TDE MACNO DSC Series User manual

BRUSHLESS DRIVES

DSC SERIES

User manual

TDE MACNO S.p.A Viale Dell’Oreficeria, 41 – 36100 Vicenza, Italy tel. ++39-0444-565444

User manual 1-1 DSC/DSCT Series

CONTENTS

1. GENERAL SAFETY INFORMATION...................................................................................................... 1-1

1.1. WARNINGS...................................................................................................................................... 1-2

2. CHARACTERISTICS .............................................................................................................................. 2-1

2.1. TECHNICAL DATA FOR DSC/DSCT DRIVES .............................................................................. 2-2

2.1.1. REGULATING MAGNITUDES ...................................................................................................... 2-2

2.1.2. POWER CIRCUIT (DSC)............................................................................................................... 2-2

2.1.3. POWER CIRCUIT RATINGS......................................................................................................... 2-3

3. FIRST INSTALLATION INSTRUCTIONS...............................................................................................3-1

3.1. GENERAL SCHEME OF THE DSC DRIVE CONNECTIONS (3 X 220VAC) .................................. 3-1

3.2. GENERAL SCHEME OF DSCT DRIVE CONNECTIONS (3 X 380 VAC). ...................................... 3-2

3.3. DEFAULT CONNECTIONS.............................................................................................................. 3-3

3.4. KEYPAD ........................................................................................................................................... 3-4

3.4.1. DESCRIPTION OF KEYBOARD OPERATION............................................................................. 3-4

3.4.2. IDLE STATE .................................................................................................................................. 3-4

3.4.3. SETTING AND READING OF PARAMETERS AND CONNECTIONS......................................... 3-4

3.4.4. DISPLAY OF INTERNAL MAGNITUDES...................................................................................... 3-4

3.4.5. DISPLAY OF I/O AND ALARMS ................................................................................................... 3-4

3.5. SAVING AND RESETTING PARAMETERS.................................................................................... 3-5

3.6. DESCRIPTION OF FONDAMENTAL DATA .................................................................................... 3-5

3.6.1. PARAMETERS .............................................................................................................................. 3-5

3.6.2. CONNECTIONS ............................................................................................................................ 3-5

3.7. GETTING STARTED........................................................................................................................ 3-6

3.8. MALFUNCTIONING WITH ALARM SIGNAL : DIAGNOSIS ........................................................... 3-6

4. ANTI-INTERFERENCE MEASURES...................................................................................................... 4-1

5. DESCRIPTION OF THE SIGNALS ON THE CONNECTORS ............................................................... 5-1

5.1. CONNECTING CABLE TO RESOLVER (CONNECTOR J4) ..................................................... 5-1

5.2. SERIAL LINE CONNECTOR (CONNECTOR J5) ............................................................................ 5-1

5.3. SIGNALS ON THE CONNECTORS................................................................................................. 5-2

5.3.1. LOGIC SIGNALS (CONNECTOR J1) ........................................................................................... 5-2

5.3.2. ANALOG SIGNALS (CONNECTOR J2)........................................................................................ 5-2

5.3.3. FREQUENCY INPUT CONNECTOR (CONNECTOR J6) ............................................................ 5-2

5.4. SIGNALS ENCODER EMULATION (CONNECTOR J3) ................................................................ 5-3

6. POWER: CONNECTIONS AND SIZING.................................................................................................6-1

6.1. POWER OF DSC DRIVE ................................................................................................................. 6-1

6.1.1. TRANSFORMER SIZING .............................................................................................................. 6-1

6.2. POWER OF DSCT DRIVE ............................................................................................................... 6-1

6.2.1. CALCULATION OF THE REACTANCE OR OF THE AUTOTRANSFORMER ............................ 6-1

6.2.2. SIZING OF PROTECTIVE FUSES AND CABLES........................................................................ 6-2

6.3. AUXILIARY POWER SUPPLY (OPTIONAL) ................................................................................... 6-2

6.4. CONNECTION WITH SOFT-START CIRCUIT................................................................................ 6-3

7. CONFIGURATIONS ................................................................................................................................ 7-4

7.1. LOGIC INPUTS CONFIGURATION ................................................................................................. 7-4

7.2. LOGIC OUTPUTS CONFIGURATION............................................................................................. 7-5

7.3. ANALOGIC OUTPUT CONFIGURATION........................................................................................ 7-5

7.4. OUTPUT ENCODER SIMULATION CONFIGURATION ................................................................. 7-6

8. DIAGNOSTICS ........................................................................................................................................ 8-1

8.1. DISPLAYS ........................................................................................................................................ 8-1

8.2. EXCLUSION AND ALARMS ............................................................................................................ 8-1

User manual 1-2 DSC/DSCT Series

9. AVAILABLE DATA FROM KEYPAD...................................................................................................... 9-1

9.1. PARAMETERS ................................................................................................................................. 9-1

9.2. CONNECTIONS ............................................................................................................................... 9-2

9.3. MAGNITUDES WHICH MAY BE DISPLAYED ................................................................................ 9-3

10. SETTING AND CALIBRATION ......................................................................................................... 10-1

10.1. ADAPTATION WITH MOTOR .................................................................................................... 10-1

10.2. SETTING REFERENCES AND SPEED LIMITS ........................................................................ 10-1

10.3. SETTING MINIMUM SPEED, MAXIMUM SPEED AND SPEED RANGE SIGNAL LEVEL....... 10-1

10.4. SETTING OF THE PEAK CURRENT LIMIT VALUES AND CURRENT RANGE ...................... 10-2

10.5. CURRENT LOOP AUTO-TUNING COMMAND ......................................................................... 10-3

10.6. RESOLVER PHASE AUTO-TUNING COMMAND ..................................................................... 10-3

11. DESCRIPTION OF THE SPEED REGULATION .............................................................................. 11-1

11.1. EXPLANATION OF THE BLOCK-DIAGRAMS........................................................................... 11-1

11.2. BLOCK DIAGRAM OF THE REGULATION .............................................................................. 11-1

11.3. SPEED REFERENCE BLOCK ................................................................................................... 11-1

11.4. RAMP AND SPEED LIMITS BLOCK.......................................................................................... 11-2

11.4.1. STOP IN PLACE........................................................................................................................ 11-3

11.5. SPEED REGULATOR AND CURRENT LIMITS ........................................................................ 11-3

11.6. CURRENT LIMITS...................................................................................................................... 11-4

11.7. THERMAL MOTOR PROTECTION............................................................................................ 11-5

11.8. LOGIC SEQUENCES ................................................................................................................. 11-5

12. REPLACING AN SC DRIVE WITH A DSC (SCT WITH A DSCT).................................................... 12-6

13. POSITIONER ..................................................................................................................................... 13-1

13.1. USE OF THE BRUSHLESS MOTOR DRIVE AS POSITIONER................................................ 13-1

13.2. ZERO-POSITION SEARCH........................................................................................................ 13-2

13.3. POSSIBLE USES ....................................................................................................................... 13-4

13.3.1. TWO SPEEDS AND TWO POSITIONS .................................................................................... 13-4

13.3.2. TWO ABSOLUTE POSITIONS WITH LIMIT SWITCH.............................................................. 13-5

13.3.3. SPEED, POSITION WITH INITIAL ABSOLUTE NUMBER....................................................... 13-6

13.4. POSITIONER IMPROVEMENTS ............................................................................................... 13-6

14. FREQUENCY INPUT(OPTIONAL).................................................................................................... 14-1

14.1. END OF MOVEMENT LOGIC OUTPUT .................................................................................... 14-2

14.2. IMPROVEMENTS FOR THE FREQUENCY REFERENCE INPUT ........................................... 14-2

15. DIMENSIONS AND SIZES ................................................................................................................ 15-3

15.1. DIMENSIONS AND SIZES OF DSC DRIVES ............................................................................ 15-3

15.2. DIMENSIONS AND SIZES OF DSCT DRIVES.......................................................................... 15-4

User Manual 1-1 DSC/DSCT series

1. GENERAL SAFETY INFORMATION

All the drives manufactured by TDE MACNO S.p.A. of Vicenza which belong to the DSC and DSCT series

comply with the Low Tension Directive CEE 73/23, as amended by the Directive CEE 93/68 and the

corresponding law of the country of destination.

In their manufacture parts and articles have been applied which comply with the harmonising legislation

EN 60204-1.

Important safety norms

In the design, installation, starting up, maintenance and checking of the drives the safety and accident

prevention norms must be observed with regard to their specific use.

•Among others the following norms in particular must be observed :

∗CEI 64.8

Electrical plant using a nominal voltage not greater than 1000V AC - 1500V DC

∗CEI EN 60204-1

Machine safety; Electrical equipment in machinery

∗CEI EN 60146-1-1

∗LEGISLATIVE DECREE 626/94

Accident prevention legislation

User Manual 1-2 DSC/DSCT series

1.1. WARNINGS

•Carefully read the manual before installing and using the equipment.

•The manufacturer declines any liability for any improper use of the equipment different from

that set out in the manual.

•No alteration or operation not prescribed by the manual is permitted except with the express

authorisation of the manufacturer, and must by carried out by qualified personnel. Failure to

observe this rule will mean that the manufacturer shall decline any liability for any possible

consequences and the guarantee will cease to have effect.

•The setting up and installation may only be carried out by qualified personnel who are

responsible for observance of the safety rules imposed by the laws in force.

•If the drive is installed without the proper E.M.C. filter and plugged in low voltage public mains

supply, it can cause radio frequency noises or interferences.

•In the specific case for which the equipment is being used it is necessary to take into account

the safety regulations for the prevention of accidents. The installation, cabling and opening of

the equipment and the drive must all be done with the voltage supply cut off.

•Equipment and drives must be installed in a contact proof case with IP grade protection which

complies with the norms.

•Position the equipment in such a way that access for maintenance operations is easy and that

there is no danger of interference with moving parts.

•Ensure that there is always sufficient ventilation to discharge what is lost from the drive.

•Do not use extinguishers containing water when there is fire in proximity to the equipment.

•Avoid at all times the penetration of water and other fluids into the equipment.

•Any work carried out within the equipment must be done with the supply of voltage cut off. As

there are condensers wait at least 8 minutes before accessing the inside of equipment to work

on it.

User Manual 2-1 DSC/DSCT series

2. CHARACTERISTICS

Sinusoidal Brushless motors DSC and DSCT drives are realized with a high performance IGBT power

module structure, which can operate to high frequency with low losses. Some of the principal characteristics

are the following:

•Speed and torque digital regulation. Drive parameters can be set by on-board keypad or serial line. The

3-key keypad allow quick data setting and displaying (4 1/2 digits).

•Speed and position feedback from motor resolver; resolver phase auto-tuning.

•Analog speed, torque and external current limit references from connector (+/-10V), or digital references

from memory (set by keypad or by serial line).

•Digital inputs are isolated from regulation; connection with optocouplers.

•Automatic current loop parameters adaptation to the motor. The band of the current regulation is 2kHz.

•Possibility to connect directly to the mains by transformer or autotransformer.

•Regulation circuits can be supplied directly from the power connections or from optional auxiliary supply

(to keep data in case of mains supply power fault).

•On-board clamping circuit, except the resistor connected externally.

•Cooling fan, if necessary, incorporated and supplied from the circuit control supplier.

•Parameters saving on EEPROM.

•Easy diagnostic of the drive “ state” on the on-boarddisplay or the serial line.

•Fault protections displayed on the on-board keypad or on the serial line: MIN. and MAX. voltage, motor

overheating, radiator over-temperature, resolver fault, power alarm (IGBT in protective block), etc.

•Simulated encoder output, tho channels and zero signal, number of pulses per revolution selectable by

keypad.

•Single overcurrent protection on every power element.

•Transitory overloading (T<=100msec. from stop and T=2sec. With f>2.5Hz) equal two times the nominal

current, with automatic reentry to nominal current.

•Frequency input by standard encoder TTL or by frequency & up/down directional signals.

•Possibility to use drive as point-to-point positioner.

•Sample time for logic inputs and ouputs : approx. 10ms

•Sample time for analog output : approx. 2ms

User Manual 2-2 DSC/DSCT series

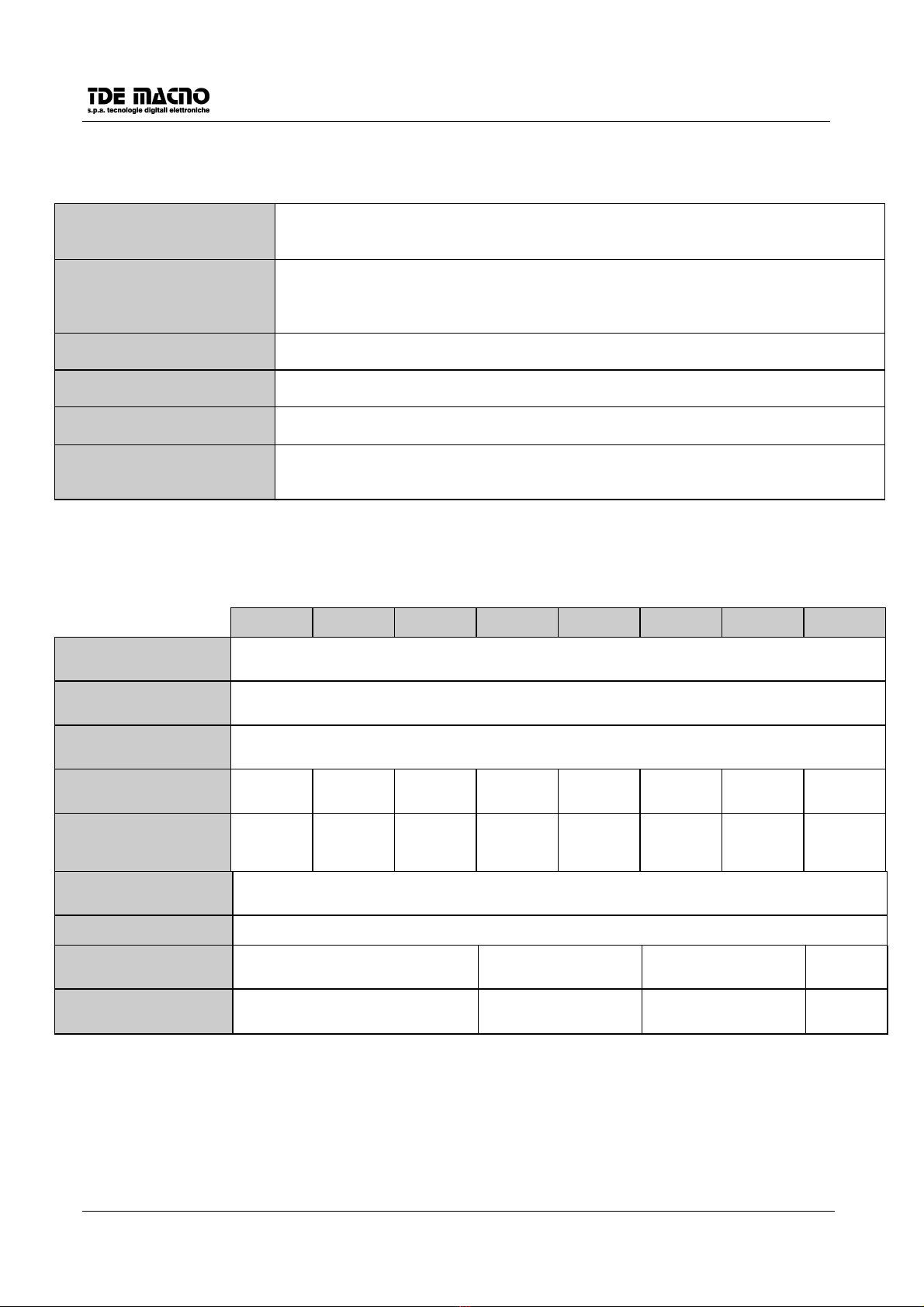

2.1. TECHNICAL DATA FOR DSC/DSCT DRIVES

2.1.1. REGULATING MAGNITUDES

Analog inputs Range ± 10 V for speed and torque reference

0 - 10V for current limit

Input impedance >20KΩ

Digital inputs Opto-isolated, with separate supply

Input impedance 1.5KΩwith series threshold 12V (≅8mA)

level L : < 6V

level H : > 18V

Digital outputs Opto-isolated, transistor NPN with open collector and emitter

Drive capacity = 30 Ma

Voltage reference outputs +10V ± 2% Drive capacity 10 mA

Analog programmable output

(A.P.O.)

Range ±10 V with 100 Ωimpedance

Drive capacity 2 mA

Analog outputs:

tachometer (TG.O)

Current (IOUT)

±10 V with 100 Ωimpedance

Drive capacity 2 mA

2.1.2. POWER CIRCUIT (DSC)

DSC-03N DSC-06N DSC-10N DSC-15N DSC-20N DSC-30N DSC-40N DSC-60N

INPUT VOLTAGE 3 x (140 - 240 ) Veff. 45-65 Hz

MAX OUTPUT VOLTAGE

(Veff)

3 x Vi x 0.9 (Vi = input voltage)

OUTPUT FREQUENCY 0 - 400 Hz

NOMINAL RMS CURRENT

( A ) 3.5 6 10 15 20 30 40 60

MAX RMS CURRENT ( A )

100 ms for f=0

2.5 s for f>2.5 Hz

7 122030406080120

CLAMPING VOLTAGE 380 V c.c.

OVERVOLTAGE LEVEL

( V )

410

MAX PEAK CURRENT

(t<0.3 sec.) ( A )

15 25 38 50

MINIMUM VALUE OF

RESISTIVE LOAD Ω(W)

27 (100W) 15 (200W) 10 (300W) 15 (200 W)||

15 (200 W)

User Manual 2-3 DSC/DSCT series

2.1.3. POWER CIRCUIT RATINGS

DSCT-03N DSCT-07N DSCT-15N DSCT-22N DSCT-28N DSCT-37N DSCT-47N

3-PHASE MAIN SUPPLY 3 x (340 ÷ 460 ) Veff. 45÷65 Hz

MAX OUT.3-PHASE

VOLTAGE

3 x Vi x 0.9 (Vi = voltage input)

OUTPUT FREQUENCY 0 ÷ 400 Hz

NOMINAL RMS CURRENT

(A ) 3.5 7 15 22 28 37 47

MAX RMS CURRENT

( A )

100 ms per f=0

2.5 s per f>2.5 Hz

7 143044567494

CLAMPING VOLTAGE 720 V c.c.

OVERVOLTAGE LEVEL

(V)

800 Vcc

PEAK CLAMP CURRENT

A (t<0.3 sec.)

91824 36

MINIMUM VALUE OF

RESISTIVE LOAD ȍ(W)

82 (100W) 82 (100W)||

82 (100W)

≅40Ω200W

15 (300W) +

15 (300W)

≅30Ω600W

10 (300W) +

10 (300W)

≅20Ω600W

User manual 3-1 DSC/DSCT Series

3. FIRST INSTALLATION INSTRUCTIONS

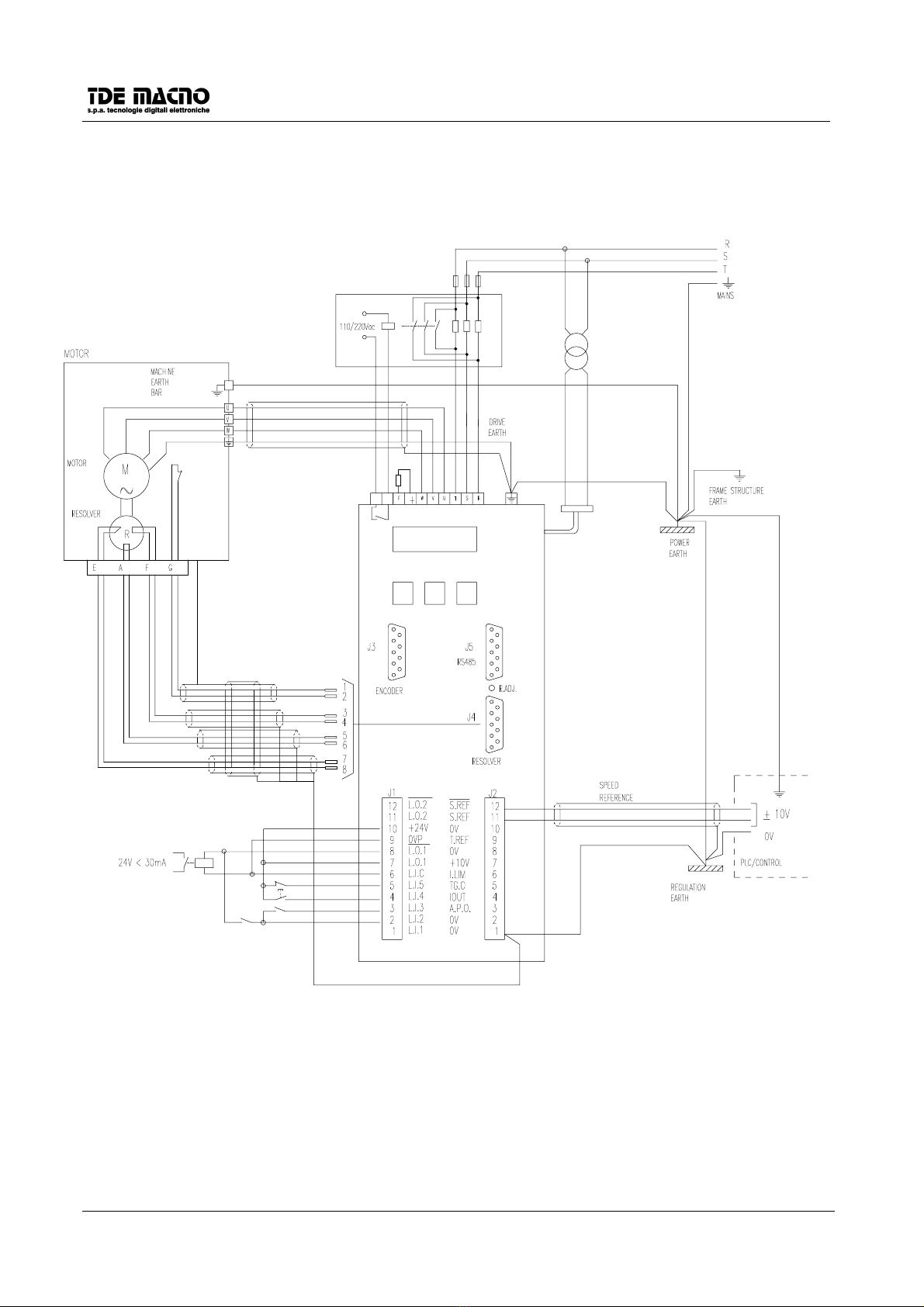

3.1. GENERAL SCHEME OF THE DSC DRIVE CONNECTIONS (3 X 220VAC)

+

F

Tr

RF

F

AUX. POWER

EXTERNAL ENABLE

RESET

REF. ENABLE

ON-LINE

SW SUPPLY WITH

380V/220V

30VA MAX.

TRANSFORMER

CONNECTOR FOR AUX.

POWER SUPPLY

(OPTION)

User manual 3-2 DSC/DSCT Series

3.2. GENERAL SCHEME OF DSCT DRIVE CONNECTIONS (3 X 380 VAC).

CONNECTOR FOR

AUX.POWER SUPPLY

AUX.POWER

EXTERNAL ENABLE

RESET

REFERENCE ENABLE

ON-LINE

K

SUPPLY WITH

380V/220V

30VA MAX.

TRANSFORMER

RSS

F

IC IC

RF

INTERNAL RELAY, ONLY FOR

SIZES 37 AND 47A

K2

K1

External switch-on current limitation

device only necessary for sizes 37A

and 47A

SW

(OPTION)

User manual 3-3 DSC/DSCT Series

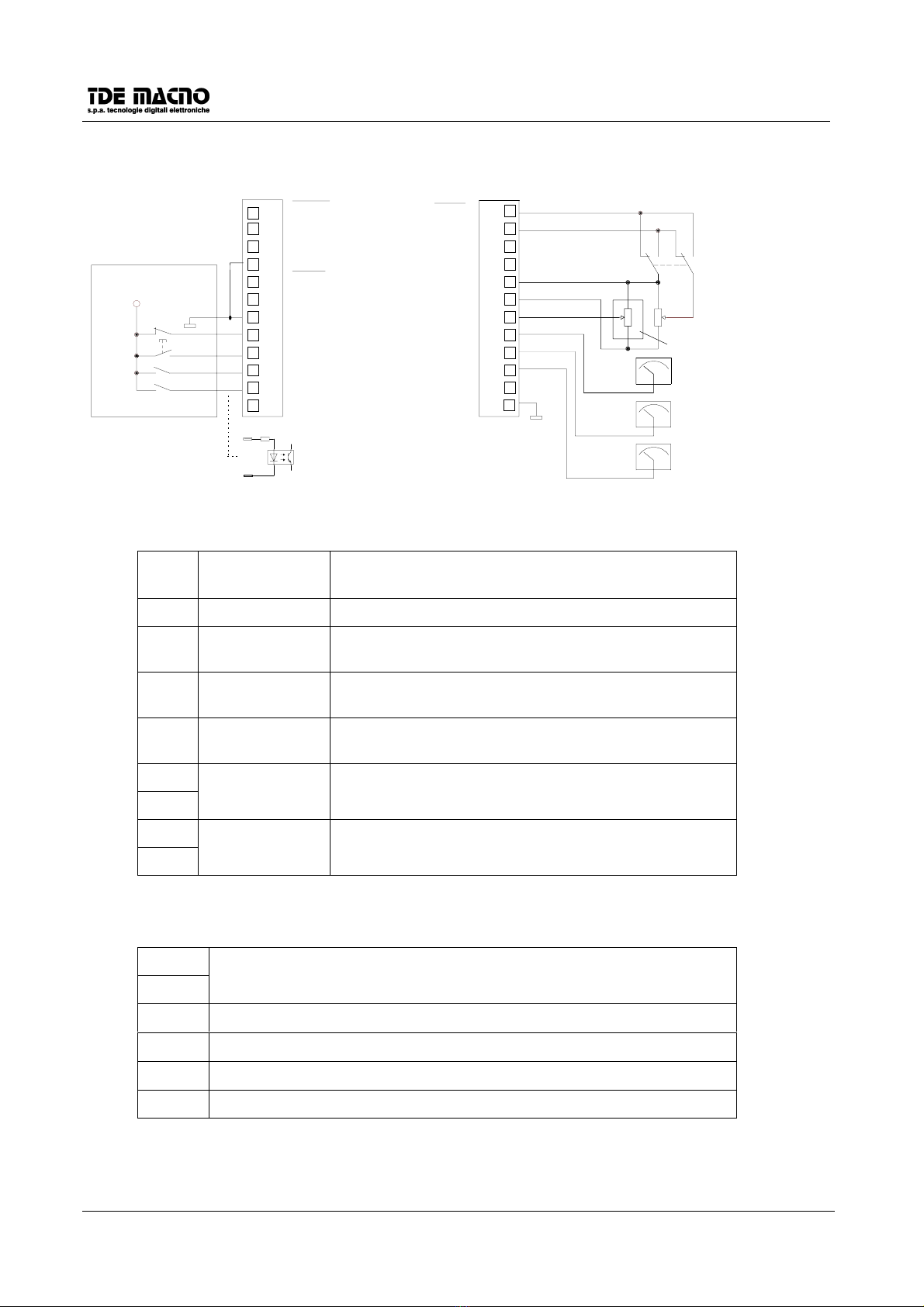

3.3. DEFAULT CONNECTIONS

J1

10

11

12

2

3

4

5

6

7

8

9

1

L.O.2

L.O.2

+24V

0VP

L.O.1

L.O.1

L.I.C

L.I.5

L.I.4

L.I.3

L.I.2

L.I.1

+24V

0

PLC o CNC

0V

0V

0V

A.P.O.

IOUT

TG.O

I.LIM

+10V

T.REF

S.REF

S.REF

0V

J2

0V

(∗

∗∗

∗)

(∗) If used it will be enabled with c31

10K

10

11

12

2

3

4

5

6

7

8

9

1

CW/CCW

1-2-3-4-5

6

Meaning and programming of digital I/O defaults (connector J1):

L.I.1 Torque enable Enables the drive to work with external torque reference

signal T.REF(±10V)

L.I.2 Run Enables the power to the motor.

L.I.3 Reference 1

enable

Enables the speed reference present in S.REF and

S.REF/.

L.I.4 Alarm reset Resets the alarms if the alarm causes have been

removed (minimum time of transition T=100mS).

L.I.5 External enable If this input is in the LOW state, the drive is in alarm A8,

and is not ready. (External emergency)

L.O.1

L.O.1/

Drive ready Active when the drive is ready to run (no alarm

presence).

L.O.2

L.O.2/

Drive running Active when the drive is running.

Meaning of the analog signals (connector J2):

S.REF

S.REF/

Differential speed reference input ±10V

I.LIM Maximum current limit 0÷+10V

TG.O Actual speed output -10V ÷+10V

IOUT Torque current request output -10V ÷+10V

A.P.O. configurable analogic output.

Note: L.I.1÷

÷÷

÷L.I.5 are comanded by signals between the range of 18V÷

÷÷

÷27V.

User manual 3-4 DSC/DSCT Series

3.4. KEYPAD

3.4.1. DESCRIPTION OF KEYBOARD OPERATION

The keyboard has three keys: 'S' (selection), '+' (increase) and '-' (decrease), and it has a display with four

and a half digits plus the decimal points and the minus sign '-'.

3.4.2. IDLE STATE

When the equipment is switched on, the keyboard displays "Stop"; if there are any alarms, the keyboard

flashes, displaying "Stop" intermittently. When the drive is working, if no special magnitude to be displayed

has been set (see 'c13'), magnitude d5 is displayed. The keyboard automatically returns to the rest state ten

seconds after the last operation, expecting that it doesn,t display an internal quantity or a digital state.

3.4.3. SETTING AND READING OF PARAMETERS AND CONNECTIONS

Press push-button 'S' and the keyboard will display the last parameter or magnitude selected, then, by using

the '+' and ' -' keys, scroll the menu up and down until you find the address of the parameter (P) or of the

connection (c) to be read and, if necessary, corrected. Next to the number of the parameter or connection

the letter 'r' appears if the parameter is reserved, 't' if it is TDE-reserved and 'n' if it is a parameter that can

be modified only when the drive is not running; all the reserved parameters are 'n'-type parameters which

may be modified only when the drive is not running (off-line).

On pressing key 'S', the parameter value is displayed and can therefore be read; press 'S' again to go back

to the menu and the system also automatically goes back to the menu 10 seconds after the beginning of the

display; to correct the parameter or connection value, when this is displayed, press the '-' and '+' keys at the

same time; the decimal point of the first figure at the left then starts to flash, which means that, from that

moment on, pressing the '-' and '+' keys changes the value set. The value is changed only from stop if the

parameter is OFFLINE or only after the access code, P50, has been set, if the parameter is reserved, or P80

for TDE-reserved parameters.

The TDE-reserved parameters and connections are not listed, unless access code P80 is set.

Once the value has been corrected, press 'S' to go back to the menu confirming the modified parameter or

connection; to exit without confirming, just wait for ten seconds and then the keyboard will display the

address discarding the changed value; if the value is not touched, just press 'S' to exit (the previous value

will be confirmed). Once in the menu, the keyboard automatically returns to the rest state.

3.4.4. DISPLAY OF INTERNAL MAGNITUDES

Move from the menu with the '+' or '-' keys until the address of the magnitude to be displayed 'dxx' appears;

on pressing 'S' the address disappears and the value is displayed.

Return to the menu from this state by just pressing 'S'; returning from the menu to the rest state is automatic

after 10 seconds.

3.4.5. DISPLAY OF I/O AND ALARMS

From the menu use the '+' and '-' keys to move to the address required for the digital inputs (i), the outputs

(o) and the alarms (A); the box to the right shows this and the state: 'H' = active (high), 'L' = not active (low).

To return to the rest state from this state, just press 'S'.

ATTENTION: For the complete list of all the magnitudes given by the keypad, refer to the chapter 9 on the

user manual.

User manual 3-5 DSC/DSCT Series

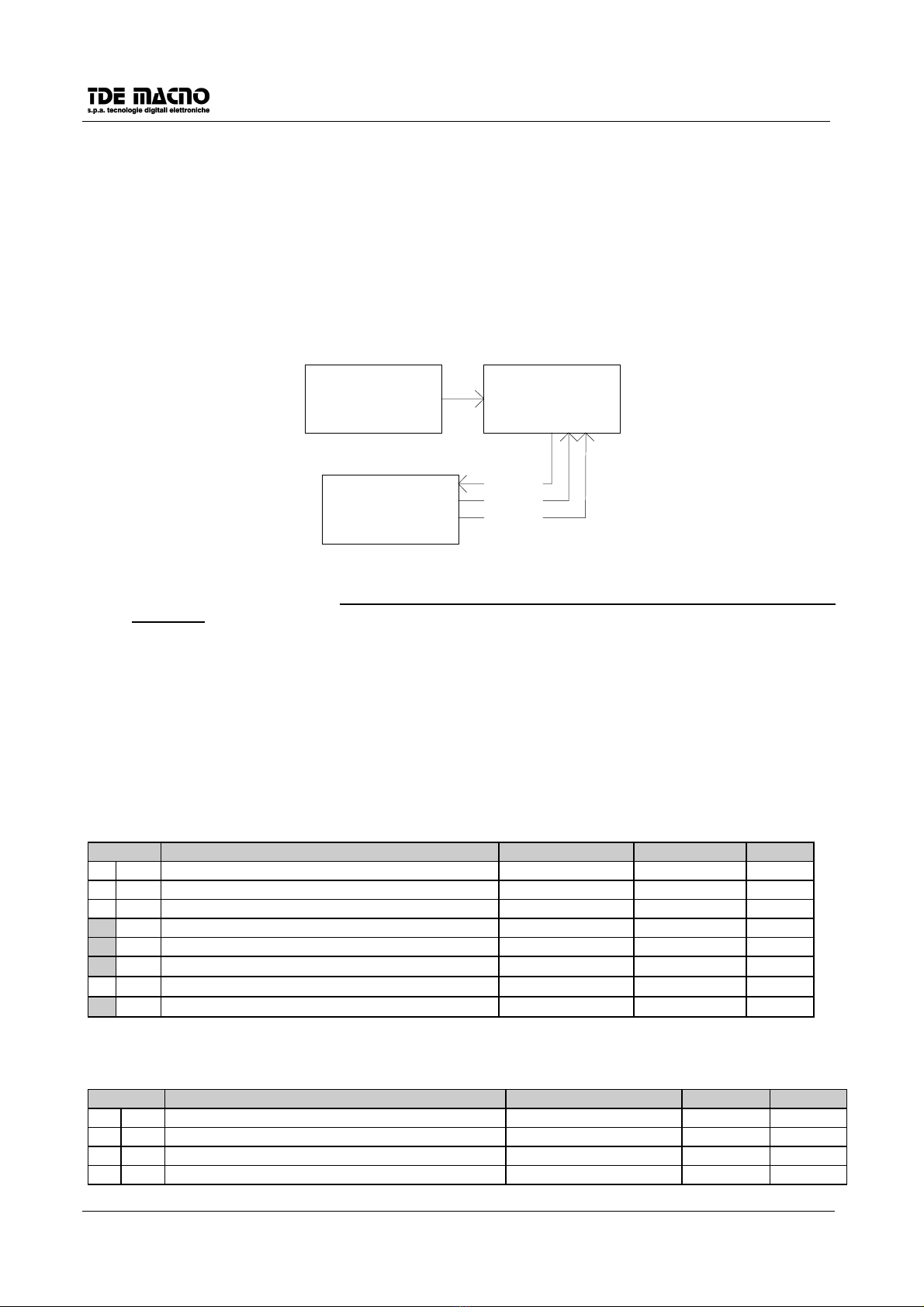

3.5. SAVING AND RESETTING PARAMETERS

The drive has a permanent memory (EEPROM) where parameters are stored. When the drive is switched

on, the drive transfers the parameters from the user permanent memory (EEPROM) to the working memory

(RAM). All the parameter changes are stored in the working memory (RAM); to save these changes in the

user permanent memory (EEPROM), activate the connection (c43=1).

If there is an EEPROM alarm (A2=H), it means that permanent values can not be read from the EEPROM; it

is necessary to reset the system: reset the default parameters (c41=1), and then save them in the user

permanent EEPROM memory (c43=1), overwriting the wrong parameters.

To return to the initial parameters in the permanent memory (EEPROM) after the changes in the working

memory (RAM) have been made, without switching off and on again, just activate connection c42 (c42=1).

These procedures are explained below :

system memory with

default parameters

EPROM

working parameters

memory

RAM

C41

User parameters

permanent memory

EEPROM

C43

C42

Power on

N.B. As the default parameters are standard parameters which are certainly different from the customised

parameters, it is important to copy the parameters of the user permanent memory carefully after the

installation for each drive, so that, if necessary, they can be copied in a spare drive, or if the memory

is resetted with the default parameters.

3.6. DESCRIPTION OF FONDAMENTAL DATA

In the following are described the parameters, the connections and the minimum displaying magnitudes

necessary for the initial function of the drive. To have the first general vision of all the data prepared for the

customer it’s necessary to read the paragraph 9 of the manual user.

3.6.1. PARAMETERS

(Note: n= off-line, r=reserved customer, t= TDE customer)

SECT. DESCRIPTION FIELD DEFAULT Notes

P 1 JOG 1 speed ±100.0% 0.0%

P 2 JOG 2 speed ±100.0% 0.0%

P 3 JOG 3 speed ±100.0% 0.0%

P 23 Speed loop proportional gain 0.5-100.0 4.0

P 24 Speed loop lead constant time 4.0-150.0 ms 40.0 ms

P50 Reserved parameter access key 0÷9999 n

P 51 Drive identification number for the serial line 1÷255 255 r

P52 Setting maximum motor speed (rpm/1') 375÷19000 2500 r

3.6.2. CONNECTIONS

(Note: n = off-line , r = reserved to the customer, t = TDE-reserved)

CON. DESCRIPTION RANGE DEFAULT Notes

c 26 Ramp inclusion 0(excluded) 1(included) 0

c 41 Reset default values 0(disabled) 1(reset) 0 n

c 42 Reset EEPROM values 0(disabled) 1(reset) 0 n

c 43 EEPROM writing 0(disabled) 1(reset) 0 n

User manual 3-6 DSC/DSCT Series

3.7. GETTING STARTED

1. Verify that the connections are well done, that the terminals are well tighten and that the correct resolver

cable is used (see par 5.1).

2. Disconnect the power terminals of the motor.

3. Supply the drive and after a laps of time it will appear at the display the stable term “ stop” if there are no

alarms, light blinks if there are.

4. Configure the drive parameters: inputs (c1 - c5), outputs(c7-c8), and the motor parameters, motor

current (P56), motor poles (P53), resolver poles (P54), ecc.

5. Set at a low value (5%) the internal limits, P35,P36, and set to zero the velocity reference.

6. Reconnect the power terminals of the motor and start running (L.I.2).

7. If no alarm appears, on the display will appear the motors speed in RPM.

8. The motor must be in stillstand the reference is digital or moving very slowly if analog.

9. Setup the limits P35 P36 and calibrate if necessary the speed offset with the P4 parameter.

10. Give some reference and verify the correct working, in particular for a correct speed and eventually tune

the controller parameters (P23, P24) for a better dynamical response of the drive.

11. Execute motor cycles and see that everything is correct.

12. Save the parameters in EEPROM.

ADVISING: If during the operativity just explained, in particular at points 8 and 10, the motor goes over

cycles or it doesn’t move or it moves in kicking way, verify the correct execution of the electric cables.

The drive is already tuned to the motor specified at the ordering.

3.8. MALFUNCTIONING WITH ALARM SIGNAL : DIAGNOSIS

SAFETY ACTIVE DESCRIPTION REMEDIES

A1 Internal supply

error

The internal voltages are

incorrect

Check the +24V in the pin J1-9 and J1-10

A2

RAM , EEPROM

alarm

The drive reads wrong

parameter values

If the problem remains after turning on/off the drive, it

is necessary to make the C41 configuration

(reloading default values) or C42 (reloading EEPROM

values) and than use C43 (EEPROM writing). See

par. 3.5

A3 Power alarm

The output current from the

drive has reached such

levels that the saturation

control circuit of the

I.G.B.T. has intervened;

this may be caused by an

overcurrent due to

dispersion in the cables or

in the motor or to a short

circuit between the drive

output phases. Or it may be

due to a breakdown in the

regulation.

Check the connection cables particularly on the motor

side of the terminal block to remove any dispersion or

short-circuiting; check the insulation of the motor

itself, doing a dielectric rigidity test, and if necessary

replace it.

Check that the drive power circuit is working by

making it run after disconnecting the motor; if the

safety device intervenes the power circuit is

damaged.

If the safety device only intervenes during working it

could be a matter of regulation (replace it along with

the current transducers) or vibrations causing voltage

transients.

A4 Radiator thermal

switch alarm

The radiator temperature

sensor has switched on

because the radiator

temperature is too high.

Check the drive cooling circuit ; the ventilator, its feed

and the slits and filters for the entry of air into the

cabinet ; if necessary replace them or clean them

and ensure that the ambient temperature (near to the

drive) is within the permitted limits for the technical

characteristics.

If everything is in order and the alarm continues even

when the drive is cold check the connecting wires to

the thermal switch.

User manual 3-7 DSC/DSCT Series

SAFETY ACTIVE DESCRIPTION REMEDIES

A5 Motor thermal

switch alarm

The motor temperature

sensor has switched on

because of excessive coil

temperature.

Check the motor cooling circuit is complete ; the

ventilator, its feed, the slits and filters for the entry of

air, and if necessary replace or clean them, and also

check that the ambient temperature (near to the

motor) is within the permitted limits for the technical

characteristics.

If everything is in order and the alarm signal is still on

even when the motor is cold, check the connector

wires of the thermal probe and of every auxiliary

devices.

If it’s used a motor with thermal bimetallic protection, if this is

measured between pins 1 and 2 of J4 it must be closed. If it’s used

a motor with thermal protection like PTC, from pins 1 and 2 of J4 it

must be measured it’s nominal value at the corrisponding ambient

temperature.

A6 Motor in thermal

overload

The motor overload safety

electronic device has been

activated by excessive

current absorption for

prolonged period.

Check the motor load and consider if its reduction

may stop the intervention of the safety function.

Check the level of the setting thermal current, if

necessary correct it, and also check that the value of

the thermal constant is sufficiently long.

Check the power of the motor being adequate to the

load and if necessary increase it.

A7 Resolver failure Resolver failure indicates

that the drive does not find

its proper resolver

connection

Check the resolver connections and that all

connections have been made according to the

connection scheme (see motor user’s manual and

connection scheme).

Check the resolver shield and grounds being

connected properly (in particular the resolver shield

must be wired to pin 1 or 2 of J6, and then the 0V

must be grounded).

A8

Intervention of

the external

alarm

The external enable signal

is no more present, and

the drive has not the

consent to work

The external safety has removed the enable signal to

the drive: give it back and reset.

The continuity of the connection has been lost; check

and remove the fault.

A9 Overspeed The drive indicates that

motor speed is above the

max. allowed. (P52)

Check the parameters that change the motor

dynamics (P23, P24, P25).

A10 Minimum voltage

in the DC power

circuit

The voltage of the

intermediate circuit of the

drive is below the

minimum range.

The safety functions is

tripped when the input

voltage drops below the

permitted value

Undervoltage may occur when the main transformer

power is not sufficient to support the loads, or in case

that there is not the correct 220 AC three phase

voltage (for instance one phase is not powered).

Check the voltage in RST .

A11 Overvoltage of

the DC power

circuit

The voltage of the

intermediate voltage circuit

is strongly increased due

to excessive regenerative

energy coming from the

motor, e.g. in slow down

phase, and the limit of

overtension is exceeded

This alarm can happen if the motor is often breaking

in his working cycle. Even overvoltage on the mains

side can lead to the intervention of this safety function.

If the drive has a clamping circuit check that the value

of the resistor is not too high to absorb the peak

power.

Check, if the resistor is not heating up, its continuity,

the connections and functionality of the circuit itself.

User manual 3-8 DSC/DSCT Series

SAFETY ACTIVE DESCRIPTION REMEDIES

A12 Input

configuration

error

Two digital input were set

with the same function.

Check inputs configuration.

A13 pole setting error The drive has been set

with a wrong poles number

(P53, P54).

Check poles number.

A14 Mains

connections error

Motor phases U,V,W are

inverted.

Check the sequence of motor phases.

User manual 4-1 DSC/DSCT Series

4. ANTI-INTERFERENCE MEASURES

Electrical and electronic equipment can interfere each other through the mains connections or other metal

connections between each other. In order to minimise or eliminate this reciprocal interference it is necessary

the drive being correctly installed in conjunction with anti-interference devices (if required).

The following advice regards a mains power supply which is not disturbed. If interference exists other

measures must be taken to reduce the interference itself.

In these latter cases giving general advice is not possible and if the anti-interference measures do not lead

the desired results we would kindly ask you please to contact TDE MACNO.

•Ensure that all the equipment in the cabinet is well connected to the ground bar using short cables with

starconnections. In particular , it is important that any control equipment connected to the drive, e.g. PLC,

is grounded by using short wires.

•The drive must be fixed with screws and washers to ensure a good electrical connection between the

external container and the metallic support, connected to ground, and to the switchboard. If necessary

remove the paint to ensure a good contact.

•For the motor connection use only shielded or armoured cable and connect the shielding to ground both

at the drive end and at the motor end. If it is not possible to use shielded cable the motor cables should

be placed in a metal channel which is connected to ground.

•Keep the motor connection, drive and control connection cables separate from each other and at a

distance from each other.

•For the braking resistance cable connection use shielded cable connecting the shield to ground on both

sides, the drive side and the resistor side.

•Lay the control cables at a distance of at least 10 cm from any parallel power cables. In this case too it is

advisable to use a separate metal channel which is also connected to ground. If the control cables should

cross over the power cables maintain a cross-over angle of 90°.

•Ensure that any RC groups or flywheel diode for coils for the remote switches, relays and other

electromagnetic switches installed in the same cabinet as the drive are mounted directly onto the coil

connections themselves.

•Make all connections of control, measuring and regulation external systems with shielded cables.

•Cables which can radiate interference must be placed separately and distant from the drive control

cables.

If the drive operates in a particularly noise sensitive environment it is also necessary to take the following

measures to reduce the conducted and radiated interference:

•Use the DSC or DSCT drive with an external EMC filter (Shaffner, …).

•Take all necessary measures with regard to the cabinet thus to block radiated emissions, like grounding

all metal parts, the use of minimum hole openings in the external walls and the use of conducting gasket

User manual 5-1 DSC/DSCT Series

5. DESCRIPTION OF THE SIGNALS ON THE CONNECTORS

5.1. CONNECTING CABLE TO RESOLVER (CONNECTOR J4)

DB9 FEMALE TYPE CONNECTOR TO BE CONNECTED TO RESOLVER AS SHOWN IN THE FOLLOWING FIGURE

J4

DB9 FEMALE TYPE CONNECTOR MOTOR

CONNECTOR RESOLVER

TRANSF. RATIO

1: 0.5

1: 0.45

R1

R3

S1

REF

0REF

0COS

3

4

5

RESOLVER FEEDER OUTLET

(6,5 VOLT RMS - 7,8 KHz - MAX 20mA)

RESOLVER SIGNAL INPUT

RESOLVER SIGNAL INPUT

COS

0SIN

6

8

S3

S4

S2SIN

SP6

0SP6

7

1

2

MOTOR THERMAL SW ITCH

J2-10V

CABLE

CONNECTING

SWITCH

THERMAL

MOTOR

THEY MUST HAVE THE SAME FEATURES.

THE RESOLVER MUST BE OF THE SAME TYPE ALREADY USED, SEE TABLE, OR

RAP.TRAS. 0.5RESOLVER ARTUS ES. 26S19RX452b.F

CABLE : INTERCOND SPECIALFLEX H

fi

g

. 1

USED TAMAGAWA ES. TS2640N71E10

4x(2x0.25SK) COD. 2MB 24P 04R

RAP.TRAS. 0.5

PLUS EXTERNAL SHIELD.

THE SHIELD ON THE CONNECTOR SIDE J4 MUST BE CONNECTED TO

TERMINAL 1 OF CONNECTOR J2 AND FINALLY CONNECTED TO THE

THE CONNECTING CABLE MUST BE 4-BIGHTS PLAIED AND SHIELDED

ADJUSTING EARTH BAR AS SHOW IN PARAGRAPH 1.2.

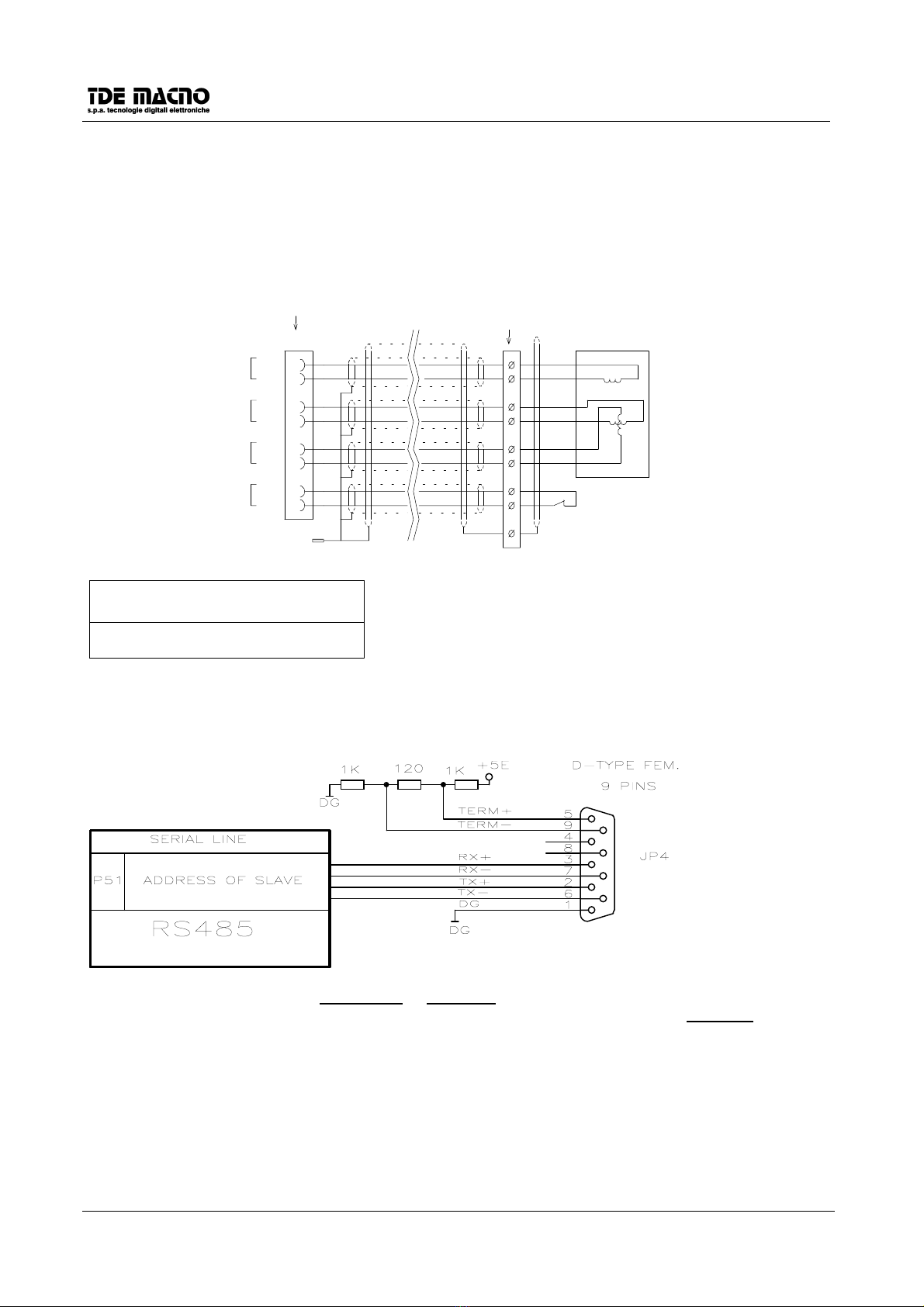

5.2. SERIAL LINE CONNECTOR (CONNECTOR J5)

The serial line communicates in half duplex on four wires: RX+ and RX- are receiving wires for the drive

while TX+ and TX- are transmitting wires. It can be done the connection with only two wires connecting

together RX+ and TX+, and RX- and TX- (each couple of wires must be twisted).

There is the possibility to ‘terminate’ the connection with 120Ωof impedance and polarizing the line

connecting the terminals 5 with 3 and 9 with 7.

It is available a simple PC supervisor software ( DOS or Windows 95) for the DSC/DSCT series drives.

User manual 5-2 DSC/DSCT Series

5.3. SIGNALS ON THE CONNECTORS

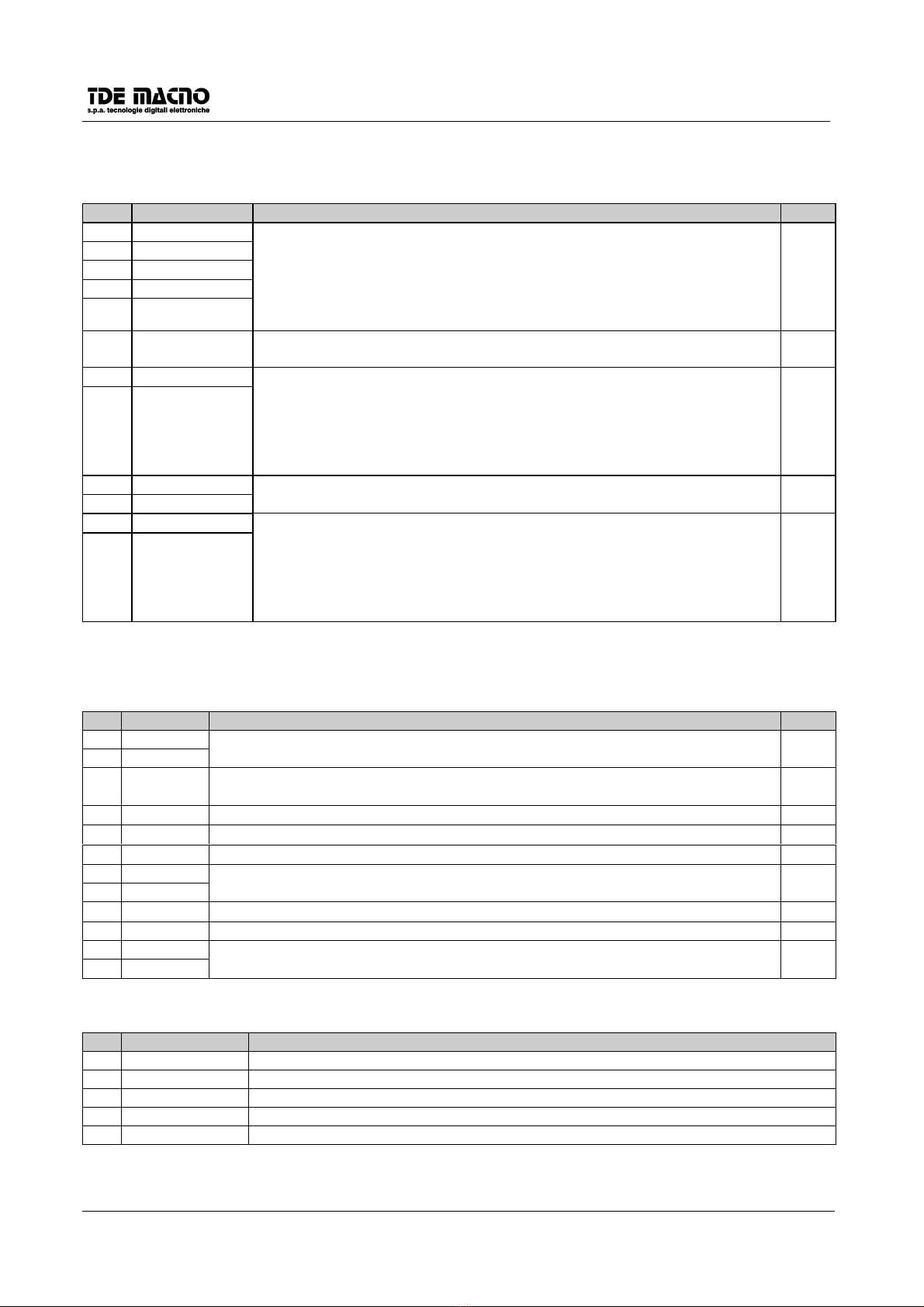

5.3.1. LOGIC SIGNALS (CONNECTOR J1)

PIN FUNCTION DESCRIPTION PAR.

1 L.I.1

2 L.I.2

3 L.I.3

4 L.I.4

5 L.I.5

Logic configurable inputs

ON = +24Vdc (>18Vcc) 10mA max.

OFF = 0Vcc (<6Vcc)

All inputs are opto-insulated from the internal regulation.

7.1

6 L.I.C Common connection of the logic inputs. Connect to the negative pole of the

inputs supply.

7.1

7 L.O.1

8/L.O.1

Logic configurable output

Transistor NPN with free collector ( L.O.1 ) and emitter ( /L.O.1 ), insulated

from the regulation and protected from overvoltage.

In CONDUCTION when output is ACTIVE : +24 Vdc 30 mA max;

7.2

90VP

10 +24V

Internal supply +24V, insulated from the regulation

11 L.O.2

12 /L.O.2

Logic configurable output

Transistor NPN with free collector ( L.O.1 ) and emitter ( /L.O.1 ), insulated

from the regulation and protected from overvoltage.

In CONDUCTION when output is ACTIVE : +24 Vdc 30 mA max;

7.2

5.3.2. ANALOG SIGNALS (CONNECTOR J2)

PIN FUNCTION PAR.

10V

20V

Regulation 0V

3 A.P.O. Analog configurable output: ±10V /2mA

Default configuration: CURRENT REQUEST(c13=11)

7.3

4 I.OUT Current request output signal ±10V <2mA

5TG.O

Motor speed analog output ±10V <2mA

6 I.LIM Analog input Max. Current Limit 0÷+10V <0.5mA

7+10V

80V

+10V / 10mA max.

Stabilized power supply

9T.REF

Analog input Torque Reference ±10V <0.5mA

10 0V 0V of the speed reference

11 S.REF Speed reference differential input.

12 /S.REF ±2.5V÷±10V <0.5mA

5.3.3. FREQUENCY INPUT CONNECTOR (CONNECTOR J6)

PIN FUNCTION

1 FA Channel /A input.

2 FA/ (F) Channel A/ input or frequency input.

3 FB Channel B input.

4 FA (UP/DOWN) Channel B/ input or UP/DOWN

5 0DG 0V of the frequency input

User manual 5-3 DSC/DSCT Series

5.4. SIGNALS ENCODER EMULATION (CONNECTOR J3)

The frequency of the signals depends on the motor revolutions, the number of resolver poles and the

selection made (see connection c10, c11 and c12) and their behaviour in time depends on the tachometer

signal and on c10 as shown in the figures below

MALE DB9 CONNECTOR

J3

d5>0 con c10=0

d5<0 con c10=1

d5>0 con c10=1

d5<0 con c10=0

1

2

3

4

5

6

7

8

9

/B

B

/A

A

VS (+)

/C

C

0VS

CHANNEL B

CHANNEL A

CHANNEL C

+VS

0VS

+VS

A

B0VS

+VS

+VS

0VS

C

0VS

+VS

0VS

*A

*B

+VS

0VS

*C

+VS

0VS

A

+VS

0VS

B

+VS

0VS

C

+VS

0VS

+VS

0VS

*A

*B

+VS

0VS

*C

5V≤VS≤30V

Fmax=500KHz for channel

The encoder simulated outputs are all driven by a “ LINE DRIVER” type ET7272.Their level in the standard

drive version is referred to +5V and than it is connect to the internal supply (TTL +5V). In option there is the

possibility to refer the signal level to an external supply whose value must be between +5V and +24V

(connection on terminals 5 and 9, (TTL 24V)).

For the immunity it is better to use a differential input (where the signal arrives) in order to avoid loops with

zero reference; to limit noise effects it is better to load this input (10mA max).

It is necessary to use a twisted shielded cabe to make a proper connection.

Attention, the external power supply zero is connected with the drive zero; (it is not

optoisolated).

Attention, for the encoder simulation with external supply (standard drive version)

you must not connect the terminal 5 (VS) because it could seriousuly demage the

drive.

This manual suits for next models

16

Table of contents