THK SHS-LE User manual

Version 1.0

LM Guide with Linear Encoder

SHS-LE

INSTRUCTION MANUAL

Contents

1. Introduction 1-1

1-1 Acknowledgment---------------------------------------------------------------------- 1-1

1-2About this manual --------------------------------------------------------------------- 1-1

1-3Intended use--------------------------------------------------------------------------- 1-2

1-4About product support---------------------------------------------------------------- 1-2

1-5Product and company information--------------------------------------------------- 1-2

2. Precautions on Use 2-1

2-1 Safety Related Warning Displays ---------------------------------------------------- 2-1

2-2Transportation and Storage ---------------------------------------------------------- 2-1

2-3Mounting and Installation------------------------------------------------------------- 2-2

2-4Operation ------------------------------------------------------------------------------ 2-2

2-5Lubrication and Maintenance -------------------------------------------------------- 2-3

3. Marking on the Master Rail and Combined Use

3-1

4. About Product 4-1

4-1 System configuration ----------------------------------------------------------------- 4-1

4-2Product Specifications---------------------------------------------------------------- 4-2

5. Mounting 5-1

6. Permissible Error of the Mounting Surface 6-1

7. Cables and Wiring 7-1

7-1 Wiring ---------------------------------------------------------------------------------- 7-1

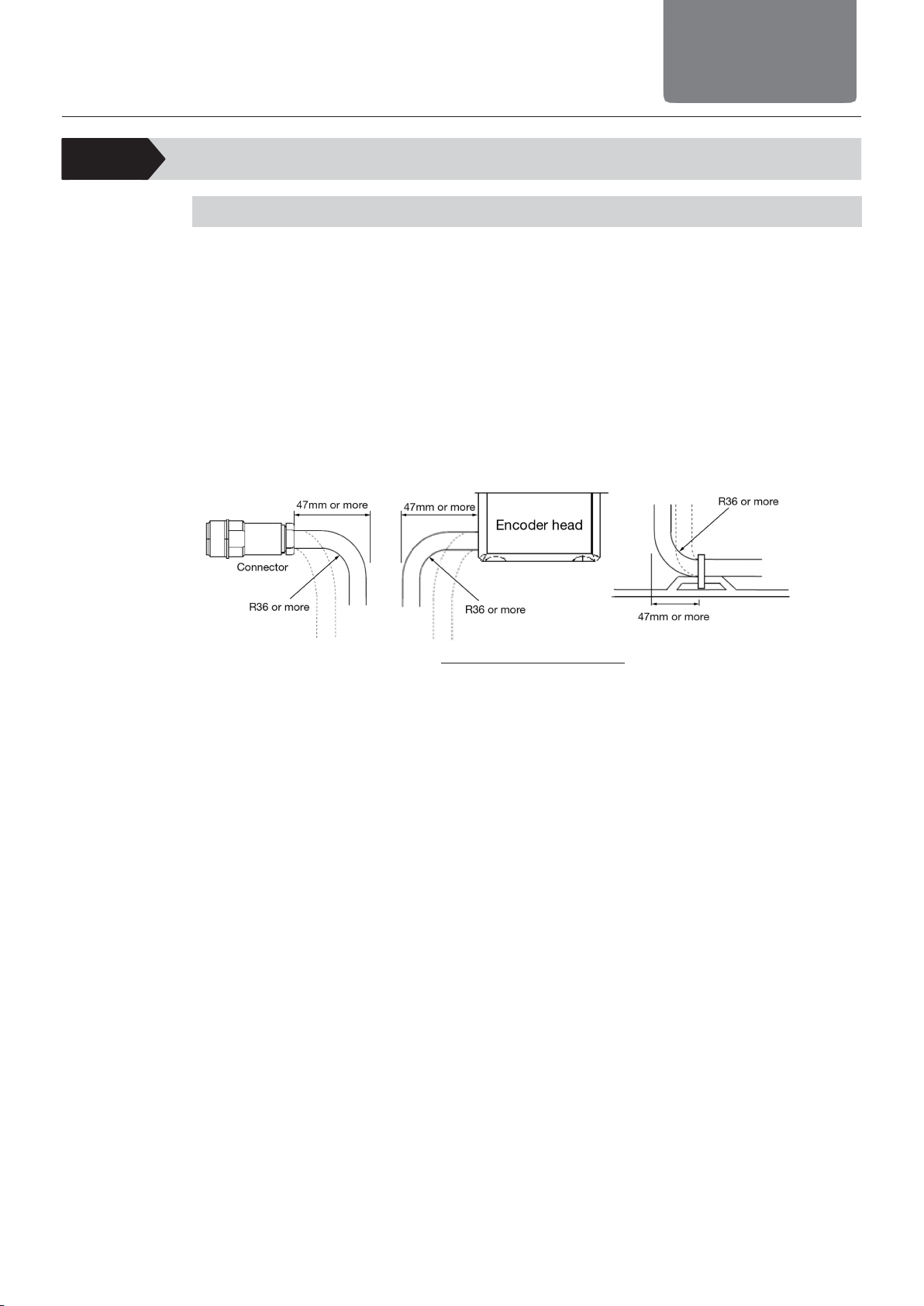

7-2Minimum bending radius ------------------------------------------------------------- 7-2

8. Lubrication 8-1

9. Troubleshooting 9-1

10.

Appendix 10-1

10-1 Resolution Check -------------------------------------------------------------------- 10-1

10-2 Effective Stroke----------------------------------------------------------------------- 10-1

10-3 Standard Length and Maximum Length-------------------------------------------- 10-2

1-1

1. Introduction

1. Introduction

1-1 Acknowledgment

Thank you for purchasing the THK products.

This document will explain any precautions involved with using the LM Guide with Linear

Encoder SHS-LE (this product) as well as mounting and wiring method.

1-2 About this manual

1-2-1 Intended audience

The person in charge of designing embedded systems of the product and installing, and

maintaining the product, and the person who actually uses the product.

1-2-2 Using this manual

This manual describes correct handling methods and precautions for the product.

For the maximum performance and long life of the product, carefully read and understand this

manual to safely and correctly use the product.

If you use the printed version of this manual, be sure to keep it in the place that the audience can

refer to it when needed.

1-2-3 Notice and attention

●Do not use or handle the product in the ways that are not described in this manual.

●Do not reproduce, reprint, or lend the whole contents or a part of this manual without

permission.

●Please note that the description in this manual is subject to change without prior notice in

the future, due to improvements of the product or other reasons.

●We have made all possible efforts to make the content of this manual accurate. However, if

you find any mistake or uncertainty in this manual, please contact THK.

●Drawings throughout this manual are only intended as typical examples, and may differ from

your product.

●Note that THK shall not be liable for any result incurred by applying this manual, regardless

of the reason.

●This manual is also applied to custom products. However, the descriptions provided in the

delivery specification drawings of that custom products take precedence over this manual.

* Custom products represent the products that have different materials and specifications

from those of the standard products on catalogs.

1-2

1. Introduction

1. Introduction

1-3 Intended use

●This product is assumed for use only in linear features such as position measurement, linear

guiding or positioning with the feedback loop control system.

●This product must not be used for the devices or systems that are used under the situations

that may be fatal to human life.

●Consult with THK beforehand when considering using this product for special applications

such as in equipment or system for passenger vehicles, medical, aviation and space,

nuclear power, electrical power or weapon, or in a place where there is a risk of explosion.

●This product is manufactured under the strict quality control, however, that does not mean

that the product is free from failure. For applications to the equipment that may suffer

serious accidents or loss from the failure of this product, install safety devices or backup

devices that prevent such serious accidents or loss.

●Installation of this product is allowed only in a machinery or machinery partially completed.

●The equipment that this product is installed must satisfy to comply with related standards,

regulations or laws.

●Follow regional or industrial laws when using this product.

1-4

About product support

Consult with our sales fronts or IOT Innovation Division for inquiries regarding this product.

1-5

Product and company information

Follow the latest information for this product or components to use.

To find the latest product and company information, we recommend you to periodically access

our website.

●Website URL: https://www.thk.com

●Technical support website URL: http://www.tech.thk.com/

2-1

2. Precautions

2. Precautions on Use

2-1

Safety Related Warning Displays

This manual uses the following safety related warning displays. Descriptions containing safety

related warning displays are serious and must be followed.

2-2 Transportation and Storage

●This product is sealed in a plastic bag with anti-rust oil and then packaged in a card-board

box. (Fig. 2-1)

●When storing this product, please keep it the THK packaging and store it horizontally without

subjecting it to high temperatures and/or humidity. Also, do not store it in an environment

where a magnetic field could occur.

Fig. 2-1 Example of Packing

●After the product has been in storage for an extended period of time, lubricant inside may

have deteriorated, so add new lubricant before use.

Caution

Warning

Caution

"A matter which, if mishandled, could result

in physical injury or material damage."

"Prohibited (never do this)"

"Must (always do this)"

2-2

2. Precautions

2. Precautions on Use

2-3 Mounting and Installation

●Do not attempt to apply external force on the linear scale, encoder holder or encoder head.

●Design the assembly with the scale not to have anything that could give influence partially to

the magnetic field such as metal positioning pins.

●Avoid any use in an environment with strong external magnetic field such as a place near a

magnet.

It may cause a reading error of an encoder or damage on this product.

Consult with our IOT Innovation Division in case of use in an environment with external

magnetic field.

●Perform wiring properly following this manual (7-1 Wiring).

●The users are required to evaluate the performance, safety and EMC by them selves when an

extension cable other than our standard types is used. Shielded cable is recommended in

such kind of modification.

●Use protection gears before start working.

●Make sure there is nobody around you when you transfer a product with long dimension.

●As a countermeasure for noise from the power supply cable, separate the power supply

cable from the cables on this product for wiring.

●Thoroughly remove anti-rust oil and feed lubricant before using the product.

2-4 Operation

●Do not operate the product when there is someone in the operation range or in a dangerous

area.

●Do not operate the product in a range that exceeds the effective stroke. There is a concern that

the encoder position data cannot be read. Especially when the product is used as the feedback

control, the equipment may go out of control, which could cause critical damage, if operation is

made in a range that exceeds the effective stroke.

* See this manual (10-2 Effective Stroke) for the effective stroke.

●Ensure safety by means of installation of an appropriate mechanical stopper.

●Use a device applied with noise countermeasure for the power supply device.

●Use a higher-level device equipped with power storage feature for a countermeasure of

power flicker.

●Set up parameters such as resolution properly.

Especially when the product is used as the feedback control, the equipment may go out of

control, which could cause critical damage, if setting of resolution is wrong.

* See this manual (10-1 Resolution Check) for how to check the resolution.

●In order to avoid any serious accident in the first operation due to such as wrong wiring, set

up the torque of the power source low, speed slow and stroke small.

Caution

Warning

Warning

2-3

2. Precautions

2. Precautions on Use

2-5 Lubrication and Maintenance

●Turn the driving power off in the devices assembled in the equipment before getting close to

this product for greasing or maintenance purpose.

●In case the lubricant is found turned into black, wipe off excess lubricant and then grease up

excessively so the lubricant inside the block can be replaced.

●When it is necessary to take off cables for cleaning or maintenance, follow this manual (7-1

Wiring) to set the cables back properly.

●When starting up the equipment after lubrication or maintenance, set up the torque of the

power source low, speed slow and stroke small.

●Do not perform operation in a condition that the LM guide part does not work properly as

there may be a case that the position data of the encoder cannot be read.

●Do not attempt to dismantle or modify this product without our permission. It may cause a

trouble such as the encoder position not being able to read.

●Grease up this product in an appropriate frequency and way following the Instruction Manual

of the LM Guide [No. 1030-T34667] (6-1 Lubrication Interval).

●Do not mix different lubricants. Mixing greases using the same type of thickening agent may

still cause adverse interaction between the two greases if they use different additives, etc.

●When using the product in locations exposed to constant vibrations or in special

environments such as clean rooms, vacuum and low/high temperature, use the grease

appropriate for the specifi cation/environment.

●When lubricating the product having no grease nipple or oil hole, apply grease directly on the

raceway and stroke the product several times to let the grease spread inside.

●The consistency of grease changes according to the temperature. Take note that the slide

resistance of the LM Guide also changes as the consistency of grease changes.

●After lubrication, the slide resistance of the LM Guide may increase due to the agitation

resistance of grease. Be sure to perform a break-in to let the grease spread fully, before

operating the machine.

●Excess grease may scatter immediately after lubrication, so wipe off scattered grease as

necessary.

●The properties of grease deteriorate and its lubrication performance drops over time, so

grease must be checked and added properly according to the use frequency of the machine.

●Although the lubrication interval may vary according to use conditions and the service

environment, lubrication should be performed approximately every 100 km in travel distance

(three to six months). Set the fi nal lubrication interval/amount based on the actual machine.

●If the mounting orientation is other than horizontal use, the lubricant may not reach the

raceway completely. For the mounting orientation and the lubrication, see General catalogue,

respectively.

●When adopting oil lubrication, the lubricant may not be distributed throughout the LM block

depending on the mounting orientation of the block. Contact with our IOT Innovation Division

in advance for details.

Caution

Warning

3-1

3. Marking and

Combined Use

3.

Marking on the Master Rail and Combined Use

See the Instruction Manual of the LM Guide [No. 1030-T34667] for Marking on the Master Rail

and Combined Use regarding the LM guide.

Note) This product is not applicable for use in joint.

4-1

4. About Product

4. About Product

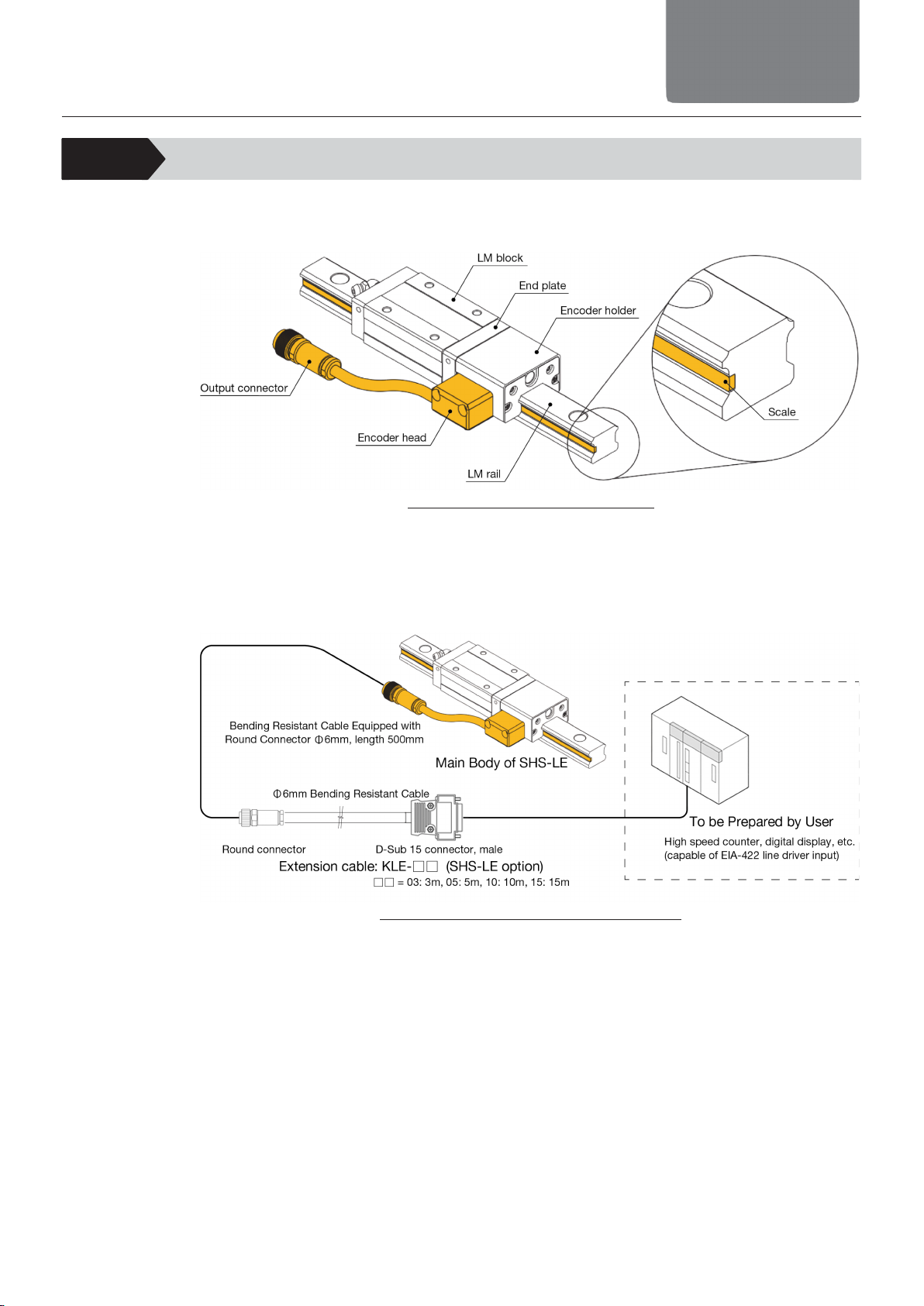

4-1 System configuration

This is a product that is capable of position measurement, linear guiding, and positioning with

the feedback loop control system in the LM rail directions.

Fig. 4-1 Names of individual parts

●The LM block is integrated with the encoder holder and encoder head.

●The encoder head reads the positions of N and S magnetic poles recorded in the scales

equipped on the sides of the LM rail. The interpolated NS magnetic pole pitch data is output

as the incremental A/B-phase differential outputs complied with EIA-422.

Fig. 4-2 Example of System Construction

4-2

4. About Product

4. About Product

4-2 Product Specifications

4-2-1 Dimensions/Lineup

●Block type: C/LC

Fig. 4-3 Block type C/LC

Model No.

Dimension [mm] Mass

M W L W1 W2 W3 L1 L2 K H3 E e0

LM Block

[kg]

LM Rail

[kg/m]

SHS20C/LC

30 63 115 (134)

20 21.5 72 59 (78) 46 25.4 4.6 12 4.3 0.61 (0.76) 2.3

SHS25C/LC

36 70 129 (146)

23 23.5 76.3 71 (88) 47.5 30.2 5.8 12 4.5 0.89 (1.06) 3.2

SHS30C/LC

42 90 143 (168)

28 31 88.3 80 (105) 50 35 7 12 5.8 1.56 (1.88) 4.5

SHS35C/LC

48 100 162 (192)

34 33 96 93 (123) 54.5 40.5 7.5 12 6.5 2.18 (2.82) 6.2

SHS45C/LC

60 120 180 (214)

45 37.5 111.3 106 (140) 57 51.1 8.9 16 8 3.64 (4.59) 10.4

●Block type: V/LV

Fig. 4-4 Block type V/LV

Model No.

Dimension [mm] Mass

M W L W1W2W3L1L2K H3E e0

LM Block

[kg]

LM Rail

[kg/m]

SHS20V/LV 30 44 115 (134)

20 12 62.5 59 (78) 46 25.4 4.6 12 4.3 0.5 (0.61) 2.3

SHS25V/LV 36 48 129 (146)

23 12.5 65.3 71 (88) 47.5 30.2 5.8 12 4.5 0.71 (0.84) 3.2

SHS30V/LV 42 60 143 (168)

28 16 73.3 80 (105) 50 35 7 12 5.8 1.16 (1.38) 4.5

SHS35V/LV 48 70 162 (192)

34 18 81 93 (123) 54.5 40.5 7.5 12 6.5 1.68 (2.12) 6.2

SHS45V/LV 60 86 180 (214)

45 20.5 94.3 106 (140) 57 51.1 8.9 16 8 2.94 (3.59) 10.4

*1 Values in brackets ( ) describe those for L Type

*2 The diameter of the attachment holes and attachment hole pitch on the rail should be the

same as those on SHS Type

Cable dimensions [mm]

Cable dimensions [mm]

4-3

4. About Product

4. About Product

●Block type: R/LR

Fig. 4-5 Block type R/LR

Model No.

Dimension [mm] Mass

M W L W1W2W3L1L2K H3E e0

LM Block

[kg]

LM Rail

[kg/m]

SHS25R/LR

40 48 129 (146)

23 12.5 65.3 71 (88) 47.5 34.2 5.8 12 4.5 0.83 (0.97) 3.2

SHS30R/LR

45 60 143 (168)

28 16 73.3 80 (105) 50 38 7 12 5.8 1.26 (1.58) 4.5

SHS35R/LR

55 70 162 (192)

34 18 81 93 (123) 54.5 47.5 7.5 12 6.5 2.08 (2.62) 6.2

SHS45R/LR

70 86 180 (214)

45 20.5 94.3 106 (140) 57 61.1 8.9 16 8 3.64 (4.59) 10.4

*1 Values in brackets ( ) describe those for L Type

*2 The diameter of the attachment holes and attachment hole pitch on the rail should be the

same as those on SHS Type

Cable dimensions [mm]

4-4

4. About Product

4. About Product

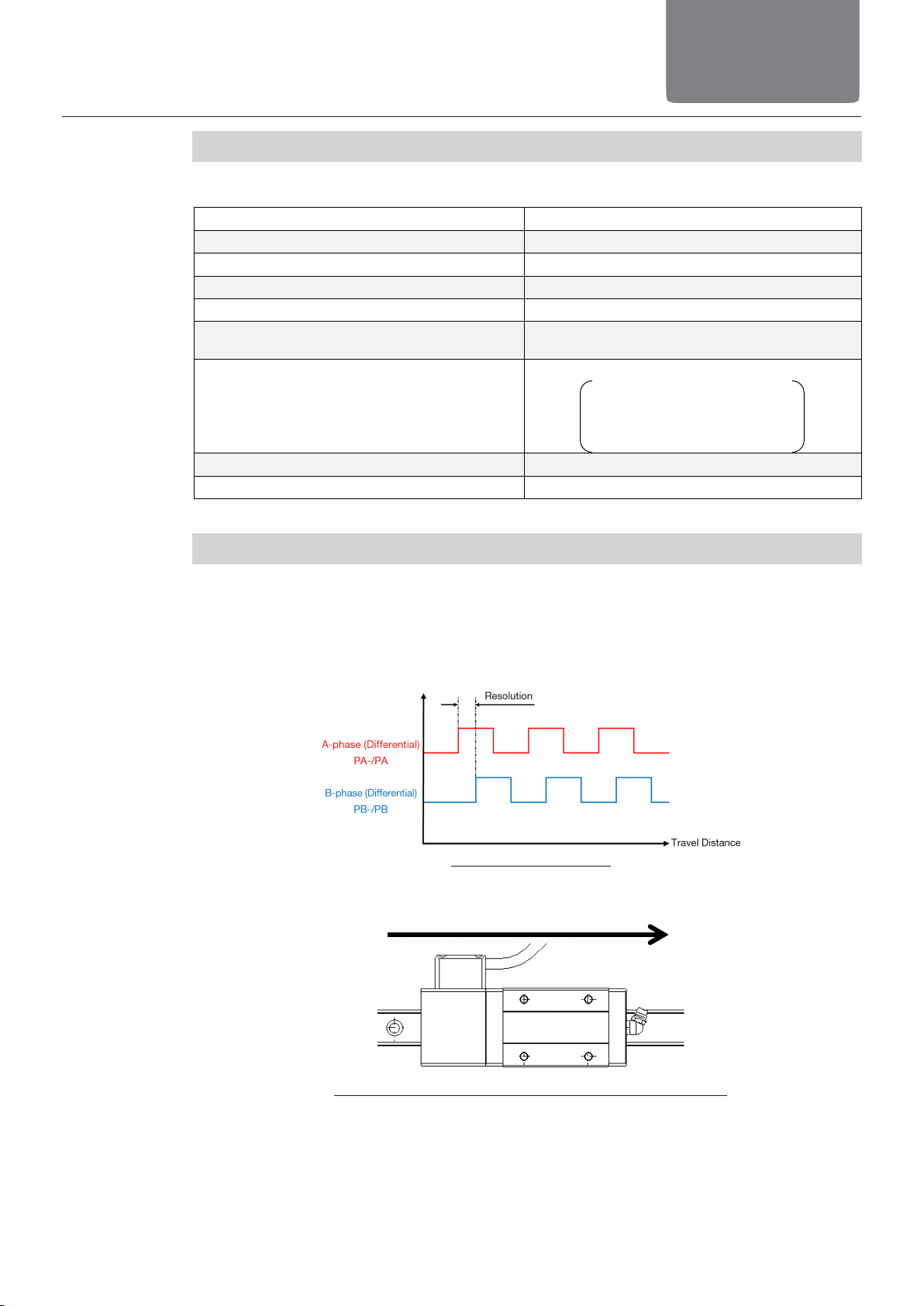

4-2-2 Encoder Specifications

●Linear Encoder Basic Specifications

Typ e Incremental magnetic encoder

Resolution [μm]* 1/5/10

Accuracy Repeatability in One Direction ± Resolution or less

Power supply [V] DC5V±5%

Max. Current Consumption [mA] 50 or less

Output

Incremental A-B phase differential output

EIA-422 line driver

Standard compliance

CE

EMC directive (2014/30/EU)

EN 61800.3:2004/AI!2012,

EN 550112009/AI:2010,

EN 610006-2:2005

Use and Storage Ambient Temperature 0 to 50°C (No freezing)

Use and Storage Ambient Humidity 20 to 80%RH (No condensation)

* It is the value after multiplying by 4.

4-2-3 Output Specifications

●The output signals from SHS-LE should be complied with EIA-422,

A/B-phased, differential outputs and in the line driver format.

●The higher-level device (e.g. counter) that you prepare yourself

should receive in the line receiver circuit.

Fig. 4-6 Output Signal

Fig. 4-7 Moving Direction and Output Signal Direction

When moving in cable direction: Lead by A-phase

(Encoder Positive Direction)

4-5

4. About Product

4. About Product

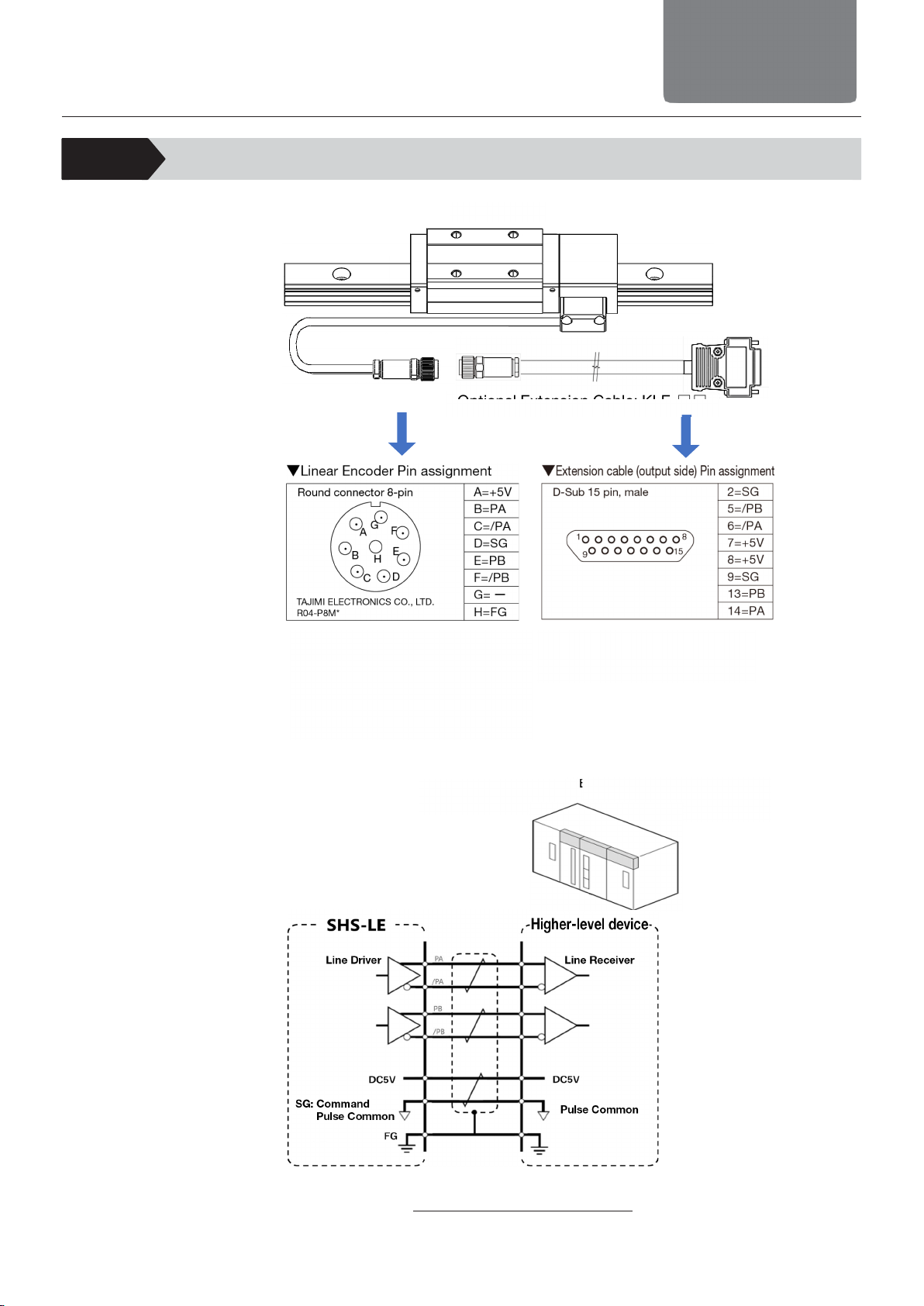

4-2-4 Extension cable

Fig. 4-8 Specifications of Extension Cable

●Make sure to connect the connector hood as it works as the frame grounding (FG).

●Consult with our IOT Innovation Division when an extension cable is to be made by yourself.

4-2-5 Max. Response Speed

Resolution [μm] 1 5 10

Maximum speed [m/s] 9.34 23.34 23.34

Shown above is the response speed of the encoder reading.

The maximum speed of the LM guide gives an impact to many conditions such as lubricant

condition and payload condition.

Consult with our IOT Innovation Division for details.

4-2-6 General Specifications

Temperature

Min. – Max.

In use 0 to 50°C

No freezing or

condensation

Storage 0 to 50°C

Humidity Use and Storage 20 to 80%

External Vibration / Impact

Encoder section : (BS EN 60068-2-6,7) (Vibration) frequency

55 to 2000Hz / max. acceleration 100m/s2

(Impact) Acceleration 500m/s2/ activating

time 6ms

LM Guide section : See the general catalog.

External Strong Electromagnetic Field Nonexistent

Extension cable: Bending Resistant ɸ6mm

□□=03: 3m, 05: 5m, 10: 10m, 15: 15m

L=□□m

◆Optional Extension Cable: KLE-□□

5. Mounting

5-1

5. Mounting

5. Mounting

See the Instruction Manual of the LM Guide [No. 1030-T34667] for mounting.

6-1

6. Permissible

Error

6. Permissible Error of the Mounting Surface

See the Instruction Manual of LM Guide [No. 1030-T34667] for permissible error of the

mounting surface.

7-1

7. Cables and

Wiring

7. Cables and Wiring

7-1 Wiring

Fig. 7-1 Wiring Specifications

* Because R04-P8M is a discontinued

product it will be replaced with its next

generation model ER04-P8M as the

stock ends.

There should be no change to

appearance dimensions, pin assignments

and communication configurations.

* Make sure to connect the

connector hood as it works as

the frame grounding (FG).

SHS-LE

Optional Extension Cable: KLE-□□

Example) Counter,

digital display,

motor driver etc.

To be Prepared by User

Higher-level device

7-2

7. Cables and

Wiring

7. Cables and Wiring

7-2 Minimum bending radius

Handling of Encoder Cable

The encoder cable is a bending resistant type with the minimum bending radius R36. Pay

attention to the following points when installing.

Note) If the installation is inappropriate, it may cause earlier line breakage.

●Cable Twist

Cables should be wired straightly without any twist.

Fixing or bending of cable while twisted may cause earlier line breakage.

●Fixation of Cable

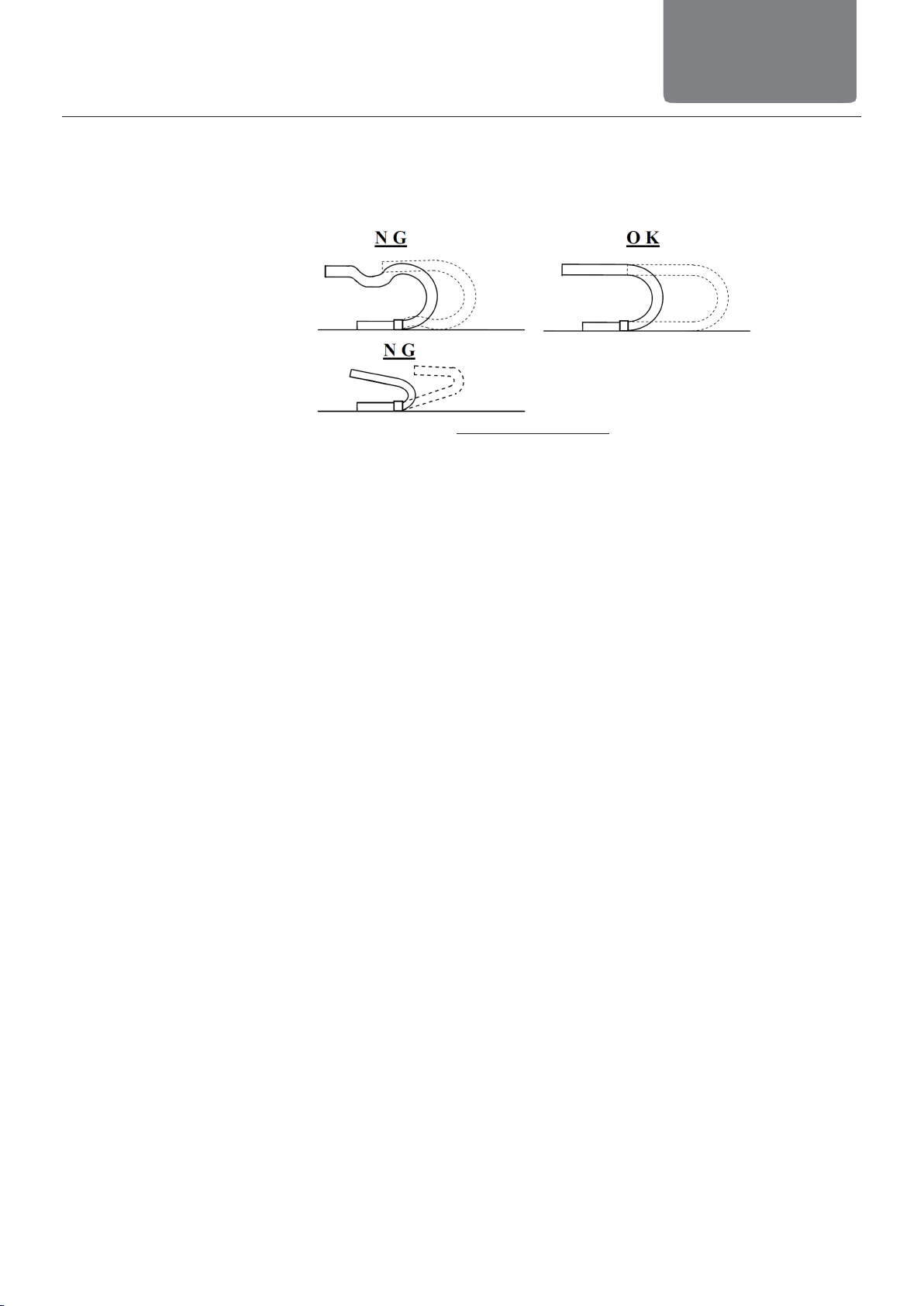

Do not attempt to fix a cable where it moves.

Load will be concentrated at the fixed part, which may cause earlier line breakage. Fixing

points should be as minimum as possible.

Fig. 7-2 Fixation of Cable

Cable condition shown with dotted lines in the figure above could cause earlier line breakage

of a cable.

Consider wiring in the way that the solid lines show.

7-3

7. Cables and

Wiring

7. Cables and Wiring

●Cable length

Too long cable length could cause looseness while too short may cause tension at the fixing

point.

This may cause earlier line breakage. Adjust a cable to an optimum length when used.

Fig. 7-3 Cable length

●Cable Wiring

In order to avoid interface of cables as much as possible, keep a space for cables to be laid

in a row.

8-1

8. Lubrication

8. Lubrication

See the Instruction Manual of the LM Guide [No. 1030-T34667] for lubrication.

9-1

9. Troubleshooting

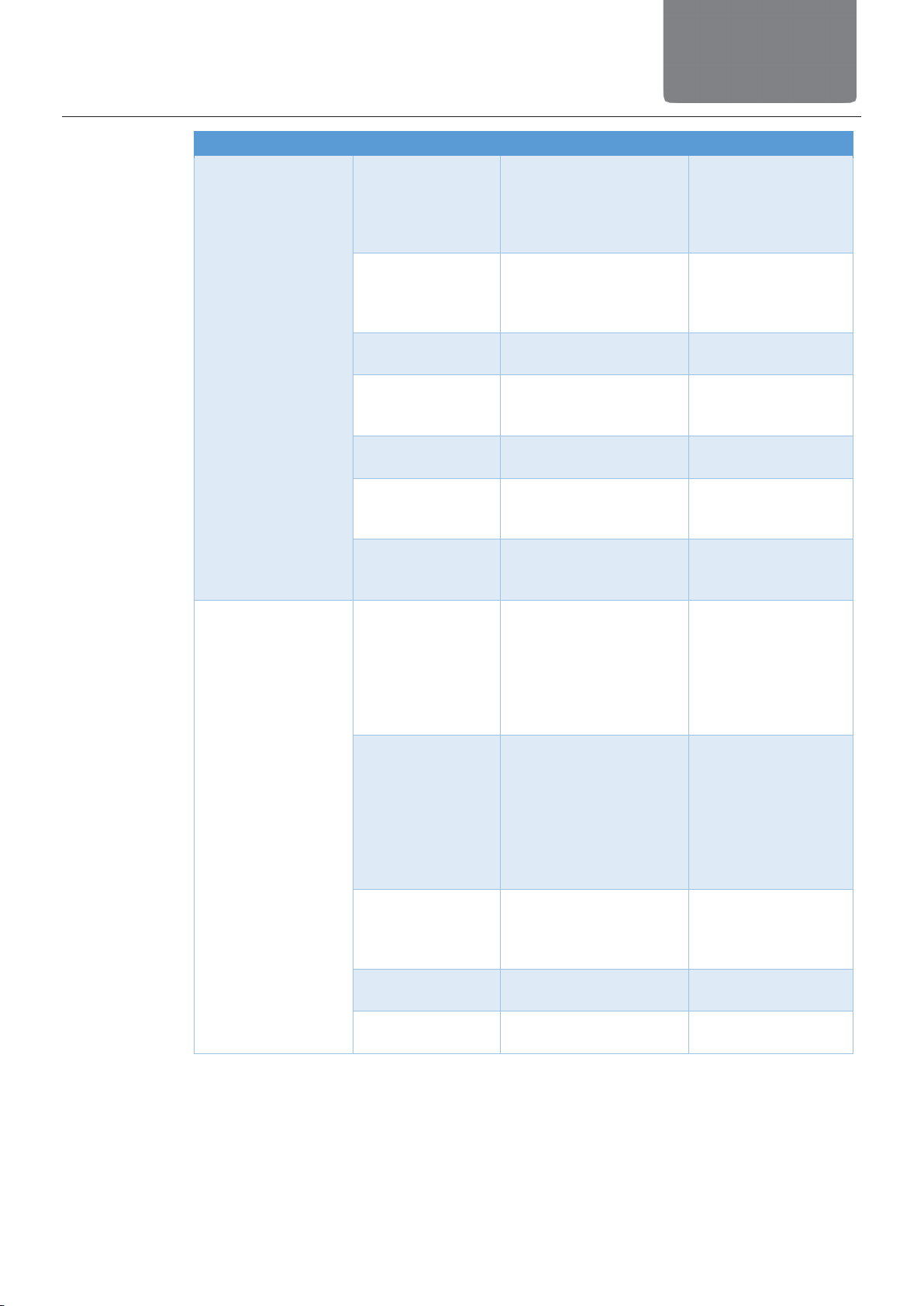

9. Troubleshooting

Symptom

Cause

Countermeasure

Related Page

Pulses cannot be

counted in higher-level

device

Power is not supplied

to the encoder head

Supply 5V DC power to the

linear encoder. Make sure

that there is no voltage drop

when the cable length is

extended.

4-2-2

Encoder Specifications

Interface is not

matched

Confirm that the interface to

receive signals is a line

receiver circuit complied

with EIA-422.

4-2-3

Output Specifications

Wrong Wiring Check the pin assignments

and lay them out correctly.

7-1 Wiring

Cable connector is

disconnected

Check if the connection at

connectors are performed

properly.

7-1 Wiring

Cable line breakage Check if there is any line

breakage on a cable.

Encoder head

malfunction

Consult with our IOT

Innovation Divisions if

replacement is necessary.

Scale malfunction Consult with our IOT

Innovation Divisions if

replacement is necessary.

Pulse count

significantly differ to

travel distance

Scale Error Check the entire stroke on

the scale surfaces with a

magnet viewer sold in

general. If there is an error in

arrangement of magnets, it

is necessary to have a

replacement.

Noise Check if there is any

influence of noise caused by

such as peripheral

servomotor, and take a

counteraction against noise

such as electrical isolation

and grounding if there is an

influence.

Gap error between

scale and encoder

head

Check if there is any

loosened or dropped screw

on the encoder head or

encoder holder.

Cable Error Check if there is any line

breakage on a cable.

Contact error on

cable connector

Check if joint on connectors

are connected properly.

Table of contents