SPORTARREDO MASTERSUN 360 Service manual

30020 GRUARO-ITALY - VIA DELL’INDUSTRIA 7

Tel. 0421/767676 Fax 0421/767670

INSTALLATION, USE AND MAINTENANCE MANUAL

Cod.man.:11084.112.0.0 (05/01/06) Cod.app.:10097.026.0.0 (230V 3~ 60Hz)

USA

Cod. man.11084.112.0.0 (05/01/06) 1/38

USA

INDEX

INDEX OF SECTIONS

1 - GENERAL INFORMATION

1.1 Labels pag. 2

1.2 Introduction 4

1.3 General tanning instructions 4

1.4 Transport and handling 5

1.5 Preparation for installation by the client 5

2 - SAFETY INFORMATION

2.1 General 6

2.2 Noise 6

2.3 Regulations 6

3 - TECHNICAL DATA

3.1 Dimensions and technical data MASTERSUN

360 7

4 - INSTALLATION

4.1 Pre-installation 7

4.2 Connections 7

4.3 Assembly instructions 8

4.4 Voltage-change 19

5 - USE

5.1 Control board 20

5.2 Safety of the persons exposed to UV 21

5.3 Programming the pre-defined session times 22

6 - ORDINARY MAINTENANCE MADE BY THE

CUSTOMER

6.1 Ordinary maintenance 23

7 - EXTRAORDINARY MAINTENANCE MADE BY A

SKILLED TECHNICIAN

7.1 Extraordinary maintenance 25

7.2 Periodic control procedure 25

8 - CONTROL BOARD PROGRAMMING

8.1 Programming 30

8.2 Electronic control board connections 34

9- TROUBLESHOOTING AND RAPID DIAGNOSTICS

9.1 Troubleshooting and rapid diagnostics 35

10 - DEMOLITION AND WASTE MATERIALS

10.1 Waste materials 35

10.2 Demolition of the machine 35

11 – REPLACEMENTS AND CIRCUIT DIAGRAMS

11.1 Spare parts list 36

11.2 Circuit diagrams legend 37

12 - MEDICATION

12.1 Medication 38

13 - WARRANTY

13.1 Limited warranty 38

Cod. man.11084.112.0.0 (05/01/06) 2/38

USA

1 - GENERAL INFORMATION

1.1 LABELS

Cod. man.11084.112.0.0 (05/01/06) 3/38

USA

1 - GENERAL INFORMATION

Cod. man.11084.112.0.0 (05/01/06) 4/38

USA

1.2 INTRODUCTION

IMPORTANT

BEFORE OPERATING THE MACHINE, READ

THE INSTRUCTIONS CONTAINED IN THIS

OPERATING MANUAL CAREFULLY AND

COMPLETELY.

KEEP THIS MANUAL AND ALL ENCLOSURES

IN AN ACCESSIBLE PLACE WHERE IT CAN BE

REFERRED TO BY ALL USERS (OPERATORS,

MAINTENANCE PERSONNEL AND THOSE

CLIENTS WHO ASK FOR DETAILED

INFORMATION).

This Technical Manual is designed for use by installers

and operators, and should be read carefully and

completely before the machine is operated. The manual

should always be available for reference and should be

kept in a safe place so that it stays in good condition for

future reference. For further copies or updates of the

manual, contact the manufacturer at the address on the

front page.

Sportarredo SpA reserves the right to make changes to

the product and to the manual without being obliged to

update the preceding manuals.

This manual contains all the instructions and

information necessary to operate the machine:

•Correct installation of the machine.

•Description of the functions of the machine.

•Circuit diagrams.

The installers and the operators can use this manual to

understand the characteristics of the machine and to

learn the correct operating procedure.

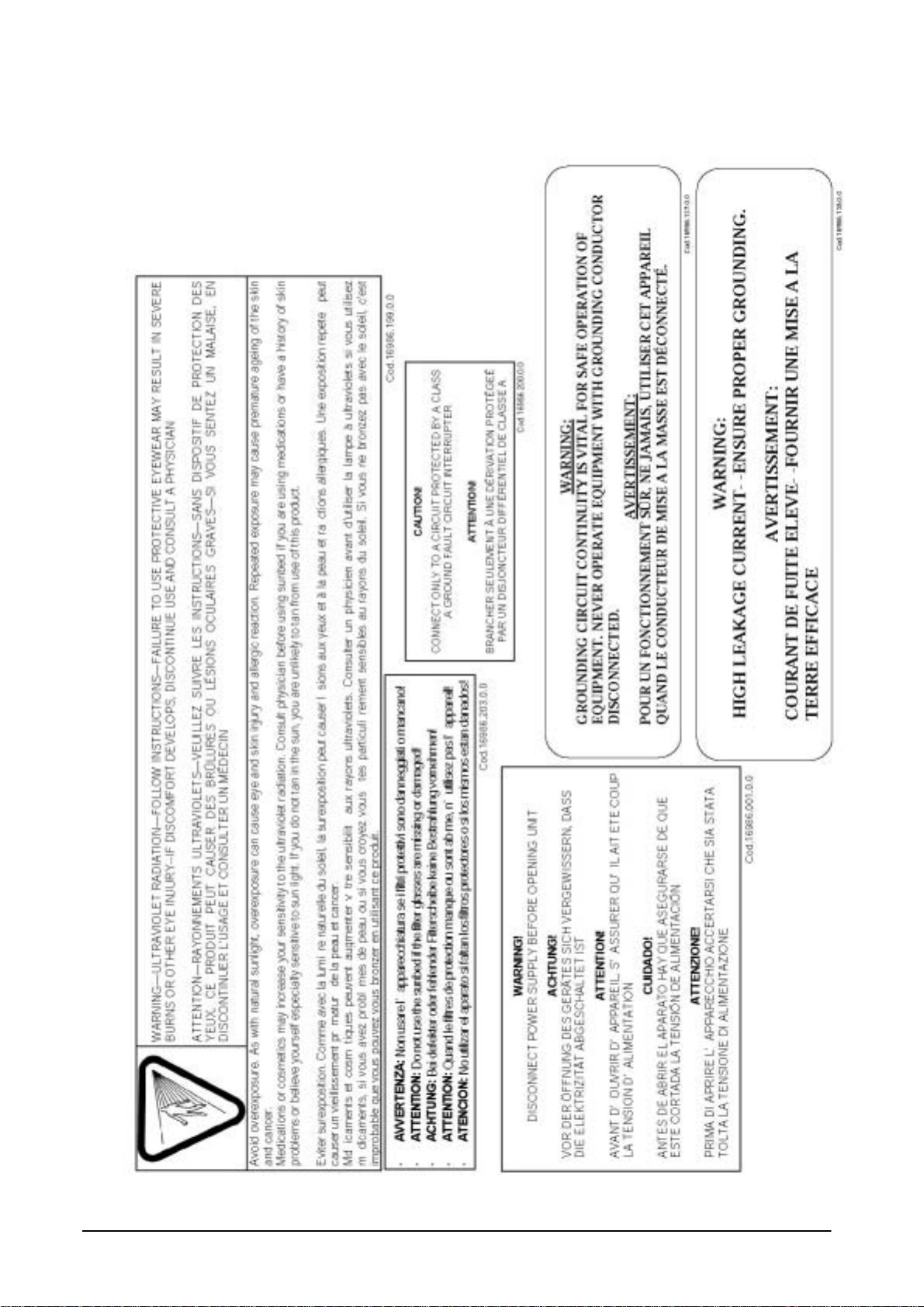

1.3 GENERAL TANNING INSTRUCTIONS

DANGER! Ultraviolet Radiation.

Follow instructions. Avoid overexposure. As with natural

sunlight, overexposure can cause eye and skin injury

and allergic reactions. Repeated exposure may cause

premature ageing of the skin and skin cancer.

WEAR PROTECTIVE EYEWEAR; FAILURE TO MAY

RESULT IN SEVERE BURNS OR LONG-TERM

INJURY TO THE EYES.

Medications or Cosmetics may increase your

sensitivity to the ultraviolet radiation. Consult physician

before using sunbed if you are using medications or

have a history of skin problems or believe yourself

especially sensitive to sunlight. If you do not tan in the

sun, you are unlikely to tan from the use of this product.

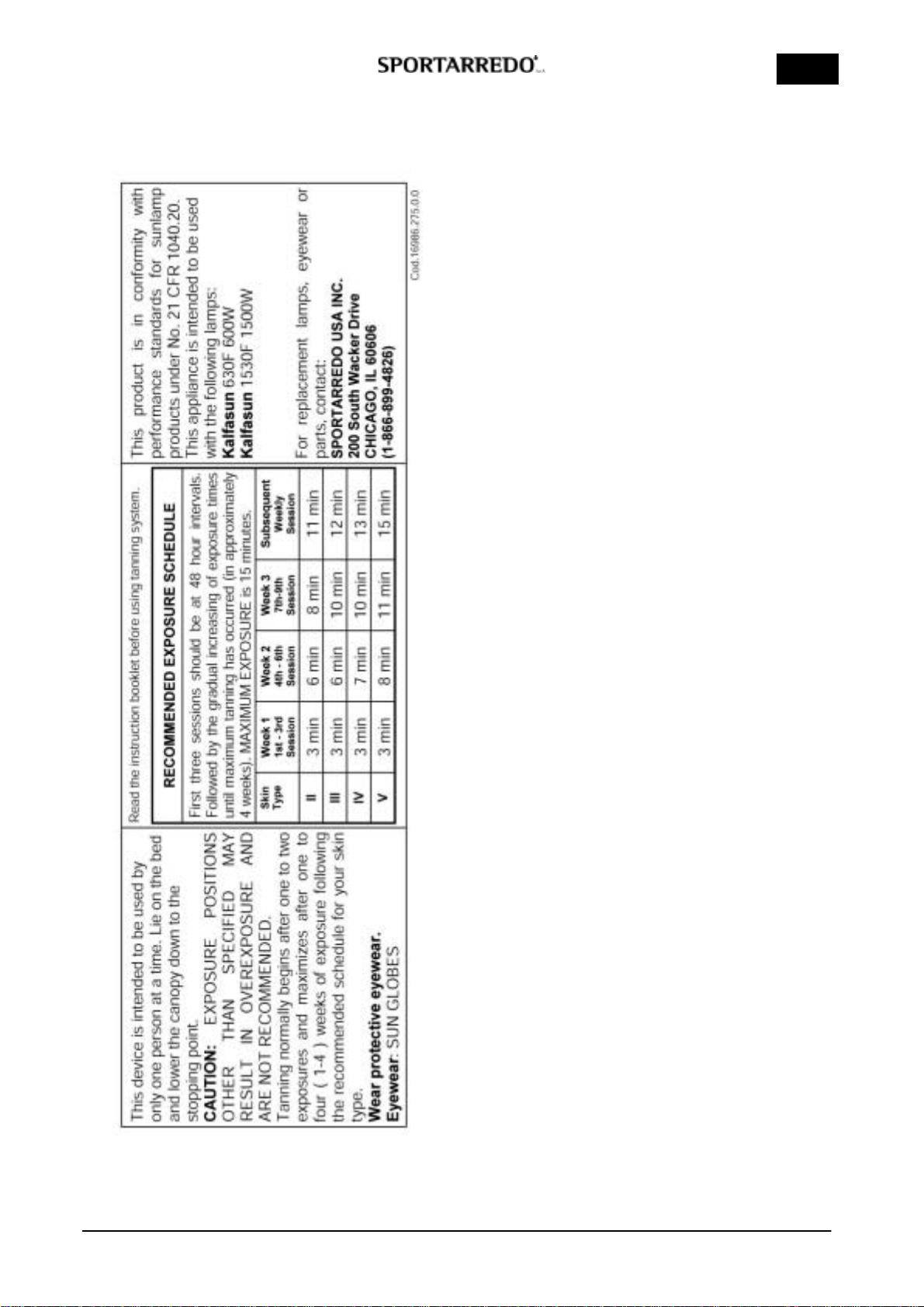

This device is intended to be used by only one person

at a time. Lie on the bed and lower the canopy down to

the stopping point.

CAUTION: EXPOSURE POSITIONS OTHER THAN

SPECIFIED MAY RESULT IN OVEREXPOSURE AND

ARE NOT RECOMMENDED.

Tanning normally begins after one to two exposures

and maximizes after one to four ( 1-4 ) weeks of

exposure following the recommended schedule for your

skin type.

Skin type II.

This is the individual that usually burns easily and

severely. Tans minimally or lightly and peels.

Skin type III.

Often referred to as “average” complexion burns

moderately and tans about average.

Skin type IV.

This individual burns minimally, tans easily and above

average.

Skin type V.

This individual’s system rarely burns, tans easily and

substantially.

Session times are calculated for a supply voltage of

208V.

This product is in conformity with performance

standards for sunlamp products under No.21 CFR

1040.20.

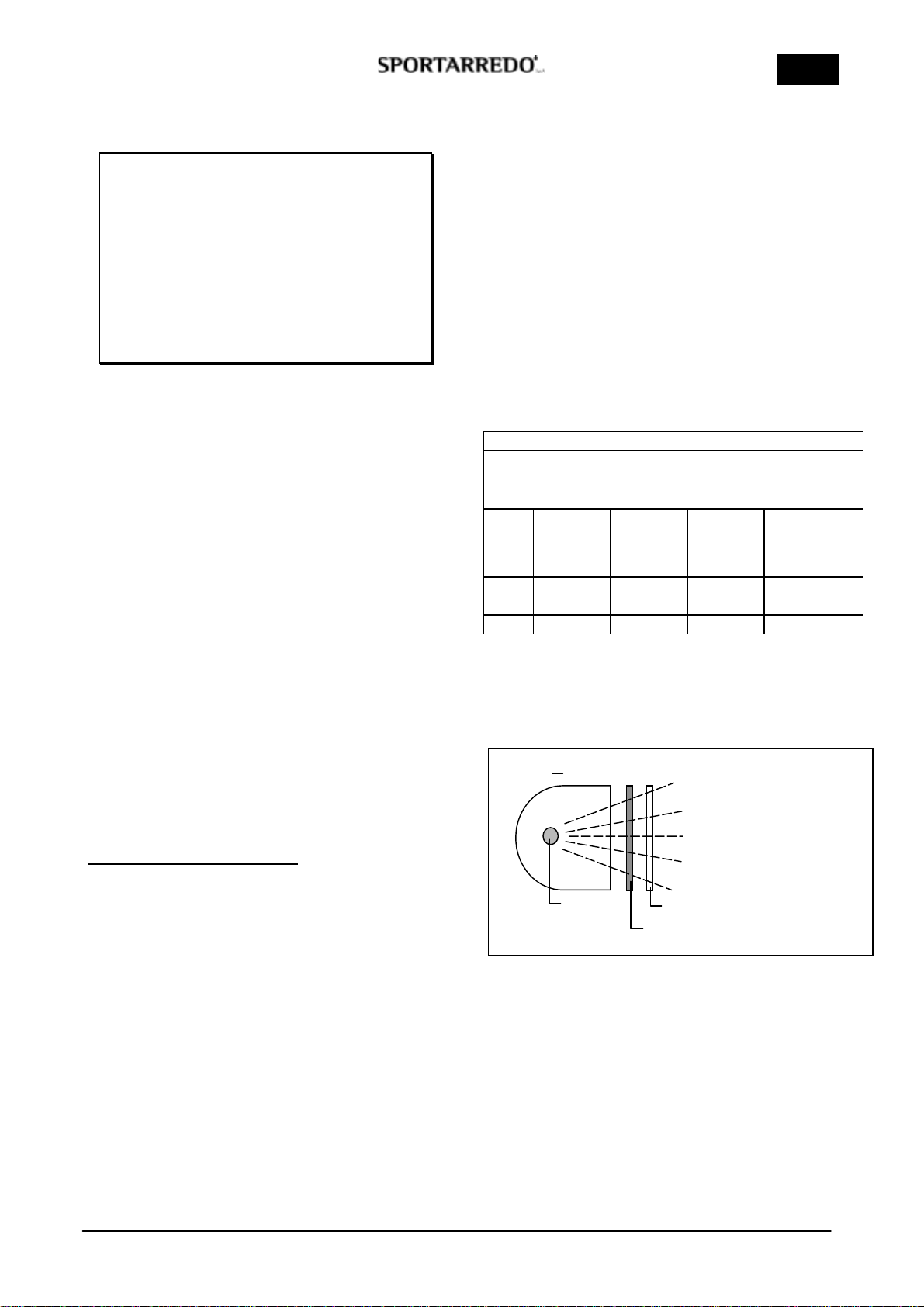

RECOMMENDED EXPOSURE SCHEDULE

First three sessions should be at 48 hour intervals. Followed by the

gradual increasing of exposure times until maximum tanning has

occurred (in approximately 4 weeks). MAXIMUM EXPOSURE is 15

minutes.

Skin

type Week 1

1st-3rd

Session

Week 2

4rd-6rd

Session

Week 3

7rd-9rd

Session

Subsequent

Weekly

Session

II 3 min. 6 min. 8 min. 11 min.

III 3 min. 6 min. 10 min. 12 min.

IV 3 min. 7 min. 10 min. 13 min.

V 3 min. 8 min. 11 min. 15 min.

This schedule is intended to be used with the following

lamps:

Kalfasun 630F

Kalfasun 1530F

Blue cobalt filter and clear Superlux TR-T filter

(together).

REFLE

C

T

O

R

LAMP

BLUE COBALT FILTER

CLEAR SUPERLUX TR

-

TFILTER

Cod. man.11084.112.0.0 (05/01/06) 5/38

USA

1.4 TRANSPORT AND HANDLING

The machine is carefully protected and loaded onto

pallets before shipping. The various parts of the

machine must never be transported or stored in

positions which differ from the positions in which they

are shipped. In this case, the warranty shall be null and

void.

The machine must be handled with care in order to

prevent the risk of damage to the packaged sections.

All handling operations should be carried out by

authorised and trained personnel. When the machine is

delivered, immediately check that the packaging

material is whole and that no damage has occurred

during transport.

Any damage to the machine must be notified to the

carrier not later than eight calendar days from the date

of delivery. If internal damage is suspected, it is

advisable to accept the machine reserving the right to

check accordingly.

THE CARRIER IS RESPONSIBLE FOR ANY

DAMAGE OCCURRING DURING TRANSPORT OF

THE MACHINE. SPORTARREDO WILL MAKE

EVERY EFFORT TO ASSIST THE CLIENT IN SUCH

CASES

ALL MAINTENANCE OF THE MACHINE MUST

BE PERFORMED BY SPECIALIZED

TECHNICIANS FROM SPORTARREDO OR BY

PERSONS AUTHORIZED BY SPORTARREDO

USA INC.

IMPORTANT !

ALWAYS DISCONNECT THE MACHINE

FROM THE POWER SUPPLY BY

PRESSING THE SWITCH BREAKER

BEFORE CARRYING OUT

MAINTENANCE

1.5 PREPARATION FOR INSTALLATION BY THE

CLIENT

Unless otherwise expressly specified in the contract, the

following must be provided by the client:

•Connections to the electrical circuit, including the

protective wire generally referred to as the "EARTH

CONNECTION", unit feeding cable, power plug

and circuit breaker.

•Canalization system for the emission of hot air.

•External air intake.

•All tools and equipment necessary for installation.

THE UNIT IS SUPPLIED FOR INPUT VOLTAGE AT

230V 3phase 60 Hz

AND IT IS SUPPLIED WITHOUT THE FEEDING

CABLE

To make a power cable connection or voltage-

change, make reference to the chapter

“INSTALLATION" paragraph “ VOLTAGE-CHANGE ”

and to the MASTERSUN 360 n° 1/10 electrical

diagram.

These operation must be done by technical

personnel.

THE BREAKER MUST BE INSTALLED IN THE

POWER SUPPLY BOARD OF THE ESTHETICAL

CENTRE AND IT MUST BE DONE BY THE CENTRE

ITSELF.

Mod. MASTERSUN 360:

3x80A-30mA to feed 230V - 3phase 60Hz

2x125A-30mA to feed 230V - 1phase 60Hz

The installation must be done by technical

personnel.

THE POWER SUPPLY CONNECTION (UNIT-

BOARD) MUST BE DONE BY THE CENTRE. THE

SKILLED TECHNICIAN MUST USE A CERTIFIED

CABLE WITH THE PROPER SECTION AND WITH

ADEQUATE MECHANICAL PROTECTION, IN

ACCORDANCE WITH THE RULES IN FORCE.

SEE CAHAPTER 2.1 TABLES FOR TECHNICAL

DATA “POWER SUPPLY CABLE SECTION”

PLEASE CONTACT THE CUSTOMER SERVICE AT

PHONE NUMBER

1-866-899-4826 FOR ANY FURTHER DOUBT

Before the evening closing, or the closing for a

prolonged period you should operate on the

breaker in order to disconnect the power supply.

TO HAVE A CORRECT USE OF THE

EQUIPMENT, THE ROOM TEMPERATURE MUST

NOT EXCEED THE 86°F DEGREES. IF ROOM

TEMPERATURE EXCEEDS THIS VALUE, WE

SUGGEST TO UTILIZE AN AIR-CONDITIONING

UNIT.

Cod. man.11084.112.0.0 (05/01/06) 6/38

USA

2 - SAFETY INFORMATION

2.1 GENERAL

The employer must ensure that the persons assigned to the

operation of the machine receive adequate training

concerning possible accident risks, the devices fitted for

the safety of the operator and the client, the risks

associated with the emission of UV light and the general

accident-prevention regulations specified by

international norms and local legislation.

Those responsible for operation, maintenance, cleaning

and control of the machine must adhere strictly to

the accident-prevention regulations applicable in the

country in which the machine is installed.

Before operating the machine, the operator must be

completely familiar with the position and the function

of all the controls and with the characteristics of the

machine. The operator must read this manual

carefully and completely.

The machine must be operated by fully-qualified

operators only.

Removal of the safety devices and protective barriers

is strictly forbidden.

No heavy weights must be placed on the moving parts

of the machine. The ventilation ducts and intake

grilles must not be obstructed by foreign bodies.

The machine must always be switched off and

disconnected from the power supply before

performing any routine or special maintenance

operations.

Unauthorised replacement of or repairs to any part or

section of the machine, or the use of accessories or

material that are not original or recommended by the

manufacturer, may represent a risk of injury, and

exonerate the manufacturer from all civil or penal

liability.

It is forbidden to stay near the appliance while it is

operating without eye protection.

"DANGEROUS ZONES": any zone internal to or in the

vicinity of the machine in which the presence of an

exposed person constitutes a risk for the safety and the

health of that person.

"EXPOSED PERSON": any person who is wholly or

partly in a dangerous zone.

"OPERATOR": person or persons assigned to the

installation, operation, adjustment, maintenance,

cleaning, repair and transport of the machine.

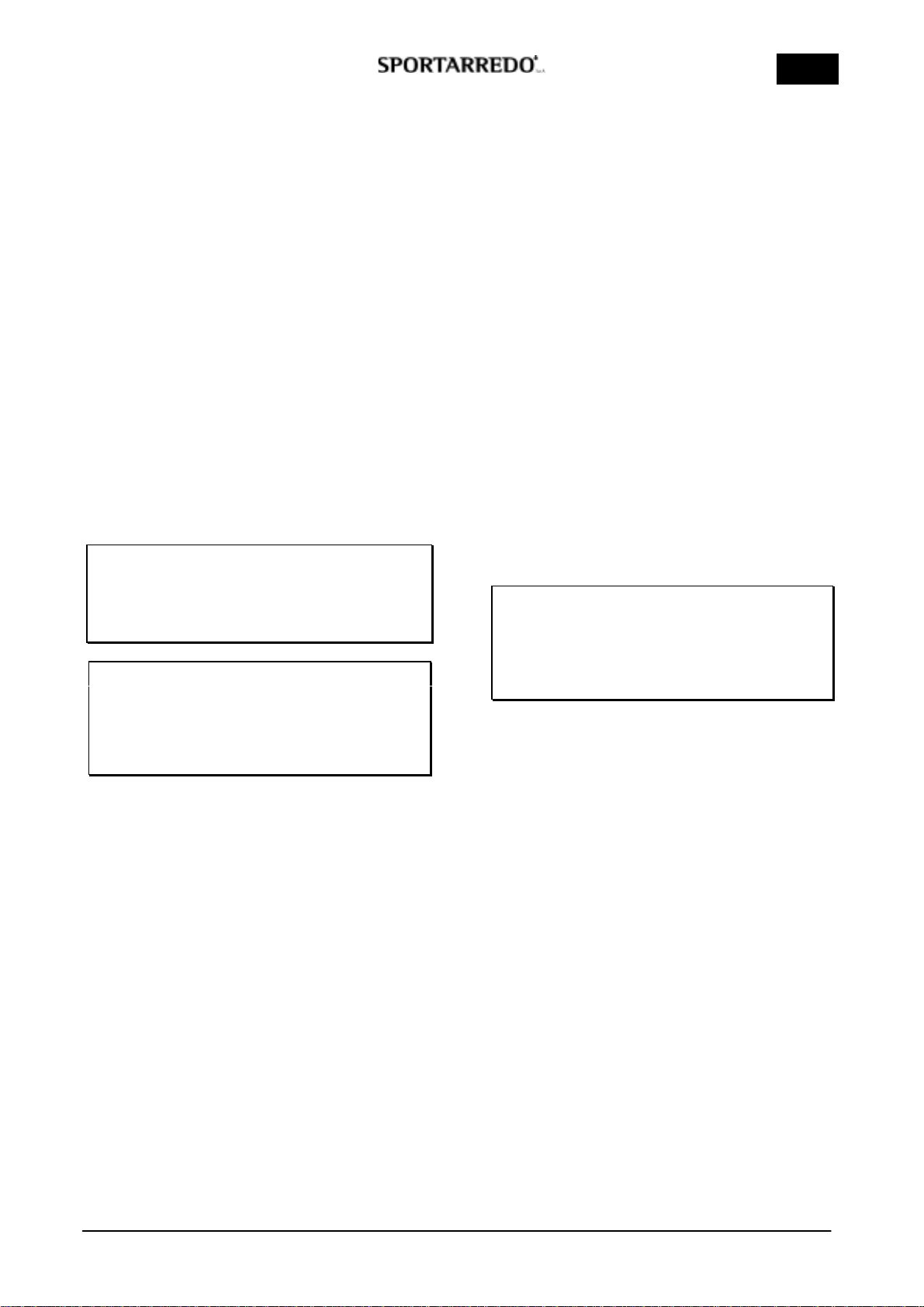

2.2 NOISE

The machine is designed and built in such a way as to

reduce operational noise as follows:

•Effective normalized sound power during operation,

see diagram below:

1= 74 dB (A) max 2= 73,5 dB (A) max 3= 73,6

dB (A) max 4= 73,3 dB (A) max

•Effective sound pressure with simulation of the actual

position of the person being treated:

A= 77,5 dB (A) max,

B= 78 dB (A) max,

C= 77,7 dB (A) max.

The figures shown above have been determined

according to ISO 3746.

2.3 REGULATIONS

Standard for Safety of Lunminaires, UL 1598, Issue:

2004/12/30 Ed: 2 Luminaires, CSA C22.2 No.250.0,

Issue: 2004/12/30 Ed: 2.

In the planning of this unit the following rules and

provisions of the European Community have been

taken in consideration:

ECC Directive N. 91/368 dated 20.06.91, N.93/44

dated 14.06.1993, N.93/68 dated 22.07.

ECC Directive N.73/23 dated 19.02.73 known as “low

voltage directive”.

ECC Directive N.89/336 dated 03.05.1989 known as

“Electronic compatibility directive”.

En 60335-2-27 II part Special standard for units for the

treatment of the skin with ultraviolet and infrared

rays for home use and similar use.

41

32

A

B

C

1m

1m

1m

1m

1m

1m

1m

1m

FRONT SIDE

Cod. man.11084.112.0.0 (05/01/06) 7/38

USA

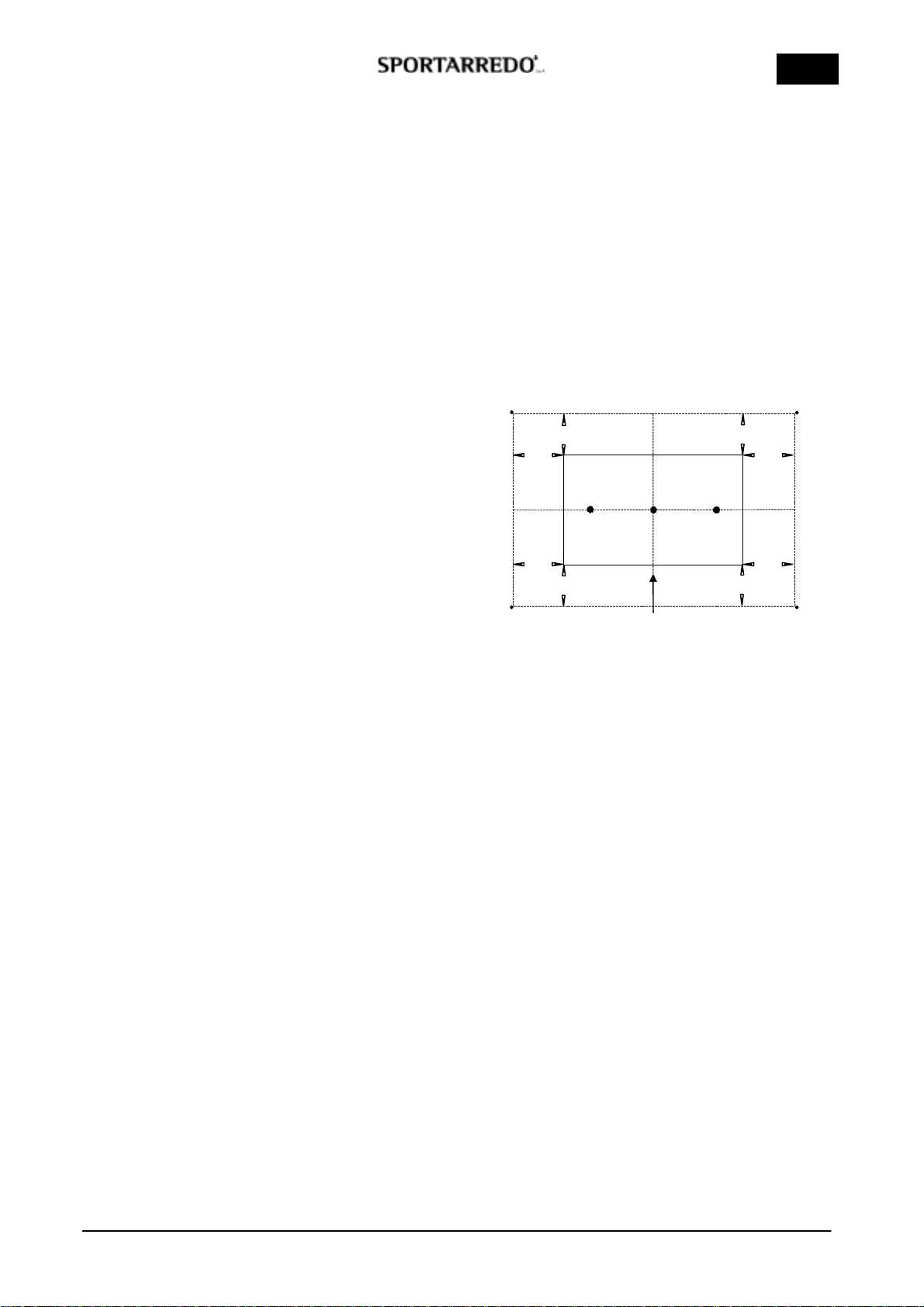

3 - TECHNICAL DATA

3.1 DIMENSIONS AND TECHNICAL DATA

MASTERSUN 360

MAXIMUM LENGTH 220 cm 86" in

MAXIMUM WIDTH 170 cm 67" in

MAXIMUM HEIGHT 200 cm 78" in

WEIGHT 880 Kg 1940 lb

MASTERSUN 360 U.M DATA

POWER SUPPLY V 230V 3ph 230V 1ph

NOMINAL POWER KW 25,3 24,1

NOMINAL CURRENT A 66 112

FREQUENCY Hz 60

WIRE SIZES AWG 4 1

NUMBER OF WIRE

REQUIRED 4 3

EXHAUST AIR FLOW m³/h 4x875

EXAUST FAN PRESSURE Pa 0÷200

HEAT PRODUCED Kcal/h 21800

HEAT EXPELLED Kcal/h 13100

FACE LAMPS TYPE No. 3xKALFASUN 1530F

CANOPY LAMPS TYPE No. 4xKALFASUN 1530F

11xKALFASUN 630F

BASE LAMPS TYPE No. 12xKALFASUN 630F

THERMIC PROTECTION 2x90°C

THERMIC PROTECTION 3x110°C

UV EMISSION

SEE RAY EMISSION CERTIFICATE

4 - INSTALLATION

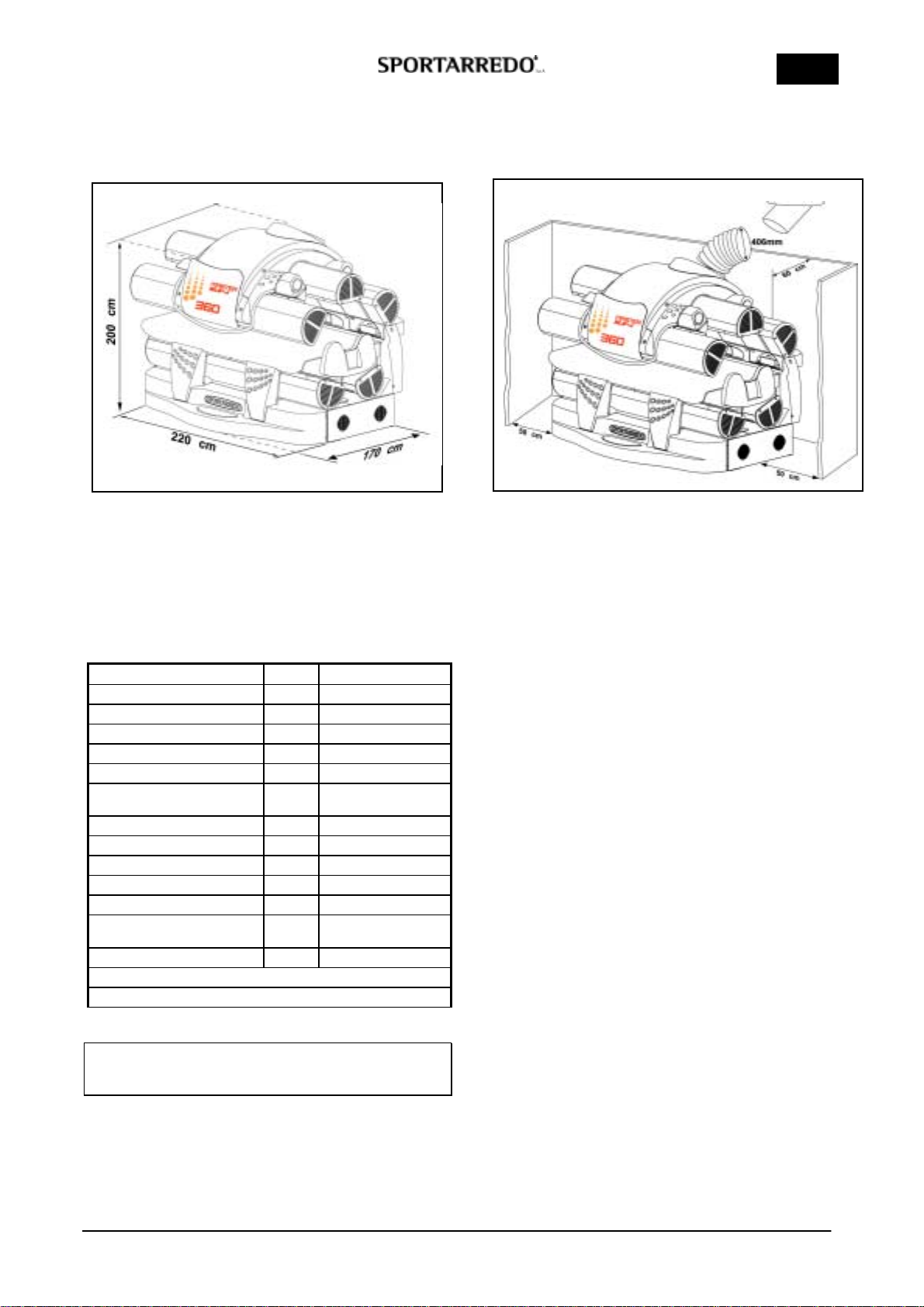

4.1 PRE-INSTALLATION

In order to ensure correct operation of the machine, it

should be installed in an area which has been prepared

as shown in the figure.

The connection of the exhaust air pipe must have on

the first part (50-60 cm / 19"-23" inch from the edge of

the fan) the minimum curving. This device has to be

done to reduce the noise of the fan caused by the

resistance of the hair, to improve the cooling of the

lamps and to have a better air flow during the tanning

session.

4.2 CONNECTION

The area in which the machine is installed must be

adequately ventilated, fit the area with an air

intake from outside if necessary. To improve the

technical comfort we suggest to connect the tube to

expel the hot air to a fixed duct to expel the air

outward

•The metal structure of the machine is earthed by

means of insulated wires connected to the earth

terminal in the electrical junction box.

•The earth circuit must be in full compliance in

accordance with the rules in force.

•The earth connection must also be fitted to low-

voltage systems situated in wet or very damp areas

(if the voltage to earth is in excess of 25V for

alternating current or 50V for direct current).

•The earth wires connected to every part of the

various sections of the machine and the earth wires

from the various power circuits and user groups

must be connected to a single earthing circuit.

•Ensure that the materials used for the earth system

are suitably robust and provided with adequate

protection.

•The connection to the main earth terminal should be

as short as possible. The earth wires should not be

subjected to mechanical stress of any kind, and

must be protected against corrosion.

FIXED DUCT FOR HOT AIR

EXHAUST

Cod. man.11084.112.0.0 (05/01/06) 8/38

USA

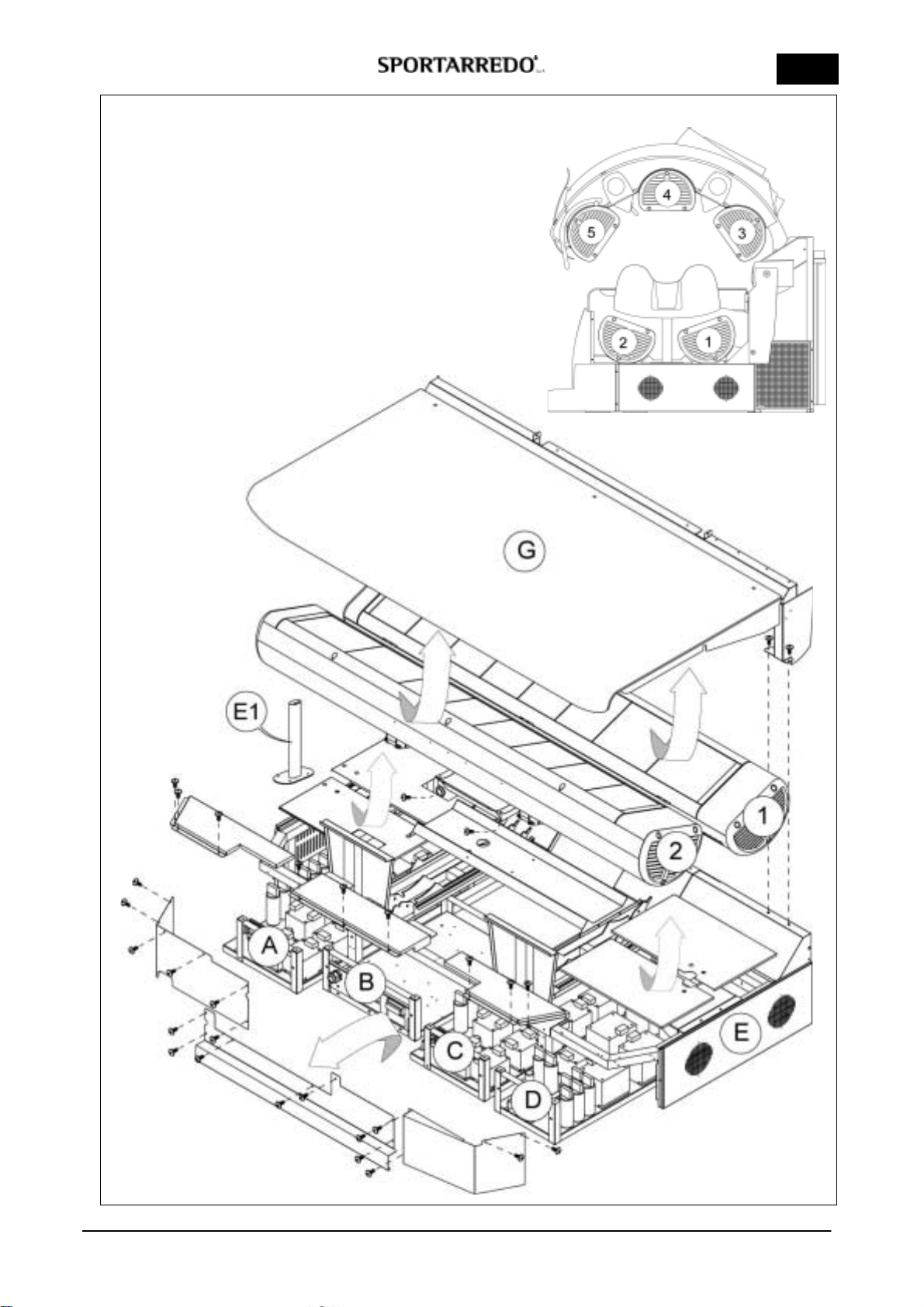

4.3 ASSEMBLY INSTRUCTIONS

SEE ENCLOSED FIGURES

1 - Position the lateral Fon the floor at the minimum

distance at least 23" inc from the wall (see

paragraph 4.1 Pre-installation).

2 Figure 1

Open the packaging of basement E.

In case you need to install the unit into the

booth/room with a narrow door it is necessary to

dismantle the basement as shown. Otherwise

follow the assembling instructions at point 3.

Remove the screws 4,8x13 of the structure that

holds the body acrylic Gand put it aside.

Remove the screws 4,8x13 of the metallic covers

that protect frontally and upper the ABCD feeding

boxes.

Remove all the 4 ABCD feeding boxes.

Remove the screws 4,8x13 of the air conveyor

positioned under the column no. 2.

Remove column 2.

Remove column 1with the conveyor assembling.

Remove the screws 6x20 of the small column E1.

Remove the metallic covers positioned under

columns 1and 2.

3 Figure 2

Now the basement Eis completely dismantled, put

it to the lateral F. Assembly the basement Eto the

lateral Fwith 4 screws M12x60 and 16x36

washer.

Remove the panel in the lateral rear, fixed with

4,8x13 screws.

4 Figure 2-3

Position the ACD ballast boxes in front of the

basement. Before inserting the Dballast box,

make the connector CNT4 come out in the rear of

the lateral. The CNT4 cable connector is very long

and it must be withdraw into itself through the left

side of the lateral. The cable must be stopped by

the provided sheets and rests next to the white

signs. It mustn’t rest on the ballasts.

Insert the ballasts box D.

Insert the ballasts box A withdrawing the cables

CMB1-CNB2 on the left side of it

Before inserting the Cballasts box, make the

CNT3 connector come out from the right side of

lateral and the CNT5 connector from the left side.

The cables of the connectors must be withdraw

into themselves.

Insert the ballasts box C.

Place and fix the metallic covers on the ballasts

boxes with 4,8x13 screws.

Take the CNL connector from the lateral and get it

through the ballasts boxes side.

Make the connectors pass through the inner side

of the head arms insertion:

-CNT3- CNW3 to right DX

-CNT4-CNT5 to left SX

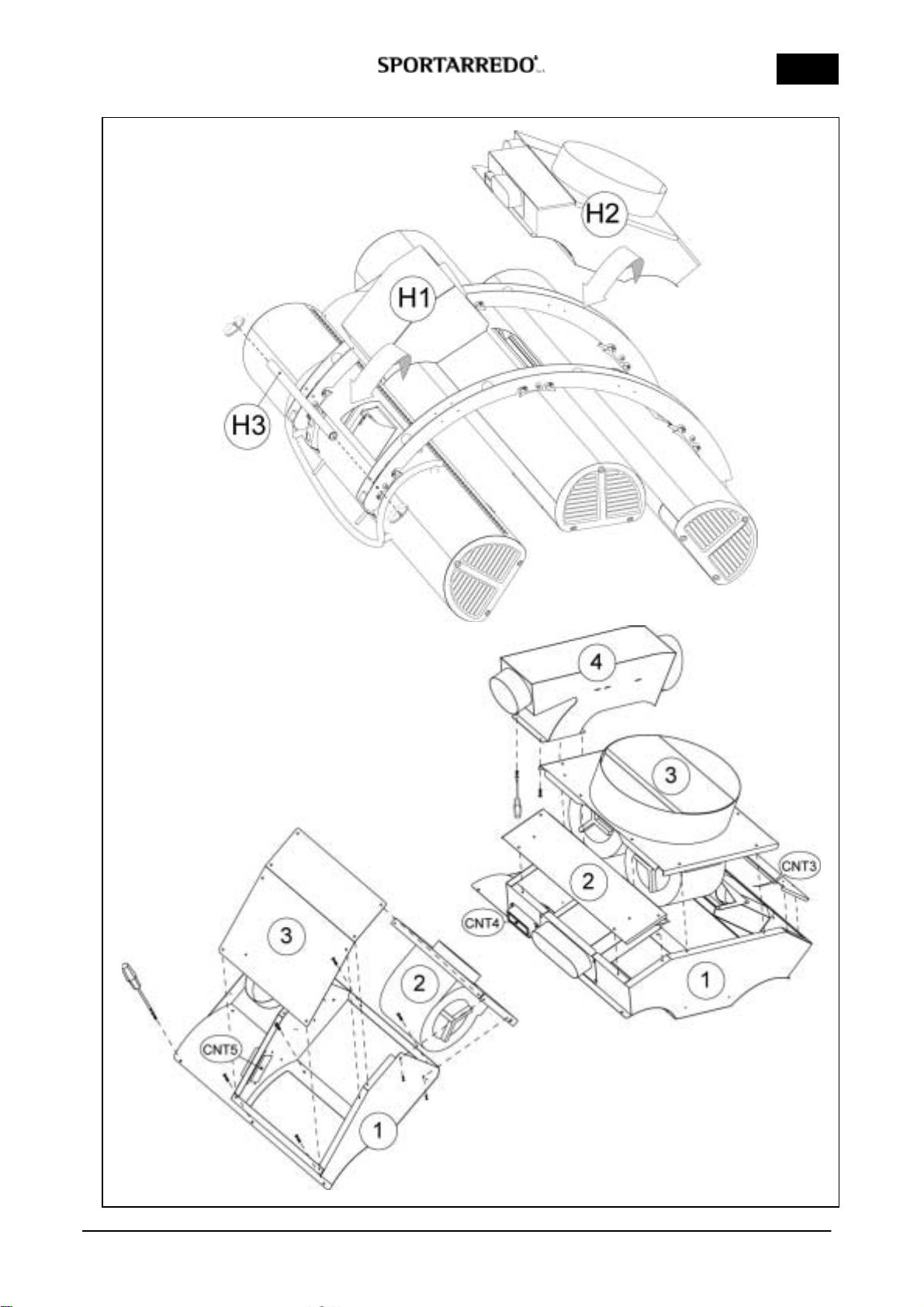

5 Figure 4

Assemble the column 1with the conveyor.

Connect the CNB1 connector from the A ballasts

box to the column 1.

Assemble the column 2and fix to it the conveyor

using 6 screws 4,8x13.

Connect the CNB2 connector from the A ballasts

box to the column 2.

Assemble the cooling conveyor of acrylic Hon the

frontal side of the lateral using 4,8x13 screws.

6 Figure and photo 5

Connect the 4 flexible grey pipes that convey the

air into the lateral white plastic clamps.

Connect the two black connectors CNW1-CNW2

of the fans into the lateral.

Fix into the provided sheets of the lateral these

connectors:

-CNT3- CNW3 to right DX

-CNT4-CNT5 to left SX

Assemble the rear panel of the lateral using

4,8x10 screws.

7 Figure 6

Assemble the structure using the screws 4,8x13

the structure that hold the body acrylic G.

Insert the brackets Zon lateral Ffixing them with

one security hexagonal-head 10x90 screw.

8 Figure 7

Insert the columns 3-4-5 in sequence. Assemble

them to the Z brackets with the security

hexagonal-head 10x90 screws and the self-

blocking bolt from inside to outside.

9 Figure 8

Assembling in sequence with 4,8x13 screws the

H2 covers with the two fans for hot air extraction.

Assembling the screws terminal- connector CNT3-

CNT4 and connect the white plugs of fans. The

part number 4 must be fixing to under with 4,8x13

screws.

Assemble in sequence with 4,8x13 screws the H1

cover fan. Assemble the screws terminal-

connector CNT5 and connect the white plug of the

fan. (Follow the sequence numbered).

Assemble the transversal tube H3 using

hexagonal-head 8x20 screws and 8x15 washer.

Cod. man.11084.112.0.0 (05/01/06) 9/38

USA

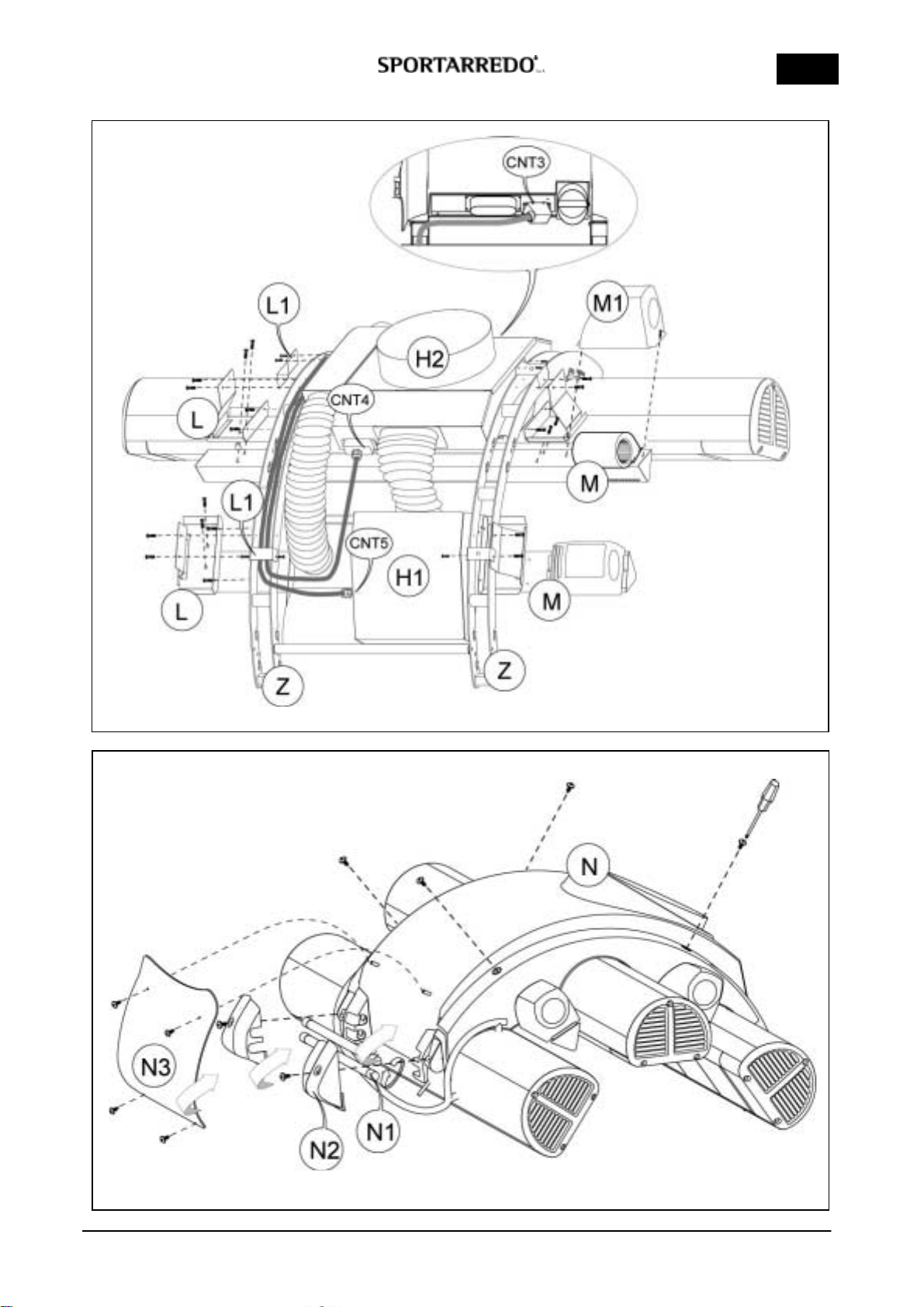

10 Figure 9

Assemble the Lsheets for the support of the

cooling body conveyors on the brackets Zusing

5x15 screws and 5x15 washer. The air body

conveyor with handle has to be inserted between

columns 4 and 5 .

Assemble the Mair body conveyors without the

fan plastic covers with hexagonal-head 6x20

screws.

Fit the canopy connectors CNT3-CNT4-CNT5

inserting them under the L1 sheets (see figure 9).

Insert the plastic covers M1 on the fans.

Connect the grey pipes for the air convey.

Make the connectors pass through CNT3-CNT4-

CNT5 inside the brackets Z(right DX-left SX), the

cables must be fixed to the provided rests next to

the white signs. Insert the cables as shown in

figure under the L1 sheet and connect they on

conveyor H1-H2 according indications.

Assemble the M1 cover plastic on fans.

Connect the flexible grey pipes that convey the air.

Connect the black connectors CNW3-CNW7-

CNW8-CNW9 positioned at the lateral of the

convey H1.

11 Figure 10

Assemble the cover Nwith 2 screws 6x20 in the

rear and in front with 2 screws 6x25 with teflon

washer.

Insert the two yellow neon lamps N1.

Assemble the two caps N2 with 6x20 screws and

teflon washer.

Insert the panel N3 silkscreen printing: Mastersun

360 with 6x20 screws and teflon washer.

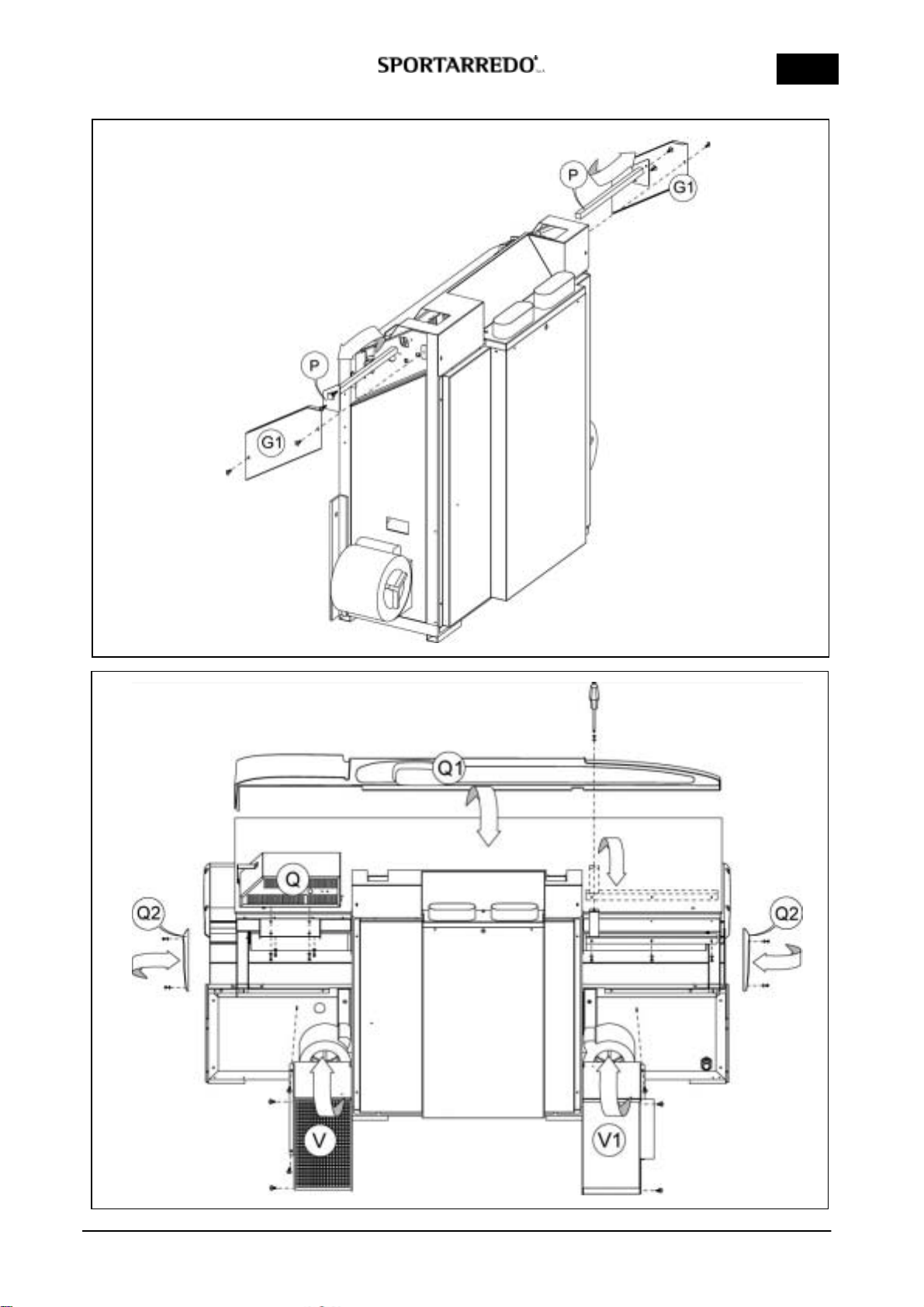

12 Figure 11

Remove the 5x15 screw with washer and remove

the tubes Pthat block the mechanical rising of

unit. Assemble the G1 sheets (right-left), with

4,8x13 screws.

13 Figure 12

Assemble the Qbox of control board using the 4

hexagonal-head 6x20 screws with 6 washers.

Connect the CNC and CN2 connectors of fan V

below.

Assemble the grating cover fan Vwith 4,8x13

screws connecting the earth wire.

Assemble the cover fan V1 with 4,8x13 screws

connecting the earth wire.

Assemble the antenna on Qcontrol board box.

Insert and fix the lateral plastic cover Q1 using

6x20 screw with teflon washers.

Assemble the lateral cover plastic Q2 with 4,2x22

black screws.

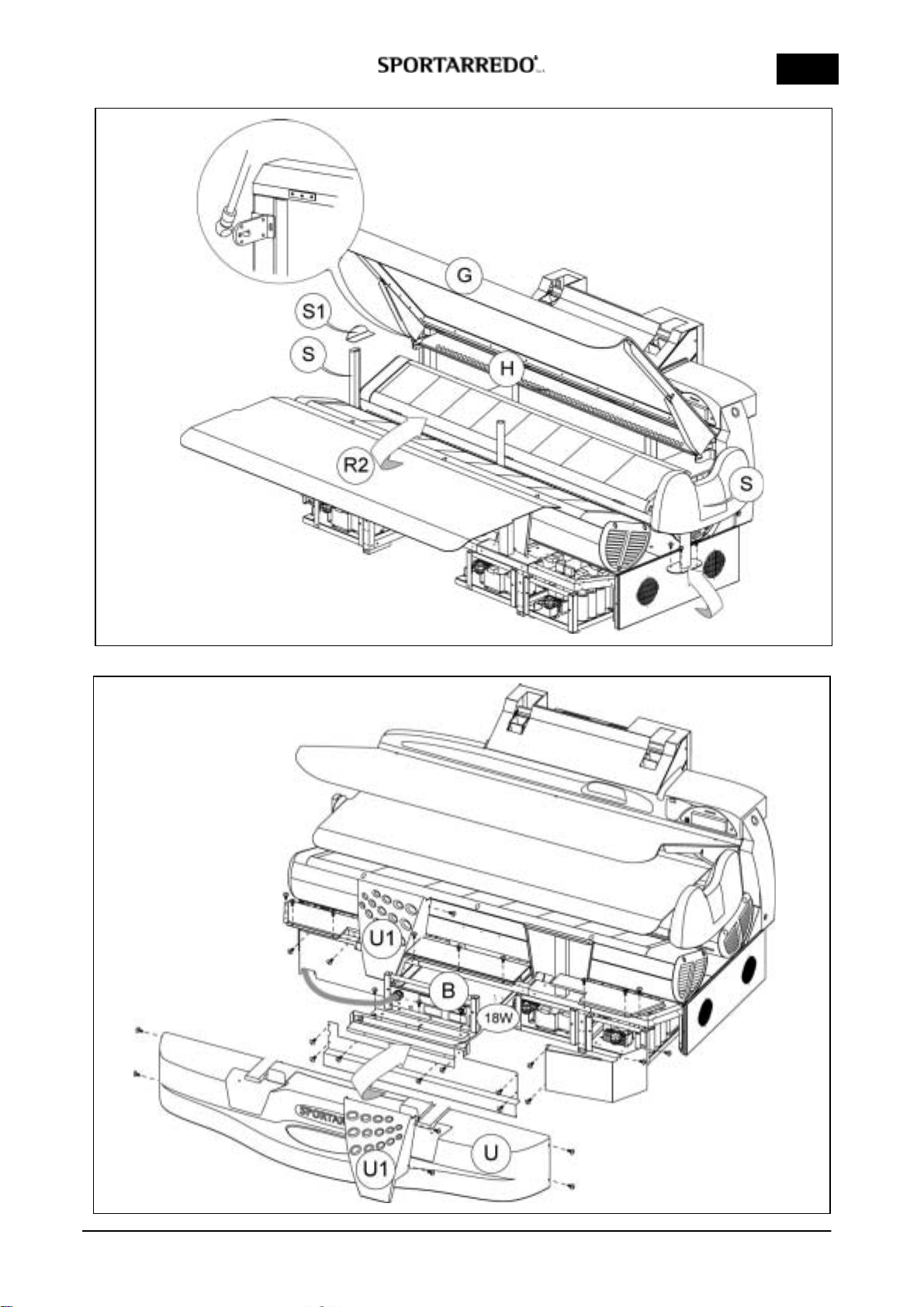

14 Figure 13

Raise the R1 body acrylic. Fix the pistons tighten

up and block with release (with small pins) in the

lower part.

Assemble the column Sand use 4 screws 6x20

with the dent facing toward inwards.

Position the loudspeakers column S and before

assembling using 4 screws 6x20 connect the

white connector CN1.

Insert on the columns Sthe sheets S1 for acrylic

supports.

Insert between the columns 1and 2the acrylic

tube.

Insert the R2 acrylic into the Hconveyor and place

it on the small sheet S1 and on the acrylic tube.

Rise the body acrylic G.

15 Figure 14

Insert partially the Bfeeding box in to the

basement. Insert the feeding cable (see also

figure 16 with change voltage) and connect it to

the power supply terminal board. Finally insert

completely the Bfeeding box in to the basement

and connect the connectors: CNRT-CNRB-CNRV-

CNL-CNW4.

Assembly the neon-holder with the 18W lamp in

correspondence of the feeding box B using 2

screws 4,8x13 and connect the connector CNW5.

Assembly the metallic cover sheets on all ballasts

boxes and afterwards those in front using 4,8x13

Screws.

16 Figure14

Assemble the Ufrontal plastic basement with

4,2x22 black screws. Lift the body acrylic and

assemble the orange covers plastic U1 on the

columns of acrylic support using 4,2x22 black

screws.

Rise the body acrylic.

Place the gel carpet on the Ubasement.

Place the gel cushion on body acrylic.

Switching on the equipment the lamps don't switch

on at the same moment but in sequence: in order

to avoid excessive picks if current absorption.

Check that the all fans emit air, just putting the

hand in front.

Remove the numbers labels 1-2-3-4-5 on

columns.

WARNING!

In the control box there is a safety timer set this

timer at a value 10% longer than the maximum

session time.

e.g.: session time 15 min set the safety timer to

16,5 min.

Cod. man.11084.112.0.0 (05/01/06) 10/38

USA

FIGURE 1 COLUMNS NUMBERS

Cod. man.11084.112.0.0 (05/01/06) 11/38

USA

FIGURE 3

FIGURE 2

Cod. man.11084.112.0.0 (05/01/06) 12/38

USA

FIGURE 5

FIGURE 4

Cod. man.11084.112.0.0 (05/01/06) 13/38

USA

FIGURE 6

FIGURE 7

Cod. man.11084.112.0.0 (05/01/06) 14/38

USA

FIGURE 8

Cod. man.11084.112.0.0 (05/01/06) 15/38

USA

FIGURE 9

FIGURE 10

Cod. man.11084.112.0.0 (05/01/06) 16/38

USA

FIGURE 11

FIGURE 12

Cod. man.11084.112.0.0 (05/01/06) 17/38

USA

FIGURE 13

FIGURE 14

Cod. man.11084.112.0.0 (05/01/06) 18/38

USA

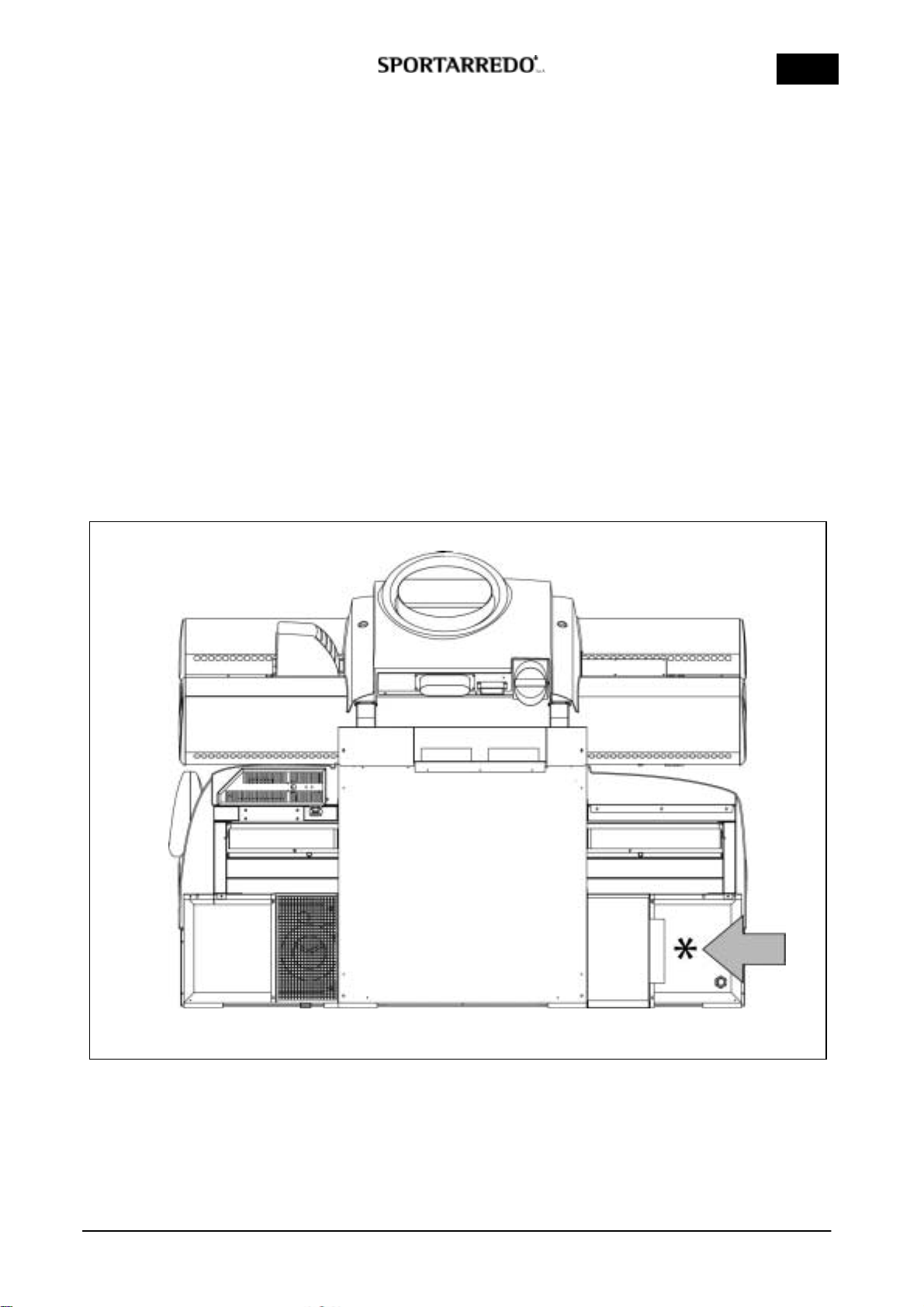

AIR-CONDITIONING CONNECTION

The unit can be connected to an external air-

conditioning system (separate system, not equipped

with the unit or directly to the tanning centre air-

conditioning system) to increase the user’s comfort.

The connection to the air-conditioning system permits to

cool the surface of the acrylic that support the client

during the session, increasing the comfort of the unit.

The unit can also function without the connection to an

auxiliary air-conditioning system, but for a better

comfort of the user, Sportarredo always suggests to

connect the unit to an auxiliary cooling system.

The connection must be done as follows:

Use a flexible pipe diameter 254 cm, max. 2m long

avoiding narrowing or a sharp turn.

Connect the pipe to the air socket placed on the cover

of the cooling base fan behind the base of the unit (see

figure *).

Connect the other end of the pipe to the external air

duct from the air-conditioning system (centralised or

external air-conditioning system).

The air-conditioning system must be able to supply the

following performance:

Air Output: min. 900-1000 m3/h

Cooling Power: 9.000-12.000 BTU

Air outlet temperature: at discretion of the user,

however no higher than 25 °C

FIGURE 15

Cod. man.11084.112.0.0 (05/01/06) 19/38

USA

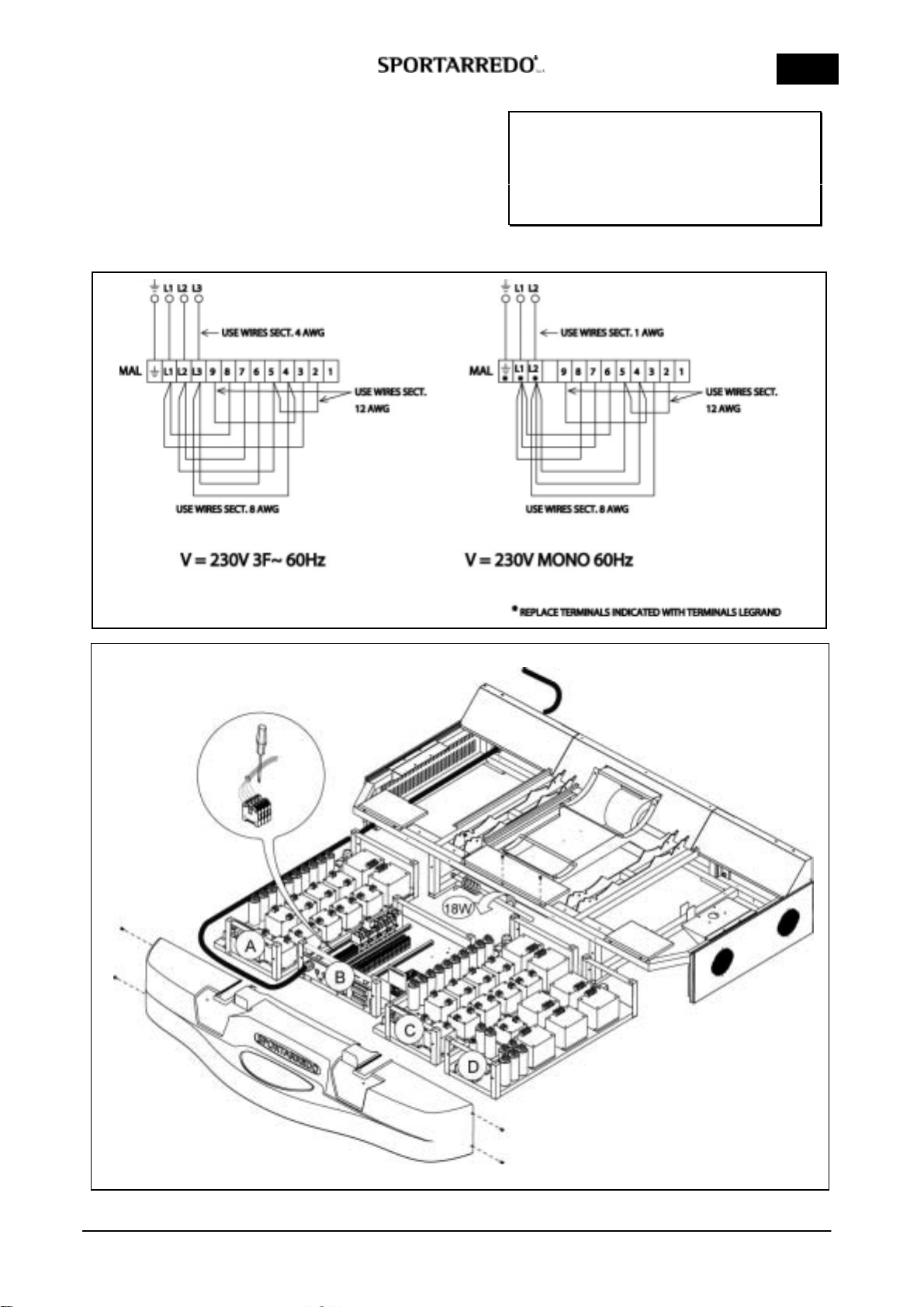

4.4 VOLTAGE CHANGE

To enter the terminal board for power supply, placed

inside the basement (control box B).

Before taking the control box Boff, remove the bracket

with the lamp 18w.

Make reference to Picture 1 and Figure 16.

IMPORTANT !

ALWAYS DISCONNECT THE MACHINE

FROM THE POWER SUPPLY BY

PRESSING THE SWITCH BREAKER

BEFORE CARRYING OUT

MAINTENANCE

FIGURE 16

Picture 1