Therma-Ray SmartRooms User manual

Floor Warming Installation Guide Using

Floor Warming Installation Guide UsingFloor Warming Installation Guide Using

Floor Warming Installation Guide Using

=

=

tÜÉíÜÉê=óçìÛêÉ=~=Åçåíê~ÅíçêI=~êÅÜáíÉÅíI=ÄìáäÇÉê=çê=

ÜçãÉçïåÉêI=ÅêÉ~íáåÖ=íÜÉ=éÉêÑÉÅí=áåÇççê=

ÉåîáêçåãÉåí=Ü~ë=~äï~óë=ÄÉÉå=~=ÅÜ~ääÉåÖÉK==

qÜÉêã~Jo~óI=íÜÉ=ïçêäÇÛë=@N=å~ãÉ=áå=íÜÉêã~ä=

ÅçãÑçêí=ëóëíÉãë=áåíêçÇìÅÉë=óçì=íç=íÜÉ=ìäíáã~íÉ=

ëçäìíáçåI=Smart

SmartSmart

SmartRoomsK== äÉ~ëÉ=í~âÉ=íÜÉ=íáãÉ=íç=

êÉ~Ç=íÜáë=áåëí~ää~íáçå=ÖìáÇÉ=Å~êÉÑìääó=ÄÉÑçêÉ=óçì=

ÄÉÖáåK==oÉãÉãÄÉêI=~ÅÅìê~íÉ=ãÉ~ëìêÉãÉåíë=~êÉ=íÜÉ=

âÉó=íç=ëìÅÅÉëë=Ñçê=~=éêçéÉê=áåëí~ää~íáçå>=

=

=

=

=

Install a wire every 24” through the floor

joist to form a suspended system Use

sufficient wire to securely hold the panels

Slide the Therma

·

Ray panel above wire

Secure wire to the nail

Drill holes in joists near the Therma

·

Ray

panel lead wires and connect wiring

Therma·Ray Ceiling Panels

Therma·Ray Ceiling PanelsTherma·Ray Ceiling Panels

Therma·Ray Ceiling Panels

NOTE:

NOTE:NOTE:

NOTE: This application is used in existing homes where the owner wants warm floors but does

not want to replace the floor covering The existing finished floor can be any type of wood

flooring or natural stone finish such as ceramic tile, stone, slate, etc or vinyl flooring Please

check with the manufacturer of the floor covering may occur Use under properly installed

ceramic tile, stone or slate is perfectly acceptable

This method is not recommended for floors with carpets

MECHANICAL INSTALLATION

MECHANICAL INSTALLATIONMECHANICAL INSTALLATION

MECHANICAL INSTALLATION

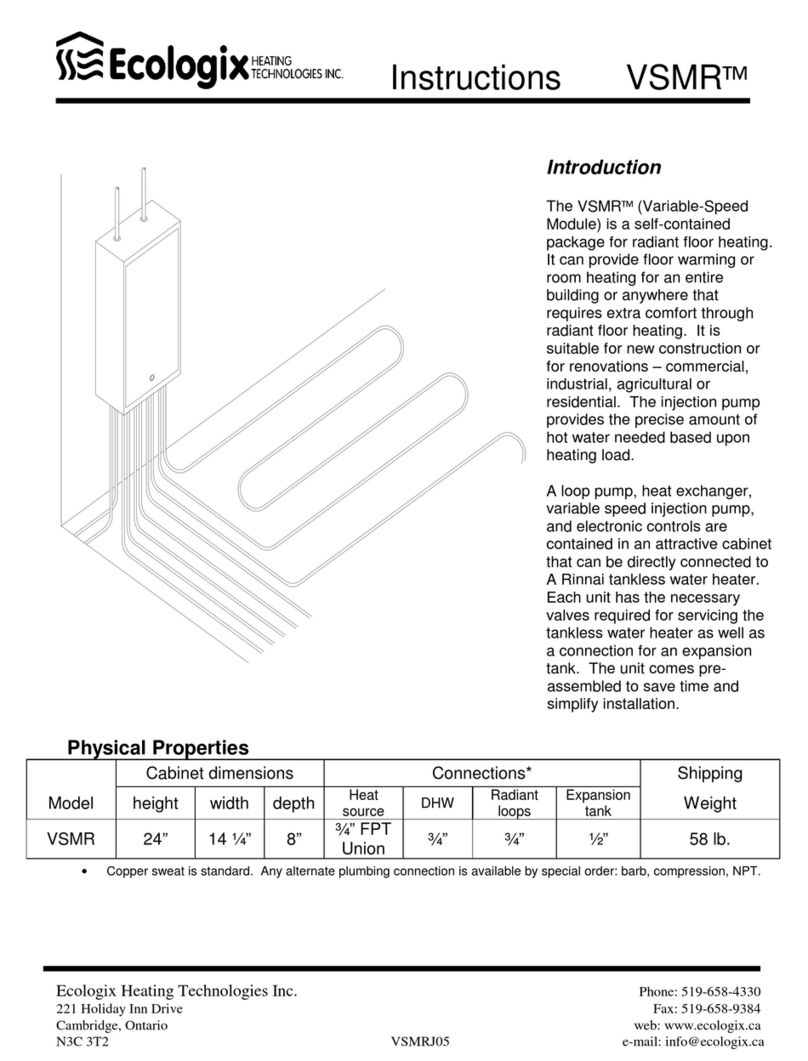

Therma·Ray panels are placed between the floor joists Panels are to be installed in open,

unobstructed floor joists The panels are held in place by a wire (0 5cm) The panels must be a

minimum of 2 inches from the floor Drill holes through the joists so that you can install wire

every 24 inches Be sure to use sufficient wire to securely hold the panels in place The number

of panels needed should fill the floor joist spaces in the area to be heated Do not install panels

below cabinet, appliances etc Slide the Therma·Ray Ceiling Panels above the wire Once the

panels are in place, secure the wire to a nail or hook

BRANCH CIRCUIT CONNECTION

BRANCH CIRCUIT CONNECTIONBRANCH CIRCUIT CONNECTION

BRANCH CIRCUIT CONNECTION

Drill holes in the joists near the lead wires of the Therma·Ray panel

Therma·Ray panels are connected in parallel to the branch circuit Canadian installation shall be

made according to the provision of Section 62 of the Canadian Electrical Code, part 1 and to

regulations of all authorities having jurisdiction U S installations are to be made in accordance

with the National Electrical Code and local codes where applicable Installations outside North

America should conform to applicable local codes The heater load, once determined, can be

divided into as many circuits as needed 12AWG (2 0 mm) copper conductor, non-metallic

sheathed cable is recommended for installation of panels In areas where type NM cable is not

permitted, metal enclosures are available for use with rigid or flexible, metallic conduit or tubing

(See Installation Instructions Supplement for Metal Wiring Enclosures ) When determining the

number of branch circuits required to accommodate the heating load, note that the branch

circuit must be de-rated in accordance with either the Canadian Electric Code, National Electrical

Code, or local coded as applicable It is not recommended that wire size greater than 12AWG

(2 0 mm) be used to connect the panels to the branch circuit After the panels are secured in

qÜÉ=ÇáÑÑÉêÉåÅÉ=ÄÉíïÉÉå=ÜÉ~í=~åÇ=Å

qÜÉ=ÇáÑÑÉêÉåÅÉ=ÄÉíïÉÉå=ÜÉ~í=~åÇ=ÅqÜÉ=ÇáÑÑÉêÉåÅÉ=ÄÉíïÉÉå=ÜÉ~í=~åÇ=Å

qÜÉ=ÇáÑÑÉêÉåÅÉ=ÄÉíïÉÉå=ÜÉ~í=~åÇ=ÅçãÑçêíK

çãÑçêíKçãÑçêíK

çãÑçêíK=

==

=

Connection the main feed to the individual panel

is easily done using tap-on connectors. Note that

ONLY the outer insulation jacket of the main

feed is removed.

place and the number of branch circuits determined, they are connected to the branch circuit

For proper performance ensure the supply voltage matches the voltage stamped on the panel

DO NOT connect heating panel to a higher voltage Connection to lower voltages is permitted,

but will cause the panel to operate at a reduced wattage and may lead to a system with

insufficient capacity to heat the intended area The supply wire of 12AWG (2 0mm) non-metallic

cable is connected to the transient lead (pigtail lead) of the heater panels with 3M Scotchlok®

self-stripping electrical tap connectors (Type 567) Upon completion of the wiring assembly, the

panel connectors are visible and available for inspection by local authorities

PANEL OPERATION TEST

PANEL OPERATION TESTPANEL OPERATION TEST

PANEL OPERATION TEST

Each heater has been individually checked at the factory After panel installation, the entire

circuit should be tested, to check the on-site electrical work Two methods of testing will be

discussed in the following paragraphs

Full Power Available

Full Power AvailableFull Power Available

Full Power Available- Apply rated voltage to the heater load circuit Branch loads are to be read

with a suitable ammeter The ammeter value should be the same as that calculated for the

heating load and, if the values agree, all panels are operating If the values do not agree,

installation should be re-checked For a physical check without a meter, it is only necessary to

feel the panels If they are warm, they are working

Without Power Available

Without Power AvailableWithout Power Available

Without Power Available-

--

-

This check of the panel installation requires the use and knowledge of

an ohmmeter A resistance measurement is taken at the load circuit, with all other circuits

isolated This will give the total resistance of the heater load Knowing the total heater load of

the panel in watts and heater rated voltage, a simple calculation will give the same values as that

read on the ohmmeter

Example: for the branch circuit of 1500 watts and panel rated voltage of 240, the resistance will

be 38 4 ohms:

voltage x voltage 240 x 240

Formula: ------------------------------ = resistance in ohms, Example: --------------- = 38 4 ohm

Wattage 1500

Final Installation

Final InstallationFinal Installation

Final Installation

After inspection and completion of the equipment check, the wiring enclosure (Endcap) is

completely filled with drywall ready-mixed compound, quick-setting drywall compound, or

fireproof caulking compound The Endcap is then placed over the connector and slid onto the

panel Alternatively, a bulk-loading caulking gun may be used to completely fill the enclosure

from each end, after it has been mechanically attached to the panel

To attach the Endcap to the panel, slide the Endcap over the panel, connectors and feed wire

Align the hole in the Endcap with the Fastener Line marked on the panel The Fastener Line is

located between (and marks the location of) the two cold panel connection leads Then use the

screw supplied with the Endcap to secure the Endcap to the panel (Endcap, screw and

connectors are available from the distributor for each panel)

=

==

=

=

The use of high quality Smart

SmartSmart

SmartRooms Comfort Controllers are recommended for proper system

performance and warranty The sensor must be placed over a panel with a heat shield The heat

shield could be something as simple as a piece of aluminum foil The heat shield stops the

radiant heat from directly affecting the sensor, which in turn would affect temperature accuracy

The Smart

SmartSmart

SmartRooms Comfort Controller can be placed anywhere that is convenient for the owner

Warning sticker must be attached to the electrical service panel Ensure that all branch circuits

supplying radiant heating are clearly marked as such

Panel installation is now complete Insulation must then be installed over an A) heated area use

3” (R10) insulation B) unheated area use 6” (R20) insulation C) crawl space use 9” (R30)

insulation

CAUTION:

CAUTION:CAUTION:

CAUTION:

- Panels must be turned off until joint compound has fully cured

- Therma·Ray panels must not be placed over wood framing members, partitions,

cupboards, or other obstructions or come in contact with plastic piping

- Cellulose insulation is not recommended unless it meets or exceeds standard CGSB

510GP-60M or equivalent and must not contact face of heater panel

- Use only copper conductor supply wire

- Do not install heating panels in a room over an unheated crawl space unless floor

is properly insulated

Listed

ListedListed

Listed

Therma·Ray Inc.

67 Wilsey Road, Unit 6

Fredericton, NB, Canada E3B 7K4

Tel: 5 6-457-46 Fax: 5 6-457-4699

E-mail: [email protected]

www.thermaray.com

Printed in Canada

FLOOR PANEL SYSTEM

FLOOR PANEL SYSTEMFLOOR PANEL SYSTEM

FLOOR PANEL SYSTEM

CATALOGUE # WATTS LENGTH

WIDTH WEIGHT

RC6A- 95-24 95 6 9 9

RC4A- 7 -24 7 4 9 6

RC7B-15 -24 15 7 12 14

RC6B-13 -24 13 6 12 12

RC5B-1 5-24 1 5 5 12 1

RC4B- 85-24 85 4 12 8

RC3B- 7 -24 7 3 12 6

RC7C-23 -24 23 7 18 24

RC6C-195-24 195 6 18 18

RC5C-16 -24 16 5 18 15

RC4C-13 -24 13 4 18 12

RC3C- 95-24 95 3 18 9

RC2C-070-240 70 2 18 6

100, 120, 200, 208, 220, 230, 240, 277 volts available

ACCESSORIES

ACCESSORIESACCESSORIES

ACCESSORIES

PC-1 Endcaps regular

3M567 Connector for #12 Wire

SR-LV Smart

SmartSmart

SmartRooms Comfort Controller low voltage c/w sensors

SR-240/120 Smart

SmartSmart

SmartRooms Comfort Controller 240/120 volt c/w sensors

revised October 25, 2012