Copyright By SRC

Design and Specification are subjected to change

Page 6

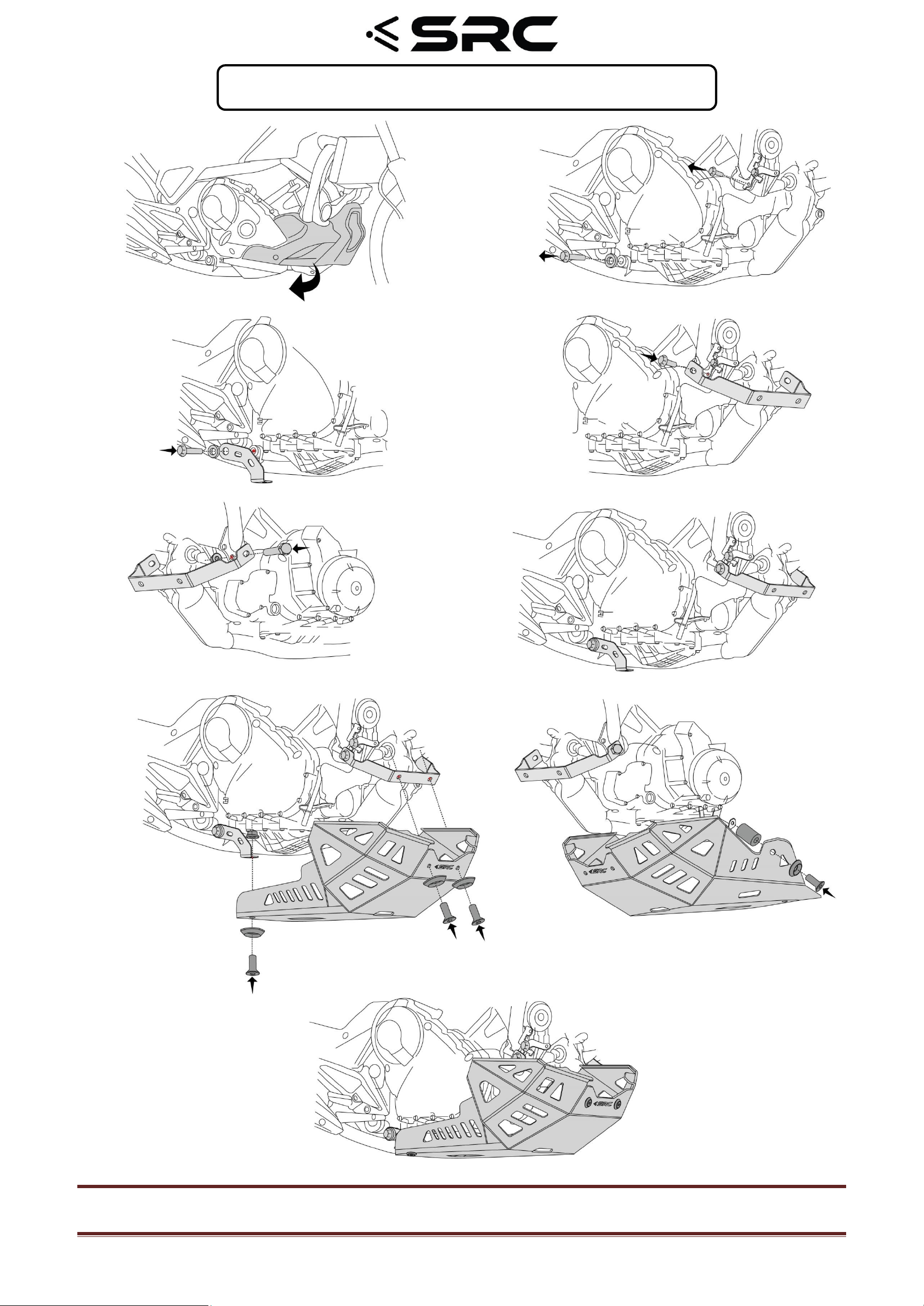

General Instructions

1. We request you to pay attention to the Mounting Instructions in this document and follow the step-by-

step procedures.

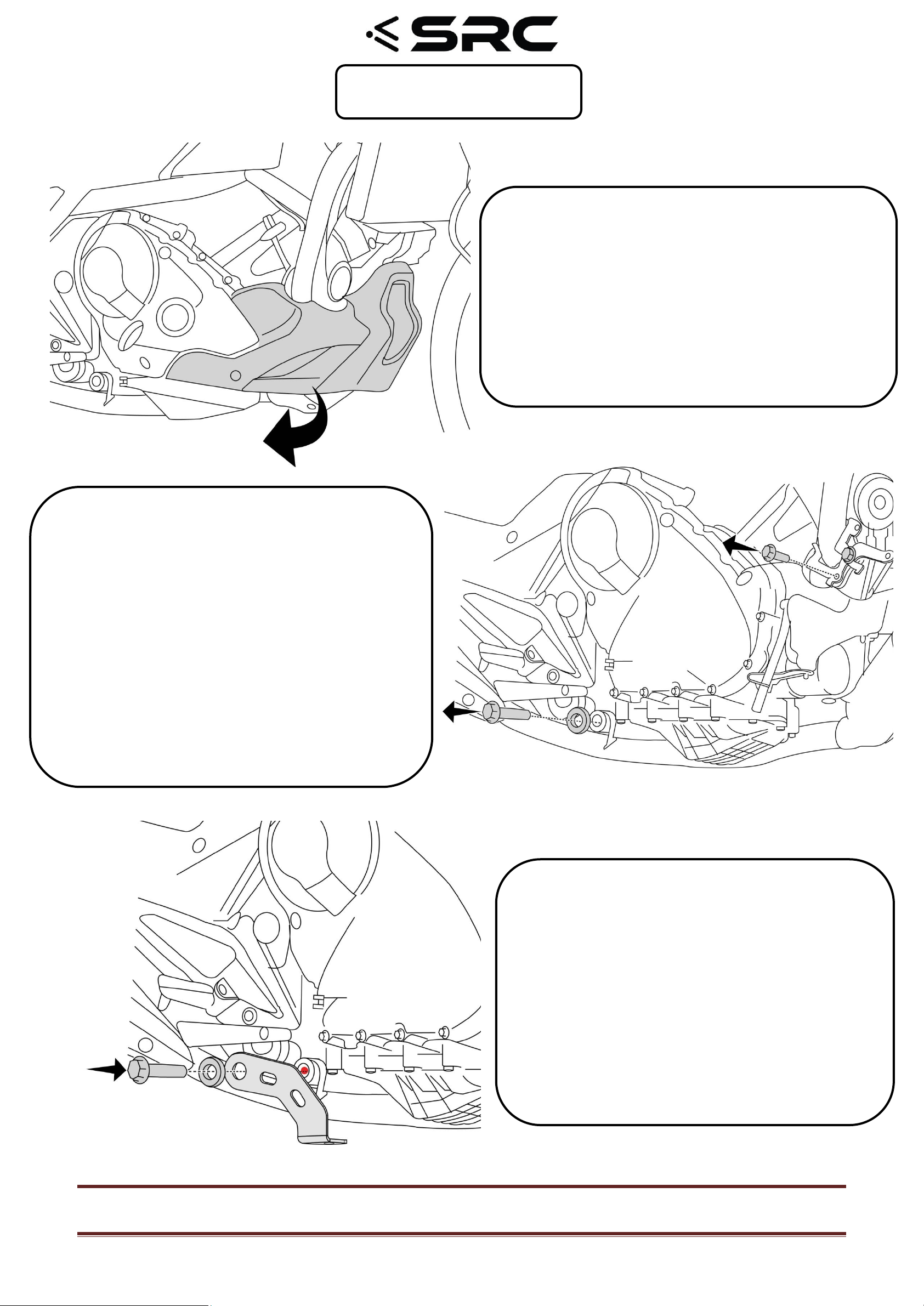

2. This Mounting Instruction manual is a “Do It Yourself” (DIY) fitment manual of the Accessory part to the

Vehicle. We have prepared this based on our experience and knowledge, related to the Vehicle, Part and

its functional aspects.

3. SRC cannot guarantee the interchangeability of the parts to any other manufacturer’s accessory part. It

is advised to the User, to inspect and ensure the original state of all other Vehicle parts.

4. We request you to bear in mind, that the Installed part can change the driving behaviour and/or the

stability during driving or any other dynamic conditions.

5. If you have the appropriate tools and another person to assist you in the mounting, it will help.

6. After Completion of the Mounting and before taking on a First ride, Ensure and Check all functions of

the Vehicle. It is always advised to check loosening of the fasteners after the first 50 kilo meters of ride and

at regular intervals.

7. To the maximum extent possible, our design use the current Mounting/Fitment of the Original

Equipment, so that Installation of these accessories will not affect the Payload or Function of the Vehicle or

the Part on which it is mounted to protect it

8. If any additional modifications are to be done, prior to the fitment of the accessories, it will be explicitly

specified in the instruction sheets