core mount 2340700 1

Washer Under lm tension handle 2340701 1

Washer Smaller, under lm tension handle 2340599 2

Washer Above lm core 2340217 1

PalletPal Stretch Wrapper

18 PALLETPAL STRETCH WRAPPER OWNER’S MANUAL

Fig. 3 Wiring Diagram

SOUTHWORTH

PALLETPAL STRETCH WRAPPER OWNER’S MANUAL 19

Southworth Products Corp warrants this product to be free from defects in

material or workmanship for a period of two years of single shift usage from

date of shipment, providing claim is made in writing within that time period. This

warranty shall not cover modied designs for special applications, failure or

defective operation caused by misuse, misapplication, negligence or accident,

exceeding recommended capacities, failure to perform required maintenance

or altering or repairing, unless alteration is authorized by Southworth Products

Corp. Except as set forth herein, there are no other warranties, express or

implied, including the warranties of merchantability and tness for a particular

purpose, all of which are hereby excluded.

Southworth Products Corp makes no warranty or representation with respect

to the compliance of any product with state or local safety or product standard

codes, and any failure to comply with such codes shall not be considered a de-

fect of material or workmanship under this warranty. Southworth Products Corp

shall not be liable for any direct or consequential damages arising out of such

noncompliance.

Southworth Products Corp’s obligation under this warranty is limited to the

replacement or repair of defective components at its factory or another location

at Southworth Products Corp’s discretion. The Southworth Warranty is for prod-

uct sold with in North America. For products shipped outside of North America

the warranty will be for replacement of defective parts only. Labor is not includ-

ed. This is buyer’s sole remedy. Except as stated herein, Southworth Products

Corp will not be liable for any loss, injury or damage to persons or property, nor

for direct, indirect, or consequential damage of any kind, resulting from failure

or defective operation of said product.

This warranty may be altered only in writing by Southworth Products Corp,

Portland, Maine.

SOUTHWORTH PRODUCTS CORP

P.O. Box 1380, Portland, ME 04104-1380

Telephone: (800) 743-1000 • (207) 878-0700

Fax: (207) 797-4734

www.SouthworthProducts.com

2 YEAR WARRANTY

For more information, contact Southworth Products

Telephone (800) 743-1000 Fax (207) 797-4734

Southworth is the world class supplier of products designed to improve productivity and enhance

safety. Our staff has over 400 years of engineering experience. If one of our standard products

does not meet your needs, our engineers can custom design equipment specifically suited to your

material handling application.

SpringPalletPalLoadLeveler LiftwithFlushMountTurntable PortableContainerTilters

RollonLevelLoaders

PortableLifts

Floorto

MezzanineLifts

Stack‐n‐GoPoweredStacker

PalletRotators

DockLifts

FloorHeightLifts

Roll‐E

Table of contents