Thank you for choosing our kit of the Me-163B. We ask you to read the instruction once in

advance before building this kit in order to avoid mistakes. Make sure that you identify

which photos accompany which step of the build before you start. Please keep in mind that

this is a model airplane suited for turbines of up to 16 Kg of thrust. Please beware that all

parts used in the construction of this kit have to be strong and large enough. Sunshine

Modell is making an effort to keep the kit as light as possible while not making any

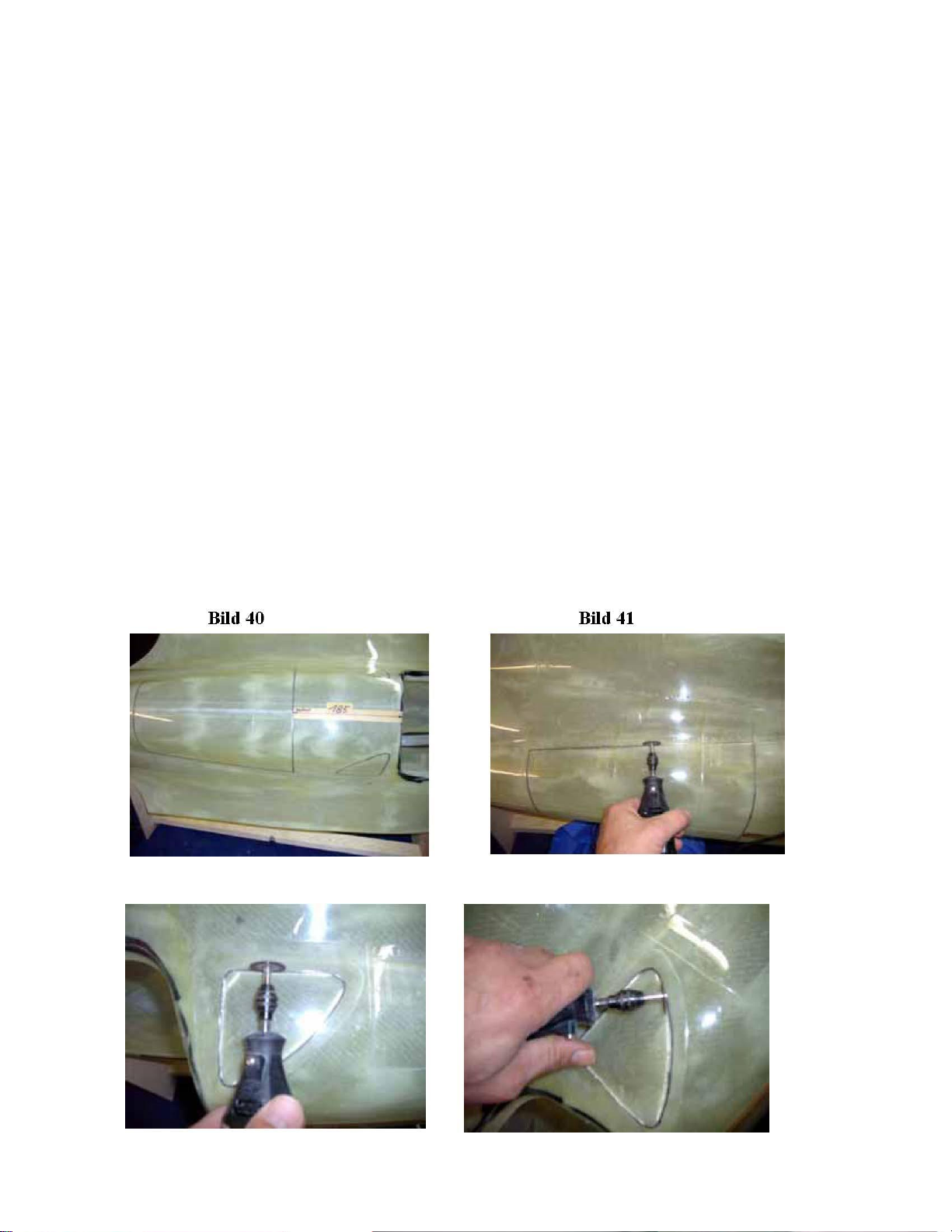

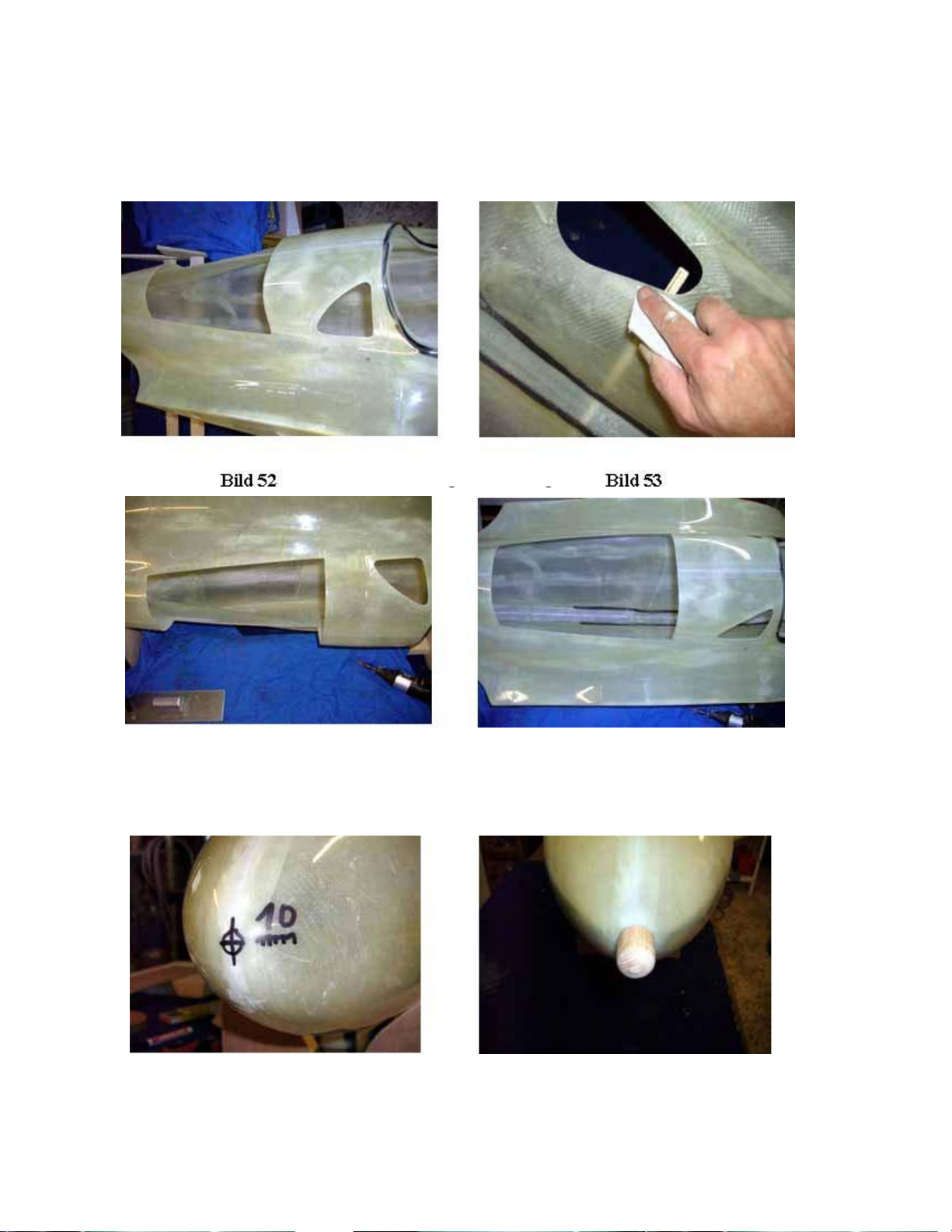

compromises regarding the stability of the airplane. In order to keep the assembly of the

components as straightforward as possible we deliver all GRP parts with a clear coat instead

of a colored gel coat. This way you have the opportunity to check all fits and glue-joints. The

wings are preassembled except for the rudder assembly, the slats and servo-trays.

Our Me-163 comes with the original s-shaped airfoil design used by Mr. Alexander Lippisch.

The model aircraft possesses excellent slow-flight characteristics and does not tend to stall.

The function of the different control surfaces has to be maintained as described in this

manual as the airfoil design differs from other airplanes and kits. The ailerons serve as

ailerons and elevators in typical delta style. The inner control surfaces, called Flettner Flaps,

are to be set slightly up for takeoff and landing. The deflection should be at around 5 to 6mm

up. It is necessary to test the function of the Flettner Flaps in mid air in order to get a good

feeling for how they work and what they do and to learn at what speed to deploy the flaps

before your first landing approach with deployed Flettners. The airplane will climb in case it

is still too fast for Flettners but at the correct speed it will simply continue to fly straight and

you can initiate your approach. The rate of glide is excellent and the airplane will fly stable

and true with deployed Flettner flaps, even at slower speeds. Without deployed Flettner flaps

and in zero or low wind conditions it will be difficult to maintain a controlled approach.

Since the Me-163 has a wide speed range it is up to the pilot to get familiar with the flaps and

what they do at what speed. Again, do so before you come in for your first landing.

Should you experience any problems during the build or flight of your Me163, please

feel free to contact Vogelsang Aeroscale. They will, together with us, assist you.