TOYODenki EDM series User manual

INSTRUCTION MANUAL

Permanent magnet type synchronous motor

Series

CONTENTS

Please read surely the following precautions

I. Preparation for operation -------------------------------------------------------------------------------1

1. Checking at arrival of motor -------------------------------------------------------------------------------1

2. Installation -------------------------------------------------------------------------------------------------------1

3. Electric wiring -------------------------------------------------------------------------------------------5

II. Trial operation and ordinary operation -------------------------------------------------------------------7

1. Before powering -------------------------------------------------------------------------------------------7

2. After powering -------------------------------------------------------------------------------------------7

III. Maintenance, checking -------------------------------------------------------------------------------8

1. Daily checking -------------------------------------------------------------------------------------------8

2. Periodical checking -------------------------------------------------------------------------------------------8

3. Bearing and lubrication -------------------------------------------------------------------------------8

4. Checking of accessories ------------------------------------------------------------------------------10

5. Service life of main accessory parts ------------------------------------------------------------------10

IV. Preparation for operation ------------------------------------------------------------------------------11

1. Storage ------------------------------------------------------------------------------------------------------11

V. Disassembly, Assembly ------------------------------------------------------------------------------12

1. Procedures of disassembly and assembly ------------------------------------------------------12

2. Replacement of bearing ------------------------------------------------------------------------------16

3. Structural drawing of motor ------------------------------------------------------------------------------17

VI. Troubleshooting of motor ------------------------------------------------------------------------------19

VII. Industrial Product Warranty ------------------------------------------------------------------21

Please read surely the following precautions

Introduction

We thank you for your adoption of Toyo Denki ED Motor (permanent magnet type synchronous

motor). This Manual shows handling method of ED motor and precautions on use for customers

having general knowledge on permanent magnet type synchronous motor. Before use, please

read this Manual carefully until getting of enough knowledge on our ED motor and use it when

it is in optimum condition. After reading, please keep this Manual close to the place where ED

motor is used. In case of lease or transfer of ED motor, deliver this Manual together. When ED

motor is used combining with machine or equipment, please arrange this Manual to be handed

to the end user surely. If this Manual is lost or damaged, please order new one from us or our

distributor. Meanwhile there is a possibility that we change parts of ED motor for the purpose

of improvement of quality/performance or for safety. At such time, there may be a case that a

part of content and illustration, etc. of this Manual does not conform to the original parts, for

which please understand. If there are any points which are unclear, please consult us or our

distributor.

Safety precautions

Before works of installation, operation, maintenance, inspection, etc., please read carefully this

Manual and the manual of Inverter equipment (VF66B, etc.) and all of other attached documents

surely for correct use. Please use ED motor after getting enough knowledge on it as well as

information on safety and all precautions. After reading, keep this Manual close to the place

where operator can read it easily at anytime. In this Manual, ranking of safety precautions is

classified to [Danger] and [Caution].

! Danger : In case of error in operation, dangerous situation may occur and it could result

in death or serious injury.

! Caution : In case of error in operation, dangerous situation may occur and it could result

in medium or light injury, or damage to physical property only.

Even in case of above ! Caution , there is a possibility to lead to serious result depending on

the situation.

Since important contents are written in both safety precautions, make sure to observe them.

! Danger

(General)

・Works of transportation, installation, piping, wiring, operation, maintenance, inspection

must be carried out by qualified expert. Otherwise, that could result in electric shock, injury,

fire, etc.

・Avoid the work in state of hot-line. Be sure to work after breaking of power supply.

Otherwise, that could result in electric shock.

・Even in state that power supply is interrupted, voltage is generated at motor terminal while

motor is running. Do not touch the motor until perfect stop of rotor and also avoid the work.

Otherwise, that could result in electric shock and injury.

・In state that the power supply is interrupted, do not apply the motor to the usage which has

a possibility of being rotated faster than motor rating speed by the load. Otherwise, that could

result in burning and fire.

・Never use the motor in explosive atmosphere. Otherwise, that could result in injury, fire, etc.

(Installation)

・Surely ground the terminal for earthing. That could result in electric shock.

・In case of use of motor fitting on the ceiling or on the wall, it may drop depending on the

conditions. Therefore, please obey to catalog and technical materials in regard to the details

of range of use. Otherwise, that could result in injury.

・Operate the motor after confirmation that protection devices are firmly connected and they

activate normally. Otherwise, that could result in injury and fire.

! Danger

・Do not operate the motor in state that the cover of terminal box is removed. After work, fit

the cover of terminal box at the original position. Otherwise, that could result in electric

shock.

(Piping, wiring)

・Connection with power supply cable should be done in accordance with connection diagram

or Instruction Manual. Erroneous wiring could result in electric shock and fire.

・Do not bend or pull or put between something the power supply cable and lead wire of motor

forcibly. Otherwise, that could result in electric shock.

(Operation)

・Never approach to or contact the rotating objects (shaft, etc.) during operation. Otherwise,

that could result in injury by being caught.

・When power is interrupted, turn off the power supply surely. Otherwise, that could result in

injury when power is supplied again.

(Maintenance and inspection)

・Connection with power supply cable should be done in accordance with connection diagram

or Instruction Manual. Erroneous connection could result in electric shock and fire.

! Caution

(General)

・For installation place of motor, secure safe and adequate space for maintenance and

inspection. Otherwise, trouble of electric shock and injury could occur.

・Do not use the motor under out of specifications of that motor. Otherwise, that could result in

electric shock, injury, breakage, etc.

・Do not insert finger or object into the aperture of motor. Otherwise, that could result in

electric shock, injury, fire, etc.

・Do not use damaged motor. Otherwise, that could result in injury, fire, etc.

・In case of work at high place, prepare enough measures for prevention of drop. Otherwise,

trouble of injury by drop could occur.

・Since remodeling by user is out of range of our guarantee, we are not responsible for it.

・Do not put obstacles in front of motor name plate in order for operator to see it at any time.

・Do not remove the name plate.

(Transportation)

・Since drop and falling down of the product during transportation is dangerous, please pay

enough attention for such work. As to motor, surely use designated position for hanging. After

installation of motor combined with machine, do not hang whole set of motor-machine at the

position for hanging of motor only. Before hanging, confirm mass of motor by name plate,

packing case, outline drawing, catalog, etc. and do not hang the heavier motor than the rated

load of hanger. Breakage of hanger and consequent drop as well as falling down could result

in breakage of motor and injury.

(Unpacking)

・Unpack the case after confirmation of top and bottom. Otherwise, that could result in injury.

・Confirm whether reached product is just the ordered one. Installation of erroneously

delivered product could result in injury, breakage, etc.

(Installation, adjustment)

・Never place any inflammable objects around the motor. Otherwise, that could result in fire.

・Do not place any objects which prevent ventilation, around the motor. Otherwise, that could

result in burn and fire by extraordinary overheat caused by prevention of cooling

・When motor is connected with machine, pay attention on centering, belt-setting, parallel

degree of pulley, etc. In case of series connection, pay attention on direct-connection accuracy.

In case of belt connection, adjust tensile strength of belt correctly. Before operation, tighten

clamp bolts of pulley and coupling firmly. Otherwise, trouble of injury and breakage of

equipment caused by scattering of fragments could occur.

・Avoiding touch with rotating part, mount the cover, etc. Otherwise, that could result in

injury.

! Caution

・In case of rotating of motor alone, remove temporarily fixed key to the main shaft.

Otherwise, that could result in injury.

・Before connection of motor with machine, confirm its direction of rotation. Otherwise, that

could result in injury and breakage of equipment.

・Never get on and dangle from motor. Otherwise, that could result in injury.

・Do not touch with bare hand the keyway at shaft end of motor. Otherwise, that could result

in injury.

(Piping, wiring)

・At the time of measurement of insulation resistance, do not touch the terminals. Otherwise,

that could result in electric shock.

・Carry out wiring work in accordance with [Electrical Facilities Technical Standards] and

[Inner Wiring Regulations]. Otherwise, that could result in fire.

(Operation)

・Since motor gets very hot during operation, do not touch it with hand or body. Otherwise,

that could result in burn.

・When error occurred, stop operation immediately. Otherwise, that could result in electric

shock, injury, fire, etc.

(Maintenance, inspection)

・At the time of measurement of insulation resistance, do not touch the terminal. Otherwise,

that could result in electric shock.

・At the time of injection/discharge of grease to/from bearing, do not touch rotating object.

Otherwise, that could result in injury.

・Since frame of motor gets very hot, pay attention at the time of maintenance and inspection

in order to avoid burn.

(Repair, disassembly)

・Repair and disassembly should be done by qualified expert. Otherwise, electric shock,

injury, fire, etc. could occur.

EDM Series ED motor is the most suitably designed motor for Inverter

drive by Toyo Denki having high level technology in rotary machine and

control equipment.

Explanation of type name

EDM 1 9 1 1 V - C 1 A A - H 0 1

Main mechanical variation on

external form

Details of protection system or

cooling system

Electrical specifications

Cooling system

Installation structure of motor

Frame spigot diameter

Series number

Fig. 1

- 1 -

I. Preparation for operation

1. Checking at arrival of motor

When the ordered motor arrived, please check paying attention to the following points.

(1) Check the motor with our invoice separately sent.

(2) Check the motor for damage, rusting, dropping of accessories, etc.

(3) There is a case that the rotor of motor is fixed in order to prevent the bearing from being

damaged during transportation. Check the rotor and remove it.

(4) Rotate the shaft end manually to confirm smooth rotation.

(5) Check the motor output, voltage, current, frequency, rotation speed, etc. shown on the name

plate.

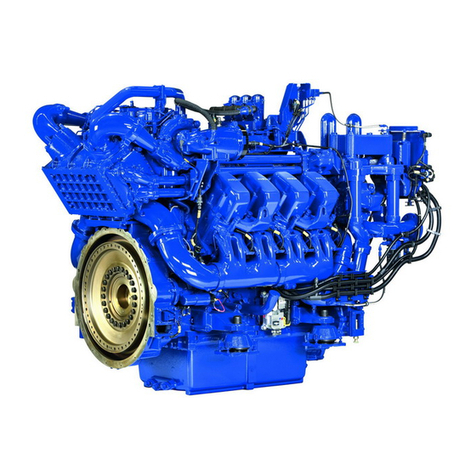

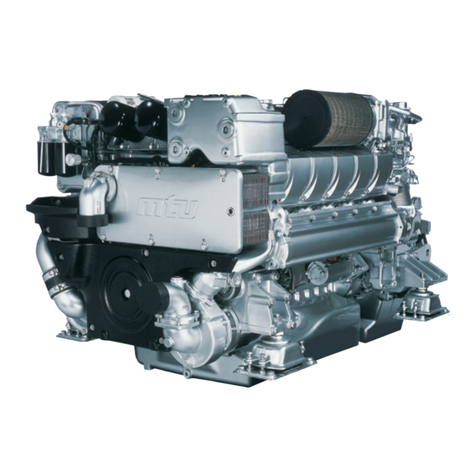

Photo. of external appearance of motor

2. Installation

2.1 Installation place

(1) Install the motor at a well-ventilated place and arrange not to return the coming out heat from

the motor, to the intake side by circulation. At a place where the ambient temperature is high or

when the motor is influenced by heat radiation/conduction, take measures such as heat

insulation, reduction of load, etc.

(2) Distance between the inlet of cooling fan of the motor and the wall should be 20cm or more for

EDM13~EDM31 and 30cm or more for EDM35~EDM68.

(3) Place with less humidity.

(4) Place with less dust. If dust is accumulated on the fins of frame, cooling effect will be reduced

causing overheating. Therefore, periodical cleaning should be done in case of dusty place.

(5) Place where motor is not influenced by noxious gas and acid/alkaline chemicals, etc. When

motor is used at a place where flammable gas exists, re-check whether selected explosion proof

structure conforms to the regulations of Ministry of Economy, Trade and Industry and the

Ministry of Health, Labor and Welfare.

(6) Place where such works as disassembly, inspection, cleaning and maintenance can be carried

out easily.

(7) Install the motor on a strong foundation and rigid common base so that external vibration will

not be conducted to the motor. If vibration during operation is large, bearing life will be

shortened and it will cause the vibration fatigue failure of fan, rotor, etc.

(8) Place with less fluctuation of supply voltage and less voltage drop.

Connector for pulse oscillator

Fram

e

Main

terminal box

Shaft

Bracket

Fan cover

Auxiliary terminal box

(for cooling fan)

- 2 -

2.2 Connection with counterpart machine

(1) Foundation work

In order to minimize the vibration and misalignment during operation, strong foundation is

required. If foundation is incomplete, machine will vibrate and bearing life will be shortened,

to which please pay attention. The most ideal foundation in order to prevent generation of

vibration is a strong concrete foundation but

if such concrete foundation cannot be made

because of counterpart machine and

relation with the place, install the motor on

the steel frame with bolts firmly arranging

that the motor shaft exactly level (or

perpendicular for a vertical motor) surely.

For the base, achieve the level degree of

0.2/1000mm or less accurately. Also, clean

the surfaces of concrete foundation / steel

frame and of the leg of motor for ideal

installation.

(2) In case of flexible coupling

1) Mark the matchmarks on the outer

surface of coupling.

2) In order to rotate the couplings together,

connect couplings of the counterpart

machine and of the motor by one bolt.

3) Fix a dial gauge firmly to outer surface of one coupling. (Fig. 2)

4) Move the matchmark of the coupling to the top and measure the dimension-g by clearance

gauge and dimension-h by dial gauge.

5) Rotate the coupling and carry out same measurement as above item 4) at every 90 of

quadrant positions.

6) Adjust using shim plates so that the difference between maximum and minimum of the

measured values will be 0.03mm for both g and h. Every time the measurement for

adjustment is carried out, tighten the installation part with bolt sufficiently. When dial

gauge cannot be fitted for a small motor, apply the stretch to the outer surface of one

coupling and measure the clearance between stretch and the other coupling.

Stretch

Fig. 2

h : Parallelism

g : Eccentricity

Matchmark

- 3 -

(3) In case of belt drive

Set the counterpart machine shaft and motor

shaft accurately parallel and apply the belt in

such a way that both pulley centers coincide each

other.

The belt is apt to be stretched too much however,

excessive stretching will damage the bearing and

cause unexpected accidents such as breakage of

motor shaft, etc., to which please pay attention.

1) Belt stretching method

Step 1 : Firstly, find the belt span (Ls). Belt span

is the length of the portion of belt

between contact points with both pulleys.

Step 2 : Apply the force ( Pk ), which is required

for deflection ( δ), at the center of the

belt span. This required force for

deflection ( δ) should be calculated by

the formula 5 shown below and it should

be within the range of Pk1 - Pk2.

Step 3 : Stretch the belt in such a way that the

deflection ( δ), when the force is applied,

will be the value found by the following

formula.

δ= 0.016・Ls

2) Calculation formula

Step 1 : How to find belt contact angle (small pulley side) ... Formula 1

Formula 1

θ = 180° -2 sin-1

Step 2 : How to find initial tension (Fo) .................................. Formula 2

Formula 2

Fo = 0.9 { 500 ( ) + m・v2}

Fo : Initial tension (N)

Table 1

Kθ: Contact angle

correction factor

Contact angle (θ)

140°

150°

160°

170°

180°

Pd: Design power (kW)

Correction factor (K

θ)

0.89

0.92

0.95

0.98

1

Pd= PNx ( Ko + Ki ) PN: Load power (motor output, in general) (1kW)

Ko : Load correction factor (1.0 ~1.5)

Ki : Idler correction factor (0 ~0.2)

Z : Number of belt v : Belt speed (m/sec) m : Mass/unit of belt (kg/m)

Note) Determine Ko, Ki depending on the machine to be used and operation time,

referring JIS Standard or catalog, etc. of belt maker.

Step 3 : How to find span (Ls) ................................. Formula 3

Formula 3

Ls : Span (mm)

C : Distance between shafts (mm)

d2: Large pulley nominal diameter

(mm)

d1: Small pulley nominal diameter

(mm)

Z・v

Pd

d2-d1

2C

Motor

Counterpart

machine

Motor side

pulley

θ(Belt cont-

act angle)

Fig. 3 Belt stretching method

2.5 –Kθ

Kθ

Ls = C2-

(d2-d1)2

4

- 4 -

Step 4 : How to find deflection (δ) ........................... Formula 4

Formula 4 δ= 0.016・Ls δ: Deflection (mm)

Step 5 : How to find necessary force (Pk1, Pk2) for deflection (δ) ... Formula 5

Formula 5

Pk1 : Necessary force (min. value)

(N) for deflection (δ)

Pk2 : Necessary force (max. value)

(N) for deflection (δ)

Table 2

Kind of belt

Y(N)

m(kg/m)

Standard V belt

A type

15

0.12

B type

20

0.20

C type

30

0.36

D type

60

0.66

Narrow V belt

3Vtype

20

0.08

5Vtype

39

0.20

8Vtype

98

0.50

Table 3

Type of motor

EDM

1711

EDM

1721

EDM

19

EDM

22

EDM

27

EDM

31

EDM

35

EDM

43

Permissible shaft load F(N)

1600

2240

2930

5360

9080

12100

18800

24200

Q (mm)

80

110

110

110

140

140

170

175

Q' (mm)

31.5

41

50.5

68

93.5

106

91.3

108.8

[Note] Type of motor, for which the belt can be applied, is till EDM4321V. EDM4331V and

EDM54, EDM68 are for direct connection only.

Belt speed should be : -

Standard V belt (A, B, C, D types) ..... 30m/sec or

less

Narrow V belt (3V, 5V, 8V types) ....... 40m/sec or

less

This matter should be taken into consideration when

pulley diameter is determined. The belt tension differs

depending on the kind of belt however, the radial load

imposed on the motor shaft should be less than the values in the above table.

(4) Mounting of coupling and belt pulley

Coupling and belt pulley should be mounted carefully not to damage the motor bearing.

Lightly press-fit them by wooden or plastic hammer. In case of heating, heat them until about

100°C uniformly. In case of press-fitting, remove the rust preventive agent on the shaft end by

petroleum solvent or alkali solvent, and apply molybdenum disulfide.

[Caution]

In case that the pulse oscillator for speed detection is provided on the shaft end of non-

transmission side, be careful not to give impact to it when coupling and belt pulley are

inserted since it may be damaged by such impact. (See Structural Drawings Fig.17~Fig.20)

(5) In case of flange type motor flange engagement surface is accurately machined. If

contaminant, paint, rust, etc. are found there, remove them surely.

Pk1(min.value) =

Fo + Y

16

Pk2(max.value) =

1.25 x Fo + Y

16

- 5 -

3. Electric Wiring

3.1 Terminal box

There are main terminal box for motor main body terminals and thermistor, and auxiliary

terminal box for electric fan. Connect external wirings correctly and firmly. Connection with

pulse oscillator of motor side is connector-connection.

3.2 Connection diagram

Fig. 5 shows the standard connection diagram. In case that the temperature sensing element

(pt100Ω), temperature element (bimetal type) and electromagnetic brake are provided, all these

terminals are housed in the main terminal box and their terminal symbols are as shown in Fig.

6.

[Caution]

If electromagnetic brake and main power supply circuit are connected erroneously with terminals

of ptc thermistor (terminals MG1, MG2), temperature sensing element (terminals T1, T2, T3) and

temperature element (XB1, XB2), motor coil will be damaged caused by breakage of elements and

so, enough attention should be paid. Also, do not measure insulation resistance by insulation

resistance meter (Megger). If the power was turned on with wrong connection, carry out

disassembly and inspection.

Note : Cooling fan is single phase for EDM19 or less.

Therefore, it has 2 terminals of FU and FV.

Main terminal

Auxiliary terminal box

ptc thermistor

Main terminal

Temperature

element

Temperature

sensing element

Ele. mag brake

Fig. 6

Fig. 5

Cooling fan

oscillator

- 6 -

3.3 Direction of rotation

(1) Direction of rotation must be correct.

(2) Direction of rotation of the motor is expressed as seen from the shaft end of drive side.

Standard direction of rotation of the motor is counterclockwise (CCW) in case that the phase

sequence of power supply side is R, S, T and when these phases are connected with the motor

terminal symbols U, V, W.

3.4 Checking of wiring

(1) Terminals must be connected correctly in accordance with connection diagrams (Fig. 5, Fig. 6).

Due attention should be paid to the following points.

1) For the signal cable between pulse oscillator (PG) and controller, the twisted pair, shielded

cable should be used for protection against noise. The length should be 100m or less. Also,

connection with pulse oscillator of motor side is connector connection and therefore,

undermentioned straight plug and cable clamp are needed in addition to the cable.

Recommendable cable ...Twisted pair, shielded cable ... CO-SPEV-SB(A)7P-0.5SQ

(product of Hitachi Metals, Ltd.)

Straight plug ... MS3106B-20-29S

(product of Japan Aviation Electronics Industry, Limited or equivalent)

Cable clamp ... MS3057-12A

(product of Japan Aviation Electronics Industry, Limited or equivalent)

2) As to the shielded cable (N), ground that of the motor side only.

3) Never carry out the measurement of insulation resistance (Megger test) of pulse oscillator.

Use tester for this measurement.

4) For the wiring cable of ptc thermistor, use twisted pair cable.

5) The earthing terminal (E mark terminal) provided in the main terminal box must be

grounded. The earthing terminal (E mark terminal) is provided also in the auxiliary terminal

box for cooling fan. Please ground it surely.

(2) Checking of the direction of rotation of electric fan

After finish of wiring work, check that the electric fan for cooling rotates to the correct direction,

before starting of normal operation. (direction of rotation and cooling air flow are indicated on

the fan cover.)

3.5 Detailed drawings of terminal boxes

Main terminal box (Fig. 7) and cooling fan terminal box (Fig. 8) are terminal block type.

However, for the motors EDM43 or over, main terminal box is lug type.

In case of single phase, terminal

symbols are FU and FV.

Fig. 7 Detailed drawing of

main terminal box

Fig. 8 Detailed drawing of

cooling fan terminal box

ptc thermistor lead wire

primary lead wire

earth terminal

symbol

earth terminal

symbol

- 7 -

II. Trial operation and ordinary operation

1. Before powering

All of your purchased motors from us passed severe tests at our factory however, they may have a

possibility of being damaged during transportation or affected by long storage, and so carry out

following checking, confirmation before starting of operation.

(1) Precautions for working before trial operation

1) Check that the shaft fixer and cover for the time of storage were removed.

2) Check whether electric wiring was correctly carried out and terminal box cover was fitted.

3) Check whether loose tightening bolts are found at individual part.

4) Check whether the motor is well ventilated.

5) Check whether rotating part contacts fixed part when the shaft is rotated manually.

6) Measurement of insulation resistance of stator coil to earth. Disconnect the motor main

circuit at the terminal block of the controller side and measure insulation resistance using

500V Megger between motor terminal and earth. Although it is difficult to generally indicate

the insulation resistance value, criterion is 1MΩ or over.

7) Check whether earth terminals of individual part are completely connected.

(2) Lubrication

For the grease lubrication type motors, the bearing portion is filled with grease before

shipment. However, if they are not used for more than 6 months after arrival at the site, the

grease must be replenished soon after starting of operation. This work is not necessary in case

of use of sealed-grease type bearing.

(3) Others

Check the status of direct connection and belt tension as well as tightening of bolts and nuts of

the individual part.

2. After powering

(1) In the initial operation, the motor should be operated with no load independently at as low as

possible speed in order to confirm no abnormality. After that, the motor should be connected

with the counterpart machine.

(2) After starting of operation, check the following points.

1) Whether direction of rotation (standard direction of rotation is clockwise as seen from non-

load side) is correct.

2) Whether abnormal sound is heard from the bearing part.

3) Whether abnormal sound is heard from inside of the motor.

4) Whether burning smell of insulator, etc. is sensed.

5) Whether abnormal vibration is sensed. If the total amplitude exceeds 30μm, investigate the

cause and take necessary measures.

6) Whether supply voltage and phase current are balanced.

7) Whether starting time is abnormally long.

Checking the above points, proceed independent operation, no-load operation, full-load operation

sequentially and if all of them are normal, start full scale operation.

- 8 -

III. Maintenance, checking

In order to prevent accidents in operation of the machine, daily monitoring or checking is required.

1. Daily checking

By touching and hearing, check the vibration and sound at the time of starting and during operation

of the machine and confirm that there is no abnormality. User is recommended to put the status of

operation on record.

Records of daily checking :-

(1) Date, time of measurement. Weather of the day of measurement

(2) Voltage, load current, frequency, rotation speed

(3) Ambient temperature

(4) Temperature of stator winding or frame

(5) Temperature and sound of bearing

(6) Abnormal vibration

(7) Cooling air condition of cooling fan

2. Periodical checking

(1) Measurement of insulation resistance

(2) Checking of bearing related items

(3) Condition of ventilation

(4) Measurement of vibration

(5) Looseness of tightening nuts

(6) Condition of direct connection of coupling and belt tension

(7) Cleaning of individual part

(8) Checking of power supply condition

(9) Checking of pulse oscillator, cooling fan

Checking items are as shown above. The insulation resistance should be measured every 6 months

and the other items should be checked once a year.

To measure and monitor the machine vibration periodically is very important for the

maintenance/checking of the machine. If vibration is large, it affects the bearing, winding and

condition of direct-connection badly and therefore, investigate the cause and repair the faulty part.

3. Bearing and lubrication

3.1 Shielded bearing

For the motors of EDM13~EDM22 and EDM27~EDM35 (non-load side), shielded type ZZ (non-

contact type sealed grease) bearing is used. Generally, the bearing should be replaced at the time

of periodical checking. Until that time, grease maintenance is not required.

- 9 -

3.2 Grease replenish type bearing

For the motors of EDM43 or over, kind, quantity and interval of replenishing of grease are indicated

on the name plate.

(1) Replenish the grease during operation at every replenishment interval (operation time)

indicated on the name plate. In case that the net operation time is short due to short-time or

repetitive operation, grease should be replenished in such a way that the elapsed time including

stoppage will not become twice or more of the interval indicated on the name plate, or at least

every 6 months - one year.

(2) When grease is replenished, be sure to rotate (300 r/min or more) the motor, clean the grease

nipple, and replenish necessary quantity by grease gun through the nipple. At every time of

grease replenishment, scrape out old grease from grease drain port.

(3) When the grease is replenished, bearing sound will become temporarily louder a little or the

bearing temperature will rise 5°C~10°C higher than the normal one, because of excess grease,

but it will return to normal one in several hours to 1 day.

(4) Table 4 shows approximate values of grease replenishment quantity and replenishing timing.

Table 4 Grease replenishment quantity

Type of

motor

Load side bearing No.

Replenishment

quantity

Replenishing timing (cumulative

operating time) (Hr) at specified speed

Non-load side

bearing No

(g)

1800 r/min

1500 r/min

1200 r/min

EDM2761V

EDM2771V

NU313

33

3400

4200

5400

6312ZZ

--

--

--

--

EDM2772V

EDM2781V

NU316

47

3000

3700

4800

6312ZZ

--

--

--

--

EDM3141V

NU316

47

3000

3700

4800

6315ZZ

--

--

--

--

EDM3151V

EDM3161V

EDM3541V

NU320

72

2600

3200

4200

6315ZZ

--

--

--

--

EDM3551V

EDM3561V

EDM43**V

NU324

102

2300

2900

3700

6318

24

2300

2900

3700

EDM54**V

6324

102

4700

5800

7600

6318

48

4700

5800

7600

EDM68**V

6326

116

4400

5500

7200

6324

96

4400

5500

7200

Table 5

At the forwarding from our factory, bearings are filled

with Multemp SRL (of Kyodo Yushi Co.) unless otherwise

specified, (or grease of the brand specified by user). For

replenishment of grease, we recommend this Multemp

SRL. If grease of this brand is not obtainable, the

equivalent greases shown in the table below can be used.

Maker name

Brand of grease

Kyodo Yushi

Multemp SRL

Nippon Oil

Multi Knock Wide 2

MOBIL

Mobil Temp SHC100

SHELL

Variant M2

ESSO

Templex N2

3.3 Use of grease of different type for the grease replenish type bearing

(1) Avoid mixed use of different brands of grease. Depending on the combination, properties of

grease may greatly change.

(2) In case that the user is compelled to use a grease of different brand from the grease of the time

of delivery, the following method should be taken.

1) Open the grease drain port and inject new grease while scraping out the old grease, during

operation or by manual rotation of the shaft.

2) Repeat this work until the new grease comes out of the grease drain port.

(3) When the grease is injected, bearing temperature may rise. In such a case, stop the injection

until lowering of bearing temperature. After that, repeat the injection of the grease.

- 10 -

3.4 Sound of bearing (Grease replenish type)

Sound of bearing during operation is classified as follows.

(1) Normal sound

The normal sound is continuous one. The race sound, jarring sound and retainer sound are

considered as normal. The jarring sound may be misunderstood as an abnormal noise but it

does not mean the abnormality of bearing. The jarring sound dies away temporarily when the

grease is injected in general.

The jarring sound may be generated in the following cases.

1) In case of bearing clearance C3 or C4 for high speed machine

2) In case of cylindrical roller bearing

3) In case of operation in winter of low ambient temperature and of the beginning of operation

after long stoppage.

(2) Abnormal sound

1) Flaw noise or dust noise, etc. are abnormal sound.

2) Abnormal sound is discontinuous and in some cases it accompanies vibration.

3)When abnormal noise sounds, inject new grease and observe change in sound and

temperature for a while. If abnormal noise does not stop, the bearing should be replaced.

4. Checking of accessories

For checking of accessories of electromagnetic brake, speed reducer, etc., see the Instruction of

Manual for accessories of the separate volume.

5. Service life of main accessory parts

Some parts of motor have their service life limit. It differs depending on the service

environment/conditions and therefore, carry out checking or replacement of parts making the

undermentioned service life limit as a criterion.

5.1 As to motor related parts

(1) Motor bearing (at ambient temperature of 40°C or lower and speed of 1800 r/min)

1) Grease replenish type bearing ..... About 50,000 hours

2) Shielded bearing .................. About 32,000~47,000 hours

・Sealed grease is of Multemp SRL of Kyodo Yushi, or equivalent.

・Life of shielded bearing is determined depending on the life of sealed grease. Life of

sealed grease is affected by the ambient temperature and is shortened about 1/1.5 every

time the ambient temperature rises 10°C from 40°C.

(2) Fan motor .......... About 3~4 years (at ambient temperature of 40°C or lower)

(3) Pulse oscillator ... About 4~5 years (at ambient temperature of 40°C or lower and speed of

1800 r/min)

(The shielded bearings of fan motor and pulse generator will reach the limit of their service life.

This limit differs depending on the ambient temperature.)

(4) V ring .................... About 25,000 hours

(It is recommended to also replace the V-ring when the encoder is replaced.)

5.2 Helical speed reducer (at ambient temperature of 40°C)

(1) Each bearing ....... About 25,000 hours

(2) Oil seal .................About 10,000~15,000 hours as a criterion (Life differs greatly depending on

the environmental conditions for use.)

(3) Replacement cycle of lubrication oil

First time : 500~1,000 hours after starting of operation.

Subsequently : Every 2,500 hours.

- 11 -

IV. Storage

1. Storage

(1) In case that the motor is stored for 3 months or longer till the initial operation after receiving

it or its operation is stopped for 3 months or longer, take the following steps.

1) Storage

: The motor should be placed in the same posture with

correct installation state, covered with waterproof sheet,

and be kept at a dry place.

2) Exposed machined surface

: Apply rust-preventive agent every 6 months. If motor is

export-packed, unpack it after elapse of one year and apply

the rust-preventive agent.

3) Rotation of shaft

: Operate the motor for a few minutes every 3 months (and

before long storage) or rotate the shaft manually about 10

times. If motor is export-packed, follow item 4) below.

4) Bearing and lubrication

・Shielded bearing

: After storage of motor for 2 years or longer, pay attention

whether abnormal sound is heard from bearing during trial

operation. If it is heard, replace the bearing.

・Grease replenishment type

: Replenish the quantity shown on the name plate, rotating

the shaft manually or operating the motor every one year.

(If the motor is export-packed, unpack it temporarily and

replenish the grease.)

5) Insulation resistance of

winding

: In case that the motor is not used for a long time, measure

the insulation resistance of winding of the winding every 6

months and before starting of operation. If resistance is

lower than 1 MΩ at ordinary temperature and its cause is

not the moisture adsorption in the terminal box, dry the

winding.

6) Space heater

(when provided)

: When the motor is stopped for 1 day or longer, energize the

heater.

7) Surface painting

: Re-paint every 2 years, as the need arises.

8) Drain plug

(when provided)

: Open the drain plug periodically (at least every 6 months)

and before starting of operation.

- 12 -

V. Disassembly, Assembly

This motor incorporates permanent magnet in its rotor. Owing to this composition, pulling out of

the rotor from the stator is quite difficult. Therefore, do not pull out the rotor from the stator at the

time of disassembly/assembly of motor, such a case of replacement, etc. of bearing. Replacement of

bearing can be carried out keeping the rotor inserted in the stator. Also, at the time of

disassembly/assembly, do not proceed the work at load side and non-load side simultaneously.

Surely after completion of work of one side, start the work of the other side (As to the order of work,

starting from any of both side is available). Since magnetism of the magnet of rotor acts to outside

a little during the works of disassembly/assembly of motor, do not make Watch, Magnetic Card, etc.

approach to the motor.

1. Disassembly/assembly procedures

(See Fig. 9 below and structural sectioned drawings (Fig. 17~Fig. 20)

(1) Break the power supply.

(2) Remove the connection with the load.

(3) Remove all the external wirings connected with the terminals in the terminal box.

(4) Remove the connection part of pulse oscillator output cable connector at upper part of fan cover.

1.1 Non-load side

(1) Remove pulse oscillator output cable connector from fan cover.

(2) Remove fitting bolts of fan cover and remove fan cover. At this time, cooling fan installed at fan

cover is also removed in combined state with fan cover.

(3) Remove fitting screws of pulse oscillator cover and remove pulse oscillator cover. At this time,

pulse oscillator output cable is led from lower part of pulse oscillator and therefore, pay attention

not to be pulled this cable.

(4) Remove screws, which fix the plate spring of pulse oscillator stator to the mount of pulse

oscillator.

Fig. 9 Detailed drawing of non-load side pulse oscillator and bearing part

position cross section

of motor shaft (See

[Note] of P15 )

Position of plate spring

fitting screw

Pulse oscillator output cable

Detail of A-A

Set screw (M4-2

positions)

(applied with

screw lock for

loosening-stop)

Pulse oscillator output cable connector

Non-load side

bearing

Fan cover

Frame

Non-load side bracket

Inner cover of

non-load side

bearing

Plate

spring

Pulse oscillator mount

Pulse oscillator cover

Pulse oscillator

Motor shaft

C-type snap ring

- 13 -

(5) Loosen about 3 turns the 2 setscrews fixing the pulse oscillator rotor to the motor shaft and

remove pulse oscillator. (Do not take off the setscrews.) However, an adhesive (TB1342H) is used

to prevent the set screws from loosening. Before removing the set screws forcibly, warm them up

to about 100°C using a thin soldering iron and then remove them.

(6) Remove the fixing screws of the pulse oscillator mount, and remove that mount. When the mount

is removed, mark the matchmarks. (For EDM22~EDM68, it is unnecessary to remove the pulse

oscillator mount.)

(7) Remove the V-ring. Refer to Fig. 10 for motors with

encoder only (EDM3551V and EDM3561V, EDM43 to

EDM68), and motors with encoder and electromagnetic

brake. At that time refer to Table 6 for the V-ring type

on the non-load side.

Remove the V ring.

(8) In case that the electromagnetic brake is provided,

remove it.

(9) Remove the bearing outer cover of non-load side

(since the cover of EDM35 or less is unified type with

bracket, remove the fixing bolts of the bearing inner

cover). When that outer cover is removed, mark the

matchmarks.

(10) Remove the bracket of non-load side. When it is

removed, mark the matchmarks.

(11) Remove the insulated short shaft (this shaft is attached to EDM31 or over and not attached to

EDM27 or less, of which shaft is unified type with motor shaft.) of non-load side shaft end. When

that short shaft is removed, mark the matchmarks.

(12) Remove the C-type snap ring by the pliers. (EDM35 or less)

Remove the bearing nut, bearing washer and outer slinger. (EDM43 or over)

(13) Pull out the bearing from shaft by the puller. (As to the details of replacement work of bearing,

refer to item V-2.)

(14) After completion of replacement work of bearing, carry out assembly work under reversed

procedure of disassembly. Align the matchmarks marked at the time of disassembly and tighten

the bolts of diagonal positions alternately in order to avoid uneven tightening. Also, apply grease

(Three Bond 1805 spray type) to the lip of the V ring. The shaft runout for mounting the encoder

should be 0.05 mm or less at TIR. The measurement method of shaft runout is according to Fig.11.

At that time, use a non-magnetic dial gauge. If the dial gauge is not nonmagnetic, it may not be

possible to measure shaft runout correctly.

[Note]

T.I.R.(Total Indicator Reading) refers to the total amount of dial gauge reading when the

measurement unit is rotated once around the reference axis.

Oscillator

mounting base

Oscillator

V ring

Apply grease to lip at reassembly

Fig.10 Position of V ring at

non-load side

- 14 -

The shaft runout correction method is as follows.

(a) If the encoder mounting shaft is integral with the

motor shaft (Refer to Fig.12 (a)), adjust by tapping the

shaft end with a plastic hammer (Less than 2LB) and

a rod of soft material that does not damage the shaft.

(For example, Duracon) Be careful as the impact may

cause an abnormality if the shaft is subjected to an

extremely strong impact.

(b) If the encoder mounting shaft is fixed to the motor

shaft with bolts (Refer to Fig.12 (b)), loosen its bolts

and adjust the mounting position. Be careful not to

forget to tighten the bolt tightly at the end.

(15) After assembling, rotate the shaft manually to

confirm smooth rotation.

Table 6 V ring type on the non-load side (Only motors with an oscillator)

Type of motor

Type of break

Type of V ring

EDM1311V~EDM3541V

None

None

EDM3551V~EDM6851V

V-40A

All types

MNB-5K

V-28A

MNB-10K

V-28A

MNB-20K

V-32A

MNB-40K

V-45A

SNB-1.2K

V-18A

SNB-2.5K-13

V-22A

SNB-6KB-03

V-28A

SNB-12KB-03

V-28A

SNB-25KB-03

V-32A

SNB-45KB-03

V-40A or V-38A

Plastic hammer

Rod

Tap the shaft

to adjust.

(a)Oscillator shaft integrated

with motor shaft

(b)Oscillator shaft mounted

with bolts to motor shaft

Bolts for mounting

encoder shaft

Motor shaft

Oscillator

shaft

shaft

Loosen bolts and

adjust the oscillator

shaft position.

Fig.12 Shaft runout correction method

Non-magnetic

type dial gauge

Measure a point 1 to 3 mm

away from the chamfer

Fig.11 Runout measurement of

oscillator mounting shaft

Other manuals for EDM series

1

This manual suits for next models

18

Table of contents

Other TOYODenki Engine manuals

Popular Engine manuals by other brands

Pegasus

Pegasus R-9/2800-200 operating, maintance and safety manual

Becker

Becker R8/17C SEF I1 Assembly and operating instructions

MVVS

MVVS 45 - V1.1 ASSEMBLY EXHAUSTS 3207S-3208S manual

White

White RE 540 Series Repair instructions

Phase

Phase TK Series Installation and application manual

Perkins

Perkins 1300 EDi Series Workshop manual