Tecumseh 5267-1900 User manual

OWNER'S MANUAL

32"- 5 H.P. RIDING MOWER

MODEL 5267-1900

WARRANTY

Lawn Mower Division Warranty Policy.

ONE YEAR LIMITED WARRANTY

For one (1) year from date of purchase by the first'consumer for residential use (thirty (30) days

commercial use), Lawn Mower Division warrants that it will replace free of charge, including

labor, any original part of anyLawn Mower Division product found to be defective by any

authorized Service Dealer orthe factory, except the battery which isWarranted for ninety (90) days

from date of purchase. 1

This warranty does not cover engines, transmissions,_trensaxles or differentials (these items are

covered by their manufacturer's own warranty). This warranty does not cover parts that have

faile d due to normal wear or parts that have failed subject to misuse or abuse. Transportation of

the unit or parts to and from an authorized Service Dealer or the factory isthe responsibility ofthe

owner.

Astep by step explanation as to what procedure should be followed for this Warranty is;

1. If a part becomes defective, contact t_te store where the unit was purchased for the name

and address of the authorized Service Dealer nearest to you.

2. If you cannot locate an authorized Service Dealer, write Service Department ofLawn Mower

Division, for the name and address of the authorized Service Dealer in your area.

3. Return the defective productoalong with proof ofpurchase tosuch authorized Service Dealer

for replacement of any defective part where covered by this warranty.

There is no other express warranty. Implied warranties, including those of merchantability and

fitness for a particular purpose are limited to one (1) year from date of purchase. Liability for

incidental or consequential damages are excluded.

Some states do not allow limitations on how long an implied warranty lasts, so the above

limitation may not apply to you. Some states do not allow the exclusion of incidental or

consequential damages, so the above exclusion may not apply to you. This warranty gives you

specific legal rights, and you may have other rights which vary from state to state.

Lawn Mower Division P.O. Box 377 Des Moines. Iowa 50302

'UNIT PARTS AND SERVICE

This manual contains instructions for safety, assembly and maintenance. Read this manual carefully and

completely so that you will know proper assembly, use and care of your unit. Also fill in and mail the warranty

registration card packed with the unit. For service other than covered in this manual, contact an authorized

service dealer. A nationwide parts and service organization has been established to provide locally available

parts and service. A list of authorized parts distributors has been included in this manual. When ordering

repair parts, always give the following information: 1. The Part Name; 2. The Part Number; 3. The

Quantity desired; 4. The Full (eight digit) Model Number of the unit. The model number will be found on a

plate attached to the unit.

Look for this symbol. It means -- ATTENTION! BECOME ALERT! A

HAZARD TO OPERATOR. BYSTANDERS, PROPERTY OR UNIT

MAY EXIST.

=art No. 62211 Rev. 3/82

LAWN MOWER DIVISION

P.O. BOX 377

DES MOINES. IOWA 50302 1182

Pwinlecl in U S A

It isimportant when using your Riding Mower that certain precautions betaken to

prevent injury or damage. Please read the following list of precautions before you

assemble or use yourRidingMower.

1. Know the controls and howto stop quickly. Read the

Owner's Manual. Wear safety glasses or eye shields when

assembling or operating unit.

2. Disengage ell attachment clutches, shift to neutral,

and set parking brake before attempting to start the en-

gine. Unless these steps are followed, the engine will not

start because of safety interlock or lockouts. When

starting your engine or mower equipped with a pull

starter, stand firm and make sure your feet are well away

from the blade(s).

3. When using vehicle with mower:

A. Do not operate this mower without either the

chute deflector or an entire grass catcher in place.

B. Mow only in daylight or good artificial light.

C. Never make a cutting height adjustment of

housing guide wheel while eKgine is running.

D. Shut engine off when removing grass catcher

and/or unclogging chute.

E. DO not operate mower when barefooted. Always

wear substantial footwear, preferably steel-toed

shoes. Do not wear loose fitting clothing that

could get caught in any moving parts. ,

F. Always keep clear of discharge chute or any

moving parts while engine is running.

4. Always place the blade control lever in a disengaged

position when not cutting grass, such as when crossing a

gravel driveway or roadway and when transporting the

mower.

5. Disengage power to attachments, stop engine,

remove ignition key. and set parking brake before leaving

operator position. AlWays dismount on the side away

from the discharge chute.

6. Handle gasoline with care; it is highly flammable.

A. Use only approved gasoline containers.

B. Never remove cap or add gasoline to a running or

hot engine or fill fuel tank indoors. Wipe up spilled

gasoline,

C. Check your fuel supply before each '_seallowing

space for expansion as the heat of the engine

and/or sun can cause gasline to expand.

D. Never store gasoline or equipment with gasoline

in the tank inside of a building where fumes may

reach an open flame or spark. Never stoze your

mower for prolonged periods {more than 15 days}

with gasoline in the tank, Store gasoline and your

mower in a locked, safe storage area secure from

children and others.

7. Allow engine to cool before storing in any enclosure.

8. To reduce fire hazard, keep engine free of grass,

leaves, or excessive grease.

9. Do not allow children to operate the mower. Never

allow adults to operate it without proper instructions.

10. Never attempt to carry passengers. TheiPsafsty, as

well as yours, may be in danger. Do not allow others,

including children and pets in the area while operating the

mower. Be especially watchful for children and passersby.

Place the blade control lever in • disengaged position and

stop the engine while others ere in the vicinity of:the

mower.

11. When using any attachments, never direct discharge

of material toward bystanders or allow anyone near the

vehicle while in operation.

12. Clear work area of objects which may be picked up

and discharged by the mower. {These include rocks,

stones, wires, cans, boards, branches, bones, and other

foreign objects).

13. Vehicles and attachments should be stopped and in-

spected for damage if vibration devolopes or after striking

a foreign object. Any damage should be repaired before

restarting and operating the equipment.

14. Stay alert for holes in terrain and other hidden

hazards. Exercise care when mowing around fixed objects

in order to prevent blade{s} from striking it. Never deliber-

ately run a power mower over any foreign object. Always

disengage blade control before attempting to remove the

mower from a hole or other obstruction.

15. Keep all nuts, bolts and screws tight to be sure equip-

ment is in safe working condition. Check blade mount

nuts or bolts for proper tightness at frequent intervals.

16. Keep vehicle and attachments in good opersting con-

dition and keep safety devices in place.

17. Disengage power to attachments, stop engine.

remove ignition k_y, set parking brake and remove spark

plug before working on any part of the mower or making

any adjustments.

18. Do not change engine governor settings or over-

speed engine.

1g. Check grass catcher bag frequently for wear end/or

deterioration. Replace with new bag for protection.

20. Do not stop or start suddenly, especially when going

uphill or downhill. Mow slowly when On slopes and mow

up and down the slope, never across it. On slopes, bevary

cautious and avoid sharp turns to prevent tipping or loss of

control. Exercise caution when changing direction on

slopes. Never operate your lawn mower in wet or slippery

grass where direction is unsure or at a speed which could

cause a skid. Avoid shifting gears on an incline whenever

possible, If necessary, be sure brake is epplled when

shifting.

21. Watch out for traffic when crossing or near

roadways.

22. Do not run the engine indoors. Open doors if engine

is run in garage. Exhaust fumes contain carbon monoxide

gas w_ich is odorless and a deadly poison.

23. Use care when pulling loads or using heavy equip-

ment.

A. Use'only approved drawbar hitch points.

B. Limit loads to those youcan safely control.

C. Do not turn sharply. Use care when backing.

D. Never shift gears to reverse your direction until

the mower comes to a complete stop. Do not

operate your mower with the parking brake :

engaged.

24. Take all possible precautions when leaving the

vehicle unattended, such as disengaging the power take-

off. lowering attachments, shifting into neutral, setting

the parking brake, stopping the engine, and removing the

key.

--2--

' Record the following information about your unit so that you will be able to provide it in case of loss or theft.

PURCHASE DATE: _MODEL NO.: 5267-1900 CODE NO.:

DEALER'S NAME & ADDRESS

CITY STATE TELEPHONE

WARNING

This unit is equipped with an internal combustion

engine and should not be used on or near any

unimproved forest-covered, brush-covered or

grass-covered land unless the engine's exhaust

system is equipped with a spark arrester meeting

app)icable state or local laws (if any). If a spark

arrester is used, it should be maintained in effective

working order by the operator.

CONTENTS OF SHIPPING CARTON

1 - 32 inch Riding Mower

1-Steering Wheel (with roll pin partially installed)

1-Engine Manual

TOOLS REQUIRED FOR ASSEMBLY

1 - '/2 inch Wrench (or adjustable wrench)

1 - 7/16 inch Wrench (or adjustable wrench)

1- Hammer (plastic or rawhide preferred)

DANGER

The operation of any powered equipment can result

in foreign objects being thrown into the eyes, which

can result in severe eye damage. Always wear safety

glasses or eye shields while assembling or operating

power equipment.

STEERING WHEEL ASSEMBLY

1. Position front wheels straight forward.

2. Push steering wheel (figure 1) onto steering shaft.

3. With one spoke of steering wheel straight 0p, align

cross holes in steering wheel wit_ holes in steering shaft.

4. Drive roll pin through holes with hammer.

ROLL PIN

I

4. Fill gas tank (located on engine) with clean, fresh,

regular grade automotive gasoline. Low-lead gasoline is an

acceptable substitute. Do not use Ethyl, high octane

gasoline or GasohoL Re certain container is clean and free

from rust or foreign particles. Never use gasoline that may be

stale from long periods of storage in the container.

DANGER A

Never fill the gas tank while the engine is running or

is hot. Immediately wipe off any spilled gasoline

before attempting to start engine. I

5. Check tire pressure. Correct tire pressure is 12 to 15

pounds in each tire. Inflate all tires equally.

6. Check all nuts and bolts to be sure none are loose.

7. Check all adjustments listed in Adjustment section of

this manual to make sure unit is properly adjusted.

8. Check to make sure that spark plug is tightened

securely into engine and spark plug wire is attached to spark

plug.

/

OIL FILL CAP

The operation of any powered outdoor equip-

ment can result in foreign objects being thrown

into the eyes, which Can result in severe eye

damage, Always wear safety glasses or eye

shields before beginning riding mower operation. We

recommend standard safety glasses or Wide Vision Safety

Mask for over spectacles.

Familiarize yourself with the equipment and with the

Operational Precautions.

STEERING WHEEL

TO SERVICE ENGINE

1. Place unit so engine is in a level position.

2. Fill engine crankcase with oil. See Engine Operation

and Maintenance Manual for proper procedure.

3. Replace oil fill cap (figure 2) and tighten securely.

ADANGER A

DO NOT operate this mower without either the

chute deflector or an entire grass catcher in place. A

riding mower can be dangerous to operate if

misused. On slopes, be very cautious and avoid

sharp turns to prevent tipping or loss of control.

Your new mower will give years of service if cared for

properly. Never run into trees, curbs, etc. Service regularly

--3--

and store in dry area. Operate your mower at slow speeds

until you become familiar with the machine. Avoid sharp

turns at high speed and uphill or downhill turns. Operate

mower carefully. Be especially cautious on hills• When

riding down inclines, keep shift control in low speed with

brake-clutch pedal out. This helps the engine control the

speed. Use brake for fast stops on hills.

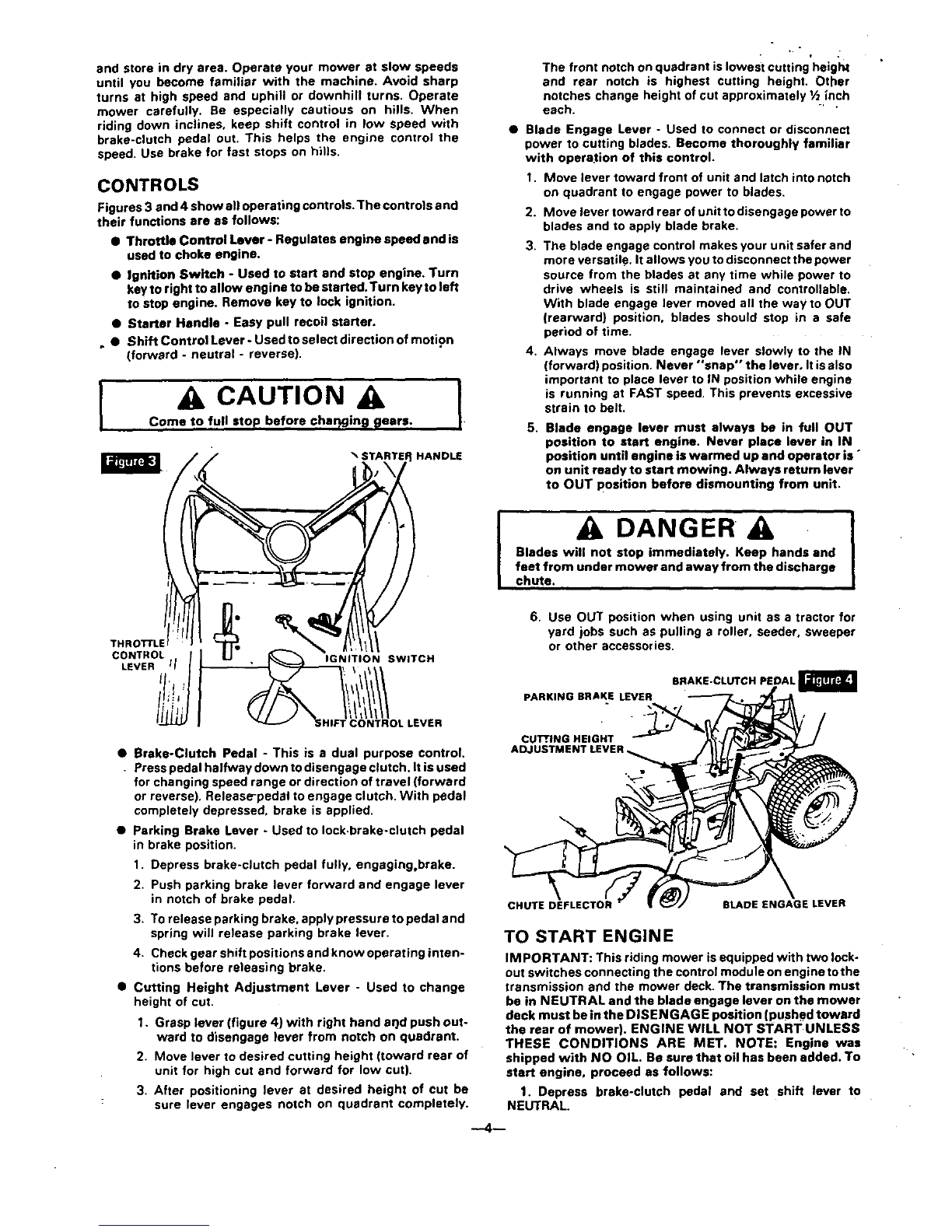

CONTROLS

Figures 3 and 4 show all operating controls.The controls end

their functions are as follows:

• Throttle Control Lever - Regulates engine speed and is

used to choke engine.

•Ignition Switch - Used to start end stop engine. Turn

key to right to allow engine to be started. Turn key to left

to stop engine. Remove key to lock ignition.

•Starter Handle - Easy pull recoil starter.

••Shift Control Lever- Used toselect direction of motion

(forward -neutral - reverse).

,CAUTION

Come to full stop before char_gin_ _ears.

HANDLE

• f

The front notch on quadrant islowest cutting height

and rear notch is highest cutting height. Other

notches change height of cut approximately 1/2inch

each. "'"

•Blade Engage Lever - Used to connect or disconnect

power to cutting blades. Become thoroughly familiar

with opera,ion of this control.

1. Move lever toward front of unit and latch into notch

on quadrant to engage power to blades.

2. Move lever toward rearofunittodisengagepower to

blades and to apply blade brake.

3. The blade engage control makes your unit safer and

more versatile. It allows you to disconnect the power

source from the blades at any time while power to

drive wheels is still maintained and controllable•

With blade engage lever moved all the way to OUT

(rearward) position, blades should stop in a safe

period of time.

4. Always move blade engage lever slowly to the IN

(forward) position. Never *'snap" the lever, It isalso

important to place lever to IN position while engine

is running at FAST speed. This prevents excessive

strain to belt.

5. Blade engage lever must always be in full OUT

position to start engine. Never place lever in IN

position until engine is warmed up and operator is °

on unit ready to start mowing. Always return lever

to OUT position before dismounting from unit.

m

m

,

DANGER

Blades will not stop immediately. Keep hands and

feet from under mower and away from the discharge

chute. I

THROTrLE

CONTROL !IGNITION SWITCH

LEVER 'l /

tl'!

!ti:, / .EVEn

6. Use OUT position when using unit as a tractor for

yard jobs such as pulling a roller, seeder, sweeper

or other accessories.

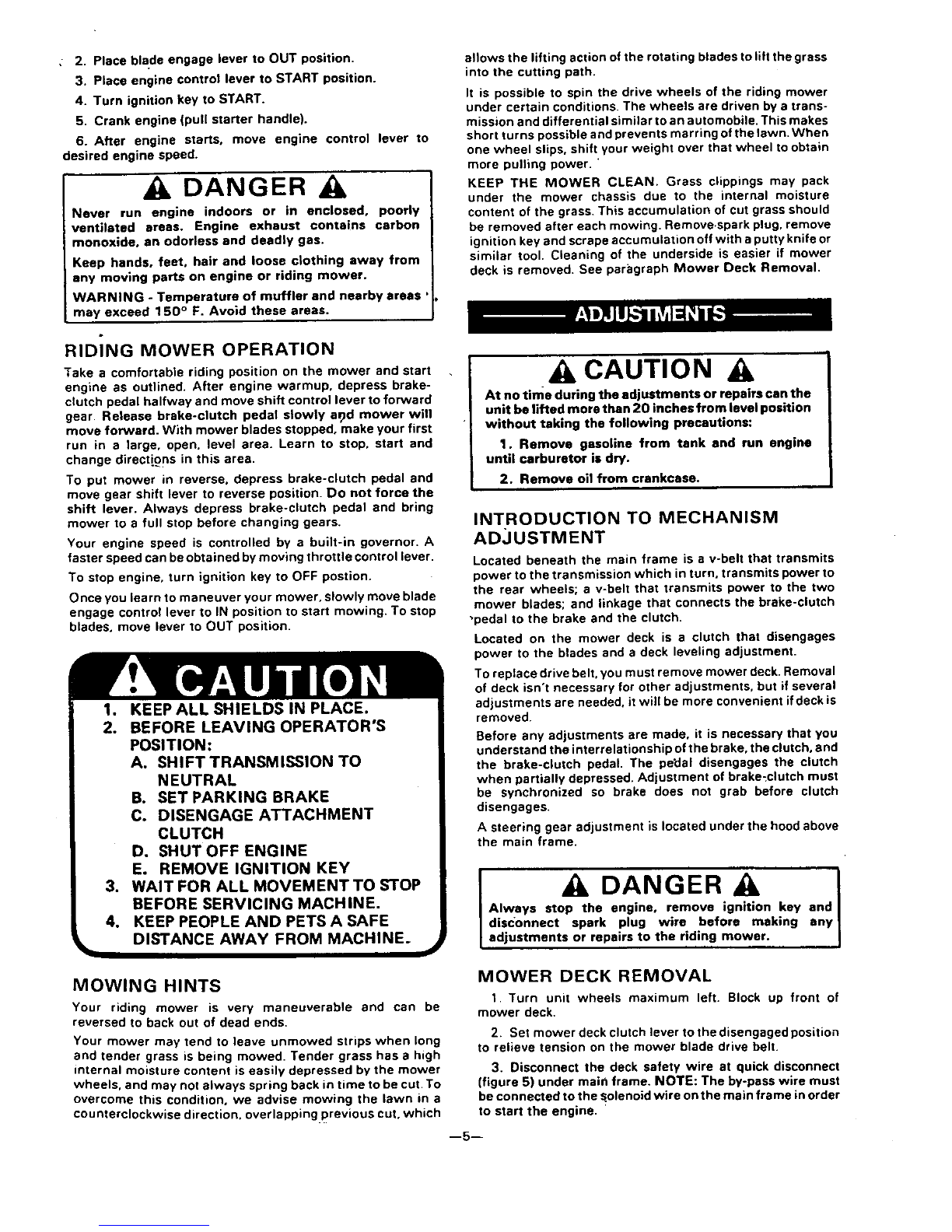

BRAKE-CLUTCH PEDAL

PARKING BRAKE LEVER

•Brake-Clutch Pedal - This is adual purpose control.

Press pedal halfway down to disengage clutch. It isused

for changing speed range or direction of travel (forward

or reverse). Release-pedal to engage clutch. With pedal

completely depressed, brake is applied.

CUl!', ING HEIGHT

ADJ

•Parking Brake Lever - Used to lock.brake-clutch pedal

in brake position.

1. Depress brake-clutch pedal fully, engaging,brake.

2. Push parking brake lever forward and engage lever

in notch of brake pedal.

3. To release parking brake, apply pressure to pedal and

spring will release parking brake lever.

4. Check gear shift positions and know operating inten-

tions before releasing brake.

•Cutting Height Adjustment Lever - Used to change

height of cuL

1. Grasp lever (figure 4) with right hand arid push out-

ward to disengage lever from notch on quadrant.

2. Move lever to desired cutting height (toward rear of

unit for high cut and forward for low cut).

3. After positioning lever at desired height of cut be

: sure lever engages notch on quadrant completely.

CHUTE DEFLECTOR BLADE ENGAGE LEVER

TO START ENGINE

IMPORTANT: This riding mower is equipped with two lock-

out switches connecting the control module on engine tothe

transmission end the mower deck. The transmission must

be in NEUTRAL and the blade engage lever on the mower

deck must be in the DISEN GAG E position (pushed toward

the rear of mower). ENGINE WILL NOT START UNLESS

THESE CONDITIONS ARE MET. NOTE: Engine was

shipped with NO OIL. Be sure that oil has been added. To

start engine, proceed as follows:

1. Depress brake-clutch pedal and set shift lever to

NEUTRAL.

:2. Place blade engage lever to OUT position.

3, Place engine control lever to START position.

4. Turn ignition key to START.

5, Crank engine (pull starter handle).

6. After engine starts, move engine control lever to

desired engine speed.

DANGER

Never run engine indoors or in enclosed, poorly

ventilated areas. Engine exhaust contains carbon

monoxide, an odorless and deadly gas.

Keep hands, feet, hair and loose clothing away from

eny moving parts on engine or riding mower.

WARNING -Temperature of muffler and nearby areas

may exceed 150 ° F. Avoid these areas.

RIDING MOWER OPERATION

Take a comfortable riding position on the mower and start

engine as outlined. After engine warmup, depress brake-

clutch pedal halfway and move shift control lever to forward

gear. Release brake-clutch pedal slowly ar)d mower will

move forward. With mower blades stopped, make your first

run in a large, open. level area. Learn to stop. start and

change directions in this area.

To put mower in reverse, depress brake-clutch pedal and

move gear shift lever to reverse position. Do not force the

shift lever. Always depress brake-clutch pedal and bring

mower to a full stop before changing gears.

Your engine speed is controlled by a built-in governor. A

faster speed can be obtained by moving throttle control lever.

To stop engine, turn ignition key to OFF postion.

Once you learn to maneuver your mower, slowly move blade

engage control lever to IN position to start mowing. To stop

blades, move lever to OUT position.

1. KEEP ALL SHIELDS IN PLACE.

2. BEFORE LEAVING OPERATOR'S

POSITION:

A. SHIFT TRANSMISSION TO

NEUTRAL

B. SETPARKING BRAKE

C. DISENGAGE ATTACHMENT

CLUTCH

D. SHUT OFF ENGINE

Eo REMOVE IGNITION KEY

3. WAIT FOR ALL MOVEMENTTO STOP

BEFORE SERVICING MACHINE,

4. KEEP PEOPLE AND PETS A SAFE

DISTANCE AWAY FROM MACHINE.

allows the lifting action of the rotating blades to lift the grass

into the cutting path.

It is possible to spin the drive wheels of the riding mower

under certain conditions. The wheels are driven by atrans-

mission and differential similar to an automobile. This makes

short turns possible and prevents marring of the lawn. When

one wheel slips, shift your weight over that wheel to obtain

more pulling power. "

KEEP THE MOWER CLEAN. Grass clippings may pack

under the mower chassis due to the internal moisture

content of the grass. This accumulation of cut grass should

be removed after each mowing. Remove.spark plug, remove

ignition key and scrape accumulation off with a putty knife or

similar tool. Cleaning of the underside is easier if mower

deck is removed. See paragraph Mower Deck Removal.

ACAUTION A

At no time during the adjustments or repairs can the

unit be lifted more than 20 inches from level position

without taking the following precautions:

1. Remove gasoline from tank and run engine

until carburetor is dry.

2. Remove oil from crankcase.

INTRODUCTION TO MECHANISM

AD_JUSTMENT

Located beneath the main frame is a v-belt that transmits

power to the transmission which in turn, transmits power to

the rear wheels; a v-belt that transmits power to the two

mower blades; and linkage that connects the brake-clutch

•pedal to the brake and the clutch.

Located on the mower deck is a clutch that disengages

power to the blades and a deck leveling adjustment.

To replace drive belt. you must remove mower deck. Removal

of deck isn't necessary for other adjustments, but if several

adjustments are needed, it will be more convenient if deck is

removed.

Before any adjustments are made. it is necessary that you

understand the interrelationship of the brake, the clutch, and

the brake-clutch pedal. The pedal disengages the clutch

when partially depressed. Adjustment of brake_clutch must

be synchronized so brake does not grab before clutch

disengages.

Asteering gear adjustment is located under the hood above

the main frame.

]DANGER

Always stop the engine, remove ignition key and

disconnect spark plug wire before making any

adjustments or repairs to the riding mower.

MOWING HINTS

Your riding mower is very maneuverable and can be

reversed to back out of dead ends.

Your mower may tend to leave unmowed strips when long

and tender grass is being mowed. Tender grass has ahigh

internal moisture content is easily depressed by the mower

wheels, and may not always spring back in time to be cut. To

overcome this condition, we advise mowing the lawn in a

counterclockwise direction, overlapping previous cut. which

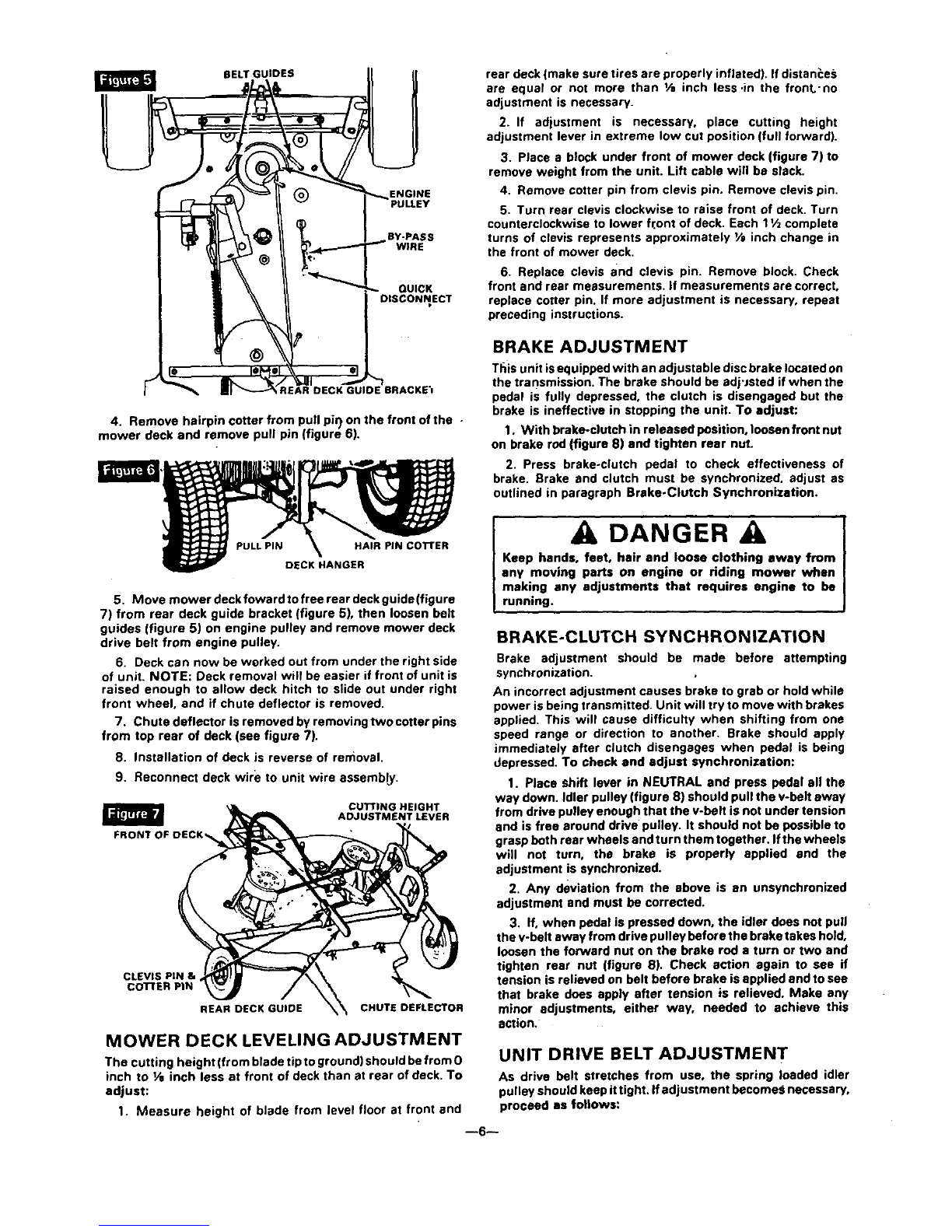

MOWER DECK REMOVAL

1. Turn unit wheels maximum left. Block up front of

mower deck.

2. Set mower deck clutch lever to the disengaged position

to relieve tension on the mower blade drive belt.

3. Disconnect the deck safety wire at quick disconnect

(figure 5) under main frame. NOTE: The by-pass wire must

be connected to the solenoid wire on the main frame in order

to start the engine.

--5--

BELT GUIDES

ENGINE

BY'PASS

WlHE

QUICK

"AR DECK GUIDE BRACKE'I

4. Remove hairpin cotter from pull pil) on the front of the -

mower deck and remove pull pin (figure 6).

5. Move mower deckfowardtofreerear deckguide(figure

7) from rear deck guide bracket (figure 5), then loosen belt

guides (figure 5) on engine pulley and remove mower deck

drive belt from engine pulley.

6. Deck can now be worked out from under the right side

of unit. NOTE: Deck removal wilt be easier if front of unit is

raised enough to allow deck hitch to slide out under right

front wheel, and if chute deflector is removed.

7. Chute deflector is removed by removing two cotter pins

from top rear of deck (see figure 7).

8. Installation of deck is reverse of removal.

9. Reconnect deck wire to unit wire assemb_.

CUTTING HEIGHT

ADJUSTMENT LEVER

_A

CLEVIS PIN &

co'n'ER PIN

REAR DECK GUIDE CHUTE DEFLECTOR

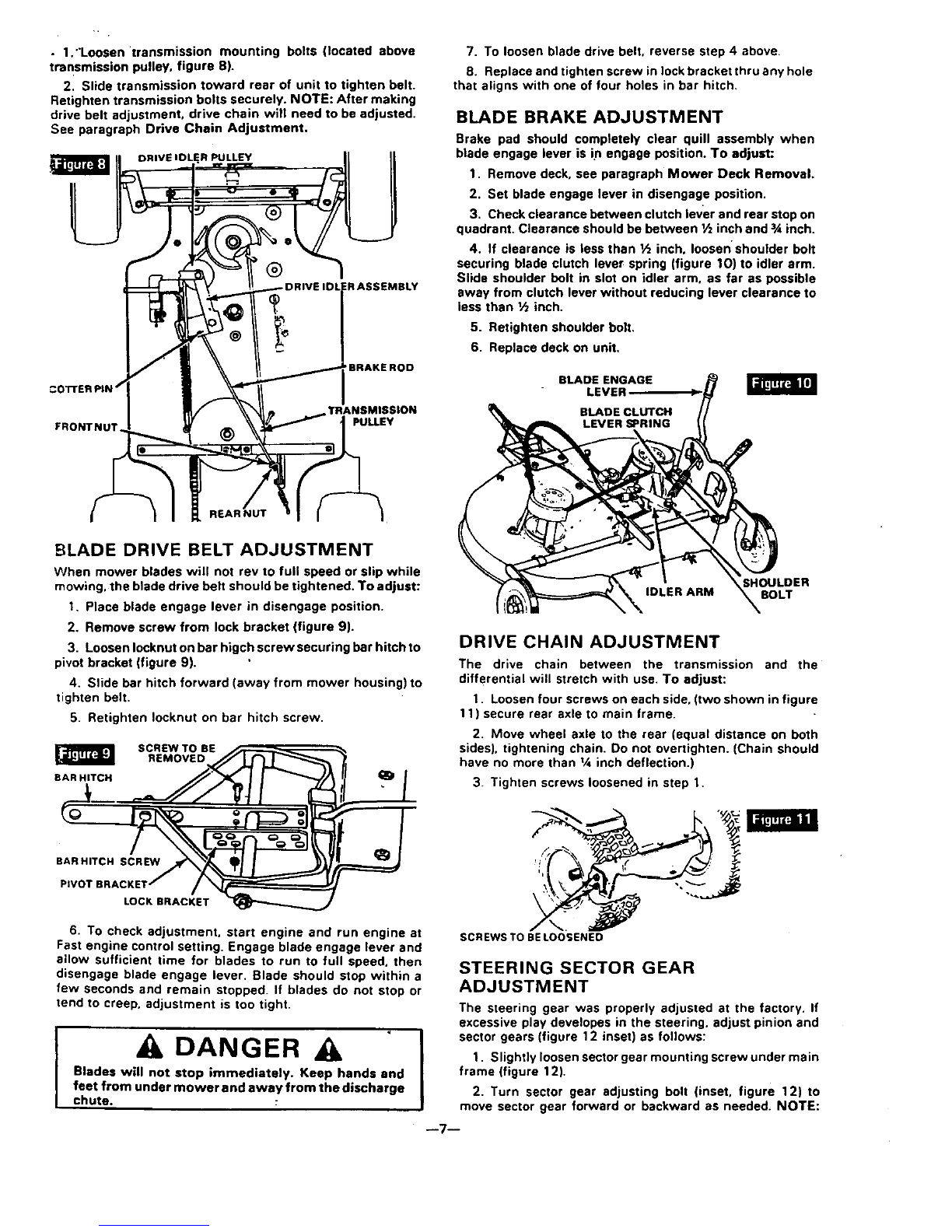

MOWER DECK LEVELING ADJUSTMENT

The cutting height (from blade tip to ground) should be from 0

inch to V, inch less at front of deck than st rear of deck. To

adjust:

1. Measure height of blade from level floor at front and

rear deck (make sure tires are properly inflated). If dlstan_:e_;

are equal or not more than I/a inch less .in the front'no

adjustment is necessary.

2. If adjustment is necessary, place cutting height

adjustment lever in extreme low cut position (full forward).

3. Place a block under front of mower deck (figure 7) to

remove weight from the unit. Lift cable will be slack.

4. Remove cotter pin from clevis pin. Remove clevis pin.

5. Turn rear clevis clockwise to raise front of deck. Turn

counterclockwise to lower fr.ont of deck. Each 11/z complete

turns of clevis represents approximately VB inch change in

the front of mower deck.

6. Replace clevis and clevis pin. Remove block. Check

front and rear measurements, if measurements are correct,

replace cotter pin. If more adjustment is necessary, repeat

preceding instructions.

BRAKE ADJUSTMENT

This unit isequipped with an adjustable disc brake located on

the transmission. The brake should be adj'Jsted if when the

pedal is fully depressed, the clutch is disengaged but the

brake is ineffective in stopping the unit. To adjust:

1. With brake-clutch in released position, loosen front nut

on brake rod (figure 8) and tighten rear nut.

2. Press brake-clutch pedal to check effectiveness of

brake. Brake and clutch must be synchronized, adjust as

outlined in paragraph Brake-Clutch Synchronization.

DANGER A

Keep hands, feet, hair and loose clothing away from

any moving parts on engine or riding mower when

making any adjustments that requires engine to be

running.

BRAKE-CLUTCH SYNCHRONIZATION

Brake adjustment should be made before attempting

synchronization.

An incorrect adjustment causes brake to grab or hold while

power is being transmitted. Unit will try to move with brakes

applied. This will cause difficulty when shifting from one

speed range or direction to another. Brake should apply

immediately after clutch disengages when pedal is being

depressed. To check and adjust synchronization:

1. Place shift lever in NEUTRAL and press pedal all the

way down. Idler pulley (figure 8) should pull the v-belt away

from drive pulley enough that the v-belt is not under tension

and is free around drive pulley. It should not be possible to

grasp both rear wheels and turn them together. Ifthe wheels

will not turn, the brake is properly applied and the

adjustment is synchronized.

2. Any deviation from the above is an unsynchronized

adjustment and must be corrected.

3. If, when pedal is pressed down, the idler does not pull

the v-belt away from drive pulley before the brake takes hold,

loosen the forward nut on the brake rod a turn or two and

tighten rear nut (figure 8). Check action again to see if

tension is relieved on belt before brake is applied and to see

that brake does apply after tension is relieved. Make any

minor adjustments, either way, needed to achieve this

action.

UNIT DRIVE BELT ADJUSTMENT

As drive belt stretches from use, the spring loaded idler

pulley should keep it tight. If adjustment becomes necessary,

proceed as follows:

--6--

• 1,"Loosen transmission mounting bolts {located above

transmission pulley, figure 8).

2. Slide transmission toward rear of unit to tighten belt.

Retighten transmission bolts securely. NOTE: After making

drive belt adjustment, drive chain will need to be adjusted.

See paragraph Drive Chain Adjustment.

DRIVEIDLER PULLEY

_R ASSEMBLY

'BRAKEROD

FRONTNUT PULLEY

7. To loosen blade drive belt. reverse step 4 above,

8. Replace and tighten screw in lock bracket thru any hole

that aligns with one of four holes in bar hitch,

BLADE BRAKE ADJUSTMENT

Brake pad should completely clear quill assembly when

blade engage lever is in engage position. To adjust:

1. Remove deck, see paragraph Mower Deck Removal.

2. Set blade engage lever in disengage position.

3. Check clearance between clutch lever and rear stop on

quadrant. Clearance should be between 1/=inch and 3Ainch.

4. If clearance is less than Ih inch, loosen shoulder bolt

securing blade clutch lever spring (figure 10) to idler arm.

Slide shoulder belt in slot on idler arm. as far as possible

away from clutch lever without reducing lever clearance to

less than ½inch.

5. Retighten shoulder bolt.

6. Replace deck on unit.

BLADEENGAGE

LEVER

BLADE DRIVE BELT ADJUSTMENT

When mower blades will not rev to full speed or slip while

mowing, the blade drive belt should be tightened. To adjust:

1, Place blade engage lever in disengage position.

2. Remove screw from lock bracket (figure 9).

3, Loosen Iocknut on bar higch screw securing bar hitch to

pivot bracket (figure 9).

4. Slide bar hitch forward (away from mower housing) to

tighten belt,

5. Retighten Iocknut on bar hitch screw,

SCREW TO BE

REMOVED

BAR HITCH

BAR HITCH SCREW

PIVOT B|

LOCK BRACKET

6. To check adjustment, start engine and run engine at

Fast engine control setting. Engage blade engage lever and

allow sufficient time for blades to run to full speed, then

disengage blade engage lever. Blade should stop within a

few seconds and remain stopped. If blades do not stop or

tend to creep, adjustment is too tight.

DANGER A

Blades will not stop immediately. Keep hands and

feet from under mower and away from the discharge

chute•

LEVERS=RING

SHOULDER

IDLER ARM BOLT

DRIVE CHAIN ADJUSTMENT

The drive chain between the transmission and the

differential will stretch with use. To adjust:

1. Loosen four screws on each side, (two shown in figure

11) secure rear axle to main frame.

2. Move wheel axle to the rear (equal distance on both

sides), tightening chain. Do not overtighten. (Chain should

have no more than tAinch deflection.)

3. Tighten screws loosened in step 1.

SCREWS TO BE LOOSENED

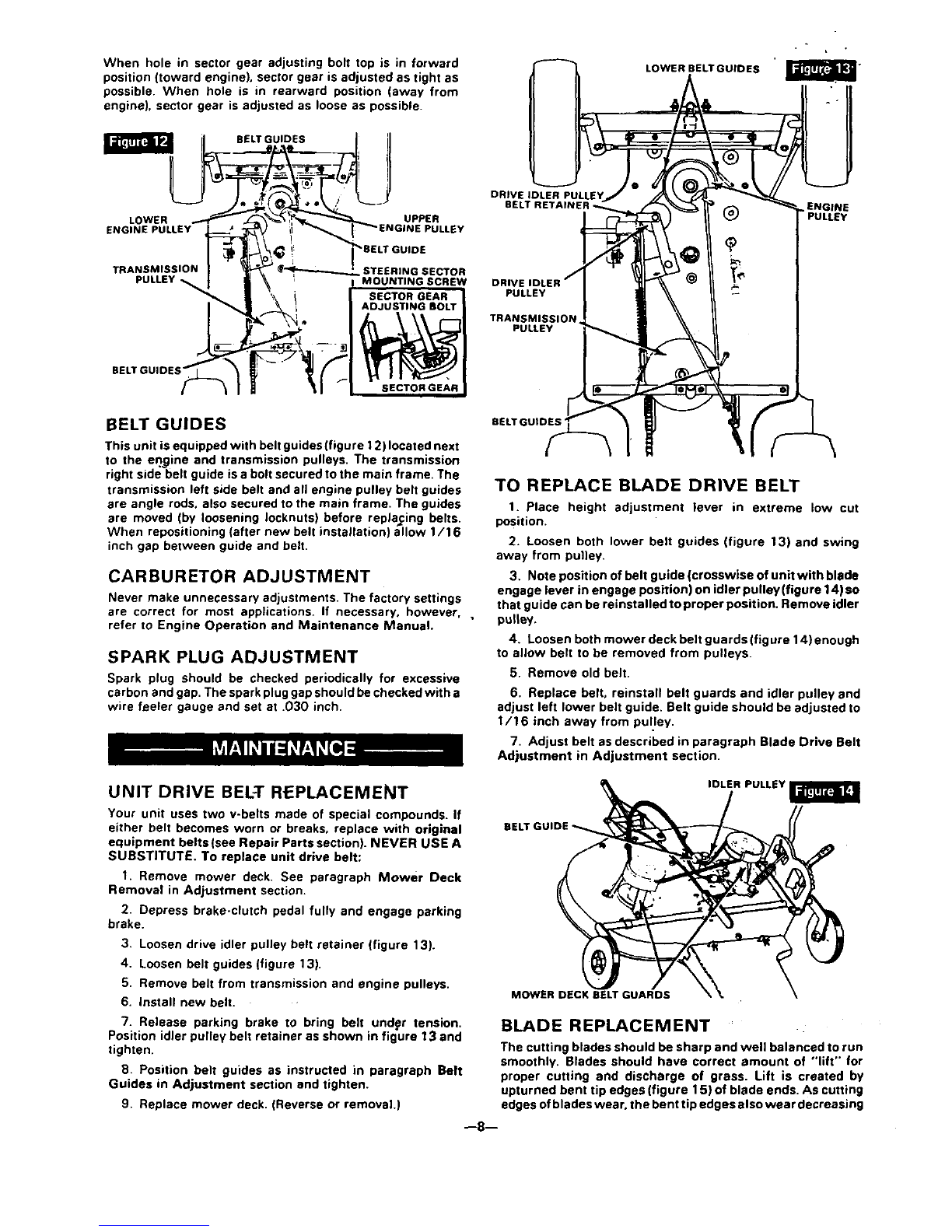

STEERING SECTOR GEAR

ADJUSTMENT

IThe steering gear was properly adjusted at the factory. If

excessive play developes in the steering, adjust pinion and

sector gears (figure 12 inset) as follows:

1. Slightly loosen sector gear mounting screw under main

frame (figure 12).

2. Turn sector gear adjusting bolt (inset, figure 12) to

move sector gear forward or backward as needed, NOTE:

--7--

When hole in sector gear adjusting bolt top is in forward

position (toward engine), sector gear is adjusted as tight as

possible. When hole is in rearward position (away from

engine), sector gear is adjusted as loose as possible.

BELT GUIDES

LOWER BELTGUIOES

LOWER UPPER

ENGINE PULLEY EY

DRIVE IDLER PULLEY

BELT RETAINI . ENGINE

PULLEY

TRANSMISSION STEERING SECTOR

MOUNTING SCREW DRIVE IDLER

PULLEY

TRANSMISSION

PULLEY

BELT GUIDES

This unit isequipped with belt guides (figure 12)located next

to the engine and transmission pulleys. The transmission

right side belt guide is a bolt secured to the main frame. The

transmission left side belt and all engine pulley belt guides

are angle rods. also secured to the main frame. The guides

are moved (by loosening Iocknuts) before replacing belts,

When repositioning (after new belt installation) allow 1/16

inch gap between guide and belt.

CARBURETOR ADJUSTMENT

Never make unnecessary adjustments. The factory settings

are correct for most applications. If necessary, however. ,

refer to Engine Operation and Maintenance Manual.

SPARK PLUG ADJUSTMENT

Spark plug should be checked periodically for excessive

carbon and gap, The spark pluggap should be checked with a

wire feeler gauge and set at .030 inch.

BELTGU|O_

TO REPLACE BLADE DRIVE BELT

1. Place height adjustment lever in extreme low cut

position.

2. Loosen both lower belt guides (figure 13) and swing

away from pulley,

3. Note position of belt guide (crosswise of unit with blade

engage lever in engage position) on idler pulley(figure 14)so

that guide can be reinstalled to proper position. Remove idler

pulley.

4. Loosen bothmower deck beltguards(figure14)enough

to allowbelttobe removed from pulleys.

5. Remove old belt.

6. Replace belt, reinstall belt guards and idler pulley and

adjust left lower belt guide. Belt guide should be adjusted to

1/16 inch away from pu!ley.

7. Adjust belt as described in paragraph Blade Drive Belt

Adjustment in Adjustment section.

UNIT DRIVE BELT REPLACEMENT

Your unit uses two v-belts made of special compounds. If

either belt becomes worn or breaks, replace with original

equipment belts (see Repair Parts section). NEVER USE A

SUBSTITUTE. To replace unit drive belt:

I. Remove mower deck. See paragraph Mower Deck

Removal in Adjustment section,

2. Depress brake-clutch pedal fully and engage parking

brake.

IDLER PULLEY_

3, Loosen drive idler pulley belt retainer (figure 13).

4. Loosen belt guides (figure 13).

5. Remove belt from transmission and engine pulleys.

6. Install new belt. MOWER DECK BELT GUARDS

7. Release parking brake to bring belt undgr tension.

Position idler pulley belt retainer as shown in figure 13 and

tighten.

B. Position belt guides as instructed in paragraph Belt

Guides in Adjustment section and tighten.

9, Replace mower deck. (Reverse or removal.)

BLADE REPLACEMENT

The cutting blades should be sharp and well balanced to run

smoothly, Blades should have correct amount of "'lift" for

proper cutting and discharge of grass. Lift is created by

upturned bent tip edges (figure 15) of blade ends. As cutting

edges ofblades wear, the bent tip edges also wear decreasing

--8--

I_la_e lift. resulting in decreased cutting ability. Because of

"this, ,resharpbning of blades will not help much. It is

recommended that blades be replaced•

IMI_ORTANT: Stop engine, remove spark plug end

inspect blades at once if you strike any solid unyielding

object. Check to make sure blade mounting screws are

tight. To remove blades:

1. Remove mower deck (see paragraph Mower Deck

Removal in Adjustment section•

2• With a 9/16 inch wrench, remove blade mounting

screws (figure 15) by turning screws counterclockwise.

When replacing blades, be sure all parts are reassembled in

proper order (see Unit Repair Parts section for proper order)

or severe vibration will occur. Bent tip edges of blades must

be up toward topof mower deck or blades will not cut. NOTE:

Make sure blade mounting screws are tightened securely.,

We recommend a 10 inch wrench or atorque wrench. If

torque wrench is used. torque blade mounting screws to

between 30 and 35 font pounds.

BENT TIP EDGE

QUILL

ASSEMBLY

AIR FILTER MAINTENANCE

The air filter should be cleaned and re-oiled after every 25

hours of operation under normal operating conditions; more

often under dusty conditions, To clean air filter, proceed as

instructed in Engine Operation end Maintenance Manual.

CAUTION A

Never run the engine without the air cleaner element

installed, a defective air cleaner can result in loss of

engine power end can cause excessive wear or

damage to engine components if dirt or dust is

permitted to enter engine through the carburetor. A

damaged air cleaner, orone that isclogged with dust

or dirt should be replaced immediately.

WIRING DIAGRAM

Parts breakdown on page 13 of this manual isdesigned to be

used as a wiring diagram.

We recommend that unless you are fully qualified to make

repairs on the electrical system on this unit, you take it to a

competent repairman for such work or adjustments.

BLADE MOUNTING SCREWS

TO CHANGE CRANKCASE OIL

Crankcase oil should be changed after first 5 hours of

operation and every 25 hours thereafter. See Engine

Operation and Maintenance Manual for proper procedure.

Check oil level before each use. Add oil as required.

1, Place flat bottom 2 quart container beneath oil drain

tube (see figure 16).

2. Remove drain plug end drain oil. NOTE: Oil fill cap

should also be loosened to serve as an air vent.

3. Replace plug. remove oil fill cap and refill crankcase as

outlined in Engine Operatlon-and'Maintenance Manual.

4. Replace oil fill cap•

OIL FILL CAP

OIL DRAIN TUBE

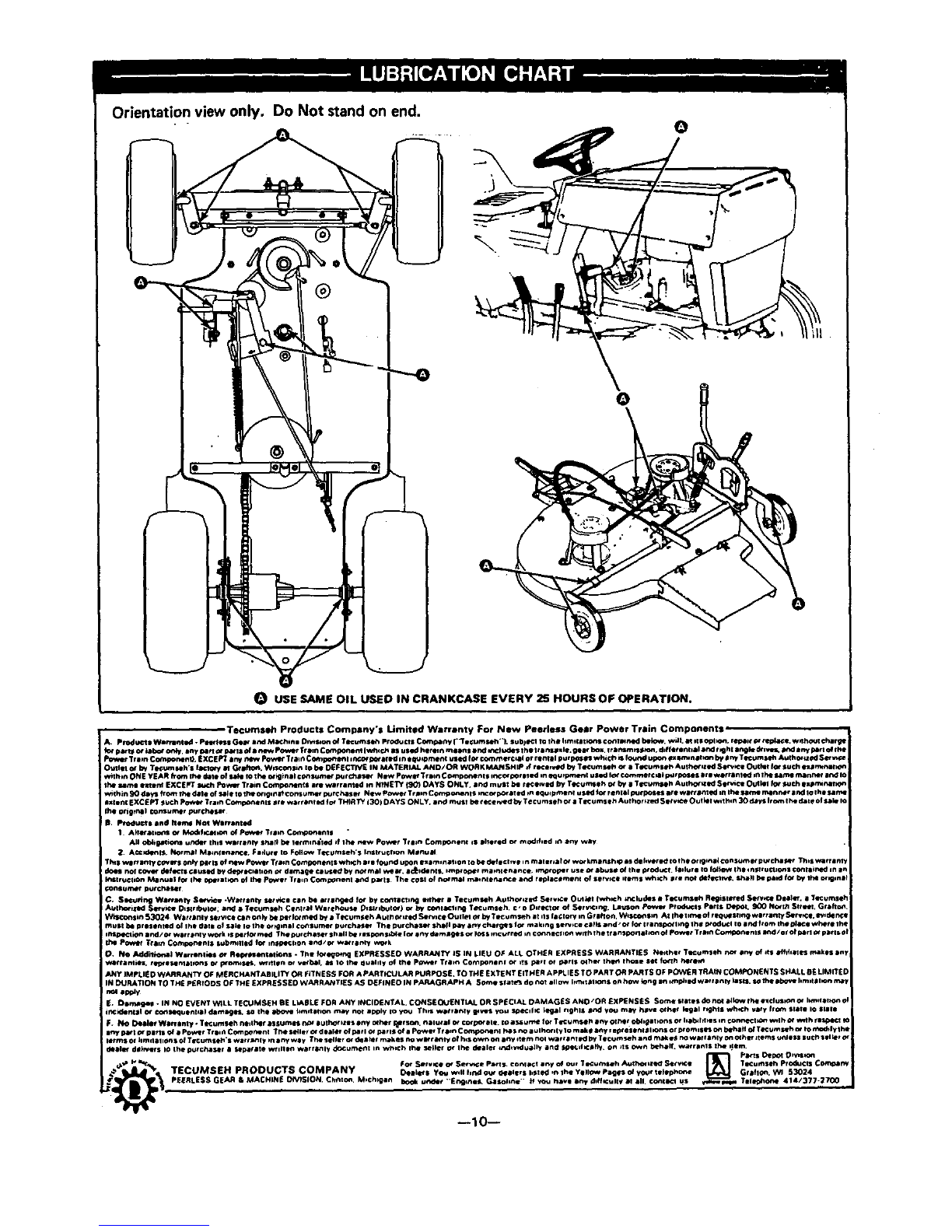

LUBRICATION

Lubricate as shown in Lubrication Chart.

ADANGER A

Never store engine with fuel in tank indoors or in

enclosed, poorly ventilated enclosures, where fuel

fumes may reach an open flame, spark or pilot light

as on a furnace, water heater, clothes dryer, etc.

Handle gasoline carefully. It is highly flammable end

careless use could result in serious fire damage to

• your person and/or property.

The riding mower should be immediately prepared for

storage at the end of the season or if the unit is to be un-used

for 30 days or more.

ENGINE STORAGE

Gasoline, if permitted to stand un-used for extended

periods (30 days or more), may develop gummy deposits

which can adversely affect the engine carburetor end

cause engine malfunction. To avoid this condition,

proceed as follows:

1 Prior to shut down for 30 days or more, drain fuel tank.

2. Run engine until fuel tank is empty end engine stops

due to lack of fuel.

3. Remove spark plug and pour one (1) ounce ofengine oil

through spark plug hole into cylinder. Crank engine several

times to distribute oil. Replace spark plug.

UNIT STORAGE

1. Clean the unit thoroughly.

2. Inspect the riding mower for worn or damaged parts,

tighten all loose hardware.

3. Oil all points shown in Lubrication Chart.

4. Store the riding mower in eprotected area end cover

the unit for additional protection.

A yearly checkup or tuneup by a qualified repairman is agood

way of insuring that your riding mower will provide

maximum performance for the next season.

--9--

Orientation view only. Do Not standon end. 0

OUSE SAME OIL USED IN CRANKCASE EVERY 25 HOURS OF OPERATION.

, Tecumslh Products Company's Limited Warranty For New Peerless Gear Power Train Components,

A. P_¢luct• Wemlnlld. pW_m Gear and M_chin| Dn_s_on of Tl_cmseh P)-oducl| Coml_ny i"[e_mseh'_, sub)•C11o t he hm_la: _Cc_III_KI bek_, w_l.ltolSOpl_,r_l¢_tl_dace.w_hC_lchargtm

f_" _Or I_b_ otdy, any N rt _, IrMlS _ • Pew P_r Tr•nn C ml_tn_ IwhlcP. 8S uSial herren ms•n | •rKt mc_u_es l he Item.hie. Ile_r box, _rJrmm ;st._on, dJferBnl0•l •rKI r_h181_kl dr .VqlL led •ny N rt of Ihe

Pr*wer _r_m c_m_n4m_ |xcEFr18rr_ _ P_ Tta1n c_m_p_en_ au_e_ed _n_n_ _ f_ _m_r©_ _ r_n_ pur_ whiCh _ _ u_ _nI_ _ D_ T_um_ _N $_

• •hi! _by Te_umseh's f_ MGr iho_. W_s_, K• be DEFECTIVE IN MATERIAL AND/OR WORKMANSHIP Jrwcelved by Tecumsel_ ¢,r •Tecumset_ Author _lSe_:l Outl_l fo_ Such ex_mmmN_

w_lhin ONIE yE_.R _ram the _i_le ol sa_l Io lhe _qlin•l ¢_summ- _t _ N_wP_w_TremC_mp_nent_o_4)r$1_dm_x_u_pm_nIu$_d_c_mm_r¢N_r_r`s-es_rIworr_medm_h1furr4m_nrmt8n_

1he Hme extent EXCEPT _PO_ Tt•in Ccm'_onent s art w•rranl_KI mI_NEI"f fO0) DAYS ONLY. an_ mu$_ be rt_ce_ by T_K.,t_e ho,' by • T_rcurnseh Authored S_C_ Outlel for t.uch •]u_rmt_al_n

w,th_n SO d_, nh-(_m lhe dale of S_l_ to th_ot0gml_consum_r purchaser NOw p_l.q_ Tr•mC_oqent$ _r_or _¢_•_•d _n •qu_pmenl u$_l for ren_•_ I;_rl_X_s are wl_t_ntqd n_ Ihe same m_nPA_r •hal lU the same

•xeenK EXCEPT _bch Pow_ Tra_ Com_._,_nl$ •¢e w_r r•n¢_l for "[HIRTY 130) DAYS ONLY. er, d muST be ¢ece ;veal by "r_¢umseh ot •Tm:umseh Au_hof _zsd S_t¥_-e Oulkfl wd_m _0 days from th_ d_le ol s_le m

i Iho origrn•l _nsumer purch_

!III, P_ucts and hem4 Not Wo_'onted

1 A;ler/*lim_ of It4_d_hr_m of Power "[film C_n#ormnl• •

All obh_mtin urger Ihh• wmrranly sha_ I_ letmln_led _f ihe _A_w power "[t •;n Component _s Idler ecl or modnhed i_ _ny way

;_ A_:_e_e$, NormD_ M•mlln•_¢, Fmdur_f I• FOI_ Tecumseh'$ InStrucfmn Monu_

"rl_ s v*l_anty Cm_lr$ only IHrlS of new pow_ Train Comoonent$ wh)Ch •ro fourKI upon exammJl_on io be _fe¢llve inma_lr_•t of wof km•nsh_ ms dmlr._ered _oCh•or rg_r,l_ ¢_nsumet pu_chJt.er This warr•m

d_es nor C_I_ de_:fl _l_lld by de_r ic_•10on _. dlma_ie r.Jt_S_ by n_'m•l wear. •c_:0dent•. _m_ _er mm_nlenance, irr_roper USe or •buS• 0# the i_ •duct a_dur eto foIk_w th• in_ruClmns con I•_ned an •

I_stru_lhon Mlnual for ihe 0get it _'1 (4 _Pcw_Jr Tram C(m_nenl •_,d Dwl$ The coal of nor m_)l m_t _*P_ln_e er.:l re_l_©emenl of serwc_ ilem$ wh:Ch •_t no€ de_'lw¢, sh•)l bl _1_ rot by lt_ _rlgln_l

ronsum_f purch_lSer

C* S_ng W•mmt_t Se_-_-I -W•rr •nty set w=e ¢•n be _t •n_d _o_ by co_l•¢l_n_l _her • TecumS41h Aulhor_zs, dSet vN:t O_,IMI fwh_:h _nc ludl• •Tlcumslh R_nsl_ed Se_;ce D_•I_, •T_c urns•;"

_lhoti_KI Setv_l D_St r_.¢ul_; and • T•¢umleh CBnlr_)l War•house DnSI_ 01_JIo_) o, by c¢_la_llnfl TeCumseh, ©, o Dit_ct _of Serv_:lng. Lauson p¢_*_l f pt _d_l• P•rl$ Depot. 900 N_;/1 Stt_L Gr•hm_

Wnl¢_n•hr_ 5_024 W•rt•nly serv_c• c_n on )y be pe_lot m_l by • Tec umseh A _11_of _ed Se_*_¢e Ou ilel _ by T ecumS_h •t nl$ r•¢lont on G r•hon, Wl_n •m AI Ihe I _,_1 of r t_u4_sl_n_ w•rren_/Set _¢_, I_rd_ _l:q

must b_ prosent•d of ih• ¢_•_• oP $•_¢ io the of _0nel Coctsumer pu¢cha_ The _urch•sl_ ShMI _ •'y chef.slot making Se_ce ©•f)s and, or |or _r•ns_lmg 1he I_0d_Cl Io •,_d f_om _he _11_ where lh_

ihspe_i_n end/_ w_r r•nly work IS i_t fof m_l The purch•$of •1_•11 be r•$_ons_ble lot •ny d_m_$ or I_$ mc_rr_l i,_¢_ne¢_lon wnlh _he t r•nspOnehO_ o# Power Tr_n Comic•hems Ind/or of p_rl o¢p•rlsoi

dm P_et Tr•m Coml_nenl• submlll•d for ms_g_on •nd/cx wart •_ly w_k

O. NO Addilkmal Wu •n _e• Or R e_m _n• - T_e fo_e_m_l EXPRE$SEO WARRANTY _S IN LIeU O. _ ALl. OTHER EXPRESS WARRANTI£$ Neither l"Kumseh nor •r,y ef ;_• Ifhk•i_ mak•$ av

v_rr•nl_es, rll_•SeP4•t_s of promises+ wtl_l_n or v_l_l_ am IO lhe _u•lnl¥ _4 _h• pm_'er Tr•m Compone_l or _!S parl or _rl$ _4 f',l_ th_ Ih_e •t_ fo_h hece_

ANY IMPLIED WARRANTY OF M_RCHANTAB_LII_ OR fiTNESS FOR APARTICULAR PURPOSE. TO THE EXTENT EITHER APPLIES TO PART OR PARTS OF pOWeR TRAIN COMPONENTS SHALL 0E LIMITS

)N DURATION TO THE p_RIOOS OF THE EXPRESSEO WARRANTIES AS DEFIN£O IN pARAGRAPH A Sore• Stern do not allow I_.'_i _1m_s on how kong •n*mp)_lw•r r•nly la$1_, _th_ •b_ I_m_t_l_n real

;_D_m_ 9e_ -IN NO £VENT WILL TSCUMSI_H 8E LL_I_ LI_ FOA ANY _NCIDENTAL. CONSEQUENT_L OR SP£_IAL DAMAGES ANO/OR £XPENS£_; Som_ •_•t_$ do no_ •_l_w Ih_ e.clus_ _ I_m,l•.on o

i_¢ m_n_l o¢ con_u•n_l•l damages, _ _he _ I_mlt •_on may nof •_¥ io YOU Thrl w_tF_nly _$ you s_ecnl_¢ _egal rlg_l$ •rid you _f h_v_ _I_g•l .ghl$ which v•ry rrom $1•1_ IO •l•le

FN_ I_t_ler W_l_•my Tl_umsehnenlh_r•$sumesP_*•u_ho_ls•nY •4her _s_, n•lU eof c_o_el_. _oessurm_ of Trcumse_•nyocr4r_bll_•t_onsofll•_r_lsm¢orm4_v_mV_lhMWdhrl_*_l_h

•r.ypatlorp•tl$of•pm_r Tr•_Com_mln_ -(_se_er_td••_er_f_r_ofp_r_$of•PGw_Tr•_nC_mp_nen_P_$rm•u_h°r_ty1_make•n¥rmpr•$en_*°n•°r_°m_ses°_beh•_ofT_um_ _tO,'N_k ylh_

I•rm$ Of heal•lions CJ T_cum$•l_'s wl_¢_l_ m•ny w•y The seller Of deek_r m_kes no wle r_niy of h_s _on _ny *tern nol werr•nTId by Te©umseh and make_ no w•rr•nly on o_h_ _tem$ unleSS such SBI;eF Of

de•let d_F_tr$ Io ihe p_r ¢;le_er •sep_r •re WtnllBn w•r rarely documerlt in w_*¢h _he seller or ihe d_•ler md_,_du_l_y and t._l_._ _c• f )y on •Is _n behalf, wet r•nl• _he 0_em,

,_ I* _*_%_ For Service _. Ser_e Perls CO_l•©t eny o/ Our 1_:umseh _lh_ll_ S_V_;t TKurnseh Products Cornel mt

TECUMS EH PR •DUCTS COMPANY _e_'• Y_ w,alf,na ou, _otr• I,_1_ ,noh• V•llow pa_eso_yourIile_,o*_ Gr•hon, W_ S3024

PEERLESS GEAR & MACHINIE ON_51ON C_rnton, M*ch_gan book ut_er "Er_llnef_ G•solln_'" ;_ vo_ have _ny dlff_¢ullv 31 •11, conll¢l us _e_. Tilephone 414/377-_700 ,

--10--

PROBLEM

Mower Cuts

Ragged or

Uneven

Mower Leaves

Unmowed Strip

Between

Blades

CORRECTION

1. Make certain blades are sharp and in good condition (not bent or incorrectly mounted).

2. Check blade mounting bolts. Blade bolts must be tight.

3. Check quill assamblyfs) for damage or bearing wear. Replace if necessary.

4. Remove any accumulation of grass clippings from underside of deck housing.

5, Check for possible damage to mower deck housing. Repair or replace if necessary.

6. Check pivot tube assembly for damage. If bent or damaged, repair or replace.

1,

2.

3.

4,

5.

6.

1,

Mower 2.

Scalps Lawn 3.

Mower Will 1.

Not Discharge 2.

Clippings

Properly 3.

Check for worn or dull blades. Replace if necessary,

Check quill assemblies and make certain none are bent. Replace if necessary.

Mowing a heavy stand of grass or grass with excessive surface moisture could allow mower

to leave a strip unmowed. Mow counterclockwise (side discharge only). Do not mow wet grass,

Forward speed should be adjusted to mowing conditions by gear selection. Engine should be

run at full throttle.

Check blade belt tension. Adjust if necessary.

Check for damage to mower deck housing, Repair or replace if necessary.

Check for bent blade(s) or bent quill assambly(s). Replace if necessary.

Check mower height adjustment setting and readjust if needed, Scalping is more likely on rough or

uneven lawns.

Check deck leveling adjustment setting and readjust if needed.

Check underside of dec_ housing for accumulation of clippings. Remove accumulated clippings.

Wet conditions can cause the discharge chute and underside of deck to become clogged

with clippings. Do not mow wet grass.

If blades have been replaced, make sure they have been correctly mounted.

1. Check belt tension. Adjust if necessary.

2. Check all belt guides. Correct clearance is 1/16 inch from belt when blade engage lever is engaged.

Blade Drive Belt 3. Make certain deck leveling adju6tment is correct. If not, readjust.

Comes Off 4. Check for and remove any foreign objects interfering with belt travel.

During Use 5. Check all pulleys on mower deck. A split or bent pulley could cause problems. Replace if needed.

6. Check engine drive pulley inner surface. If inner surface is rough or split, pulley should be replaced.

7. Check blade throwout assembly for wear. Replace necessary parts,

1. If grass is too high or wet, belt slippage may occur,

Blade Drive Belt 2. Check belt for wear or damage, Replace if necessary.

Slips 3. Check belt tension. Adjust if necessary,

4. Check blade drive belt tension spring. If spring is stretched or damaged, replace spring.

1. Check all belt guides. Correct clearance is 1/16 inch from belt when blade engage lever isengaged.

Blade Drive Belt 2. Check for and remove any foreign objects interfering with belt travel,

Wears Exces- 3. Check pulleys for damage, Replace if necessary,

sively 4, Make certain belt brake is clearing belt when mower is engaged, If brake cable is too long

or broken, adjust or replace.

!5. Make certain mower deck leveling adjustment is correct. Adjust if necessary,

Blade(s) J1. Check be_t. If worn or broken, replace, If belt is too loose, make belt adjustment if necessary.

Will Not i2. Check engagement spring on deck engagement idler, If broken or damaged, replace.

Engage 3. Check for end remove any foreign obje,"._sinterfering with engagement idler travel.

Blade(s) 1. Check belt tension. Adjust if necessary.

Will Not 2. If blade drive belt adjustment will not provide enough slack in drive belt, replace with correct

Disengage original equipment belt,

3. Check for and remove any foreignobjects interfering with engagement idler travel.

1. Check blades and make certain ;hey are not bent, out of balance or loose. Replace if necessary.

Extreme Vi- 2, Check belt for burn spots or irregularities that might contribute to vibration. Replace if necessary.

bration Occurs 3. Cneck quill assemblies for damage or wear. Replace if necessary,

When Blade is 4. Check for worn cr damaged hla,Je engagement parts. Repair or replace as necessary.

Engaged 5, Check engine drive pu!!ey inner s_rface, If inner surface is rough or split, pulley should be replaced.

6, Check underside of deck huus_n3 for accumulation of clippings. Remove accumulated clippings.

7, Check for loose or damaged engir:e mounts. Tighten or replace as necessary,

!Deck or Deck 1. Deck drive belt adjustment is tr)o tight. Readjust.

iWheel Hits Rear 2. O'.her than original equipment belt is being used and is either too long or stretched. Replace belt.

, Wheel and Tire 3. Belt is worn, Replace with new o._;ginetequipment belt.

iAssembly 4. Check pivot tube assembly for damage, R':Dair or replace if necessary.

--1 1--

DeckLift

CableBroken

UnitDriveBelt

Slips

Unit Drive Belt

Squeals When

3rake is Applied

Unit Drive Belt

Comes Off

During Use

Unit Will Not

Propel Itself

When CWtch or

Vari-Speed

Lever is

Engaged

Extreme Vi-

bration Occurs

When Clutch is

Engaged

(Let-Out)

Unit Will Not

Shift or Shifts

Hard

Steering Slips

or is Loose

Engine Will No1

Turn Over

Engine Turns

Over But Will

Not Start

CORRECTION

1. Check operating procedure. Excessive ground speed on rough lawn may cause deck bounce, resulting

in lift cable failure.

2. Remove excessive clippings from under deck housing (build up of clippings adds excessive weight

to deck).

1. Check unit drive belt adjustment(s). Adjust if necessary.

2. Check for damaged or broken clutching idler spring. Replace if necessary,

3. Check belt(s) for wear or damage. Replace if necessary.

4. Check vari-apeed control lever adjustment.

5. Check for and remove any foreign objects obstructing vari-speed or clutching idler mechanisms,

1.

2.

3.

4.

1.

2.

3.

4.

Check brake-clutch synchronization (does not apply to vsri-speed units). Adjust if necessary.

Check unit drive belt adjustment(s). Adjust if necessary.

Check for and remove any foreign objects obstructing vari-speed or clutching idler mechanisim.

Check brake adjustment.

Check belt tension. Adjust if necessary.

Check belt guides. Adjust if necessary.

Check for split or damaged pulleyS. Replace if necessary.

Check clutching idler pulley alignment. If out of alignment, idler bracket may be bent. Replace if

necessary,

1. See steps 1 through 5 in Unit Drive Belt Blips section above,

2, Check engine, transmission or trensaxle pulleys for sheared or missing key, Replace if necessary,

3. Check transmission or transsxle to make certain it is operable. Make certain chain (chain drive units

only) is intact,

1. Check for split or damaged'pulleys. Replace if necessary.

2. Check belt for irregularities or burned spots. Replace if necessary.

3. Make certain belt tension is correct. Adjust if necessary.

4. Check clutching idler assembly for wear or damage. Replace part as necessary.

5. On chain drive units, check sprockets for proper alignment and chain for damage. Replace if necessary.

6. Check for loose or damaged engine mounts. Tighten or replace as necessary.

1. Check shifting procedure. Unit must come to a complete stop before shifting. On vari-speed units,

hold firm pressure on shift lever while moving vari-speed control lever slowly forward.

2. Check brake-clutch synchronization (does not apply to vari-speed units). Adjust if necessary.

3. Check unit drive belt adjustment. Adjust if necessary.

4. Have transaxle or transmission checked by acompetent repairman.

1. Check for steering sector gear and pinion looseness. If gears are loose, make sector gear adjustment.

2. Check ball joints for wear. Replace if necessary.

3. Check center pivot bolt on front axle. If loose, tighten securely.

1. Check starting procedure. Make sure starting instructions are followed.

2. Check fuse (if so equipped).

3. Ch_ck battery for charge. Make sure battery has been activated (on new unit).

4. On new units, remove spark plug and check cylinder for accumulation of oil due to handling.

5. Make visual check of electrical wiring system to make sure all connections end lockout switches

are secure.

6. Check engine according to engine manufacturers instructions.

7. Have electrical system checked by a competent repairman.

1. Check starting procedure. Make sure starting instructions are followed.

2. Make certain tank is filled with clean, fresh, unleaded or low-lead gasoline.

3. Make certain fuel shut-off is open (if so equipped).

4. Make certain throttle is in choke or fast position.

5. Check engine according to engine manufacturers instructions.

6. On recoil start unit, make visual check of wiring system to make sure all connections and lockout

switches are secure.

7. Have wiring and lockout switches (on recoil start unit) checked by a competent repairman,

i ilrr

--12--

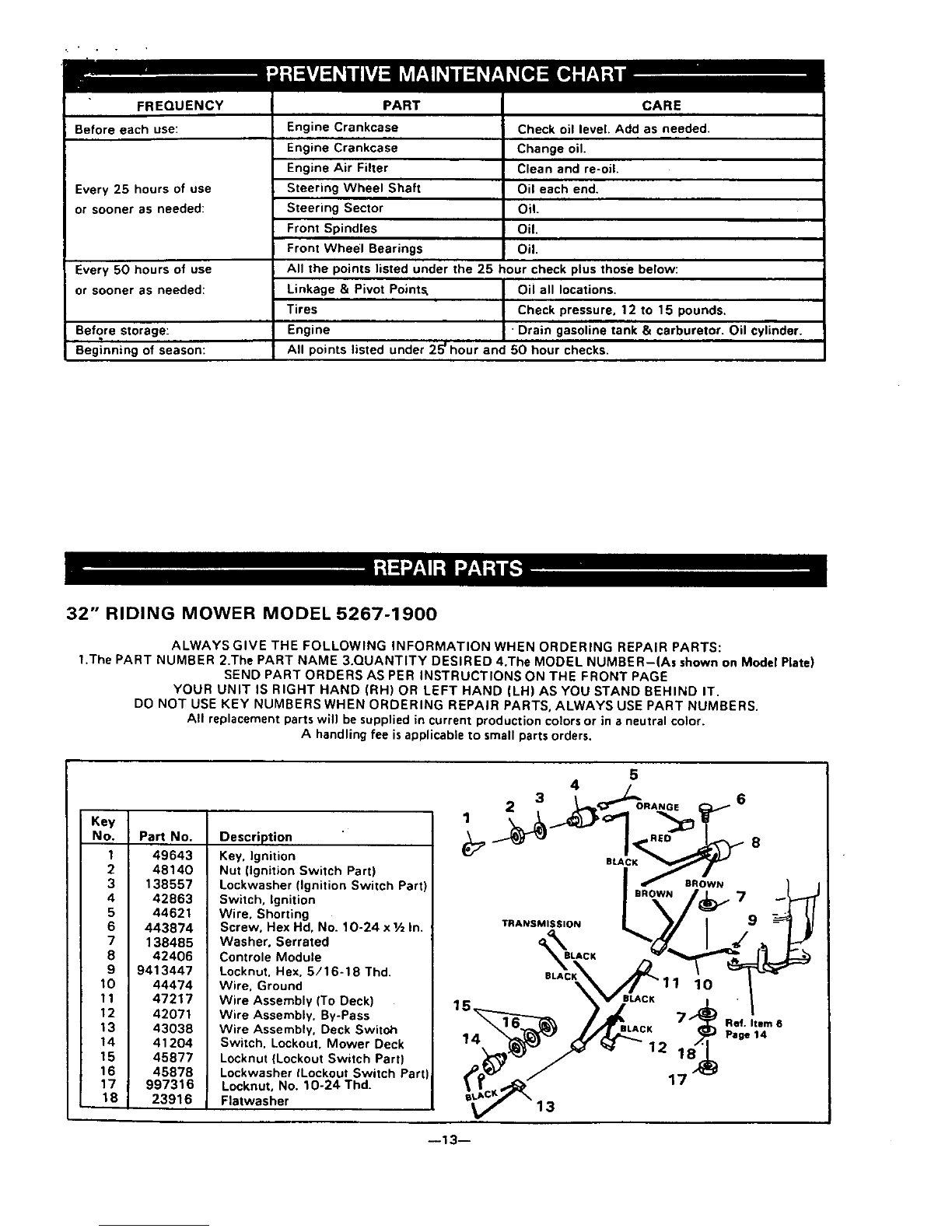

FREQUENCY

Before each use:

Every 25 hours of use

or sooner as needed:

Every 50 hours of use

or sooner as needed:

Before storage:

Beginning of season:

PART

Engine Crankcase

Engine Crankcase

Engine Air Filter

Steering Wheel Shaft

Steering Sector

Front Spindles

Front Wheel Bearings

CARE

Check oil level. Add as needed.

Change oil.

Clean and re-oiL

Oil each end.

Oil.

Oil.

Oil.

All the points listed under the 25 hour check plus those below:

Linkage & Pivot Points. Oil all locations.

Tires Check pressure, 12 to 15 pounds.

Engine ' Drain gasoline tank & carburetor. Oil cylinder.

All points listed under 25uhour and 50 hour checks.

32" RIDING MOWER MODEL 5267-1900

ALWAYS GIVE THE FOLLOWING INFORMATION WHEN ORDERING REPAIR PARTS:

1.The PART NUMBER 2.The PART NAME 3.QUANTITY DESIRED 4.The MODEL NUMBER-(As shown on Model Plate)

SEND PART ORDERS AS PER INSTRUCTIONS ON THE FRONT PAGE

YOUR UNIT IS RIGHT HAND (RH) OR LEFT HAND (LH) AS YOU STAND BEHIND IT.

DO NOT USE KEY NUMBERS WHEN ORDERING REPAIR PARTS, ALWAYS USE PART NUMBERS.

All replacement parts will be supplied in current production colors or in aneutral color.

A handling fee isapplicable to small parts orders.

Key

No. Pa_ No.

149643

2 4814O

3138557

4 42863

5 44621

6 443874

7 138485

8 42406

9 9413447

10 44474

11 47217

12 42071

13 43038

14 41204

15 45877

16 45878

17 997316

18 23916

Description

Key. Ignition

Nut (Ignition Switch Part)

Lockwasher (Ignition Switch Part)

Switch, Ignition

Wire. Shorting

Screw, Hex Hd, No. 10-24 x1/zIn.

Washer, Serrated

Controle Module

Locknut. Hex, 5/16-18 Thd.

Wire. Ground

Wire Assembly (To Deck)

Wire Assembly. By-Pass

Wire Assembly. Deck Switoh

Switch. Lockout. Mower Deck

Locknut (Lockout Switch Part)

Lockwasher tLockout Switch Part

Locknut, No. 10-24 Thd.

Flatwasher

14

5

4

TRANSMISSION

BLACK

BROWN

11 10

1"7

7

9

Ref. Item 6

Page 14

--13--

32" RIDING MOWER MODEL 5267-1900

I"

7 8 35

49 .--4

41-_'_-4L. 4.3,

Ref. Item 38

51

52

64 63

\\

ALL UNNUM8E RED

ITEMS ARE INTERCHANGEABLE

WITH OPPOSITE SIDE

32" RIDING MOWER MODEL 5267-1900

I

Key

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

Part No.

997316

41652

23916

9413447

120638

Engine

46853

23700

9413534

39628

39830

24167

40677

46836

122040

50653

49896

18 271184

19 120386

20 33200

21 120758

22 120382

23 43961

24 39659

25 35374

26 120918'

Description

Locknut, No. 10-24 Thd.

Clip, Conduit

Washer

Locknut. Hex, 5/16-18 Thd

*Lockwasher, Split. 5/16 In.

§See footnote below

Oil Drain Tube

Pipe Plug, 1AIn.

Locknut, Hex, %-16 Thd

Key, 3/16 x 3/6 x 21/z in.

Tire

Valve Stem

*Flatwasher, _,_In.

Support, Bearing Bracket

Screw. Hex Hd, 5/16-16 x 1½In,

Belt Guide, Blade Drive

Belt Guide, Transmission Drive

Belt

Nut. Hex, Keps. 5/16-18 Thd

*Flatwasher, tA In. "

Key, Engine Pulley

Screw, Hex Hd. _-24 x_= In.

Lockwasher, Split

Pulley. Engine

Belt Retainer

Pulley, Idler

"Screw, Hex Hd, _-16 x1½ In.

Key

No.

27

28

29

3O

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

Pa_ No.

28928

46848

43953

22053

43979

39266

3021

49276

121222

120385

43980

52707

52317

52316

43967

43968

40974

69191

50562

52640

48761

43956

42860

rransmission

53102

20307

Description

Shoulder Bolt

Arm, Drive Idler

Spacer

Retaining Ring

V-Belt, Transmission Drive

Pulley, Transmission

Woodruff Key

Spring, Main Drive

*Pin, Cotter, 3/32 x _i In.

Flatwasher

Rod. Clutch

Main Frame

Foot Pad, Left

Foot Pad, Right

Arm, Parking Brake

Spring, Parking Brake

Shoulder Bolt, Parking Brake

Decal, Parking Brake

Spring, Clutch Pedal

Brake Pedal Assembly

Rubber Pad, Brake Pedal

Shaft. Brake-Clutch Pedal

Knob, Gear Shift

:_FOote,Model No. 35-41

Chain Assembly

Link (Only), Chain Connector

No. 41

Key

No.

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

"Standard Hardware Items - May Be Purchased Locally.

tContact Tecumseh/Peerless authorized service dealer for parts and warranty.

:_Contact J.B. Foote Foundry Co., Fredericktown, Ohio 43019, (614) 694-2055 for parts and warranty.

§Replacement engines and parts are obtainable from Engine Manufacturer's authorized Service Stations who are also to be contacted

in regard to the Engine Warranty. See your Engine Manual for location of these stations.

Pa_ No.

446363

122089

43991

83103

52398

9424215

35410

138485

120229

998013

40394

36625

42815

49053

642

44449

43987

35345

39797

Differenlial

-67327

443874

47974

Description

*Flatwasher, 5/16 In.

*Screw, Hex Hd. 5/16-18 x 3 In.

Belt Guide, Transmission Pulley

Rod, Brake

Bracket, Brake Rod

Locknut, 1A-20 Thd.

Spring. Brake Return

*Washer. Shakeproof, 5/16 In.

Screw. hex Hd, 5/16-18 x VaIn.

*Carriage Bolt, 5/16-18 x 3,4In.

Hub Cap

"'E'" Ring, 3AIn.

Flatwasher

Wheel

Flatwasher

Spacer

Plate, Bearing Retainer

Bearing

Sprocket, 54 Tooth, No. 41

tPeerless. Model 171B

Differential Parts

Decal, Caution 10-24 x Vz In!

Screw, hex Hd, No.

Shoulder Bolt

32" RIDING MOWER MODEL 5267-1900

I

d

o_

I 57

16,

50-,_

47

67

30

4)_ 48

3

55 r" 39

59 2

60"

Ref. Item 38

Page 14

69

"37

67

45

17

-26

38- /

3 27

16

Ref. Item 38

Page 14

II

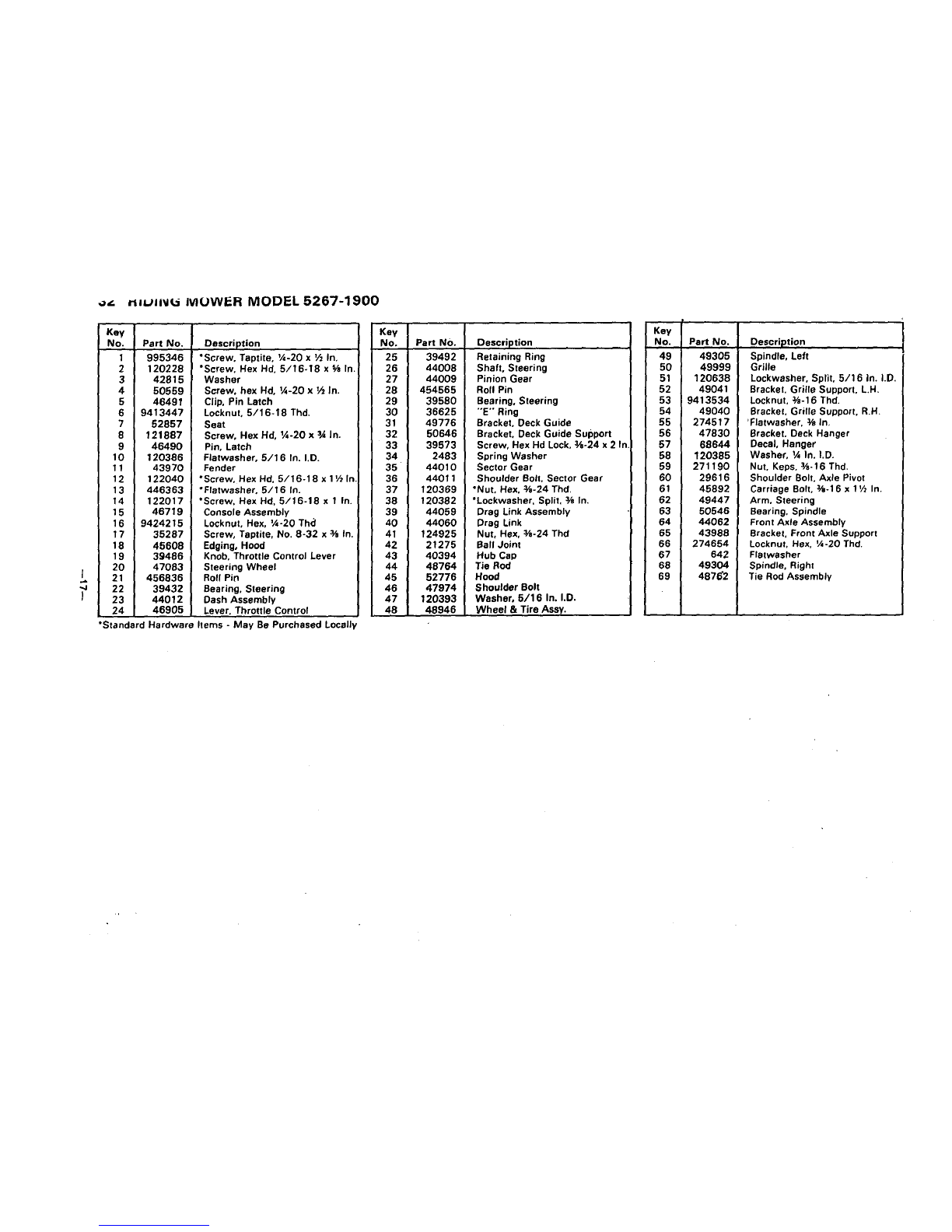

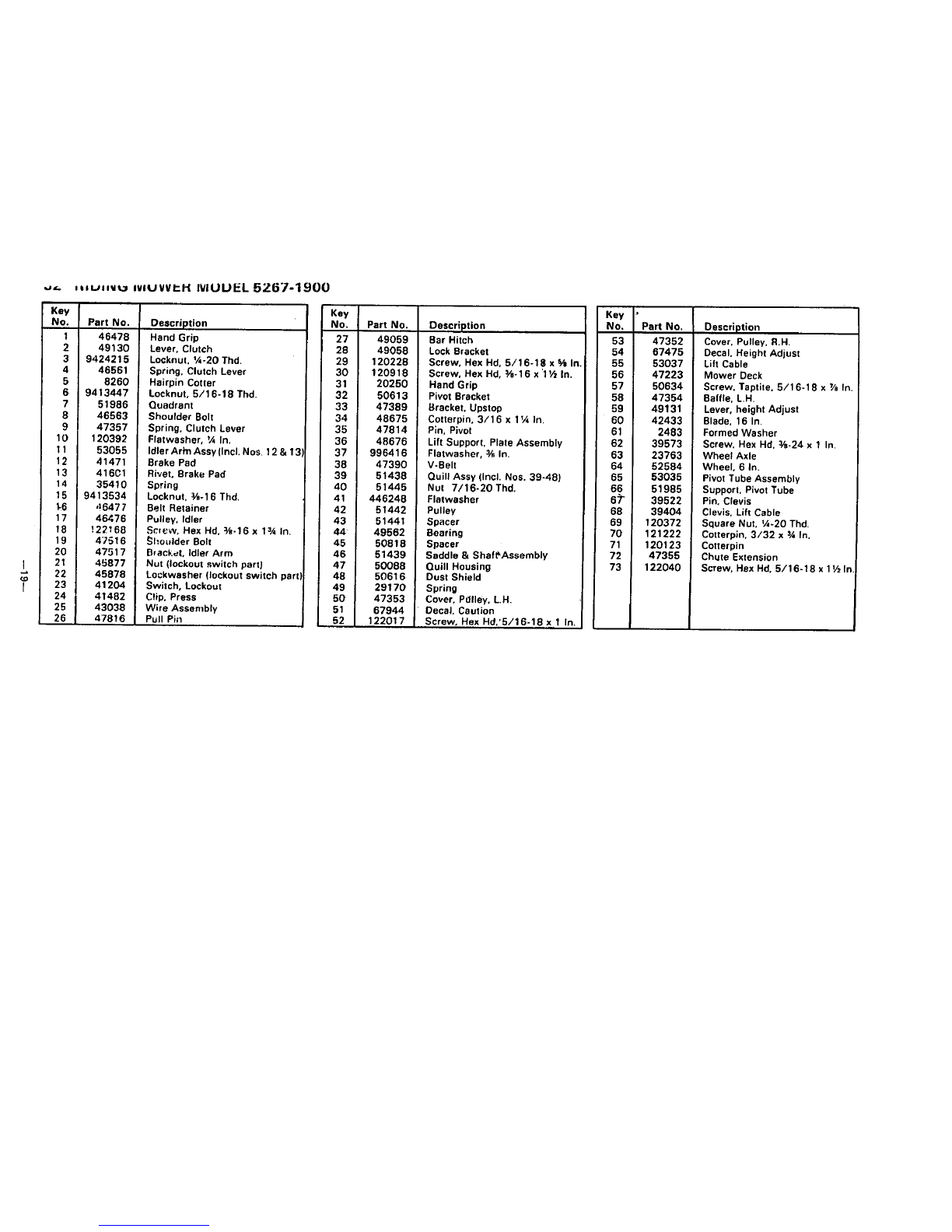

._,_ rt=uJi_ NIOWER MODEL 5267-1900

)

Key

No. Part No.

1 995346

2120228

342815

4 50559

5 46491

6 9413447

7 62857

8121887

946490

10 120386

11 43970

12 122040

13 446363

14 122017

15 46719

16 9424215

17 35287

18 45608

19 39486

20 47083

21 456836

22 39432

23 44012

24 46905

Description

"Screw. Taptite, 1A-20 x½In,

*Screw. Hex Hd, 5/16-18 x % In.

Washer

Screw. hex Hd, 1A-20 xV2In.

Clip. Pin Latch

Locknut, 5/16-18 Thd.

Seat

Screw, Hex Hd, 1A-20 x3_ In.

Pin, Latch

Flatwasher, 5/16 In. I.D.

Fender

"Screw, Hex Hd. 5/16-18 x 1½In

"Flatwasher, 5/16 In.

"Screw. Hex Hd. 5/16-18 x 1In.

Console Assembly

Locknut, Hex. IA-20 Th_

Screw, Taptite. No. 8-32 x % In.

Edging, Hood

Knob. Throttle Control Lever

Steering Wheel

Roll Pin

Bearing. Steering

Dash Assembly

Lever. Throttle Control

"Standard Hardware Items - May Be Purchased Locall

Key

No.

25

26

27

28

29

3O

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

Part No.

39492

44008

44009

454565

39580

36625

49776

50646

39573

2483

44010

44011

120369

120382

44059

44060

124925

21275

40394

48764

52776

47974

120393

46946

Description

Retaining Ring

Shaft, Steering

Pinion Gear

Roll Pin

Bearing, Steering

"'E'" Ring

Bracket, Deck Guide

Bracket. Deck Guide Support

Screw, Hex Hd Lock. %-24 x 2 In.

Spring Washer

Sector Gear

Shoulder Bolt. Sector Gear

"Nut, Hex. %-24 Thd,

*Lockwasher. Split. YeIn.

Drag Link Assembly

Drag Link

Nut, Hex, %.24 Thd

Ball Joint

Hub Cap

Tie Rod

Hood

Shoulder Bolt

Washer, 5/16 In. I.D.

Wheel & Tire Assy.

Key

No.

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

55

56

67

68

69

PaN No.

49305

49999

120638

49041

9413534

49040

274517

47830

68644

120385

271190

29616

45892

49447

50546

44062

43988

274654

642

49304

4878"2

Description

Spindle, Left

Grille

Lockwasher, Split. 5/16 In. I.D.

Bracket. Grille Support. LH.

Locknut. %-16 7hd.

Bracket. Grille Support. R.H

'Flatwasher. %In,

Bracket. Deck Hanger

Decal, Hanger

Washer, _AIn. I.D.

Nut. Keps. %-16 Thd.

Shoulder Bolt. Axle Pivot

Carriage Bolt. %-16 x 1½ In.

Arm. Steering

Bearing, Spindle

Front Axle Assembly

Bracket. Front Axle Support

Locknut. Hex, _A-20 Thd.

Flatwasher

Spindle. Right

Tie Rod Assembly

32" RIDING MOWER MODEL 5267-1900

I

ALL UNNUMBERED

I_ _ /I

29 31

"" 6 49 73

72

_-.,, lllull_u tVlUVt/I::H IVIUUEL 5Z67-1900

L

T

Key

No.

1

2

3

4

6

6

7

8

9

10

11

12

13

14

15

1.6

17

18

19

20

21

22

23

24

25

26

Part No.

46478

49130

9424215

46561

8260

9413447

51986

46563

47357

120392

53055

41471

416C1

35410

9413534

46477

46476

!22168

47516

47517

45877

45878

41204

41482

43038

47816

Description

Hand Grip

Lever, Clutch

Locknut. 1A.20 Thd.

Spring. Clutch Lever

Hairpin Cotter

Locknut, 5/16-18 Thd.

Quadrant

Shoulder Bolt

Spring, Clutch Lever

Flatwasher, _AIn.

Idler Artn Assy (Incl. Nos 12 & 13

Brake Pad

Rivet, Brake Pad

Spring

Locknut. _-16 Thd.

Belt Retainer

Pulley. idler

Screw. Hex Hd. ¥B-16 xlZA In.

_;ho_dder Bolt

Btack_t, Idler Arm

Nut (lockout switch part)

Lockwasher (lockout switch part)

Switch, Lockout

Clip. Press

Wire Assembly

Pull Pin

Key

No. Pert No.

27 49059

28 49058

29 120228

30 120918

31 20250

32 50613

33 47389

34 48675

35 47814

36 48676

37 996416

38 47390

39 51438

40 51445

41 446248

42 51442

43 51441

44 49562

45 50818

46 51439

47 50088

48 50616

49 29170

50 47353

51 67944

62 122017

Description

Bar Hitch

Lock Bracket

Screw, Hex Hd. 5/16-18 x % In.

Screw. Hex Hd, ¥J-16 x'11/2In.

Hand Grip

Pivot Bracket

Bracket. Upstop

Cottarpin, 3/16 x 1T,4In.

Pin. Pivot

Lift Support. Plate Assembly

Fletwasher, YBIn.

V-Belt

Quill Assy (Incl. Nos. 39-48)

Nut 7/16-20 Thd.

Fletwasher

Pulley

Spacer

Bearing

Spacer

Saddle & ShafPAssembly

Quill Housing

Dust Shield

Spring

Cover, Pdlley. L,H,

Decal, Caution

Screw, Hex Hd/5/16-18 x 1In.

Key

No,

53

54

55

56

57

58

59

60

61

62

63

64

65

66

6_-

68

69

70

71

72

73

Part No,

47352

67475

63037

47223

50634

47354

49131

42433

2483

39573

23763

62584

53035

51985

39522

39404

120372

121222

120123

47355

122040

Description

Cover. Pulley. R.H,

Decal. Height Adjust

Lift Cable

Mower Deck

Screw. Taptite, 5/16-18 x 7/eIn.

Baffle, L.H.

Lever, height Adjust

Blade, 16 In

Formed Washer

Screw, Hex Hd. ¥s-24 x 1 In.

Wheel Axle

Wheel, 6 In.

Pivot Tube Assembly

Support. Pivot Tube

Pin. Clevis

Clevis. Lift Cable

Square Nut. _A-20 Thd,

Cotterpln. 3/32 x 3AIn.

Cotterpin

Chute Extension

Screw. Hex Hd. 5/16-18 x 11/2In

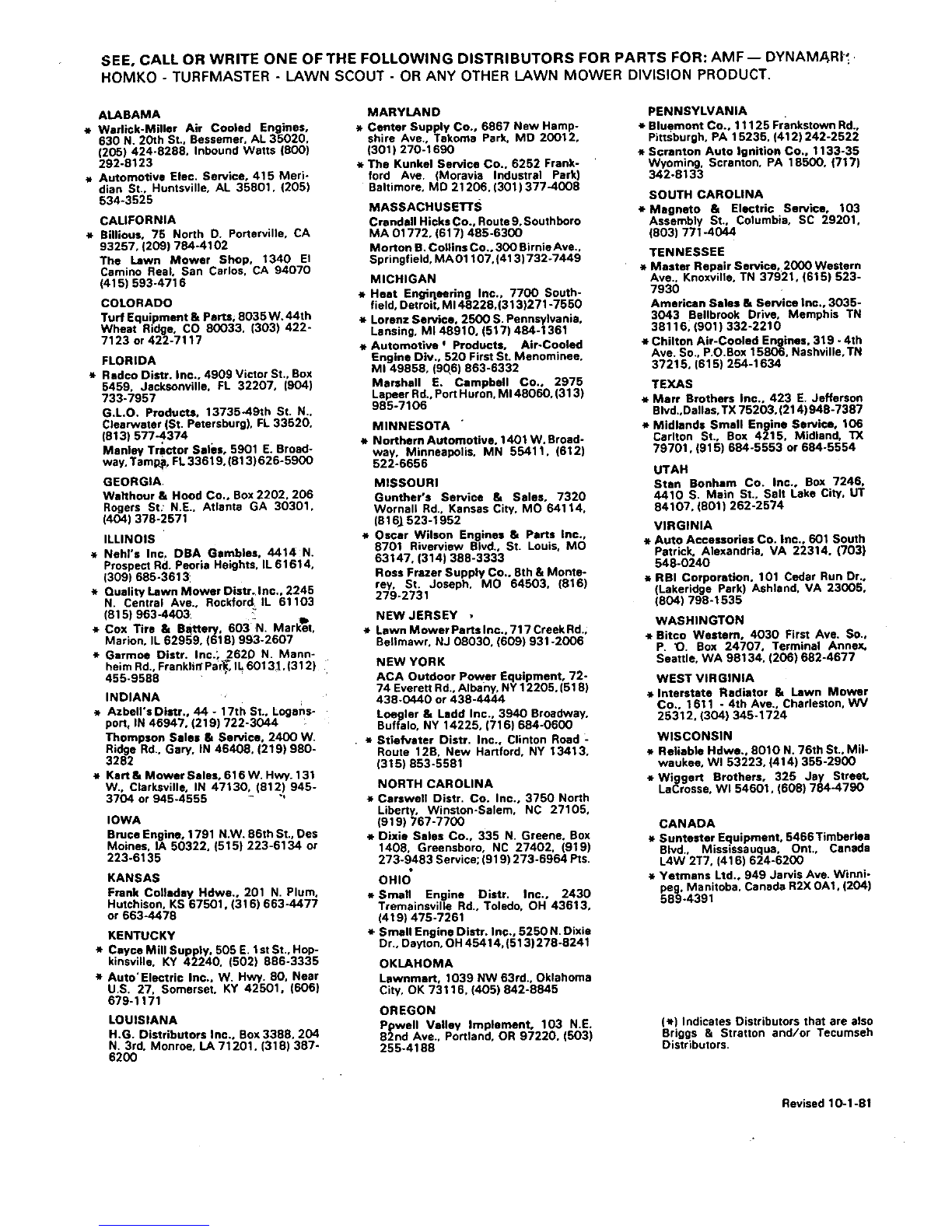

SEE, CALL OR WRITE ONE OF THE FOLLOWING DISTRIBUTORS FOR PARTS FOR: AMF -- DYNAMARI'_ .

HOMKO - TURFMASTER - LAWN SCOUT - OR ANY OTHER LAWN MOWER DIVISION PRODUCT.

ALABAMA

_* Warli¢k-Miller Air Cooled Engines,

630 N. 20th St., Bessemer, AL 35020.

1205) 424-8288. Inbound Watts (800)

292-8123

e Automotive Elec. Service, 415 Meri-

dian St.. Huntsville, AL 35801, (205)

534-3525

CALIFORNIA

*Sillious, 75 North D. Portarville, CA

93257, (209) 784-4102

The Lawn Mower Shop, 1340 El

Camino Real. San Carlos. CA 94070

(415) 593-4716

COLORADO

Turf Equipment & parts, 8035 W.44th

Wheat Ridge, CO 80033. (303) 422-

7123 or 422-7117

FLORIDA

*Redco Distr. Inc., 4909 Victor St., Box

5459. Jacksonville. FL 32207, (904)

733-7957

G.LO. Products, 13735-491h St. N..

Clearwater (St. Petersburg), FL 33520,

(813) 577-4374

Manley Tractor Sales, 5901 E. Broad-

way, Tamp_, FL 33619. (813) 626-5900

GEORGIA•

Walthour & Hood Co., Box 2202. 206

Rogers St: N.E.. Atlanta GA 30301.

(404) 378-2571

ILLINOIS

*Nehl's Inc, DBA Gambles. 4414 N.

Prospect Rd. Peoria Heights. IL 61614,

(309) 685-3613

*Quality Lawn Mower Distr, Inc.. 2245

N. Central Ave., Rockford, IL 61103

(815) 963-4403

* Cox Tire & Blttery. 603-N. Mark_st.

Marion, IL 62959, (618) 993-2607

Garmoe Distr. Inc.; 2620 N. Mann-

heim Rd., Franklill Psr_, L 60131.(312)

455-9588

INDIANA

*Azbell's Distr., 44 - 17th St., Logans-

port. IN 46947. (219) 722-3044

Thompson Sales _Service, 2400 W.

Ridge Rd., Gary. IN 46408. (219) 980-

3282

*Kart & Mower Sales, 616 W. Hwy. 131

W.. Clarksville, IN 47130, (812) 945-

3704 or 945-4555 - "

IOWA

Bruce Engine, 1791 N.W. 86th St., Des

Moines. IA 50322. (515) 223-6134 or

223-6135

KANSAS

Frank Colleday Hdwe., 201 N. Plum.

Hutchison. KS 67501. (316) 663-4477

or 663.4478

KENTUCKY

*Cayce Mill Supply. 505 E. 1st St., Hop-

kinsville. KY 42240. (502) 866-3335

*Auto'Electric Inc.. W. Hwy. 80, Near

U.S. 27. Somerset. KY 42501. (606)

679-1171

LOUISIANA

H.G. Distributors Inc., Box 3388. 204

N. 3rd. Monroe, LA 71201. (318) 387-

6200

MARYLAND

*Center Supply Co., 6867 Hew Hamp-

shire Ave., Takoma Park. MD 20012,

(301) 270-1690

_*The Kunkel Service Co.. 6252 Frank-

ford Ave. (Moravia Industral Park)

Baltimore, MD 21206. (301) 377-4008

MASSACHUSETTS

Crandell Hicks Co., Route 9.Southboro

MA 01772. (617) 485-6300

Morlon B. Collins Co., 300 Birnie Ave..

Springfield, MAO1107,(413)732-7449

MICHIGAN

*Heat Engiqsoring Inc., 7700 South-

field, Detroit, M148228,(313)271-7550

*Lorenz Service, 2500 S. Pennsylvania.

Lansing, MI 48910, (517) 484-1361

_*Automotive JProducts, Air.Cooled

Engine Div., 520 First St. Menominee,

MI 49858, (90,6) 863-6332

Marshall E. Campbell Co., 2975

Lapeer Rd, Port Huron. M148060. (313)

985-7106

MINNESOTA

*Northem Automot_e, 1401W.Broad-

way. Minneapolis, MN 55411.(612)

522-6656

MISSOURI

Gunther's Service & Sales, 7320

Wornall Rd., Kansas City. Me 64114.

(816_ 523-1952

*Oscar Wilson Engines & Parts Inc.,

8701 Riverview BIvd., St. Louis. MO

63147. (314) 368-3333

Ross Frazer Supply Co.. 8th & Monte-

rey. St. Joseph, MO 64503. (816)

279-2731

NEW JERSEY •

•m.Lawn MowerPartslnc.,717CreekRd.,

BeIlmawr. NJ 08030. (609) 931-2006

NEW YORK

ACA Outdoor Power Equipment, 72-

74 Everett Rd., Albany. NY 12205, (518)

438-0440 or 438-4444

Loegler & Ladd Inc., 3940 Broadway.

Buffalo, NY 14225, (716) 684-0600

•*Stiefvster Distr. Inc., Clinton Road -

Route 12B, New Hartford. NY 13413,

(315) 853-5581

NORTH CAROLINA

*Carswell Distr. Co. Inc., 3750 North

Liberty. Winston-Salem, NC 27105,

(919) 767-7700

Dixie Sales Co., 335 N. Greene. Box

1408. Greensboro, NC 27402. (919)

273-9483 Service; (919) 273-5964 Pts.

OHIO"

* Small Engine Distr. Inc., 2430

Tremsinsville Rd., Toledo, OH 43613,

(419) 475-7261

Small Engine Distr. Inc., 5250 N. Dixie

Dr., Dayton, OH 45414, (513) 278-8241

OKLAHOMA

Lawnmart, 1039 NW 63rd.. Oklahoma

City, OK 73116, (405) 842-8845

OREGON

Ppwell Valley Implement, 103 N.E.

92nd Ave.. Portland, OR 97220. (503)

255-4188

PENNSYLVANIA

* Bluemont Co., 11125 Frankstown Rd..

Pittsburgh, PA 15235. (412)242-2522

*Scranton Auto Ignition Co., 1133-35

Wyoming. Scranton. PA 18500, (717)

342-8133

SOUTH CAROLINA

*Magneto 8z Electric Service, 103

Assembly St., Columbia. SC 29201.

(803) 771.4044

TENNESSEE

*Master Repair Service. 2000 Western

Ave.. Knoxville, TN 37921, (615) 523-

7930

American Sales &Service Inc.. 3035-

3043 Bellbrook Drive, Memphis TN

38116, (901) 332-2210

e Chilton Air-Cooled Engines. 319 - 4th

Ave. So.. P.O.Box 15806. Hsshville, TN

37215, (615) 254-1634

TEXAS

*Marr Brothers Inc., 423 E. Jefferson

Blvd.,Dallas, TX 75203. (214) 948-7387

*Midlands Small Engine Service, 106

Carlton St., Box 4215. Midland. TX

79701. (915) 684-5553 or 684-5554

UTAH

Stan Bonham Co. Inc., Box 7246.

4410 S. Main St., Salt Lake City. UT

84107. (801) 262-2574

VIRGINIA

*Auto Accessories Co. Inc.. 601 South

Patrick. Alexandria, VA 22314. (703)

548-0240

*RBI Corporation, 101 Cedar Run Dr.,

(Lakeridge Park) Ashland. VA 23005.

(804) 798-1535

WASHINGTON

*Bitco Weetemo 4030 First Ave. So.,

P. _. Box 24707. Terminal Annex.

Seattle. WA 98134. (206) 682-4677

WEST VIRGINIA

Interstate Radiator 8= Lawn Mower

Co., 1611 -4th Ave., Charleston. WV

25312. (304) 345-1724

WISCONSIN

*Reliable Hdwe., 8010 N. 76th St.. Mil-

waukee, WI 53223, {414) 355-2900

*Wiggert Brothers, 325 Jay StreeL

LaCrosse. WI 54601. (606) 784-4790

CANADA

.Suntester Equipment, 6466 Timberlea

Blvd., Mississsuqua. Ont., Canada

L4W 2T7, (416) 624-6200

.Yetmans Ltd., 949 Jarvis Ave. Winni-

peg. Manitoba. Canada R2X 0A1. (204)

589-4391

(e) Indicates Distributors that are also

Briggs & Strstton and/or Tecumseh

Distributors.

Revised 10-1-81

Popular Lawn Mower manuals by other brands

Country Clipper

Country Clipper JAZee One SR100 Safety instructions & operator's manual

Kubota

Kubota ZG124E-AU Operator's manual

Kubota

Kubota Z232KW-AU Operator's manual

Husqvarna

Husqvarna Z 572x user manual

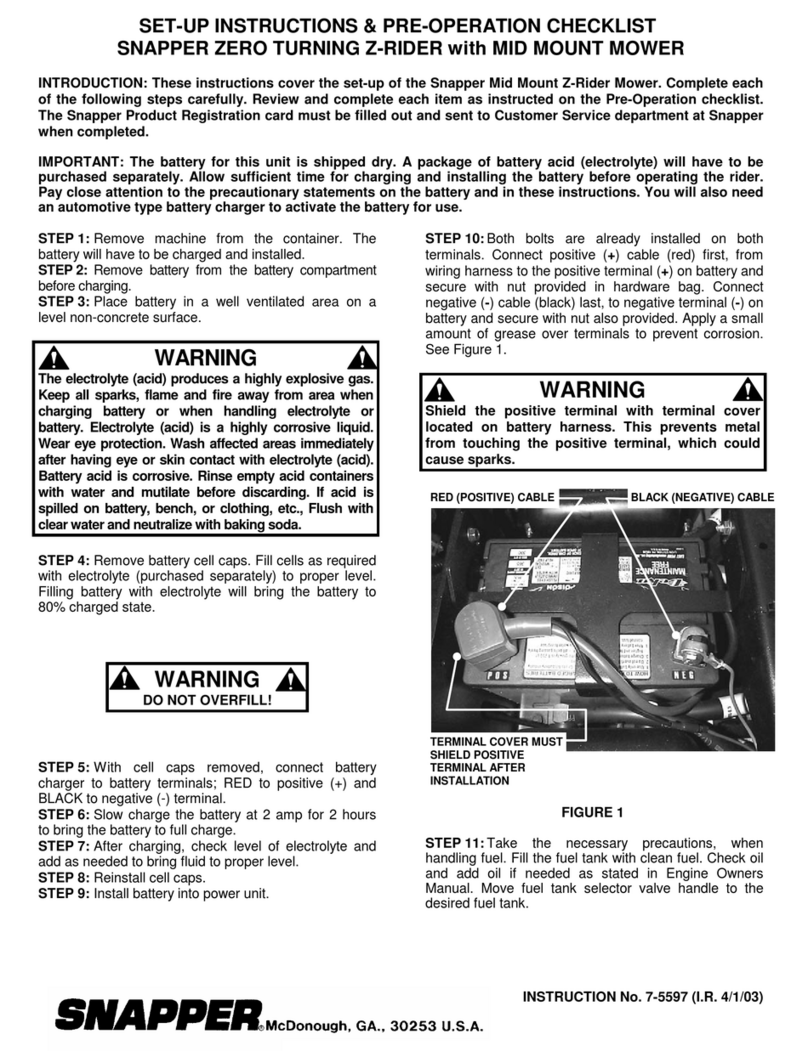

Snapper

Snapper Z-rider Set-up instructions & pre-operation checklist

AL-KO

AL-KO 660 Original instructions for use