ECOCONDENS SILVER PLUS

ISU-646:2016/GR-H str.2

Table of Contents

1. INTRODUCTION .......................................................................................................................................................................................................................................................................... 3

2. BOILER DESCRIPTION .................................................................................................................................................................................................................................................................. 3

2.1.

T

ECHNICAL SPECIFICATION

........................................................................................................................................................................................................................................................ 3

2.1.1. Technical features...................................................................................................................................................................................................................................................... 3

2.2.

D

ESIGN AND TECHNICAL SPECIFICATIONS OF THE BOILER

.................................................................................................................................................................................................................... 3

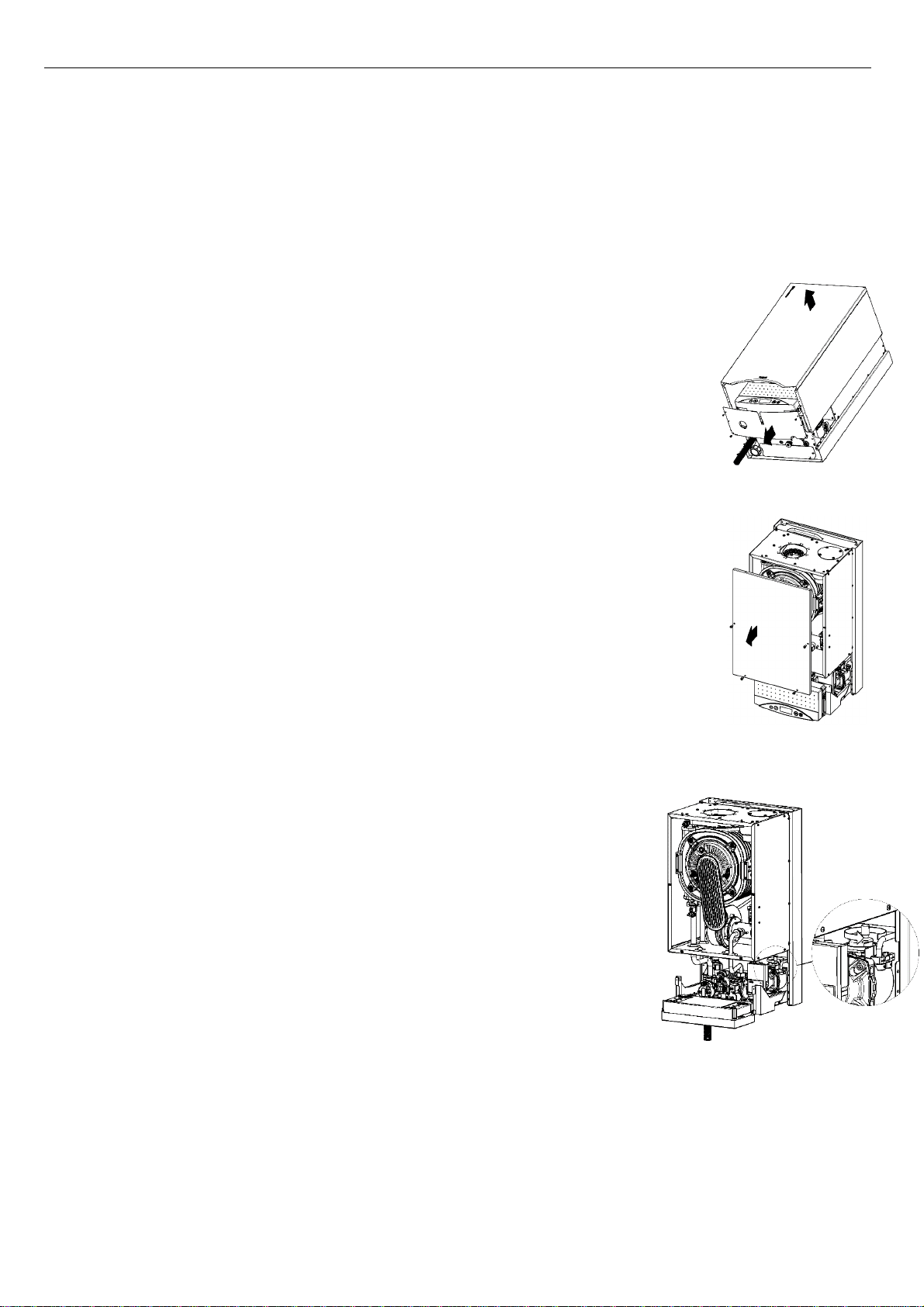

2.2.1. Main units of the boiler.............................................................................................................................................................................................................................................. 3

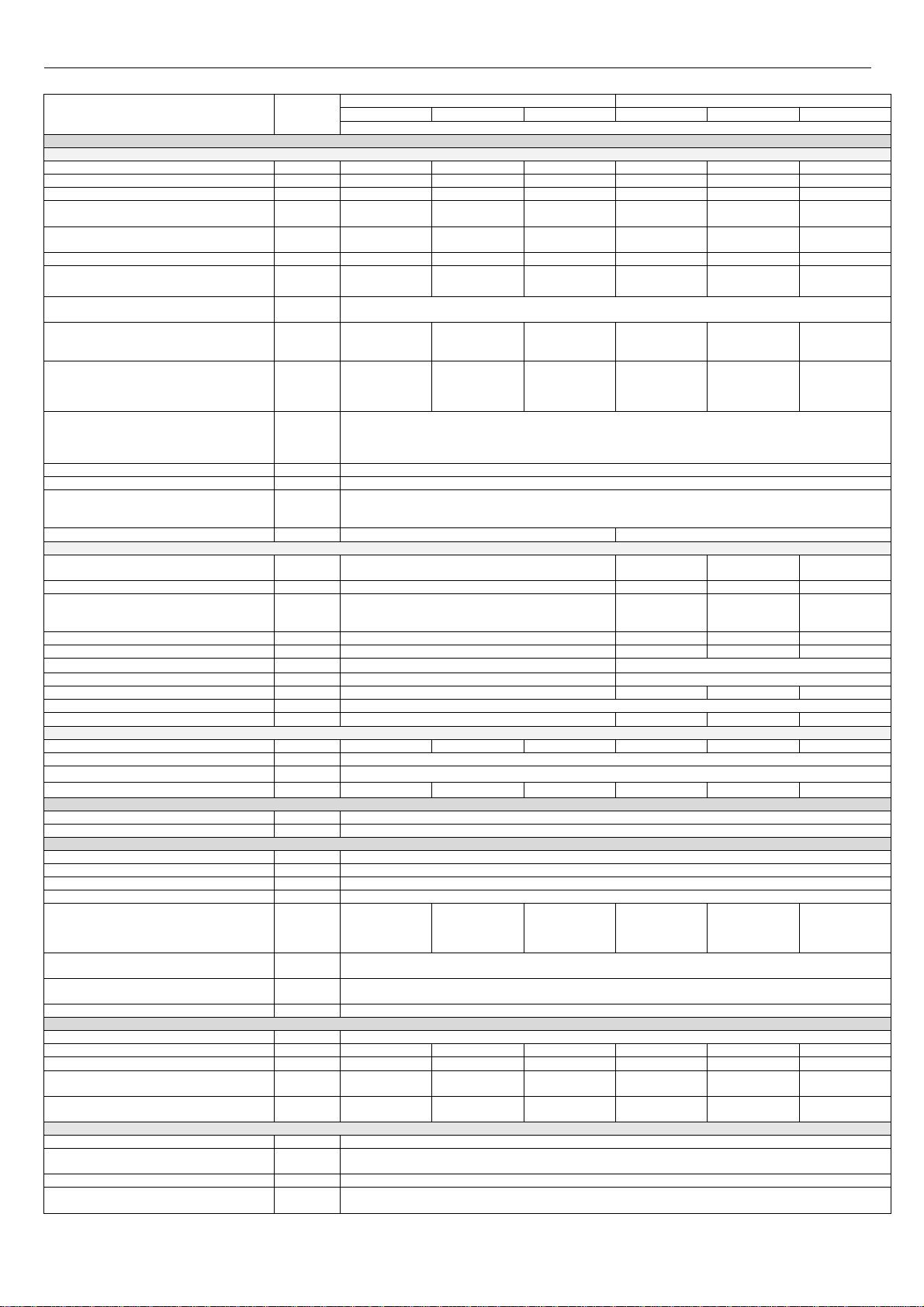

2.2.2. Technical data ........................................................................................................................................................................................................................................................... 5

2.3.

P

ROTECTION EQUIPMENT

.......................................................................................................................................................................................................................................................... 6

2.4.

O

PERATION DESCRIPTION

.......................................................................................................................................................................................................................................................... 6

2.4.1. Way of heating the water for central heating system ................................................................................................................................................................................................ 6

2.4.2. Temperature regulation dependent on e ternal temperature ................................................................................................................................................................................... 6

2.4.3. Method of D.H.W. heating in combi boilers ............................................................................................................................................................................................................... 7

2.4.4. The way of heating the water in system boiler ECOCONDENS SILER PLUS cooperating with domestic water tank. ................................................................................................... 7

2.4.5. Operation of the pump with adjustable speed. ......................................................................................................................................................................................................... 8

3. BOILER INSTALLATION ............................................................................................................................................................................................................................................................... 9

3.1.

R

EQUIREMENTS OF BOILER INSTALLATION

...................................................................................................................................................................................................................................... 9

3.1.1. The regulations on the water installation, gas and the flue gas system ..................................................................................................................................................................... 9

3.1.2. Regulations related to the room ................................................................................................................................................................................................................................ 9

3.1.3. Requirements for electrical installation .................................................................................................................................................................................................................... 9

3.2.

P

RELIMINARY CHECK ACTIVITIES

................................................................................................................................................................................................................................................ 10

3.3.

M

OUNTING THE BOILER ON THE WALL

........................................................................................................................................................................................................................................ 10

Fig. 3.3.1 Installation dimensions of boiler ECOCONDENS SILVER PLUS ............................................................................................................................................................................. 10

3.4.

C

ONNECTION TO THE GAS INSTALLATION

..................................................................................................................................................................................................................................... 10

3.5.

C

ONNECTION OF THE BOILER TO A WATER SYSTEM OF CENTRAL HEATING

............................................................................................................................................................................................. 10

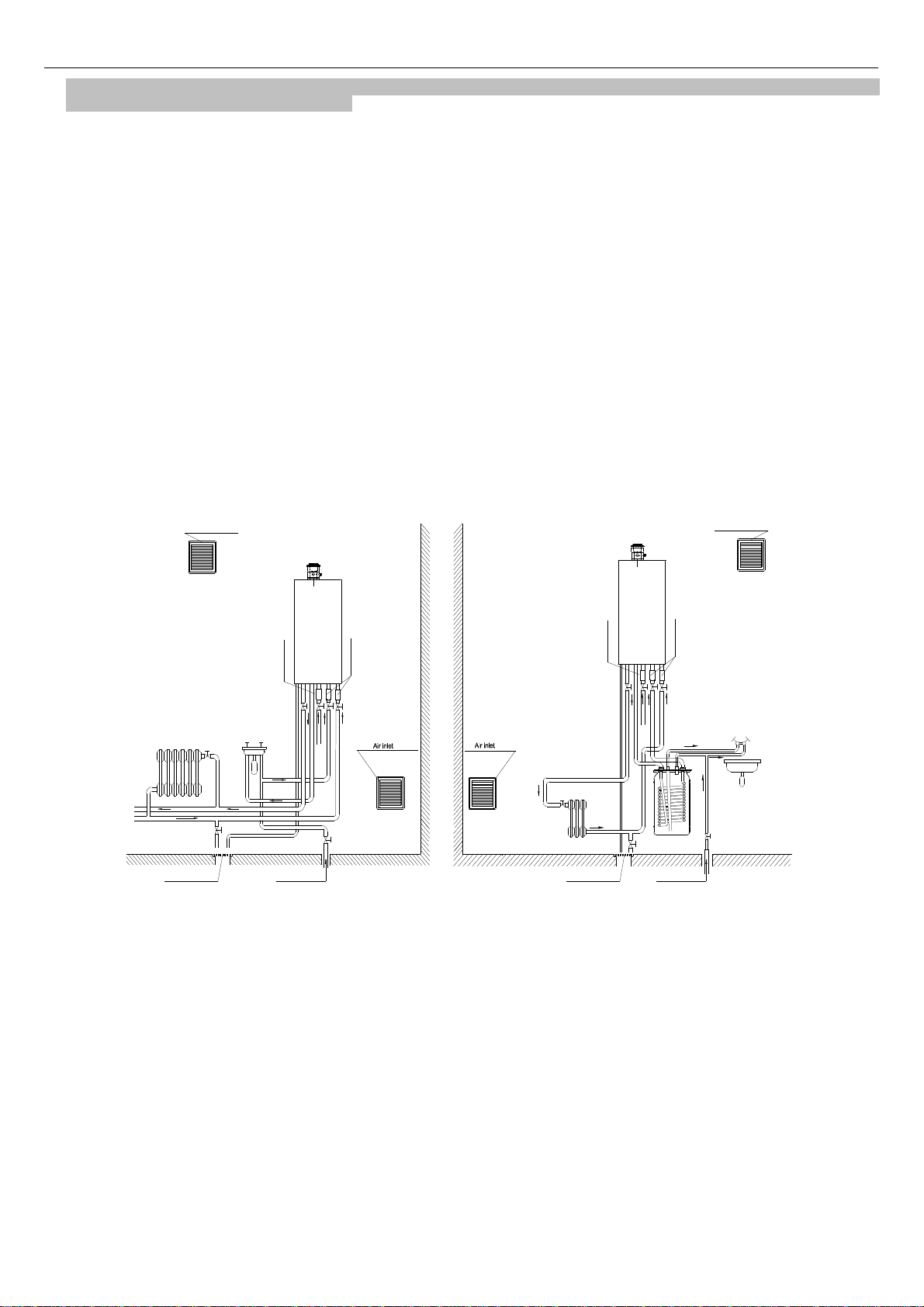

Fig. 3.5.1 Boilers installation requirements ........................................................................................................................................................................................................................ 11

3.5.2 System cleaning and water treatment for the C.H. filling. ......................................................................................................................................................................................... 11

3.6.

C

ONNECTION OF THE BOILER TO A DOMESTIC HOT WATER SYSTEM

.................................................................................................................................................................................................... 12

3.7.

C

ONDENSATE OUTLET

............................................................................................................................................................................................................................................................. 12

3.8.

F

LUE GAS OUTLET

.................................................................................................................................................................................................................................................................. 12

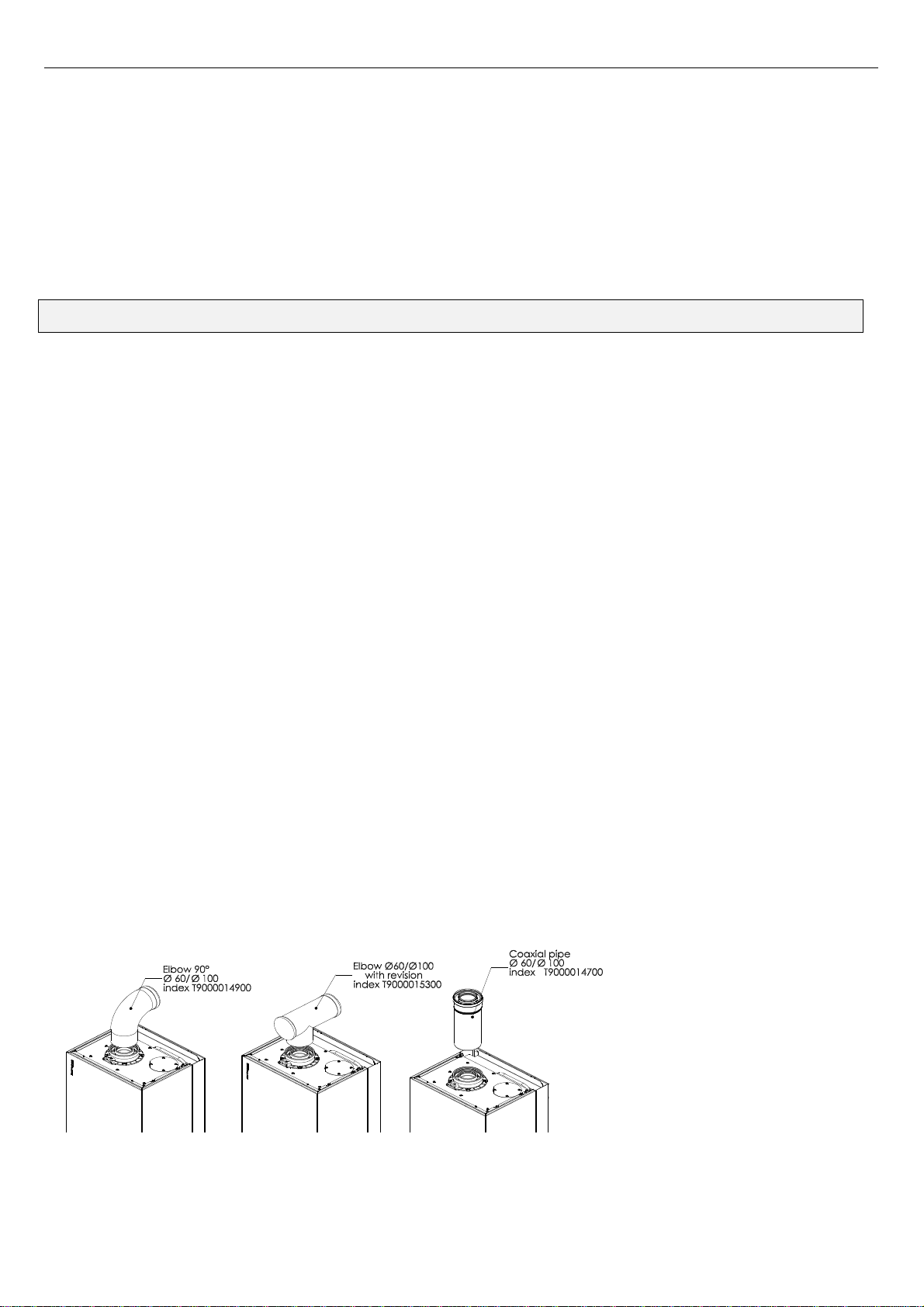

3.8.1. The ways of mounting adapters (elbows connection) to the boiler type .................................................................................................................................................................. 12

3.8.2. Horizontal outlet of air- flue system through the wall or on the roof ....................................................................................................................................................................... 13

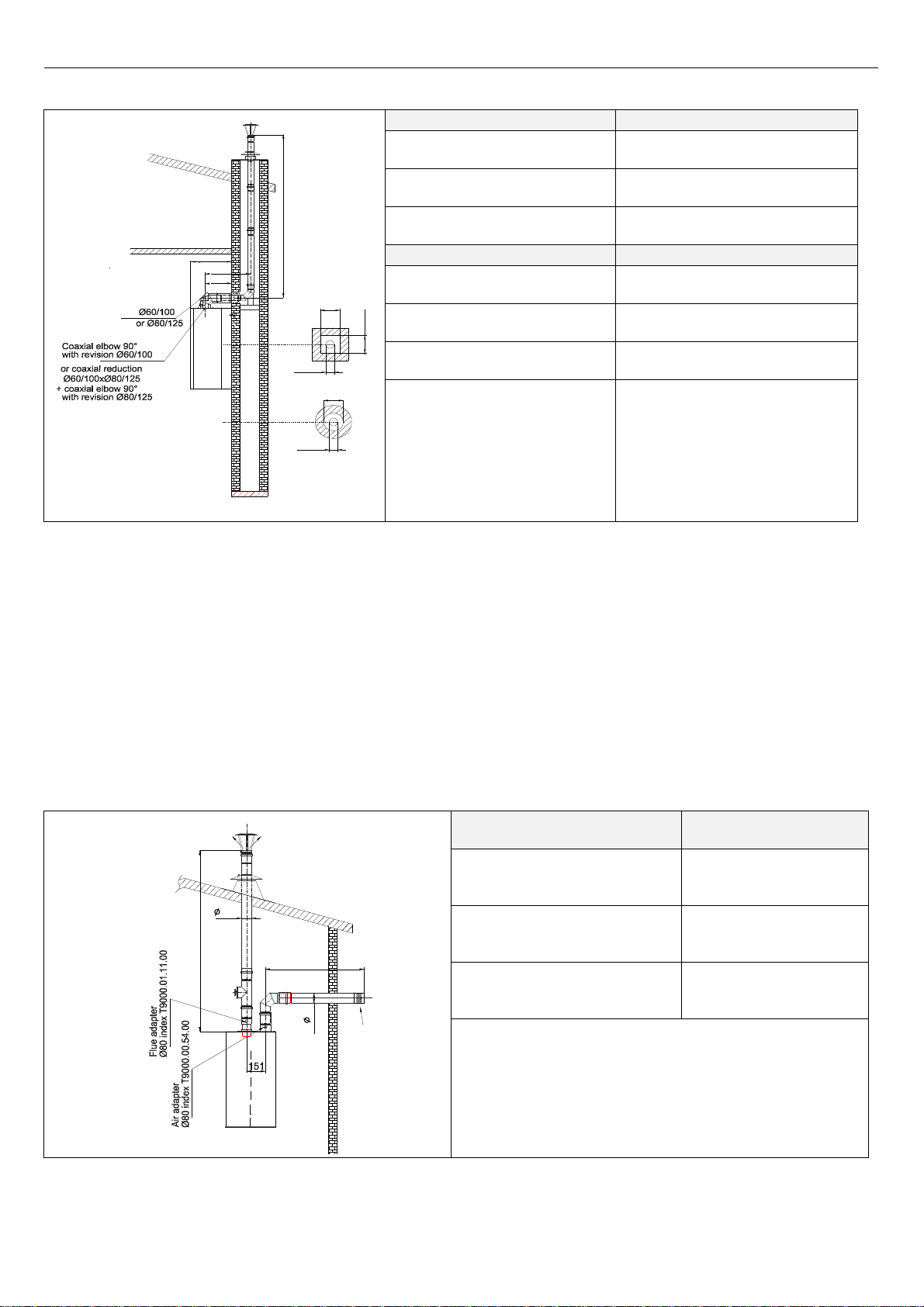

3.8.3 Vertical outlet of air- flue gas system through the roof ............................................................................................................................................................................................ 13

3.8.4 Connecting to a common chimney duct system, consisting of a duct for air inlet and flue gas outlet duct ............................................................................................................... 13

3.8.5. Flue gas air outlet and air inlet by two separate tubes ........................................................................................................................................................................................... 14

3.8.6 Reduction of the ma imum length of the air-flue system by changing the flow direction ......................................................................................................................................... 15

3.9.

C

ONNECTION OF ADDITIONAL DEVICES

........................................................................................................................................................................................................................................ 15

Fig.3.9.1 Electrical terminals of controller - a back view .................................................................................................................................................................................................... 15

3.9.2 Connection of a room temperature regulator ........................................................................................................................................................................................................... 15

3.10.

C

ONNECTING THE OUTSIDE TEMPERATURE SENSOR

...................................................................................................................................................................................................................... 15

4. BOILER ADJUSTMENT AND PRELIMINARY SETTING ................................................................................................................................................................................................................ 15

4.1.

I

NTRODUCTORY REMARKS

....................................................................................................................................................................................................................................................... 15

4.2.

A

DJUSTING THE BOILER TO COMBUST ANOTHER TYPE OF GAS

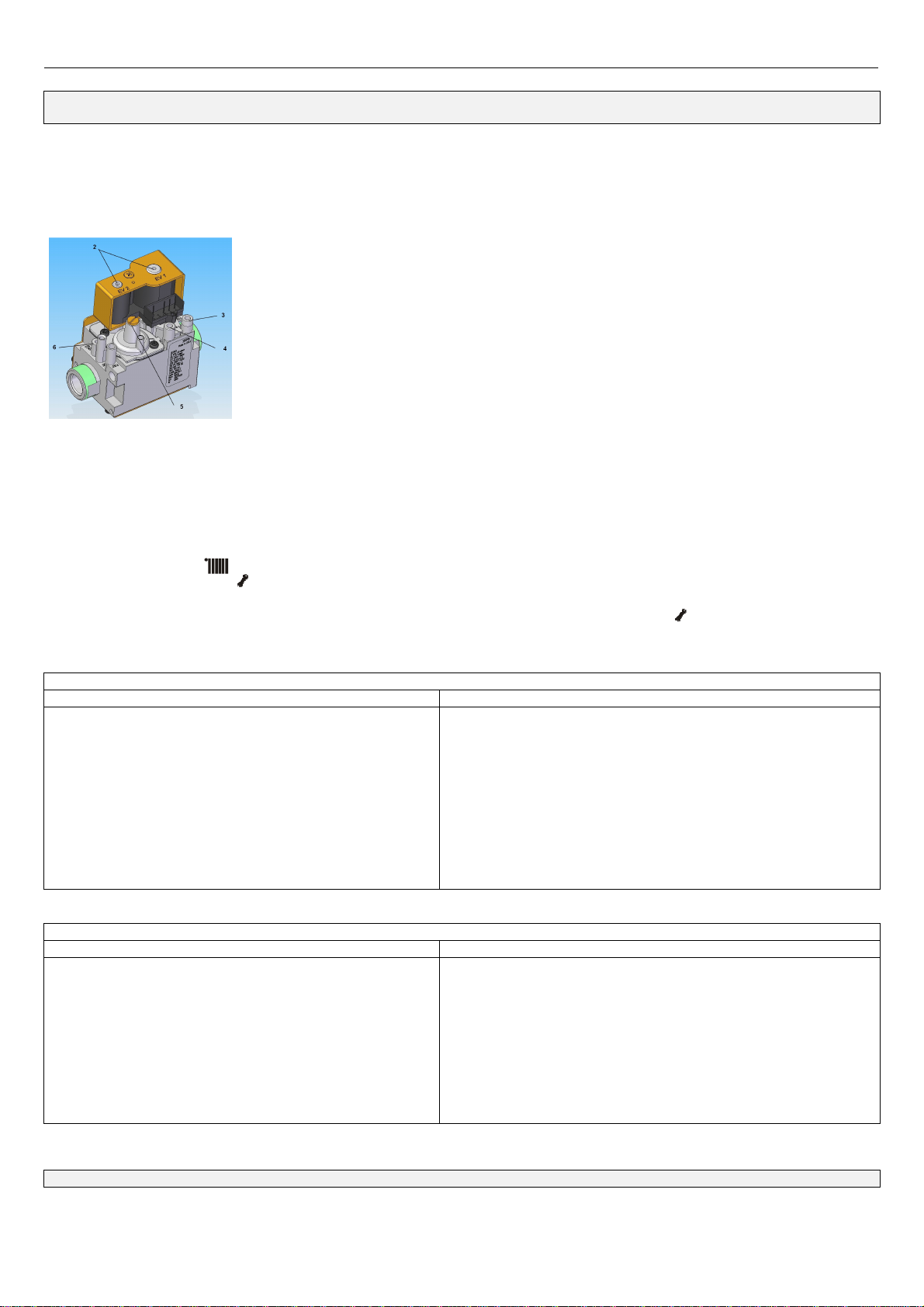

........................................................................................................................................................................................................... 15

4.3.

B

OILER ADJUSTMENT

............................................................................................................................................................................................................................................................. 16

4.3.1. Gas flow regulation in the boiler (without using the flue gas analyzer) ................................................................................................................................................................... 16

4.3.2. Adjustment of the boiler with a gas analyzer .......................................................................................................................................................................................................... 16

4.4.

F

AN CHARACTERISTICS

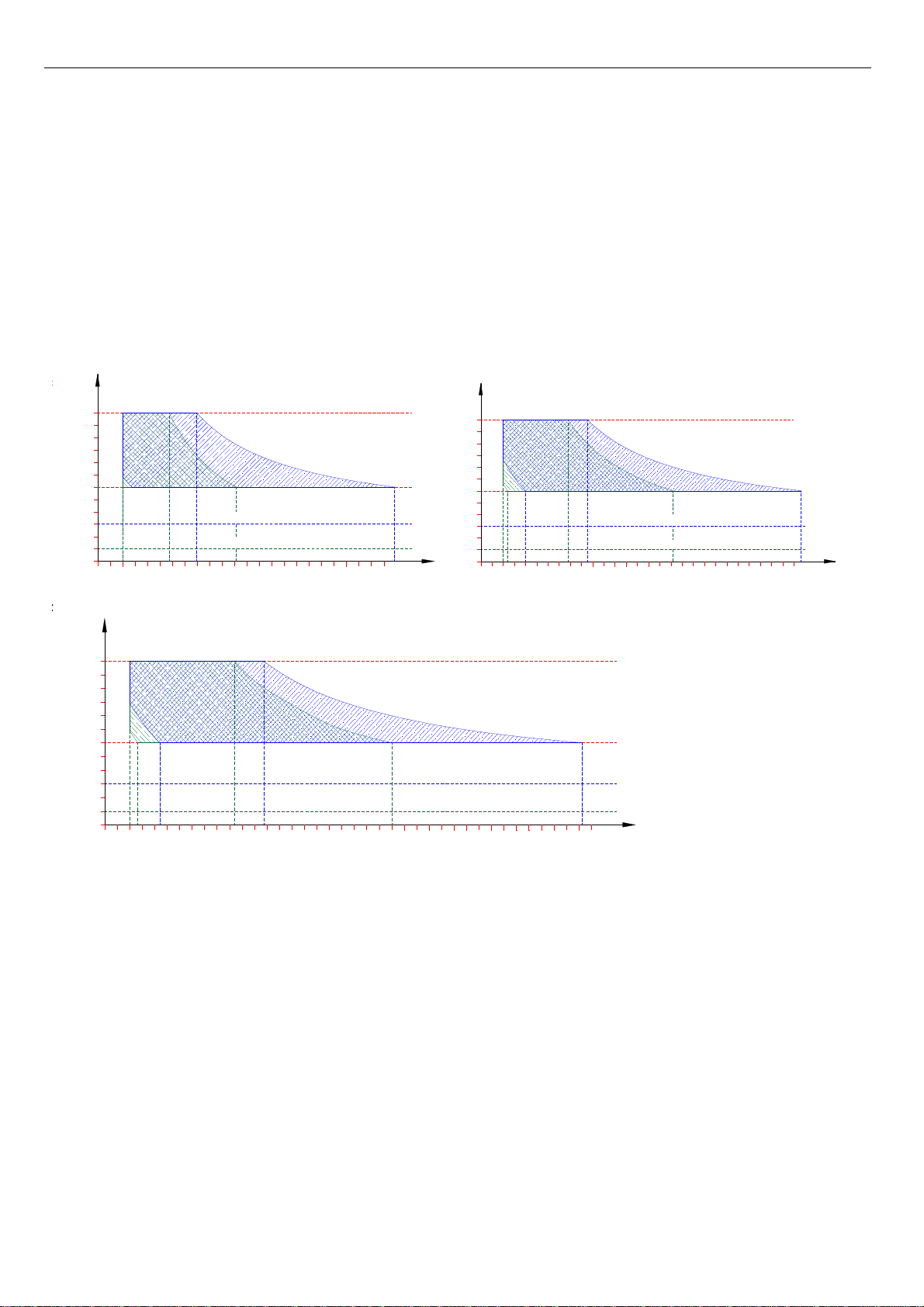

............................................................................................................................................................................................................................................................ 17

F

IG

.4.4.1.

C

HARACTERISTICS OF THE FAN

-

TYPE

NG40

M

...................................................................................................................................................................................................................... 17

5. STARTUP AND OPERATION OF THE BOILER .............................................................................................................................................................................................................................. 17

5.1.

I

NITIAL STARTUP OF THE BOILER

................................................................................................................................................................................................................................................ 17

5.2.

I

NCLUSION AND OPERATION

..................................................................................................................................................................................................................................................... 17

5.3.

O

PERATING MODES OF THE CONTROLLER

.................................................................................................................................................................................................................................... 18

5.4.

S

IGNALIZATION OF OPERATION STATES AND DIAGNOSIS

................................................................................................................................................................................................................... 18

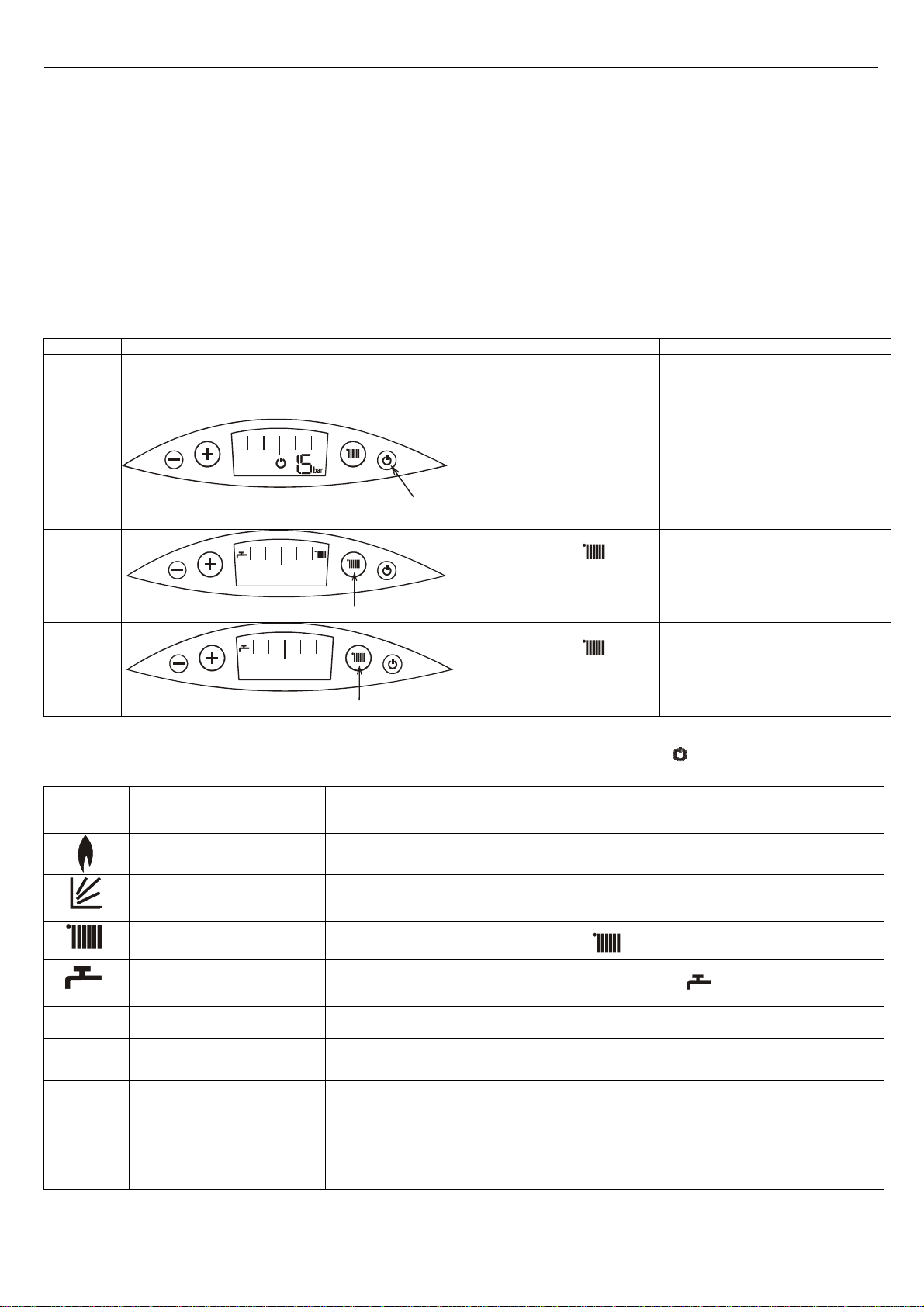

5.4.1. Signalisation of the start of heating in CH or DHW system ...................................................................................................................................................................................... 19

5.4.2. Signalisation of anti-freezing function operation in STAND BY mode ....................................................................................................................................................................... 19

5.4.3. Displaying the water pressure in CH installation ...................................................................................................................................................................................................... 19

5.4.4. Displaying parameters ............................................................................................................................................................................................................................................. 19

5.4.5 DHW heating blockade indicator for one-function boilers. ....................................................................................................................................................................................... 19

5.4.6 Support the venting of heating system ..................................................................................................................................................................................................................... 19

5.5.

C

HANGING THE

CH

OR

DHW

TEMPERATURE SETTINGS

.................................................................................................................................................................................................................. 19

5.5.1. Temperature settings in CH circuit ........................................................................................................................................................................................................................... 19

5.5.2 Temperature settings in DHW circuit ........................................................................................................................................................................................................................ 20

5.6.

C

ONTROLLER CONFIGURATION

–

BOILER PARAMETERS SETTING

........................................................................................................................................................................................................ 20

5.6.1. Programming Mode entering .................................................................................................................................................................................................................................. 21

5.7.

P

AUSE IN BOILER OPERATION

................................................................................................................................................................................................................................................... 21

5.8.

D

IAGNOSIS

.......................................................................................................................................................................................................................................................................... 21

5.8.1. Signalisation of error codes during the emergency procedures implementation ...................................................................................................................................................... 21

5.8.2. Signalisation of error codes in emergency situations without locking ...................................................................................................................................................................... 21

5.8.3. Signalisation of emergency switching off with locking ............................................................................................................................................................................................. 21

5.8.4. Error list ................................................................................................................................................................................................................................................................... 22

6. MAINTENANCE, INSPECTIONS, CHEC ING OF THE OPERATION ............................................................................................................................................................................................... 23

6.1.I

NSPECTON AND MAINTENANCE

................................................................................................................................................................................................................................................. 23

6.1.1. Maintenance of the combustion chamber, burner, electrode. ................................................................................................................................................................................. 23

6.1.2. Cleaning the condensate siphon .............................................................................................................................................................................................................................. 23

6.1.3. The pressure in the e pansion vessel ....................................................................................................................................................................................................................... 23

6.1.4. Maintenance of the flue water-water heat e changer, item.21 ............................................................................................................................................................................... 24

6.1.5. Checking the temperature sensors ........................................................................................................................................................................................................................... 24

6.1.6. Checking the water pump operation ........................................................................................................................................................................................................................ 24

6.1.7. Ionisation current measurement .............................................................................................................................................................................................................................. 24

6.2.

R

EPLACING A DAMAGED CONTROL BOARD IN THE CONTROL PANEL

.................................................................................................................................................................................................... 25

6.3.

T

HE MAINTENANCE OPERATIONS TO BE PERFORMED BY THE USER

...................................................................................................................................................................................................... 26

6.4.

R

ANGE OF TECHNICAL MAINTENANCE PERFORMED BY SERVICE COMPANY

............................................................................................................................................................................................ 26

7. BOILER EQUIPMENT ................................................................................................................................................................................................................................................................. 26