Steiner MD448 Setup guide

Owner/Operator's Manual

& Illustrated Parts List

Form # 09-254B

ROTARY MOWER

Models MD448, MD460, MD472

Starting Serial No. 1001

CAUTION

Avoid injuries. Read and understand Operator’s manual

before operating tractor or equipment.

It contains instructions for safe operation.

Date of Purchase: Month ________________Day____________________Year _______________

Dealer Name _________________________Phone__________________

Serial Number ________________________

Model Number ________________________

ALWAYS GIVE MODEL AND SERIAL NUMBER WHEN ORDERING SERVICE PARTS

• READ AND UNDERSTAND OPERATORS MANUAL

BEFORE OPERATING OR SERVICING.

• OBEY ALL SAFETY INSTRUCTIONS. FAILURE TO DO SO

MAY RESULT IN INJURY TO YOU OR OTHERS.

• BE SURE MACHINE IS IN SAFE OPERATING CONDITION

BEFORE USE.

• INSPECT MACHINE DAILY. REPLACE ALL WORN OR

DAMAGED PARTS.

• KEEP ALL GUARDS AND SHIELDS IN PLACE.

• CHECK OPERATION OF ALL SAFETY INTERLOCK

SWITCHES DAILY.

• DO NOT OVERRIDE INTERLOCK SYSTEM, IT IS FOR YOUR

PROTECTION.

• DO NOT ALLOW MINORS OR THE INEXPERIENCED TO

OPERATE MACHINE.

• KEEP PEOPLE AND PETS A SAFE DISTANCE AWAY FROM

MACHINE USING POWER DRIVEN ATTACHMENTS.

INJURY COULD RESULT FROM FLYING DEBRIS.

CAUTION

STEINER TURF EQUIPMENT, INC.

289 N. Kurzen Rd., P.O. Box 504

Dalton, Ohio 44618

Telephone: (330) 828-0200

FAX: (330) 828-1008

TABLE OF CONTENTS

INTRODUCTION SECTION 1 page

Description.........................................1-1

Specifications .......................................1-1

SAFETY SECTION 2

General Safety .......................................2-1

Operator Safety ......................................2-1

INSTALLATION INSTRUCTIONS SECTION 3

Installation Instructions ..................................3-1

OPERATION SECTION 4

Operating Precautions...................................4-1

Operating Instructions ...................................4-1

SERVICE SECTION 5

Maintenance Schedule ..................................5-1

Adjustments ........................................5-1

Drive Belt..........................................5-2

PARTS SECTION 6

Parts List and Illustrations Index..............................6-1

ASSEMBLY INSTRUCTIONS SECTION 7

Assembly Instructions ...................................7-1

Warranty .......................................last page

Form 09-254B rev 7/01

8/01 1 - 1. 09-254B

INTRODUCTION section 1

Description

A full-floating rotary mower deck is designed to fit all Steiner power units with the quick hitch front lift.

Three sizes match the power unit to the application. These decks are easy to attach and detach allowing

interchange with the many other front mounted attachments. The side discharge rotary mower provides

even distribution of clippings while the full-floating deck follows the contours of the terrain for an even cut

with cutting height controlled by the front caster wheels and full width rear roller. The deck can be safely

serviced and cleaned while still attached to the tractor. Convenient handles enable the deck to be lifted

vertically over 90 degrees so the blades are fully exposed. Exceptional visibility and maneuvering is

possible with this front mounted design mower.

Specifications

MD448 MD460 MD472

Overall Width with Discharge Chute ____60-1/2" __________73"_____________85"

Overall Height ________________19" ____________19"_____________19"

Overall Length ________________49-1/2" __________48-3/4" __________55"

Cutting Width ________________47" ____________59-3/8" __________72"

Cutting Height ________________1"to4-1/2" ________1"to4-1/2" ________1"to4"

Blades ____________________3-16-1/4"blades ____3-20-1/2"blades _____3-24-3/4" blades

Weight ____________________330lbs. _________360lbs. __________470lbs.

NOTE:

The flip-up deck feature was

added beginning with the

following Serial Numbers;

MD448 - (S/N 1494)

MD460 - (S/N 4728)

MD472 - (S/N 1970)

09-254B 2 - 1 rev 11/02

SAFETY section 2

SIGNAL WORD DEFINITIONS

Indicates an imminently hazardous situation

which, if not avoided, will result in death or

serious injury. This signal word is limited to the

most extreme cases.

Indicates a potentially hazardous situation

which, if not avoided, could result in death or

serious injury.

Indicates a potentially hazardous situation

which, if not avoided, may result in minor or

moderate injury and/or property damage. It may

also be used to alert against unsafe practices.

ATTENTION:

This symbol identifies potential health and

safety hazards. It marks safety precautions. Your

safety and the safety of others is involved.

GENERAL SAFETY

Read and understand the owner's manual, before

attempting to operate this machine.

Operate all controls from the operator's seat, (if so

equipped). NO RIDERS.

Keep all shields in place and safety switches

adjusted properly.

Do not leave equipment unattended. Park on a level

surface, set parking brake, STOP the engine and

remove the key.

Do not allow minors or the inexperienced to operate

this machine.

Keep people and pets a safe distance away from

machines using power driven attachments. Injury

could result from flying debris.

Do not attempt to work on unit or any attachments

with engine running!

Wear all the necessary protective clothing and

personal safety devices to protect your head, eyes,

ears, hands and feet. Operate the machine only in

daylight or in good artificial light.

BE ALERT!

IMPORTANT

Safe Operation Practices for

Mowers

This cutting machine is capable of amputating

hands and feet and throwing objects. Failure to

observe the following safety instructions could

result in serious injury or death.

I General operation

•Read, understand, and follow all instructions in

the manual and on the machine before starting.

•Only allow responsible adults, who are familiar

with the instructions, to operate the machine.

•Clear the area of objects such as rocks, toys ,

wire, etc., which could be picked up and thrown by

the blade.

•Be sure the area is clear of other people before

mowing. Stop the machine if anyone enters the

area.

•Never carry passengers.

•Do not mow in reverse unless absolutely

necessary. Always look down and behind before

and while backing.

•Be aware of the mower discharge direction and do

not point it at anyone. Do not operate the mower

without the discharge chute in place.

•Slow down before turning.

•Never leave a running machine unattended.

Always turn off blades, set parking brake, stop

engine, and remove keys before dismounting.

•Turn off blades when not mowing.

•Stop engine before unclogging discharge chute.

•Mow only in good light, keeping away from holes

and hidden hazards.

•Do not operate the machine while under the

influence of alcohol or drugs.

•Watch for traffic when operating near or crossing

roadways.

•Use extra care when loading or unloading the

machine into a trailer or truck.

•Always wear safety goggles or safety glasses with

side shields when operating mower.

II Slope operation

Slopes are a major factor related to

loss-of-control and tip-over accidents, which can

result in severe injury or death. All slopes

require extra caution. If you feel uneasy on it, do

not mow it.

DO:

•Mow up and down slopes, not across.

•Remove obstacles such as rocks, tree limbs, etc.

•Watch for holes, ruts, or bumps. Uneven terrain

could overturn the machine. Tall grass can hide

obstacles.

•Use slow speed on slopes.

•Follow the manufacturers recommendations for

wheel weights or counterweights to improve

stability.

•Use extra care with grass catchers or other

attachments. These can change the stability of the

machine.

•Keep all movement on the slope slow and gradual.

Do not make sudden changes in speed or

direction.

•Avoid stopping or starting on a slope. If tires lose

traction, disengage the blades and proceed slowly

straight down the slope.

rev 11/02 2 - 2 09-254B

SAFETY section 2

DO NOT:

•Do not turn on slopes unless necessary, and then,

turn slowly and gradually downhill, if possible.

•Do not mow drop-offs, ditches, or embankments.

The mower could suddenly turn over if a wheel is

over the edge of a cliff or ditch, or if an edge caves

in.

•Do not mow on wet grass. Reduced traction could

cause sliding.

•Do not try to stabilize the machine by putting your

foot on the ground.

•Do not use grass catcher on steep slopes.

III Children

Tragic accidents can occur if the operator is not

alert to the presence of children. Children are

often attracted to the machine and the mowing

activity. Never assume that children will remain

where you last saw them.

•Keep children out of the mowing area and under

the watchful eye of another responsible adult.

•Be alert and turn machine off if children enter the

area.

•Before and when backing, look behind and down

for small children.

•Never carry children as passengers, even with the

blades off. They may suddenly fall off and be

seriously injured or interfere with safe machine

operation.

•Never allow children to operate the machine.

•Use extra care when approaching blind corners,

shrubs, trees, or other objects that may obscure

vision.

IV Service

•Use extra care in handling gasoline and other

fuels. They are flammable and the vapors are

explosive.

−Use only an approved container.

−Never remove gas cap or add fuel with engine

running. Allow engine to cool before refueling.

−Do not smoke.

−Never add or drain fuel with machine indoors.

−Never store the machine or fuel container

inside where there is an open flame, such as in

a water heater.

•Never run the machine in a closed area.

•Keep nuts and bolts, especially blade attachment

bolts, tight and keep equipment in good condition.

•Never tamper with safety devices. Check their

proper operation regularly.

•Keep machine free of grass, leaves, and other

debris build-up. Clean up oil or fuel spillage. Allow

machine to cool before storing.

•Stop and inspect the equipment if you strike an

object. Repair, if necessary, before restarting.

•Never make adjustments or repairs with the

engine running.

•Discharge chute components are subject to wear,

damage, and deterioration, which could expose

moving parts or allow objects to be thrown.

Frequently check components and replace with

manufacturer’s recommended parts, when

necessary.

•Mower blades are sharp and can cut. Wrap the

blade(s) or wear gloves, and use extra caution

when servicing them.

•Check brake operation frequently (if equipped).

Adjust and service as required.

09-254B 2 - 3 rev 11/02

SAFETY section 2

rev 1/99 2 - 4 09-254B

SAFETY section 2

MOWER DECK SAFETY DECALS

Location:

On mower deck, front center.

Location:

On mower deck and discharge chute.

09-254B 2 - 5 rev 1/99

SAFETY section 2

DANGER

Location:

On mower deck top front center and both sides.

ROTATING BLADES

LOOK AND LISTEN FOR EVIDENCE OF ROTATION.

DO NOT REMOVE SHIELDS OR ATTEMPT TO SERVICE

UNIT UNTIL ALL COMPONENTS HAVE STOPPED.

Location:

On mower deck top shield.

rev 10/02 3 - 1 09-254B

INSTALLATION section 3

ATTACHING MOWER TO TRACTOR:

-Operate latch control to open hitch latches.

-Drive tractor into position aligning the quick hitch.

-Be sure both latches engage fully and and are placed in the locked position.

-Stop engine! Do not attempt to install drive belt with engine running.

-Release idler assembly to facilitate easy installation of the drive belt.

-Put belt over drive pulleys and engage or adjust idler assembly.

(See Power Unit Operator's Manual for PTO belt tension adjustments.)

-Set mower to desired cutting height.

-Start engine and engage PTO slowly to prevent shock load on mower components.

-Mow with front lift lever in “FLOAT” position only.

REAR WEIGHT REQUIREMENTS

The table of requirements for rear weights is based upon average mowing condi-

tions and operator’s weight of 150 lbs. The recommendations may vary with the weight of

the operator, other accessories, and the mowing conditions. It is the operator’s responsi-

bility to determine the correct amount of weight needed to improve stability. All weights

must be removed when the mower is removed. (See Caution in Power Unit Operator’s

manual.)

Power Unit Model 48” Deck 60” Deck 72” deck

220 / 230 0 weights 0 weights 2 weights

410 2 weights 4 weights This deck is not

recommended.

420/430 2 weights 4 weights 5 weights

425 2 weights 2 weights 4 weights

525 0 weights 0 weights 0 weights

09-254B 4 - 1 rev 11/02

Operating Instructions

-Do not operate mower with discharge chute removed.

- Mow with front lift lever in “FLOAT” position only.

- Engage PTO slowly at low engine r.p.m.

- Mower is designed to operate at full throttle for mowing heavy turf, but 3/4 throttle is adequate for

average conditions. Set mower blade speed with throttle and control ground speed with Forward

- Reverse control.

- Use extreme caution when operating on hills. Mow up and down whenever possible.

- See Section 3 for weight recommendations.

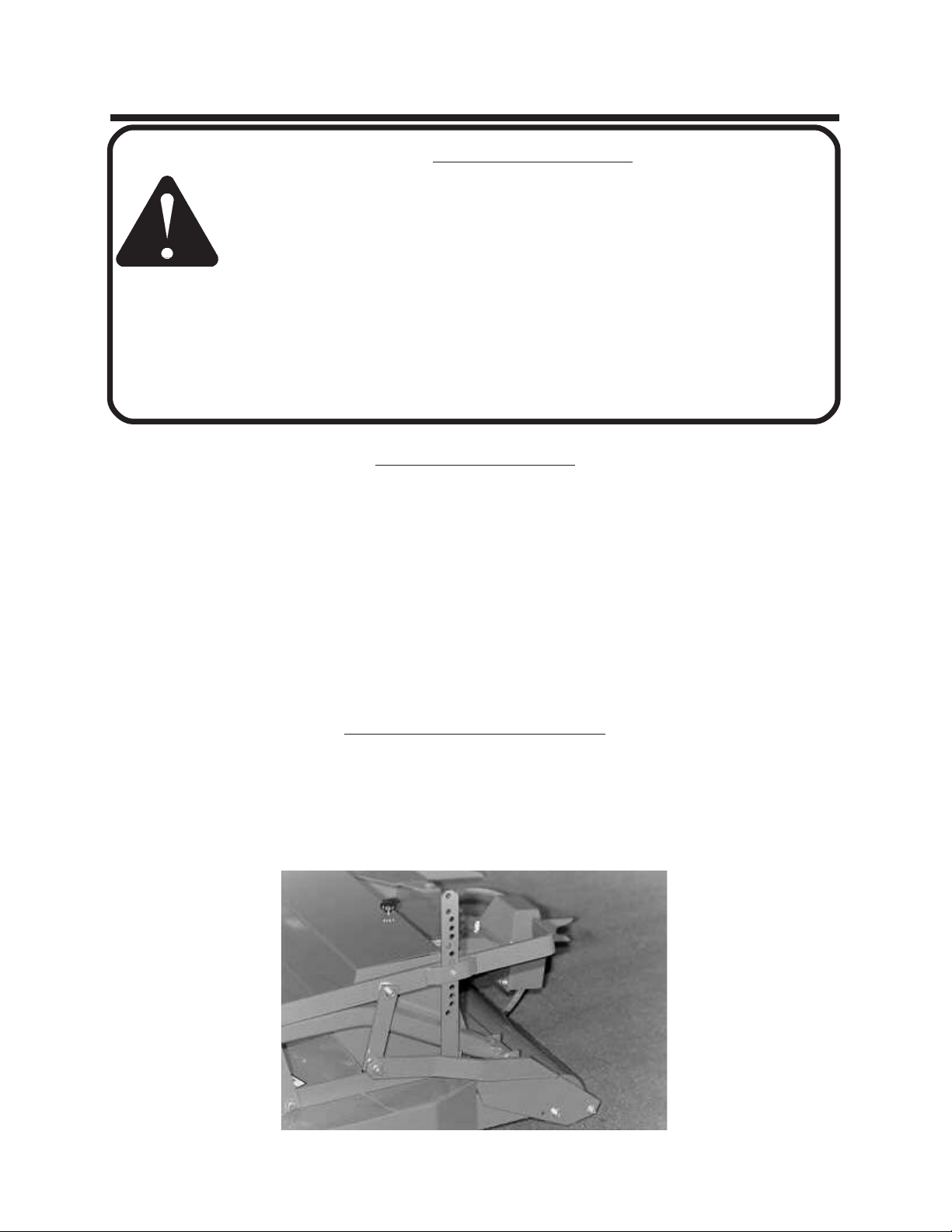

Setting Mower Cutting Height

-Lift mower deck off the ground and shut off tractor engine.

-Remove clevis pin from height adjustment link. See photo 1.

-Raise or lower deck to desired height.

-Replace clevis into height adjustment link.

OPERATION section 4

Operating Precautions

Observe all safety decals.

Keep all shields in place. Do not operate mower with discharge chute removed.

Do not operate mower with other persons in the area. Irregularities in ground

surface can permit foreign material to be propelled from beneath deck to cause

serious injury or death.

Before leaving tractor, stop on a level surface, move Forward - Reverse control to

neutral position, disengage PTO, set parking brake, lower mower deck and stop

engine.

Remove key from ignition if maintenance procedures are to be performed or

tractor is to be left unattended.

Photo 1

rev 8/02 5 - 1 09-254B

SERVICE section 5

MAINTENANCE

Daily maintenance:

·Visual inspection for loose parts and accumulation of grass and dirt.

·Clean accumulation of grass clippings from beneath deck daily for better mowing performance.

·Keep blades sharp. Check the tips of the blades for wear.

25 hour maintenance:

·In addition to daily maintenance, grease roller and all bearings.

·Spindle housings must be kept full of grease. Grease spindles until grease “shows” at the relief hole

under the spindle drive pulley. NOTE: The relief hole is under the spindle hub and is not visible. As

grease enters the spindle housing you can hear the sound of escaping air at the relief hole. Stop

greasing when the sound of escaping air ceases.

·Check drive belt tension. See Drive Belt Installation on page 5-2.

·Check 1/4" cap screws on pulley bushings. Torque should be 95 inch pounds. Tighten these cap screws

in alternating sequence 10-12 times to assure equal torque on all cap screws.

·Check blade bolts. Torque should be 75-85 foot pounds.

Annual Maintenance:

·In addition to daily and 25 hour maintenance, remove the drive belt and check for cracks or wear.

Rotate each spindle to check for roughness which would indicate bearing wear. Remove and sharpen

blades, clean and wash deck prior to storage. The acid in grass clippings causes premature corrosion

and rusting of mower parts.

·Grease all bearings after washing.

ADJUSTMENTS

Sharpening blades

Be careful while sharpening blades that the

corners of the blade do not become rounded at the

tips. This reduces the blades overlap and will cause

skipping. While sharpening, it is essential to ensure

the balance of the blades is maintained to prevent

vibration. Blade bolt torque should be 75-85 foot

pounds. Rotate blades after re-installing to check

for bent or bowed blades and blade alignment.

Blade alignment

When installing sharpened blades or new

blades be sure the mating surfaces are clean and

the retaining washer is not bent. Check for bent

blades by rotating blades until tips are near each

other. (It is easier to do this with main drive belt idler

spring unhooked.)

Leveling mower deck

The front to rear leveling adjustment is pro-

vided by two slots in the linkage which supports the

front of the deck. This allows each side to be ad-

justed independently. Check the blade level with

mower resting on a level floor and the cutting height

set at about 2-1/2" setting. Measure to the tip of the

left blade at the rear, then rotate the blade 180 de-

grees and measure again to the tip of the blade at

the front. The cutting height should be equal or

1/16" lower at the front. Change adjustment in the

left slot as required and measure again until proper

setting is reached. Repeat procedure for blade at

right end of the deck and adjust right slot.

09-254B 5 - 2 rev 8/02

To Remove Belt:

1. Serial Numbers (MD448=1001-1493,

MD460=1001-4727, MD472=1001-1969)

Remove top shield and the bolts which fasten

the hitch arms to the deck brackets. No further

disassembly is necessary.

Serial Numbers (MD448=1494 & Up,

MD460=4728 & Up, MD472=1970 & Up)

Remove the six ¼ x ¾ bolts from the flip-up

braces and remove the pivot stop pin and the

idler spring. Remove the braces.

2. With the idler spring released, move the idler

toward the drive shaft.

3. Slip belt off the outer spindle pulleys.

4. Slip belt off the front center idler and spindle.

5. Remove belt.

To Install Belt:

1. Form loop for drive pulley and idler pulley as

shown. (Photos2&3)

2. Slip loop over drive pulley on left hitch arm.

(Photos2&3)

3. Form a loop around the center spindle pulley

and fixed idler pulley. (Photos2&3)

4. Position belt on the outer spindle pulleys.

(Photos2&3)

5. Serial Numbers (MD448=1001-1493, MD460=

1001-4727, MD472=1001-1969)

Re-install hitch arms and bushings in place .

Serial Numbers (MD448=1494 & Up,

MD460=4728 & Up, MD472=1970 & Up)

Re-install hitch arms and pivot braces. Torque

1/2" attaching bolts to 85 foot pounds. (Photos 2

&3)

6. Hook idler spring in place.

Serial Numbers (MD448=1001-1493, MD460=

1001-4727, MD472=1001-1969)

Choose chain link that stretches spring to an

overall length of 8-9 inches.

Serial Numbers (MD448=1494 & Up,

MD460=4728 & Up, MD472=1970 & Up

Choose chain link which stretches spring

approximately one inch on MD460 or 1-1/2" on

MD448 & MD472.

7. Re-install top shield.

SERVICE section 5

CHANGING MAIN DRIVE BELT

Photo 2 Photo 3

rev 11/02 5 - 3 09-254B

SERVICE section 5

USING THE FLIP-UP OPTION ON THE

MD448, MD460 AND MD472 ROTARY MOWERS

1. Stop on a level surface, set parking brake and shut off the tractor.

2. Lift the deck.

3. Remove the top deck shield and set aside.

4. Standing at the front of the deck, pull the handle on the idler arm so the belt comes loose.

5. Remove the belt from the drive pulley.

6. Remove the presto pin and slide pin from holes.

7. Grasp the handles and lift the deck up and back until you hear a click. This indicates that the latch has

engaged.

8. Lower the deck until the roller touches the ground. This gives stability when working on the deck.

9. Complete your work under the deck.

10. Start the tractor and lift the deck again. Shut off the tractor.

11. Grasp the handles at the front of the deck. Push the deck back slightly and release the catch.

12. Pull the deck forward and down, keeping a firm grip on the handles.

13. Lower the deck to the ground.

14. Replace the pin and clip in the hole above the lift arm.

15. Grasp the idler arm handle again and pull to stretch the spring. Place the belt onto the drive pulley.

16. Make sure the belt is around all pulleys. Release the idler arm.

17. Replace the top shield and secure with the rubber latches.

18. Moving the power unit with the deck in the flipped up position is not recommended. Serious injury and

or damage could result.

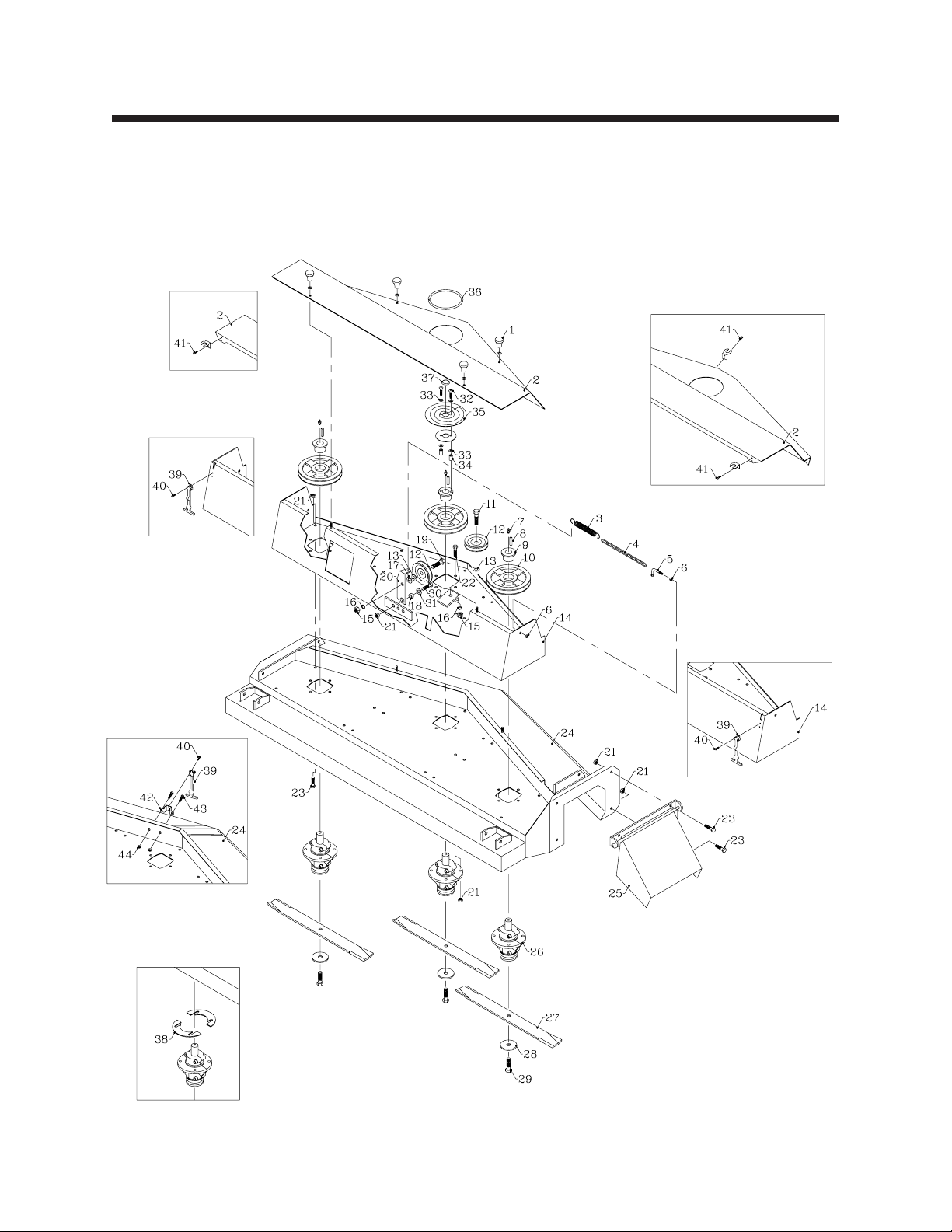

09-254B 6 - 1 rev 7/99

PARTS section 6

PARTS INDEX

GROUP FIGURE PAGE

Deck Parts ................

Model MD448 .............Figure 1 .....................6-2

Model MD460 .............Figure 1A.....................6-4

Model MD472 .............Figure 1B.....................6-6

Frame Parts ...............

Model MD448 .............Figure 2 .....................6-8

Model MD460 .............Figure 2A.....................6-10

Model MD472 .............Figure 2B.....................6-12

Hitch and Drive Parts ...........Figure 3 .....................6-14

Spindle Parts ...............Figure 4 .....................6-16

Flip-Up Decks...............Figure 5 .....................6-18

Warranty ............................................last page

ALWAYS GIVE MODEL AND SERIAL NUMBER WHEN ORDERING SERVICE PARTS.

Model MD448 begins with Serial Number 1001

Model MD460 begins with Serial Number 1001

Model MD472 begins with Serial Number 1001

8/01 6 - 2 09-254B

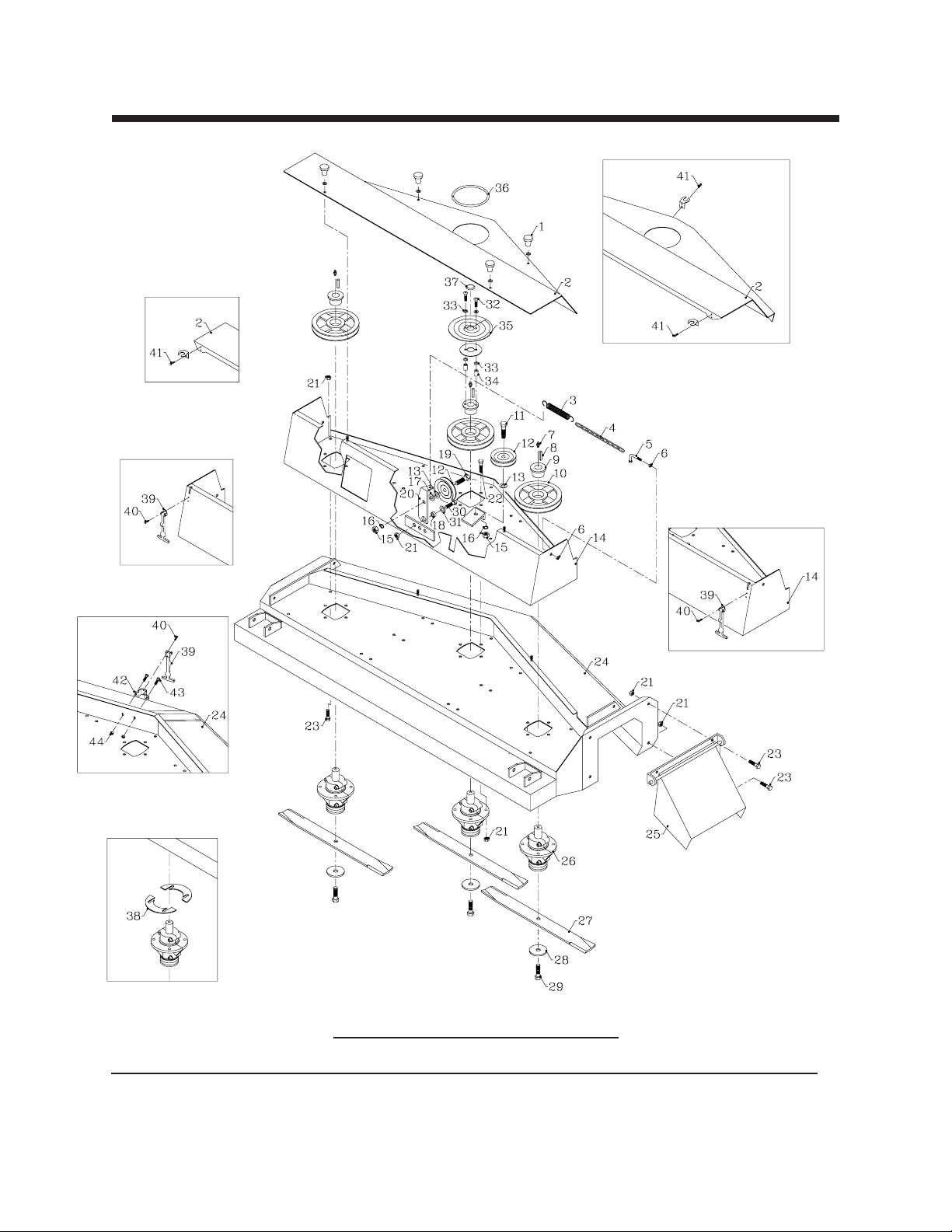

PARTS section 6

Serial No.

1434 & Up

Serial No. 1434 & Up

Serial No. 1434

&Up

Serial No. 1434

&Up

Serial No. 1434

&Up

Deck Parts

Model MD448

Figure 1

Optional Repair

Shims

09-254B 6 - 3 rev 3/03

1 47-050 Knob, Ribbed W/ 1/4-20 Threads (Serial No. 1001 - 1433) 4

99-G03 Shakeproof Washer, 5/16" (Serial No. 1001 - 1433) 4

2 60-535 Shield, Top (Serial No. 1001 - 1009) 1

60-567 Shield, Top Deck (Serial No. 1010 - 1433) 1

60-652.17 Shield, Top Deck (Serial No. 1434 - ) 1

3 41-052 Spring, Ext. 0.875 X 6.750 1

4 56-055-11 Chain, Idler Tension (Serial No. 1001 - 1577) 1

5 64-534 Hook, Spring (Serial No. 1001 - 1577) 1

6 99-E20 Flange Nut, 1/4 2

7 29-010 Grease Fitting,1/4 Short 3

8 85-K0408 Key, 1/4 X 1 3

9 83-H16SPL Bushing,HX1"Split Type 3

10 83-BK50H Pulley, 5", H1 Bushing 3

11 90-0812 Bolt, 1/2 X 1-1/2 1

12 83-012 Idler, “V” 1/2" ID X 4-1/2" OD 2

13 99-B12 Washer, 1/4 X 17/32 X 1-1/8 2

14 62-723 Deck, Top (Serial No. 1001 - 1433) 1

62-843 Deck, Top (Serial No. 1434 - 1577) 1

62-872.17 Upper Deck Weldment MD448 (Serial No. 1578 - ) 1

15 92-08 Nut, 1/2 2

16 96-08 Lock Washer, 1/2 2

17 95-08 Flat Washer, 1/2 SAE 1

18 85-B29 Bushing, .406 X .740 X .258 Thick 1

19 90-0814 Bolt, 1/2 X 1-3/4 1

20 40-290 Idler Arm (Serial No. 1001 - 1577) 1

40-329 Idler Arm MD460 & MD448 (Serial No. 1578 - ) 1

21 99-E13 Flange Nut, 3/8 21

22 99-K22 Bolt, Flange 3/8 X 1-1/4 12

23 99-K11 Bolt, Flange 3/8 X 3/4 8

24 62-716 Deck, Mower (Serial No. 1001 - 1433) 1

62-844.17 Deck, Mower (Serial No. 1434 - ) 1

25 60-534.17 Chute, Side Discharge 1

26 87-143 Spindle, Mower 1/2-20 RH Threads 3

27 79-062 Blade, 16-1/4" .700 Air Lift 3

79-064 Blade, 16-1/4" 1-3/8 Air Lift (Optional) 3

28 99-B14 Washer, 1/4 X 1/2 IDX3OD 3

29 91-0810 Bolt, 1/2 X 1-1/4 NF 3

30 90-0608 Bolt, 3/8 X 1 1

31 64-799 Washer, 13/32 x 1-9/32 1

32 99-K38 Bolt, 1/4 X 1-1/4 Button Head (Serial No. 1010 - ) 2

33 95-04 Flat Washer, 1/4 SAE (Serial No. 1010 - ) 4 A/R

34 64-687 Spacer, Rotation Indicator (Serial No. 1010 - ) 2

35 00-137 Decal, Spiral Indicator (Serial No. 1010 - ) 1

60-568 Support, Rotate Indicator (Serial No. 1010 - ) 1

36 56-059-17 Trim-loc, Rubber 17" (Serial No. 1010 - ) 1

37 06-010 Cap Plug,1" (Serial No. 1010 - ) 1

* 00-139 Decal, Warning-Discharge Chute (Serial No. 1010 - ) 2

* 00-140 Decal, ANSI Certification (Serial No. 1010 - ) 1

* 00-138 Decal, Danger-Rotating Blade (Serial No. 1010 - ) 1

* 00-004 Decal, Steiner 1

* 00-092 Decal, Keep Hands & Feet 3

* 00-093 Decal, Warning-Read Owner's 1

* 00-129 Decal, Belt Installation 1

38 64-866 Shim, Spindle 22 Ga.(1 Pair) (Optional) 1

64-867 Shim, Spindle 16 Ga.(1 Pair) (Optional) 1

64-868 Shim, Spindle 12 Ga.(1 Pair) (Optional) 1

39 47-090 Latch, Rubber 3" Long (Serial No. 1434 - ) 3

40 04-008 Pop Rivet, 1/8 X 1/4 SS. (Serial No. 1434 - ) 6

41 04-007 Pop Rivet, 1/8 X 1/8 SS. (Serial No. 1434 - ) 6

42 64-900 Bracket, Top Shield Latch (Serial No. 1434 - ) 1

43 99-K31 Bolt, Flange 1/4 X 1/2 (Serial No. 1434 - ) 2

44 99-E20 Flange Nut, 1/4 (Serial No. 1434 - ) 2

* Not Illustrated

PARTS section 6

Parts List for Model MD448 - Figure 1

Ref. Part No. Description Quantity

rev 3/03 6 - 4 09-254B

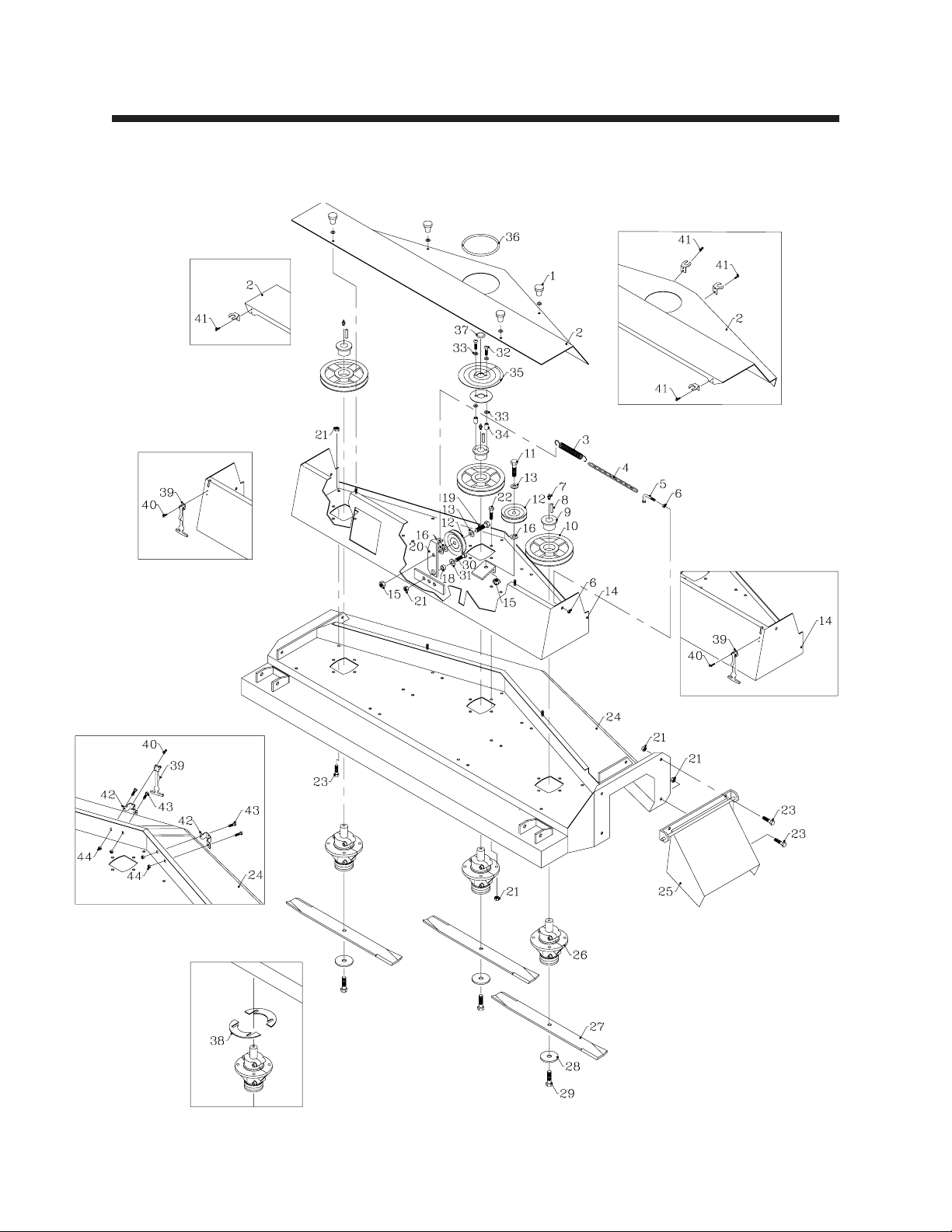

PARTS section 6

Serial No.

4189 & Up

Serial No. 4189 & Up

Serial No. 4189

&Up

Serial No. 4189

&Up

Serial No. 4189

&Up

Parts List for Model MD460 - Figure 1A

Ref Part No. Description Quantity

1 47-050 Knob, Ribbed W/ 1/4-20 Threads (Serial No. 1001 - 4188) 4

99-G03 Shakeproof Washer, 5/16" (Serial No. 1001 - 4188) 4

2 60-526 Shield, Top Deck (Serial No. 1001 - 1224) 1

60-544 Shield, Top Deck (Serial No. 1225 - 4188) 1

60-647.17 Shield, Top Deck (Serial No. 4189 - ) 1

Deck Parts

Model MD460

Figure 1A

Optional Repair

Shims

09-254B 6 - 5 rev 3/03

3 41-052 Spring, Ext 0.875 X 6.750 (Serial No. 1001 - 5456) 1

4 56-055-15 Chain, #2 Straight Link (Serial No. 1001 - 5456) 1

5 64-534 Hook, Spring (Serial No. 1001 - 5456) 1

6 99-E20 Flange Nut, 1/4 2

7 29-010 Grease Fitting, 1/4 Short 3

8 85-K0408 Key, 1/4 X 1 3

9 83-H16SPL Bushing,HX1"Split Type 3

10 83-BK72H Sheave, BK72H 3

11 90-0812 Bolt,1/2 X 1-1/2 1

12 83-012 Idler, “V” 1/2" ID X 4-1/2" OD 2

13 99-B12 Washer, 1/4 X 17/32 X 1-1/8 2

14 62-700 Deck, Top (Serial No. 1001 - 1194) 1

62-729 Deck, Top (Serial No. 1195 - 4188) 1

62-835 Deck, Top (Serial No 4189 - 5456) 1

62-868.17 Upper Deck Weldment MD460 (Serial No. 5457 - ) 1

15 92-08 Nut,1/2 2

16 96-08 Lock Washer, 1/2 2

17 95-08 Flat Washer, 1/2 SAE 1

18 85-B29 Bushing, .406 X.740 X.258 Thick 1

19 90-0814 Bolt, 1/2 X 1-3/4 1

20 40-289 Idler Arm (Serial No. 1001 - 1194) 1

40-290 Idler Arm (Serial No. 1195 - 5456) 1

40-329 Idler Arm MD460 & MD448 (Serial No. 5457 - ) 1

21 99-E13 Flange Nut, 3/8 21

22 99-K22 Bolt, Flange 3/8 X 1-1/4 12

23 99-K11 Bolt, Flange 3/8 X 3/4 8

24 62-694 Deck, Main (Serial No. 1001 - 1194) 1

62-727 Deck, Main (Serial No. 1195 - 4188) 1

62-834.17 Deck, Main (Serial No. 4189 - ) 1

25 62-696.17 Chute, Side Discharge 1

26 87-143 Spindle, Mower 1/2-20 RH Threads 3

27 79-050 Blade, 20-1/2" .700 Air Lift 3

79-053 Blade, 20-1/2" 1-3/8 Air Lift (Optional) 3

28 99-B14 Washer, 1/4 X 1/2 IDX3OD 3

29 91-0810 Bolt, 1/2 X 1-1/4 NF 3

30 90-0608 Bolt, 3/8 X 1 1

31 64-799 Washer, 13/32 x 1-9/32 1

32 99-K38 Bolt, 1/4 X 1-1/4 Button Head (Serial No. 1225 - ) 2

33 95-04 Flat Washer, 1/4 SAE (Serial No. 1225 - ) 4 A/R

34 64-687 Spacer, Rotation Indicator (Serial No. 1225 - ) 2

35 00-137 Decal, Spiral Indicator (Serial No. 1225 - ) 1

60-568 Support, Rotate Indicator (Serial No. 1225 - ) 1

36 56-059-17 Trim-loc, Rubber 17" (Serial No. 1225 - ) 1

37 06-010 Cap Plug,1" (Serial No. 1225 - ) 1

* 00-139 Decal, Warning-Discharge Chute (Serial No. 1225 - ) 2

* 00-140 Decal, ANSI Certification (Serial No. 1225 - ) 1

* 00-138 Decal, Danger-Rotating Blade (Serial No. 1225 - ) 1

* 00-004 Decal, Steiner 1

* 00-092 Decal, Keep Hands & Feet 3

* 00-093 Decal, Warning-Read Owner's 1

* 00-129 Decal, Belt Installation 1

38 64-866 Shim, Spindle 22 Ga.(1 Pair) (Optional) 1

64-867 Shim, Spindle 16 Ga.(1 Pair) (Optional) 1

64-868 Shim, Spindle 12 Ga.(1 Pair) (Optional) 1

39 47-090 Latch, Rubber 3" Long (Serial No. 4189 - ) 3

40 04-008 Pop Rivet, 1/8 X 1/4 SS. (Serial No. 4189 - ) 6

41 04-007 Pop Rivet, 1/8 X 1/8 SS. (Serial No. 4189 - ) 6

42 64-900 Bracket, Top Shield Latch (Serial No. 4189 - ) 1

43 99-K31 Bolt, Flange 1/4 X 1/2 (Serial No. 4189 - ) 2

44 99-E20 Flange Nut, 1/4 (Serial No. 4189 - ) 2

* Not Illustrated

PARTS section 6

Parts List for Model MD460 - Figure 1A (Continued)

Ref. Part No. Description Quantity

8/01 6 - 6 09-254B

PARTS section 6

Deck Parts

Model MD472

Figure 1B

Serial No.

1838 & Up

Serial No. 1838 & Up

Serial No. 1838

&Up

Serial No. 1838 & Up

Serial No. 1838

&Up

Optional Repair

Shims

Other manuals for MD448

1

This manual suits for next models

2

Table of contents

Other Steiner Lawn Mower manuals