Steffes DLF30B User manual

DLF4

OWNER'SAND

INSTALLER'SMANUAL

for

DoubleLoop(Central)Furnaces

"Manufactured in North America"

U.S. Pat. #5201024

Can. Pat. #2060881

Models:DLF30B&DLF40B

General Information

GeneralOperation .................................................................................................................................................................... 2

Terminology............................................................................................................................................................................ 3

Safety Information

SafetyPrecautions ................................................................................................................................................................... 4

BuiltinSafetyDevices............................................................................................................................................................ 4

Maintenance and Cleaning........................................................................................................ 4

Furnace Control Panel................................................................................................................... 56

Operating the Furnace

FurnaceStartup ...................................................................................................................................................................... 7

RoomTemperatureControl...................................................................................................................................................... 7

BrickTemperatureControl(CoreCharging)........................................................................................................................... 78

HowtoTurntheFurnace"OFF"and"ON".............................................................................................................................. 8

Installing the Furnace

Shipping................................................................................................................................................................................. 9

Placement ................................................................................................................................................................................ 9

ClearanceRequirements ......................................................................................................................................................... 10

FurnaceSetup..................................................................................................................................................................1012

BrickLoading....................................................................................................................................................................1213

InstallingtheHeatingElements .............................................................................................................................................. 13

Ducting .............................................................................................................................................................................1314

LineVoltageElectricalConnections ...................................................................................................................................1518

LowVoltageElectricalConnections...................................................................................................................................1922

FurnaceFinalTestProcedure ................................................................................................................................................. 23

Furnace Specifications................................................................................................................... 24

Exploded View Parts Diagram ............................................................................................... 25

Furnace Parts List...............................................................................................................................2627

Troubleshooting Information

BrickCoreTemperatureTesting............................................................................................................................................. 28

TroubleshootingGuides....................................................................................................................................................2934

Warranty

Table of Contents

1

• ThismanualprovidesinformationforcorrectinstallationproceduresandelectricalconnectionsforSteffesETS

DoubleLoopFurnaces,ModelsDLF30BandDLF40B.Theinformationinthismanualwillhelpyouutilizethe

product'smanyfeaturesandensuremanyyearsofsafe,reliableoperation.Readalltheinformationcontained

withinthismanualbeforeinstallingthesystem.Storethismanualinasafeplaceforfuturereference.

• Assemblyofand/orservicetotheseunitsshouldbeperformedonlybyaqualifiedelectricianinaccordancewith

informationcontainedhereinandinaccordancewithnational,state,andlocalelectricalcodes.

• Thismanualmustberetainedbynewownersifownershipofthefurnacechanges.

• Anydeviationfromtheseinstructionsmayvoidthewarrantyandcouldresultinhazardousoperatingconditions.

• Thewarrantyregistrationcardprovidedaspartoftheunitdocumentationsetmustbecompletedandreturnedto

SteffesCorporation.Failuretodosomayadverselyaffectwarrantyclaims.

• Recordtheserialnumberandmodelnumberinthespacesprovidedonthebackpageofthismanual.These

numbersarelocatedontherightsideofthefurnacebase,ontheshippingbox,andonthewarrantyregistration

card.Retainthismanualforaquickreferencetothesenumbers.

• DISCLAIMER: Incompilingthismanual,SteffesCorporationhasuseditsbestjudgementbaseduponinfor

mationavailablebutdisclaimsanyresponsibilityorliabilityforanyerrorsormiscalculationscontainedherein,or

anyrevisionshereof,orwhichresult,wholeorinpart,fromtheuseofthismanualoranyrevisionshereof.

2 General Information

GENERAL OPERATION

TheSteffesETSDoubleLoopCentralFurnace(DLF)utilizesoffpeakelectricitywhichisavailableduring

timesofthedayornightwhenthepowercompanycansupplyelectricitymoreeconomically.Byusingthisoff

peakelectricityforheating,thepowercompanymayofferaspecialincentivesuchasareducedelectricrate,

anoffpeakheatingrate,atimeofuse(TOU)rate,ormonthlycreditsonyourheatingbill.

Whenoffpeakhoursareavailable,thefurnaceconvertselectricitytoheatwhichisthenstoredinitsceramic

brickcore.Theamountofheatstoredinthebrickcorevariesinrelationtooutdoortemperature,owner

preference,utilitypeakconditions,andtherequirementsofthespacebeingheated.Thisstoredheatbecomes

availableforspaceheatingneedsasdeterminedbythewallthermostatthatisstrategicallylocatedintheliving

space.

Whenthewallthermostatsensesaneedforheat,thecoreblowerandsupplyblowerinthefurnaceoperate.

Thecoreblowercirculatesthehotbrickairandwarmstheheatexchangerlocatedinthebaseofthefurnace.

Thesupplyairblowercirculatesroomairthroughtheexchangerwhereitisheatedandthendeliversittothe

conditionedspace.

1

Automatic Charge Control Methodofbrickcorechargeregulationwhereasensormonitorsoutdoor

temperaturetoautomaticallyadjustthebrickcoretemperaturesettinginrelation

totheoutdoortemperature.

Brick Core Charge Level Theamountofheatthatisstoredintheheater’sbrickcore.

Charge Period Offpeaktimeinwhichthefurnaceisallowedtostoreheatinitsbrickcore.

Control Panel Containsthetoggleswitchestoadjustanddisplaylightstoindicatefurnace

operation.Locatedonthelowerfrontofthefurnaceontheelectricalpanel.

Control Period Onpeaktimeinwhichthefurnaceisnotallowedtostoreheatinitsbrickcore.

Heat Call Whenroomtemperaturefallsbelowtheroom’sthermostatsetting,thethermo

statsignalsthefurnacetooperateitsblowersanddeliverwarmairintothe

spacetoraisethetemperaturetothedesiredthermostatsetpoint.

Heat Exchanger Deviceinthebaseofthefurnacewherethestoredheatfromthebrickcore

transferstotheductsystemfordeliveryintothelivingspace.

Manual Charge Control Methodofbrickcorechargingregulationwheretheusermustperiodicallyadjust

thebrickcoretemperaturesettinginrelationtotheoutdoortemperature.

OffPeak Thetimeduringthedayornightwhenthepowercompanycansupplyelectricity

moreeconomicallyandmayofferaspecialincentivesuchasareducedelectric

rateorbillingcreditsfortheelectricityconsumedduringthistime.Typically,

uncontrollableelectricalusageisallowedduringthistime.(Furnaceisallowed

tochargeorstoreheatinitsbrickcoreduringthistime.)

OnPeak Thetimeduringthedayornightwhenthepowercompanyexperiencesahigh

demandforelectricity.Tolimitdemand,certainappliancesarecontrolledto

avoidusagebythemand/orapremiumfortheelectricityconsumedduringthis

timemaybecharged.(Furnaceisnotallowedtochargeorstoreheatinits

brickcoreduringthistime.)

Outdoor Temperature Sensor Devicethatsensesoutdoorairtemperatureandcommunicatesthisinformation

tothefurnaceforautomaticchargecontrol.

Peak Override Enableselectricalusageinadevicethatistypicallycontrolledbythepower

companyduringanonpeaktime.Somepowercompaniesmayneverpermit

anycontrolleddevicestobeusedduringanonpeaktime.Othersthatdomay

penalizetheuserbychargingapremiumonenergyconsumedduringthisperiod.

3

General Information (cont'd)

TERM DEFINITION

TERMINOLOGY

Thismanualcontainstermswhichmayneedexplanation.Thetablebelowlistssomeofthesetermsandabrief

descriptionofeach.

2

DEVICENAME FUNCTION

Safety Information

LOCATION

ON HEATER

SAFETY PRECAUTIONS

1. DONOTenergizethefurnacewhiledisassembledorwithoutceramicheatstoragebrickinplace.

2. Asistruewithallheatingappliances,materialsthatmayproduceexplosiveorflammablegasesMUSTNOT

beusedorstorednearthefurnace.

3. Besuretheminimumclearancerequirementsspecifiedinthismanualareneverviolated.

4. Thisunitmaybeconnectedtomorethanonebranchcircuit.Disconnectpowertoallcircuitsbeforeservicing.

BUILT-IN SAFETY DEVICES

AllSteffesDoubleLoopCentralFurnacesincorporatesafetydevicestoensurenormaloperatingtemperatures

aremaintained.The chart belowdescribesthesesafetydevices.

4

CoreChargingHigh

LimitSwitches

Theselimitswitchesmonitorbrickcorechargingandwill

interruptpowertotheheatingelementsifthenormal

operatingtemperatureisexceeded.Eachswitchcontrols

two heating elements.

Inthelimitbarpanel

ontherightsideofthe

brickstoragecavity

Thislimitswitchmonitorsthetemperatureintheheat

exchangerofthefurnace.Ifthenormaloperatingtempera

tureisexceeded,thisswitchwillinterruptpowertothecore

blower.

Heat Exchanger High

LimitSwitch

Inthebaseofthe

furnaceinsidethe

electricalpanel

Thislimitswitchmonitorsthedischargeairtemperatureand

interruptspowertothecoreblowerifthistemperature

exceeds160

o

F(nominal).

CoreBlower High

LimitSwitch

Inthesupplyair

plenumassemblyon

theblower

Thislimitswitchmonitorsthedischargeairtemperatureand

interruptspowertothesupplyairblowerifthistemperature

exceeds180

o

F(nominal).

SupplyAirBlower

LimitSwitch

Inthesupplyair

plenumassemblyon

theblower

2

Thefilterinthefurnaceshouldbereplacedonaregularbasis.Generalcleaningofthefurnace’scabinetshouldbe

conductedattheuser’sdiscretion.Noadditionalroutinemaintenanceisrequired.

Maintenance and Cleaning

1

Furnace Control Panel 5

Furnaceoperationisautomatic;however,theusercanmanuallyoperateitbychangingsettingsonitscontrolpanel.

(SeeFigure1forreferencetolocationofthecontrolpanelandcircuitbreakersonthefurnace.)

FIGURE 1

POWER ON Light

Thisgreenindicatorlightilluminateswheneverthefurnaceisenergized.

OFFPEAK Light

Thisredindicatorlightilluminatesduringoffpeaktimeswhicharethetimeswhenthefurnaceisallowedtocharge.

(Elementscanbe"ON"tostoreheatinthebrickcore.)

HEAT CALL Light

Thisyellowindicatorlightilluminateswheneverthefurnaceisreceivingasignalfromthewallthermostattodeliver

heat.

ETSCHARGING Light

Thisredindicatorlightilluminateswhenevertheheatingelementsinthefurnaceare"ON".(Furnaceisstoringheatin

itsbrickcore.)

OUTDOOR TEMP SENSOR Lights

Theseredindicatorlightsilluminatetodesignatethebrickcorechargelevelthefurnaceistargetingwheneverthe

elementsareallowedtobe"ON".(RefertoTable1,BrickCoreChargingSchedule,inthismanualformoreinforma

tiononcharginglevelsinrelationtooutdoortemperatureandthefurnacecontrolpanelsettings.)

LEVEL1 = Illuminateswhenthefurnaceistargetingaheatstoragesettingofapproximately1/3corecharge

(500

o

F,nominal)orgreater.

LEVEL2 = Illuminateswhenthefurnaceistargetingaheatstoragesettingofapproximately2/3corecharge

(900

o

F,nominal)orgreater.

LEVEL3 = Illuminateswhenthefurnaceistargetingitsmaximumheatstoragesetting(1350

o

F,nominal).

All outdoor temperature sensor lights will be illuminated when the furnace is targeting

its maximum heat storage setting.

FURNACECONTROL

TEMPSENSOR

OUTDOOR

OVERRIDE

START

SUMMER

WINTER

CANCEL

HIGH

LOW

LEVEL3

LEVE L2

AUTO

PANEL

ETSCHARGING

HEATCALL

OFFPEAK

POWERON

LEVEL 1

CIRCUITBREAKERSCIRCUITBREAKER

BLOWERS/FURNACECONTROLS CORECHARGING(ELEMENT)

SUPPLYAIRBLOWER

PLENUMASSEMBLY

WITHHEATEXCHANGER

FURNACEBASE

NOTE

6 Furnace Control Panel (cont'd)

SUMMER/WINTER Toggle Switch

Thistoggleswitchwillvarycorecharginginthefurnace.Itallowsforareducedheatingcapacityduringthesummer

monthsiftheuserpreferstoleavethefurnace"ON"foremergencyheatpurposesduringthistime.(RefertoTable1,

BrickCoreChargingSchedule,inthismanualformoreinformationoncharginglevelsinrelationtothepositionofthis

switchandoutdoortemperature.)

AUTO/HIGH/LOW Toggle Switch

Thistoggleswitchcanbeusedtooverridetheautomaticoutdoortemperaturesensingsystem.

AUTO= Normaloperatingposition.Thebrickcorechargeleveliscontrolledautomaticallybytheoutdoor

temperature sensor.

HIGH = Thefurnacewilltargetalevel3(maximum)corechargeduringanoffpeaktimeregardlessofthe

outdoortemperatureinformationitisreceiving.

LOW = Thefurnacetargetsaminimumofalevel1(1/3)corechargeduringanoffpeaktimeunlessthe

outdoortemperaturesensorissignalingforahigherchargelevel.

OVERRIDE Light (Power Company Permitting)

Thisredlightilluminateswheneverapeakcontroloverrideisinitiatedandremainsilluminatedforthedurationofthe

overrideperiod.ThefunctionoftheoverrideindicatorlightworksinconjunctionwithSTARTandCANCELtoggle

switches.

START and CANCEL Toggle Switches (Override Feature, Power Company Permitting)

Thefurnacehasabuiltinpeakoverridefeature.Thisfeatureallowstheheatingelementsinthefurnacetocome"ON"

duringapeakcontroltimeprovidedthepowercompanypermitstheuseofthisoption.Sincenotallpowercompanies

permituseoftheoverrideoption,allfurnacesareshippedwiththisfeaturedisabled.Ifthefeatureisenabledinthe

furnace,thesetoggleswitchesinitiateandcanceltheoverrideofapeakcontroltime.

START = Initiatesanoverrideofapeakcontroltimeallowingtheheatingelementstocome"ON".The

furnacetargetsalevel1(1/3)corechargeduringanoverridecycle.Ifinitiatingthepeak

controloverridefeature,theoverridewillonlylastforthedurationofthepeakcontrolperiodat

whichtimeitresetsitselfautomaticallyunlesstheusermanuallycancelsitpriortothen.(The

overridelightwillillumniateiftheSTARTswitchistoggled.)

CANCEL = Allowsformanualcancellationofapeakoverrideanytimeduringanoverridecycle.An

overridecyclewillautomaticallycancelitselfatthestartofthenextoffpeakperiod.

The peak override option may not be available in your area. Please consult your power

company if you are unsure of whether this option is available to you. If so and you desire

to enable the feature, contact your power company for instructions.

NOTE

FURNACE START-UP

Onstartupofthefurnace,youmayexperiencesomeodorsrelatingtofirsttimeoperationoftheheatingcompo

nents.Theremayalsobeanodorassociatedwithdustaccumulationinthesystemifthefurnaceisshutdownfor

anextendedperiodoftime.Uponrestart,allowingthefurnacetochargetoitsmaximumbrickcorechargelevel

willhelpexpeltheseodorsinatimelymanner.

Duringoperation,itisnormalforthefurnace,likeanyheatingsystem,toproduceexpansionnoises.Thesenoises

aretheresultoftheinternalcomponentsreactingtothetemperaturechangestheyareexposedto.

ROOM TEMPERATURE CONTROL

Roomtemperatureisadjustedatthewallthermostat.Withaheatcalltothethermostat,thecoreblowerinthe

furnaceisenergizedtocirculatehotbrickcoreairthroughthefurnace’sheatexchanger.Thecoreblower

automaticallyadjustsits'speed(loworhigh)inrelationtothebrickcoretemperature.Thebloweroperatesinlow

speedwithahotbrickcoreandinhighspeedwithlowerbrickcoretemperatures.

Afterthebrickcoreairwarmstheheatexchanger,thesupplyairblowerisenergized.Thesupplyairblower

circulatestheroomairthroughtheheatexchangertowarmit;and,then,deliversitbackintothelivingspace

throughtheductsystem.

Thedelaybetweenthecorebloweroperatingandthesupplyairblowerbeingenergizedensuresonlywarm,

comfortable,evenheatisbeingdeliveredintothelivingarea.Intermittentsupplyairbloweroperationmayoccur

withlowerbrickcoretemperaturesinanefforttomaintainaconstanttemperatureandevendistributionofheat

intothelivingarea.

Somethermostatsincorporatearoomtemperaturesetbackfeaturewhichallowsforroomtemperatureto

automaticallybesetbackaspecificnumberofdegreesatspecifiedtimes.Ifusingathermostatwiththisfeature

inaprogramwherethepowercompanyhas8ormoreconsecutivehoursofcontrol,itisimportanttobringthe

roomtemperaturebacktothedesiredoccupiedtemperatureaminimumofthree(3)hoursbeforetheoffpeak

(charge)periodends.Thiswillensureoptimumheatstorageformaintainingthedesiredroomtemperature

throughouttheonpeak(control)period.

BRICK TEMPERATURE CONTROL (CORE CHARGING)

Theamountofheatstoredinthebrickcoreofthefurnaceisregulatedautomaticallyinrelationtooutdoortem

peratureandtoitscontrolpanelsettings.Theoutdoortemperaturesensorthatshipswiththefurnaceasstandard

equipmentMUSTbemountedoutside.Itprovidestemperatureinformationtothefurnaceforproperbrickcore

charging.

Instandardconfigurationfromthefactory,theoutdoorsensorsignalsthefurnacetomaintainalevel1(1/3)brick

corechargeata55

o

Foutsidetemperature,alevel2(2/3)corechargeat35

o

F,andalevel3(maximum)core

chargeat15

o

F.Attemperaturesabove55

o

F,thefurnacewillnotmaintainacorecharge;however,ifthereisa

heatcallfromthethermostatduringoffpeaktimes,1/3oftheelementswillbeenergizedtoprovideheatforthe

durationoftheheatcall.(RefertoTable1,BrickCoreChargingSchedule,formoreinformationoncharging

levelsinrelationtooutdoortemperatureandthefurnacecontrolpanelsettings.)

If outdoor temperature charging set points other than the standard configuration are pre

ferred, the sensor must be specially ordered from the factory.

Operating the Furnace 7

2

3

1

NOTE

SUMMER/WINTER OUTDOORAIR CHARGE kWINPUT(MAX) CORETEMP.

SWITCHPOSITION TEMP.(ºF) LEVEL DLF30B DLF40B ºF(Nominal)

Winter 55* 1 9.6 12.8 500

Winter 35 2 19.2 25.6 900

Winter 15 3 28.8 38.4 1,350

Summer 35 1 9.6 12.8 500

Summer 15 3 28.8 38.4 1,350

Operating the Furnace (cont'd)

8

HOW TO TURN THE FURNACE “OFF” AND “ON”

Sinceheatcallsareunlikelyduringthesummermonths,youmaywishtoturnthefurnace"OFF".Todoso,

switchall60ampcorechargingbreakerslocatedonthefrontofthefurnace’selectricalpaneltothe"OFF"

(down)position.(SeeFigure1forreferencetothelocationofthebreakersonthefurnace.)The15amp

breakershouldremain"ON"atalltimesasthisbreakeroperatestheblowersandallothercontrolsinthefurnace.

ItMUSTremain"ON"ifusingthefurnaceinconjunctionwithanairconditioningsystem.Toturnthefurnace

"ON",switchthebreakerstotheUPposition.

Foruserswhoprefertomaintainareducedheatingcapacityduringsummermonthsratherthanshuttingthe

systemoffcompletely,theSUMMER/WINTERtoggleswitchshouldbesettotheSUMMERposition.In

standardconfiguration,aSUMMERswitchsettingenablesautomaticbrickcorechargingbutatareducedlevel.

Theoutsidetemperaturemustdropbelow35

o

Fbeforecorechargingwilloccur.(RefertoTable2,BrickCore

ChargingSchedule,inthismanualformoreinformationoncharginglevelsinrelationtooutdoortemperatureand

thefurnacecontrolpanelsettings.)

* Ifduringoffpeakhoursthewallthermostatcallsforheatandtheoutdoortemperatureisabove55

o

F,1/3of

theelementswillbeenergizedforthedurationoftheheatcall.

BRICK CORE CHARGING SCHEDULE

Table 1

Duringbrickcorecharging,theheatingelementsarestaged"ON"and"OFF"in6.4kWincrements(maximum).

4

TheAUTO/HIGH/LOWtoggleswitchonthefurnacecontrolpanelwillallowtheusertooverridetheautomatic

chargecontrolsystemofthefurnace.Innormaloperation,thisswitchissettotheAUTOpostion.Regardlessof

thepositionofthisswitch,thebrickcorechargingsysteminthefurnaceisdesignedtorespondtothecoldest

temperaturesignalitisreceiving.Asaresult,ifthetoggleswitchissettoLOWandtheoutdoorsensoriscalling

forahigherbrickcoretemperaturesetting,thefurnacewillrespondtothesensorsignal.Or,shouldthecharge

level1sensorfailtorespondtooutdoortemperature,thechargelevel2or3sensorswillinitiatecorecharging.

Thisfeatureprovidescontrolredundancywhichreducesthechanceofhavinganunchargedorundercharged

brickcoreduringcoldweather.

18"

491/2"

30"

551/2"

693/4"

DLF40B 21"

511/2"

TOPVIEW

241/2"

33/4"

SLOTFOR

16"X25"FILTER

RETURNAIRDUCTIS241/2"X15"

60"

Installing The Furnace 9

1 SHIPPING

Thefurnaceisshippeddisassembledforeaseinhandlingandmovingintolocationwhereitistobeinstalled.

(RefertoTable2forinformationontheitemsshippedwitheachfurnace.)

Table 2

MODEL BRICK ELEMENTS DUCTING

(See Note 1) (See Note 2) (See Note 3)

DLF30B 28boxesWholeBrick(3/Box) 9 1BoxReturnAirFilterRack

2boxesHalfBrick(6/Box) 1BoxSupplyAirBlowerPlenumAssembly

1 Hardware Package (See Note 4)

DLF40B 37boxesWholeBrick(3/Box) 12 1OutdoorTemperatureSensor(SeeNote5)

2boxesHalfBrick(6/Box)

NOTES: 1. The furnace ships in two sections (brick storage cavity and base assembly) banded

to one pallet.

2. Each brick box weighs approximately 72 lbs each.

3. The elements are shipped inside the brick storage cabinet of the furnace.

4. The hardware package is shipped in the base assembly portion of the furnace.

5. The outdoor temperature sensor is shipped in the supply air blower plenum assem

bly box.

PLACEMENT

Thephysicaldimensionsofthefurnacealongwiththeclearancesrequiredmustbetakenintoconsideration

whenchoosingalocationforthefurnace.Theminimumareaneededfortheinstallationofafurnaceis100

squarefeet.Thebestinstallationlocationforthefurnaceisinanareaitwillbeheating.Althoughmostofthe

heatingrequirementsofthespacewillbesatisfiedbytheheatdeliveredthroughtheductsystem,asmallamount

oftheheatingrequirementswillalsobesatisfiedthroughstaticheatdissipatingthroughthefurnace'swarm

outsidepanels.Insituationswherethefurnacewillnotbeinstalledintheareaitisintendedtoheat(i.e.garage),

itisimportanttoaccountfortheheatlostthroughitspanelsbymakingproperadjustmentsinsizingofthe

furnace.

Inadditiontothephysicalspacerequirements,theweightofthefurnacemustalsobetakenintoconsideration

whenselectingtheinstallationsurface.Alevelconcreteflooristhebestsurfaceonwhichtoplacethefurnace,

butmostwellsupportedsurfacesareacceptable.Ifindoubtaboutfloorloadcapacity,consultabuildingcon

tractororarchitect.(SeeFigure2forfurnaceandductingdimensions.)

2

FIGURE 2

0" REQUIRED

CLEARANCE

2" MIN

CLEARANCE

3" MIN CLEARANCE

36" MIN CLEARANCE

TOP VIEW

0" REQUIRED

CLEARANCE

6" MIN

CLEARANCE

Installing The Furnace (cont'd)

10

CLEARANCE REQUIREMENTS

Theminimumclearancesrequiredwheninstallingthefurnaceinto

anyareaareasfollows:

BackandSides=3inches(fromcombustiblematerial)

Top=6inches(fromcombustiblematerial)

Front=36inches(foreaseofservicing)

FurnaceRightSideandAirDuct=2inches

FurnaceLeftSideandAirDuct=zeroclearance

SidesofFurnaceDucts=zeroclearance

Theclearanceareasmustbekeptopenandfreeofdebris.Donot

placeanythingontopthefurnace.Ifthefurnaceisinstalledina

small,enclosedarea(lessthan400squarefeet),theareamustbe

wellventilated.Forventilationpurposes,aminimumofa24”X24”

openingmustbeinstalled,ifnotalreadypresent,intotheareawhere

thefurnaceislocated.Inaddition,a6”X6”nonclosingtype

registermustbecutintothereturnairductofthefurnacetominimize

heatbuildupintheroom.(SeeFigure3foradepictitionofclearance

specifications.)

3

FIGURE 3

FURNACE SET-UP

For cross reference to number coded components, see

the Exploded View Diagram and the Furnace Parts List

in this manual. Refer to Table 2 in the Shipping section

of this manual for a list of items each furnace should

contain.

Step 1 Unboxthebrickstoragecabinet

Step 2 Removepaintedfrontpanel(11)ofcabinetbyremovingthesheetmetalscrewsontheloweredge.

Rotatebottomedgeofpanelouttodetachitfromthecabinet.

Step 3 Ontherightsideofthecabinet,removethescrewsaroundthelimitbarlouvrepanel(63).(See

Figure4forreferencetothelocationofthispanelandthescrews.)

Step 4 Slidethesidesandbackpaintedouterpanels(9,71,&73)backwardsasoneassemblyandremove

fromcabinet.

Step 5 Usethehandlesonthebrickstoragecabinettomoveittoitsinstallationlocation.Setasidefornow.

Removal of the limit switches (67) on the

right side of the brick storage cabinet

may be necessary to avoid damage to

these switches during the move.

Step 6 Removethebaseassembly(50)fromitsboxandmove

ittotheinstallationlocation.Discardthewooden

packagingfromthetopofthebase.Locateandset

asidethehardwarepackageshippedontopofthebase

assembly.

Do NOT install the furnace on its

shipping pallet.

4

FIGURE 4

NOTE

NOTE

NOTE

BrickStorage

Cabinet

Installing The Heater (cont'd) 11

Step 7 Adjustthelevelinglegs(48)onthebottomofthebaseassembly(50)onceitissetinfinalposition.

The leveling legs must not be extended more than one inch. The base MUST

set securely on all four legs to prevent rocking of the furnace and/or twisting of

the heat exchanger.

Step 8 Setthebrickstoragecabinetonthebaseassembly(50)takingcarenottodamagethewiringhar

nesses(65&70).

The rope gasket around the

heat exchanger inlet

and outlet of the base

assembly must be

properly adhered and

free from damage.

Damage to any

gasketing on the

furnace will result in

improper unit opera

tion and/or furnace

damage.

Step 9 Positionwiringharnesses(65&70),

andtemperaturesensingbulband

plateassembly(77)tofacilitate

routingthroughbottomrightside

panelcutout.(SeeFigure5for

referencetowiringharnesslocations

on the furnace.)

Step 10 Installthesidesandbackpainted

outerpanels(9,71&73)onthe

brickstoragecavity.Usethescrewsfoundinthehardwarepackagetosecurethepanelstothe

cabinetbyplacingthemalongbottomedgeofthepanels.

To avoid internal wire damage, use only blunt tip screws in all areas where

screw tips could come in contact with wiring.

Step 11 Installthetemperaturesensingbulbandplateassembly(77)bytighteningthescrewsinacross

patternuntilgasketiscompressed.Donotovertighten.Makecertainthatthecapillarytubeofthe

temperaturesensingassembly(77)doesnotcomeintocontactwithanyliveelectricalterminals.

Failure to seal the sensing bulb plate will cause abnormal furnace operation and

potential component damage.

Step 12 Connectthemainandelementwiringharnesses(65&70)tothelimitswitches(67).Theswitches

aremarkedwithareddotononeside.Connecttheredwirestothereddotmarkedsideofthe

switches.Connecttheblackwirestotheunmarkedsideoftheswitches.

NOTE

NOTE

NOTE

NOTE

FIGURE 5

Installing The Heater (cont'd)

12

Step 13 Connectthebrownthermocoupleleadwire(79)inthewiringharnessestothecoretemperature

sensor(68).Theyellowwireofthethermocoupleleadattachestothescrewstudmarkedwitha

yellowdot.Theredwireattachestothescrewstudmarkedwithareddot.

The brown thermocouple lead wire must be routed in a fashion that ensures it

will be protected from physical damage and does not come into contact with any

live electrical connections in the limit bar area. Incorrect polarity on the core

temperature sensor will cause the furnace to continue to charge, even when a

high charge level has been achieved.

Step 14 Carefullyinstallthelimitbarchannelingplate(61)toprovideairsealaroundwiringharnesses

(65&70).

Step 15 Installthelimitbarlouvrepanel(63).

BRICK LOADING

Step 1 Removethesheetmetalscrewsaroundtheouteredgeofthegalvanizedfrontpanel(12)andsetthe

panelaside.

Step 2 Carefullyliftthethreeinsulationblankets(3,4,&5),oneatatime,anddrapethemoverthetopof

the furnace.

Use face mask, gloves, and long sleeved garments when handling insulation

materials in accordance with generally accepted safety practices.

Step 3 Removethealuminizedsteelpanel(10)bypullingoutatthetop.

Step 4 Removetheheatingelements(17)andthepackingmaterialfromthebrickcorecavity.Toensure

adequateroomforbrickloading,thetoporbottom1"x4"(nominal)woodencorespacercanbeused

toholdinnerbrickcavitywallsapart.

The core spacer is packaging material and can be discarded after brick loading

is complete.

Step 5 Tominimizetheamountofbrickdebrisfallingintothecoreblower,placethecardboardpackaging

materialfoundinsidethebrickcavityoverthecorebloweropening.

Step 6 Loadthebrick(15),onerowatatime,startingatthebackworkingforward.Belowisalistof

installationtipstoaidinthebrickloadingprocess:

¢Besuretoremoveloose

brickdebrisasthefurnace

isbeingloadedtoprevent

unevenstackingofthe

bricks.

¢Usethehalfbrick(boxes

marked)intheproperrows

andinthecorrectpositions.

Thehalfbricksshouldbe

loadedinrows4and8inthe

DLF30andinrows5and10fortheDLF40,withrow1beingatthebottom.(SeeFigure6for

thecorrectpositionofthehalfbricks.)

The purpose of the half brick is to make brick loading easier by evening out the

stacking. From an operation perspective, it is not essential they be placed in the

rows recommended for each model. The rows recommended simply make for the

best fit.

5

NOTE

NOTE

NOTE

NOTE

FIGURE 6

ELEMENTTERMINATION

HALFBRICK

DLF30:LOADINROWS4AND8

DLF40:LOADINROWS5AND10

¢Thesecondtolastrow,front,

middlebrickmustbethelast

brickinstalled.Ashimmaybe

usedtoholdtheupperbrickin

place,oritismoreeasily

accomplishedbyleavingthe

middlebrickinthesecondto

lastrowpulledabout4"

forwardfromitsintended

position.Inthispositionthe

brickwillactasasupportforthetopmiddlebrick.Pushthefront,middlebrickinthesecondto

lastrowintoplacewhichwillatthesametimepushthemiddlebrickthatwasleftforwardinto

place.(SeeFigure7forapicturedepictionofthisprocedure.)

INSTALLING THE HEATING ELEMENTS

Step 1 Afterallbricksareloaded,inserttheheatingelements(17)betweenthebricklayerswiththecold

pinsfacingup.(SeepicturedepictitionofelementterminationinFigure6forreferencetocoldpin

direction.)

Step 2 Maketheheatingelements(17)towiringharness(19&65)connections.(SeeFigure6forapicture

depictitionofelementtermination.)

Use two 3/8" wrenches to ensure tight connections and to avoid twisting the

threaded element cold pins off.

Step 3 Replacethefrontaluminizedsteelpanel(10).

This panel MUST be installed with its air deflectors (arrow shaped pieces) facing

inward and with the narrow ends of the deflectors pointing up.

Step 4 Lowertheinsulationblankets(3,4,&5)backintoposition,oneatatime.Carefullytuckthesidesof

thisinsulationintotheedges,corners,andaroundtheexposedportionsofheatingelements(17).

Step 5 Replacethegalvanizedfrontpanelutilizingtheoriginal#8x1"sheetmetalscrewsthatwerere

moved.

Step 6 Replacethepaintedfrontpanel(11)usingblunttipscrewsonly.

DUCTING

AirFlow

TheSteffesfurnacehasbeenspeciallydesignedforversatilityandmaybeinstalledtomeetrighttoleftorleft

torightairflowrequirements.Thefurnaceisfactoryconfiguredforalefttorightairflow.Ifitisdesiredto

reversetheairflow,dothefollowing:

Step 1 Reroutethesupplyairblowerwiringharness(55)totheoppositesideoffurnacebasebyfishingthe

harnessbetweenbottomradiantheatshield(51)andbottompanel(47).Besuretoroutethewiring

harnessawayfromthe heatexchangerandplaceanyexcesswiringbetweentheradiantheatshield

(51)andbottompanel(47).

7

Installing The Furnace (cont'd) 13

6

NOTE

NOTE

FIGURE 7

LAST(TOP)ROW

SECONDTOLASTROW

MIDDLEBRICK

Forairdelivery,thefurnaceisequippedwitha4speedsupplyairblowerwhichisfactorywiredtooperatein

mediumlowspeedforheatingandinmediumhighspeedforcoolingandafanonlythermostatsetting.The

blowerspeedmaybeadjustedforlowerorhigheroutputrequirements.Todoso,changethewiringonthe

blowerspeedselectionterminalslocatedonthesupplyairblower.(SeetheLineVoltageWiringDiagramsinthis

manualformoreinformationonthewiringandTable3forinformationonductpressurewithregardtoblower

speed.)

TABLE 3

Attaching the Ducting

Step 1 Removethesupplyairblowerplenumassembly(60)andfilterrack(18)fromtheirboxes.

Step 2 Toaccesstheblower(56),removethescrewsfromthesupplyairblowerplenumfrontaccesscover

(60)anddetachitfromtheplenum.

Step 3 Thesupplyairblower(56)isshippedbandedtotheplenumassembly(60).Cutthebandtoremove

theblowerfromtheplenumandslideitintotheplenumtrackthroughthefrontaccess.

Step 4 Attachthefrontaccesscovertotheplenum.

Step 5 Attachthesupplyairblowerplenumassembly(60)tothefurnacebydrillingtwo1/8”holesperedge.

Attachtothefurnacesupplyairsideusingtheblunttipscrewssuppliedinthehardwarepackage.

Step 6 Securethefilterrackassembly(18)onthereturnairside,againbydrilling1/8”holesperedgeand

usingtheblunttipscrewssuppliedinthehardwarepackage.Afiltershouldalreadybeincludedand

installedintheductslotofthefilterrackassembly.

Step 7 Connectboththereturnairandsupplyairhouseductstothefurnace.

If thefurnace is installed in a smallenclosed area, aminimum ofa 24" x 24" opening into

the area where the furnace is located must be installed if not already present. In addition, a

6" x 6" nonclosing type register must be cut into the return air duct. (Refer to the Clear

ance Requirements section of this manual for more information.)

STATIC PRESSURE (INCHES WATER)

SUPPLY AIR

BLOWER SPEED 0. 10 0. 25 0. 50

HIGH Not Recommended 1850CFM 1560CFM

MEDIUM HIGH 1800CFM 1780CFM 1470CFM

MEDIUM LOW 1610CFM 1580CFM 1420CFM

LOW 1230CFM 1205CFM Not recommended

Installing The Furnace (cont'd)

14

(.20StaticMaximum)

NOTE

Furnace

CircuitBreakers

LINE2

LINE1

LINE2

LINE1

CHARGECIRCUIT#3

CHARGECIRCUIT#2

CHARGECIRCUIT#1

BLOWERS/CONTROLSCIRCUIT

CHARGECIRCUIT#4

(MODELDLF40ONLY)

LINE2

LINE1

LINE1

LINE2

LINE1

LINE2

ToServicePanel

FIGURE 8

Installing The Furnace (cont'd) 15

LINE VOLTAGE ELECTRICAL CONNECTIONS

Instandardconfiguration,thefurnaceiswiredforconnectionto240Vbutareavailablewith208Vor277V

heatingelementsasspecialfactoryorders.However,theblowersandfurnacecontrolscircuitmustalwaysbe

connectedto240Vor208V.

Thefurnaceissetupformultiplefeedcircuits.The60ampbreakerslocatedintheelectricalcompartmentat

thebaseofthe furnacefeedthecorecharging(element)circuits.The15ampbreaker feedsthefurnace

controlsandblowerscircuit.Thefurnace'selementsandblowers/controlscircuitcanbefedwithseparate

circuitsortheblowers/controlscanbefedfromoneoftheelementcircuits.Ifsinglefeedofthecharging

(element)circuitsisdesired,anoptionalsinglefeedkitisavailablefromthefactory.(Orderitem#1309000.)

Thesinglefeedkitenablesthefurnacetobefedwithasinglecircuitwhichthensplitsthiscircuitinternallyto

each breaker.

All line voltage circuits must be segregated from low voltage wiring in the furnace.

Todeterminethecorrectwiresizerequiredforeachcircuitfeedingthefurnace,refertotheUnitSpecifications

sectioninthismanual.Itistheresponsiblityoftheinstallertofollowallapplicableelectricalcodesandregula

tionsfortheinstallation.

Step 1 Removetheelectricalpanelcover(46).

Step 2 Routelinevoltagewiringthroughaknockoutandintotheelectricalpanelofthefurnace.

Step 3 Maketheproperfieldwiringconnectionstothefurnacebreakers.(SeetheLineVoltageWiring

Diagramsinthismanualformoreinformationontheseconnections.)

To reduce magnetic fields that can be produced by electrical circuits, it is rec

ommended to alternate the circuit phases in the furnace. (See Figure 8 for more

information on how to phase connect the circuits.)

8

NOTE

NOTE

Installing The Furnace (cont'd)

16

Line Voltage Wiring Diagrams

DLF30B 240V OR 208V UNITS ONLY

FIGURE 9

Usecopperoraluminumconductorsratedfor75Corhigherforfieldconnectionofthisdevice.

NOTE

NOTES: 1. Supply air blower speed selection terminals wiring.

2. Line voltage field wiring connections, (see Figure 8).

350

350

350

350

350

WHITE/BLACK

BLUE/WHITE

RED

YELLOW

BLACK

WHITE

STAGING

3

1

2

3

1

2

3

1

2

N.O.

N.O.

N.O.

N.O.

N.O.

N.O.

N.O.

N.O.

STAGE1

CHARGINGSEQUENCOR

STAGE2

CHARGINGSEQUENCOR

STAGE3

CHARGINGSEQUENCOR

N.C. HEATEXCHANGERLIMIT

180°LIMIT

190° LIMIT

135°FAN

CONTROL

N.C.

N.C.

N.O.

CORE

BLOWER

N.O.

COM.

HOUSE

BLOWER N.C.

N.O.

COM.

240v24v

75VA

TRANSFORMER

10uf

Cap.

SUPPLYAIRBLOWER

HIGH

MED.HIGH

MED.LOW

LOW

COM.

COREBLOWER

HIGH

LOW

COM.

5uf

Cap.

HEATINGELEMENTS

HEATINGSPEED

BLUE/RED

COOLINGSPEED

BLUE/BLACK

SEE

NOTE#1

N.C. N.O.

COM.

170°DISK

Switchestolow

ontemp.rise

R1

125

BLACK

RED

BLUE GROUNDLUGS

BLACK

BLUE

YELLOW

RED

CONTROLS

CIRCUIT

CHARGE

CIRCUIT#1

CHARGE

CIRCUIT#2

CHARGE

CIRCUIT#3

CIRCUIT

BREAKERS

N.O.

CONTROL

135°FAN

WHITE\BLACK

BLUE

BLUE/RED

BLUE/BLACK

1

2

3

4

5

6

7

8

TOP

ROW#

BLOWERS/

SEENOTE2

Installing The Furnace (cont'd) 17

DLF40B 240V OR 208V UNITS ONLY

FIGURE 10

Usecopperoraluminumconductorsratedfor75Corhigherforfieldconnectionofthisdevice.

NOTE

NOTES: 1. Supply air blower speed selection terminals wiring.

2. Line voltage field wiring connections, (see Figure 8).

1

2

3

4

5

6

7

8

9

10

11

TOP

ROW#

N.O.

BLUE

BLUE/RED

COM.

COM.

N.C.

N.O.

WHITE/BLACK

CORE

HOUSE

BLOWER

BLUE/BLACK

BLOWER

WHITE\BLACK

YELLOW

BLACK

BLUE/WHITE

N.C. HEATEXCHANGERLIMIT

180°LIMIT

190° LIMIT

135°FAN

CONTROL

N.C.

N.C.

N.O.

N.O.CONTROL

135°FAN

CIRCUIT#4

CHARGE

BLOWERS/

CIRCUIT

CHARGE

CIRCUIT#1

CHARGE

CIRCUIT#2

CHARGE

CIRCUIT#3

350

350

350

350

350

350

RED

WHITE

STAGING

3

1

2

3

1

2

3

1

2

3

1

2

N.O.

N.O.

N.O.

N.O.

N.O.

N.O.

N.O.

N.O.

15A 60A 60A 60A 60A

STAGE1

CHARGINGSEQUENCER

STAGE2

CHARGINGSEQUENCER

STAGE3

CHARGINGSEQUENCER

240v24v

75VA

TRANSFORMER

10uf

Cap.

SUPPLYAIRBLOWER

HIGH

MED.HIGH

MED.LOW

LOW

COM.

COREBLOWER

HIGH

LOW

COM.

5uf

Cap.

HEATINGELEMENTS

HEATINGSPEED

BLUE/RED

COOLINGSPEED

BLUE/BLACK

SEE

NOTE1

N.C. N.O.

COM.

170°DISK

Switchestolow

ontemp.rise

R1

125

BLACK

RED

BLUE

BROWN GROUNDLUGS

BLACK

BLUE

YELLOW

RED

CONTROLS

SEENOTE2

Installing The Furnace (cont'd)

18

DLF30B AND DLF40B 277V UNITS ONLY

FIGURE 11

Usecopperoraluminumconductorsratedfor75Corhigherforfieldconnectionofthisdevice.The

blowersandthecontrolscircuitMUSTbepoweredwith240Vor208V.

NOTE

NOTES: 1. Supply air blower speed selection terminals wiring.

2. Line voltage field wiring connections, (see Figure 8).

HEATINGELEMENTS

N.C.

240°HEATEXCHANGERLIMIT

CHARGINGSEQUENCER

STAGE3

N.O.

N.O.

CHARGINGSEQUENCER

CHARGINGSEQUENCER

STAGE2

N.O.

N.O.

STAGE1

N.O.

N.O.

N.O.

N.O.

N.C.

LIMIT

160°

3

1

3

2

2

1

1

3

STAGING

2

BLACK

BLUE

RED

240v24v

GROUNDLUGS

(YELLOW)

277VAC

YELLOW

CORE

TRANSFORMER

BLOWER

N.O.

75VA

HOUSE

BLOWER

N.O.

N.C.

COM

135°FAN

CONTROL

CONTROL

135°FAN

N.C.

LIMIT

180°

N.O.

N.O.

COM

CIRCUIT#1

COMMON

277VOLT

60 60

CIRCUIT#1

240VAC

CIRCUIT#2

277VAC

BLACK

ontemp.rise

170°DISK

Switchestolow

N.C.

R1

RED

125

COM.

N.O.

(BROWN)

(BLACK)

LOW

COM.

HIGH

N.C.

E1

E2

E4

E3

E6

E5

E8

E7

N.C.

N.C.

N.C.

N.C.

N.C.

N.C.

N.C.

NUMBER

ELEMENT

E9 N.C.

10uf

Cap.

BLUE/RED

HEATINGSPEED

COREBLOWER

SEE

NOTE1

SUPPLYAIRBLOWER

MED.LOW

MED.HIGH BLUE

BLACK

YELLOW

RED

LOW

COM.

HIGH

60

277VAC

CIRCUIT#3

Cap.

5uf

BLUE/BLACK

COOLINGSPEED

CONTROLS

BLOWERS/

CHARGE

CHARGE

CHARGE

SEENOTE2

N.O.

N.O.

N.O.

N.O.

N.O.

N.O.

N.O.

N.O.

BACKVIEW

OFSFIII

UTILITYCONTROL

REVERSINGSWITCH

J31

J21

J41

N/A

OVERRIDE

WINTER

SUMMER

Auto

Lo

Hi

R WG C Y

AUX

Y2Y3

W G B R

TOOUTDOOR

SENSOR

N.O. N.C.

STARTCANCEL

LowVoltageField

WiringConnections

Installing The Furnace (cont'd) 19

LOW VOLTAGE ELECTRICAL CONNECTIONS

Theoutdoortemperaturesensor,roomthermostat,andpeakcontrolsignalarelowvoltagewireconnectionsto

thefurnace.Alllowvoltagewiringmustbesegregatedfromlinevoltagecircuitsinthefurnace.

Low Voltage Wiring Diagram

9

NOTES: 1. Low voltage auxiliary control contacts.

a. Y to Y2 contacts open when load control device closes.

b. Y to Y3 contacts close when load control device closes.

2. Auxiliary contacts close during offpeak heat calls.

3. N.O. used for open onpeak load control device (switch closes to charge).

N.C. used for closed onpeak load control device (switch opens to charge).

FIGURE 12

This manual suits for next models

1

Table of contents

Popular Furnace manuals by other brands

Bryant

Bryant EVOLUTION 986TA Product data

Lifebreath

Lifebreath CAF-U-S4A-24-P16 Operation, sizing and installation manual

Nordyne

Nordyne + RC 92+ installation instructions

Bryant

Bryant 820TA Installation, start-up, operating and service and maintenance instructions

Lennox

Lennox 78RGF Series user manual

Oxbox

Oxbox J801X U Series user manual

England's Stove Works

England's Stove Works 24-G Installation and operation manual

Tempstar

Tempstar F9MAC installation instructions

Unitary products group

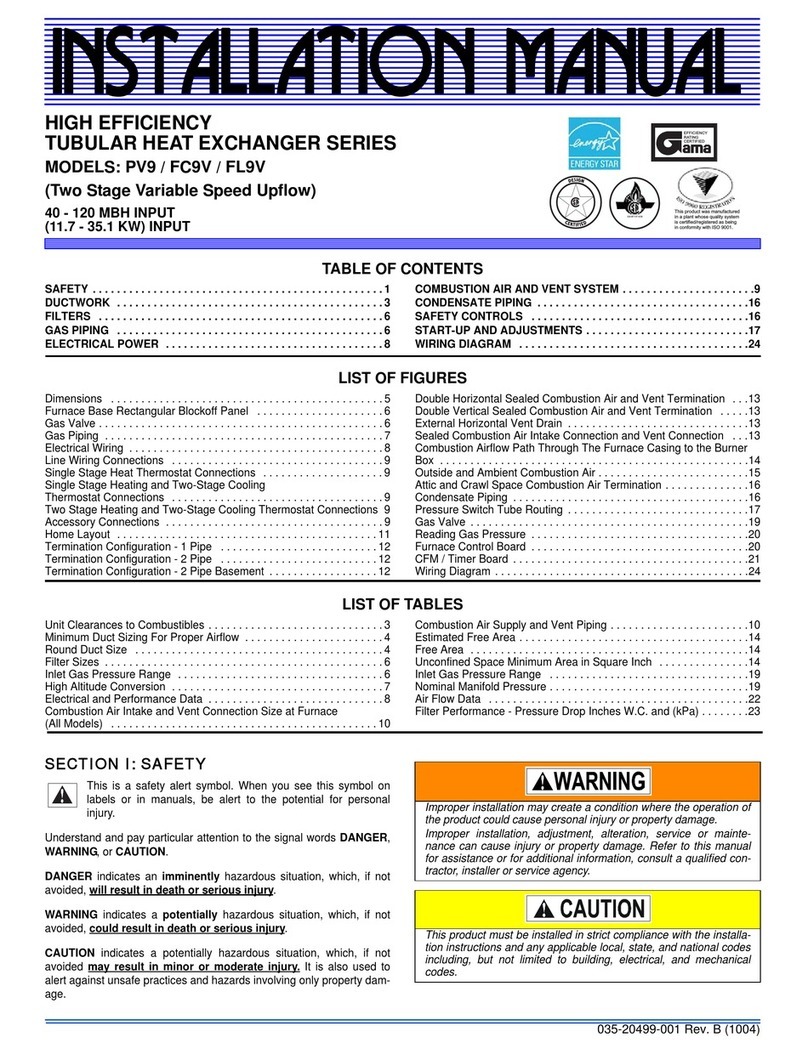

Unitary products group PV9 installation manual

Harman

Harman PF100 Installation & operating manual

Rheem

Rheem GPT series installation instructions

Payne

Payne PG8JAA042090AAJA Installation and operating instructions