Page 5

VACUUM SEAL DRAWER SAFETY

CAUTION

The vacuum chamber and glass lid become distorted

under vacuum. There must be at least a one-

centimeter gap between vessels or screw-top jars

and the appliance lid. Otherwise, the glass can

become damaged and the lid can shatter, causing

personal injury.

CAUTION

The sealing bar in the vacuum chamber gets very

hot. The sealing seam of the vacuum bag also heats

up during the sealing process. Do not touch the hot

sealing bar or other accessible parts, or burns could

result.

CONTROLS

Opening the drawer reveals the control panel, which features

touch controls and LED indicators.

Each control illuminates to indicate that it is active. For vacuum

level, auxiliary vacuum level, and sealing time, three LEDs

above each control indicate the level of vacuum or sealing.

Vacuum and Seal

Vacuum Level: Indicated by one, two, or three illuminated

dashes above .

Seal Level: Indicated by one, two, or three illuminated

dashes above .

CAUTION

Selecting an improper seal level can damage the

sealing bar. Wait at least two minutes between

sealing cycles. All contents must be at or below room

temperature prior to the sealing operation.

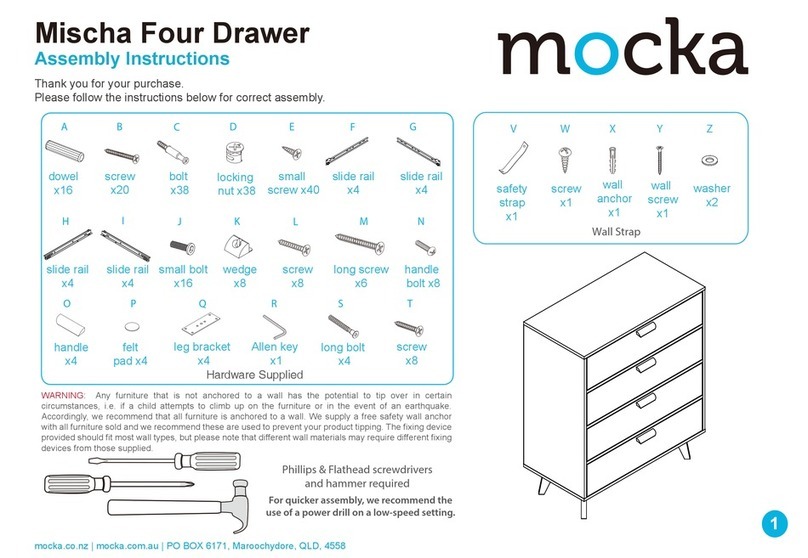

1Place food in the vacuum bag.

2Open the lid, and place the bag into the chamber.

3Place the open end of the bag under the bag clip. For

smaller bags, insert the bag support to support the bag

while sealing.

4Touch .

5Touch multiple times to select the desired vacuum level.

6Touch multiple times to select the desired seal level.

7Press down on the lid, and touch to initiate the vacuum

process.

An audible signal indicates the process is complete.

8Open the lid, and remove the food.

Vacuum Only

CAUTION

This process is not intended for canning or making

jam. All contents should be at or below room

temperature.

Jars less than 7.6 cm tall with screw-top lids can be vacuumed

to remove air. Once the vacuum seal is broken, the contents

should be placed in the refrigerator.

1Place the lid on the jar, then lightly tighten the ring and

place in the chamber.

IMPORTANT NOTE: Do not over-tighten the lid. Air must be able

to escape.

2Touch .

3Touch multiple times to select the desired vacuum level.

4Touch multiple times until no LED indicators are

illuminated.

5Touch , then press down on the lid to initiate the vacuum

process.

An audible signal indicates the process is complete.

6Open the lid, and remove the food or jar.

Seal Only

Bags can be sealed without creating a vacuum. The vacuum will

turn on and off briefly during the "seal only" operation to seat

the lid and make sure the sealing bar is in contact with the bag.

TIP: For best results, fill the vacuum seal bags less than half full

when sealing fragile foods.

The original food packaging can be sealed using the "seal only"

function. Adjust the seal level according to the thickness of the

bag. Use seal level 1 for bags thinner than Wolf vacuum seal

bags.

1Place food in the vacuum bag.

ICB Vacuum Seal Drawer

Controls and Operation

CONTROLS AND OPERATION

service.subzero.com

826148 REV. A 01/2019 4