Tradgardsteknik KX-BGC3 User manual

____________________________________________________________________________________________

0046-431 22290

info@tradgardsteknik.se

Trädgårdsteknik AB

Helsingborgsvägen 578

SE- 262 96 Ängelholm,

SWEDEN

www.tradgardsteknik.se

Operating Manual

Supermarket Refrigerator Series

____________________________________________________________________________________________

0046-431 22290

info@tradgardsteknik.se

Trädgårdsteknik AB

Helsingborgsvägen 578

SE- 262 96 Ängelholm,

SWEDEN

www.tradgardsteknik.se

I. Foreword

Dear customer:

Welcome and thank you for using our fan cooling supermarket display refrigerator. As a new

product with advanced international level researched and developed by the company according to

the market needs, this product fully absorbs the advantages of similar domestic and foreign

products and has the structure optimized based on the original knock-out products of the company,

so that the product is more concise and generous and can be used to sell food and decorate the

commodity section.

This series of supermarket refrigerators may be normally used under 30℃ environment

temperature and 60%RH relative humidity and is very suitable for Chinese conditions. It is the first

choice for various supermarkets, multiple shops and subsidiary food markets to display and sell

cooked food, beverage, fruit and vegetables and for the hotels and collective meal units for cold

storage and fresh-keeping of food.

With good exhibition, the supermarket refrigerator adopts cyclopentane foaming with excellent

thermal insulation performance, copper tube finned evaporator, high EER horizontal rotary unit and

single-layer multistage optimization air curtain, effectively reducing heat exchange with the outside

world, so as to guarantee high product performance and achieve significant energy saving effect!

★The main components are of well-known domestic and foreign brands and reliable performance.

★Integrated design, simple structure and convenient maintenance.

★Ultra-large capacity size, much placement space and good displayperformance.

★Single-layer multistage optimization air curtain, back air outlet technology application, quick

cooling and uniform refrigerator temperature.

★Each layer is designed with LED goods shelf light, which increases the display effect and is more

energy-saving than ordinary fluorescent lamp.

★The trim strips have many colors for choice to show different effects as needed.

★The microcomputer temperature controller may accurately control the refrigerator temperature,

defrosting and other parameters and store the food with high freshness.

For better services, please carefully read this manual before use.

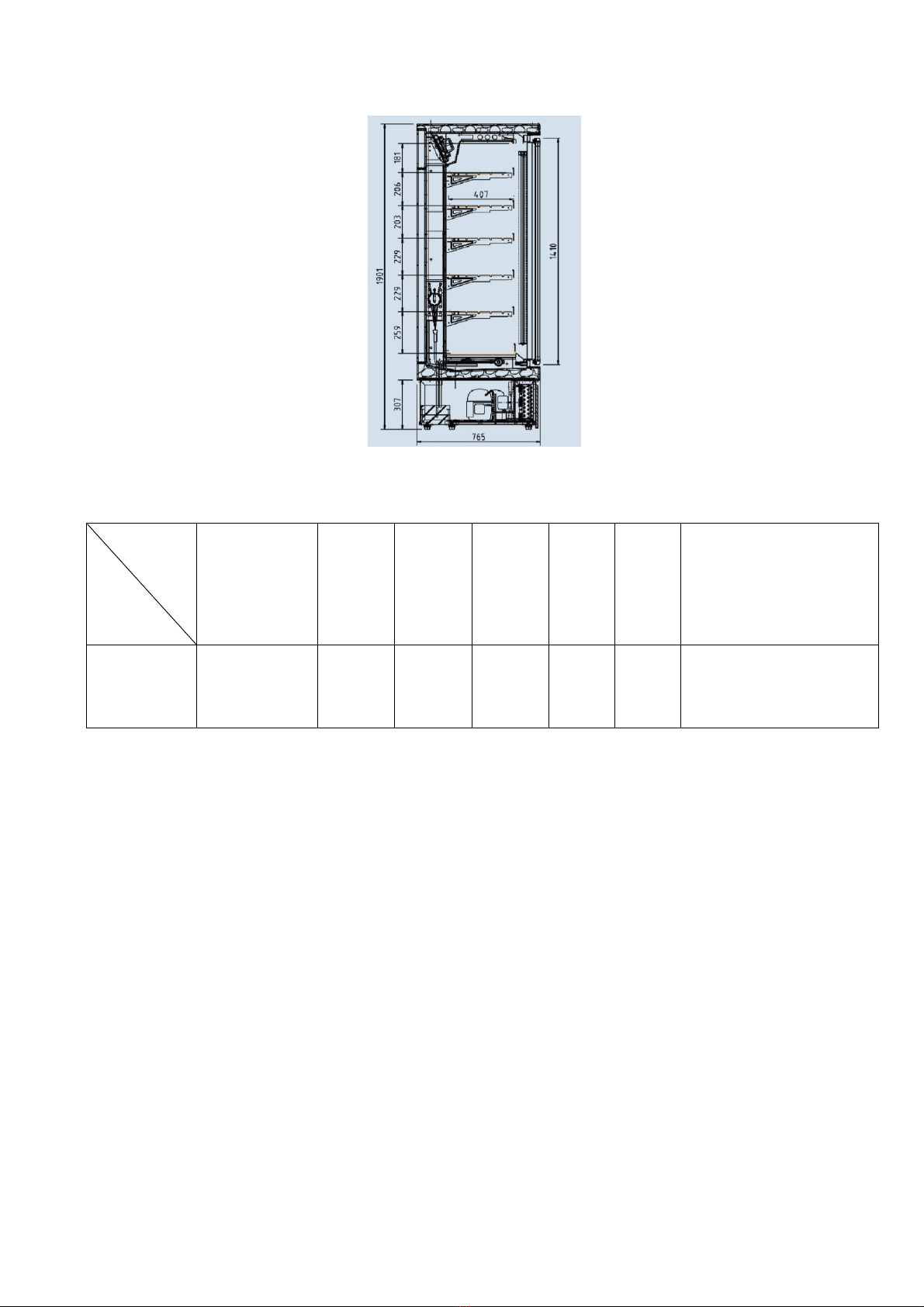

II. Main structure

This series of supermarket refrigerator mainly consists of the refrigerator body, foam end plate,

evaporator, fan unit, front and top decorative parts, exhaust system, temperature control parts,

thermostatic expansion valve or capillary tube, bottom unit parts, end plate parts, shelves and other

accessories. The specific structural layout is shown in the following sectional view:

____________________________________________________________________________________________

0046-431 22290

info@tradgardsteknik.se

Trädgårdsteknik AB

Helsingborgsvägen 578

SE- 262 96 Ängelholm,

SWEDEN

www.tradgardsteknik.se

III. Main technical parameters

Para

meter

Series

Model

Rated

power

supply

(V/Hz)

Service

power

(W)

Temperat

ure range

(℃)

Temper

ature

controll

er

model

Refrige

rant

Dimensions

(L mm W mmH mm)

Commercial

supermarket

series

KX-BGC3

220/50

1530

2~8

C401-K

X

R404a

2550*800*1910

IV. Open-box inspection

1. Check the goods received, check whether the packaging box is seriously damaged, require the

carrier to sign and approve, and timely notify the company or the company’s agent for solving.

2. Check whether the parts are damaged according to the product shipping list. For any problem,

please timely negotiate with the company or the company’s agent for solving.

3. Do not lift the refrigerator end plate and skirt board when moving the refrigerator to avoid damage.

4. Do not tread to avoid damage to the refrigerator.

5. Timely check whether the parts are loose, whether the refrigeration pipeline is damaged and

whether the electric wires and electric parts are damaged or possibly affect normal operation of the

refrigerator during installation and debugging and timely handle if any. For any problem difficult to

solve, timely notify the agent to repair.

V. Service environment and requirements

1. This series of refrigerator has the best using effect in the air conditioning environment (temperature

not higher than 30℃ and relative humidity not more than 60%). If the environment temperature

exceeds 30℃, the refrigeration effect of the refrigerator will be affected; if the ambient humidity of

____________________________________________________________________________________________

0046-431 22290

info@tradgardsteknik.se

Trädgårdsteknik AB

Helsingborgsvägen 578

SE- 262 96 Ängelholm,

SWEDEN

www.tradgardsteknik.se

the refrigerator exceeds 60%, the refrigerator defrosting effect will be affected and the power

consumption in the wet conditions will be increased.

2. When the service environment exceeds 30℃ and the relative humidity is above 65%, the water

drops will accumulate and block in some exhaust air grille holes. The water in the grille may be

absorbed regularly with sponge block to keep the exhaust air grille dry.

3. The strong air flow is not allowed around the refrigerator to interfere with the refrigerator air curtain

(such as ceiling fan installed at the top of the refrigerator and the air conditioner outlet air against the

refrigerator opening). Such air flow will destroy the air curtain and directly affect the refrigerator

cooling effect. The air flow shall be kept away from heat to avoid heat radiation and hot air

interference.

4. The refrigerator shall be installed on flat, hard and dry ground to ensure that the condenser exhausts

air smoothly. The water shall be discharged regularly or the sewer pipe is connected to the sewer.

____________________________________________________________________________________________

0046-431 22290

info@tradgardsteknik.se

Trädgårdsteknik AB

Helsingborgsvägen 578

SE- 262 96 Ängelholm,

SWEDEN

www.tradgardsteknik.se

☞Note:

To ensure good heat dissipation environment of the refrigerator, the manual is

attached with 2 sets of M8 bolts and decorative caps. Before using the refrigerator,

screw the bolt in the rear pre-positioned rivet according to the figure, ensure that the

screw outreach is no less than 140mm and finally lock the decorative cap in the screw.

Gently push the refrigerator to the using area, so that the decorate cap is slightly

against the wall.

★ Warning: Install in strict accordance with the requirements; otherwise, the

refrigeration performance will be affected!

VI. Precautions for use

1. Precautions in boot

(1) Check whether the power supply is live and whether the voltage is normal;

(2) Insert the power plug, turn on the refrigeration switch and start up after delay for 3min;

(3) Do not store goods in the refrigerator before the refrigerator temperature reaches normal

temperature.

2. Precautions in shutdown: turn off the refrigeration switch or unplug the power plug. Disconnect the

power if the refrigerator is not used for long time.

3. Ensure that the power plug of the refrigerator has reliable grounding wire. 确保陈列柜电源插头有可

靠的接地线。

4. At the initial stage of using the refrigerator, observe whether the thermostatic expansion valve or

M8 rivet

Bolt M8*150

Clockwise rotation

Decorative cap

____________________________________________________________________________________________

0046-431 22290

info@tradgardsteknik.se

Trädgårdsteknik AB

Helsingborgsvägen 578

SE- 262 96 Ängelholm,

SWEDEN

www.tradgardsteknik.se

capillary tube is working normally. In case of ice jamming or filth blockage, eliminate immediately.

5. The goods on the high level shelves shall not block the air curtain to ensure good thermal insulation

effect of the air curtain.

6. The residue shall be timely cleaned to prevent the residue from falling into the sewer port and

blocking discharge of the defrosting water in the refrigerator.

7. There is high-speed running motor in the refrigerator. Be careful when opening the pallet. In case of

exception in the motor operation, turn off the power before maintenance.

8. To ensure the use performance and cleanliness, the supermarket refrigerator must be thoroughly

cleaned each week to remove the dirt and non-emptied water.

VII. Maintenance and repair

1. In the refrigerator maintenance, the maintenance personnel must have certain refrigeration

technology knowledge and operation skills. The refrigerator shall be specially managed to ensure

reasonable use.

2. Cut off the power before maintenance of the refrigerator.

3. The refrigerator cannot be rinsed with water directly and shall be cleaned according to the following

steps:

(1) Stop the operation of the refrigeration system according to the shutdown procedures and cut off the

power in the refrigerator;

(2) Move away the goods in the refrigerator and remove the pallet and inner seal plate;

(3) Scrub the shelves and other places to be cleaned and pay attention to drying and ventilation of the

electric parts;

(4) Install the disassembled parts in sequence, start the refrigeration system and load the goods after

the refrigerator temperature is normal.

4. Protect the evaporator during maintenance to prevent refrigerant leakage due to bump.

5. Shut down according to the shutdown method in the operating manual before removing the

compressor, expansion valve, dry filter, evaporator and other parts in the system for repair.

6. Modulator tube replacement: unscrew the water joint, take down the damaged modulator tube and

put the new modulator tube in the light base.

7. Regularly clean the unit condenser (every three months), keep the heat exchange plate clean and

ensure smooth heat dissipation. Cleaning steps: shut down first, remove the dash panel, brush the

dust along the aluminum fins and finally clean the fouling between the aluminum fins with

compressed air or water. Do not splash the water on the motor and other electrical elements.

8. The common faults and maintenance methods for this series of refrigerator are as follows:

No.

Fault phenomenon

Causes

Solutions

1

The refrigerator is

not electrified

Fuse blowing out or leakage

short-circuiter disconnected

Replace the fuse or connect the short-circuiter

2

The fan motor is

running but cannot

refrigerate

1. Refrigerant leakage

2. 2. Compressor damage

3.Unit electric appliance out of

order

4. Under defrosting

5. Other reasons in the

refrigeration system

1. Notify the maintenance department to repair

2. Notify the maintenance department to repair

3.Notify the maintenance department to repair

4.Running normally after defrosting

determination

5. Notify the maintenance department to repair

3

Fluctuation in the

1. High condensing pressure

1. Clean the condenser or repair the condenser

____________________________________________________________________________________________

0046-431 22290

info@tradgardsteknik.se

Trädgårdsteknik AB

Helsingborgsvägen 578

SE- 262 96 Ängelholm,

SWEDEN

www.tradgardsteknik.se

refrigerator

temperature

and frequent start of compressor

2. Too low suction pressure

3. Expansion valve out of order

or capillary tube blocked

4. Te m pe r at u r e co n t r o lle r o u t of

order

5. Too large humidity

6. Air curtain interference by air

flow

motor

2.Notify the maintenance department to repair

3. Notify the maintenance department to repair

4. Notify the maintenance department to repair

5. Increase defrosting times

6. Prevent the air curtain from being intervened

by air flow

4

The refrigerator

temperature is

higher than the set

value

1. Refrigeration system fault

2. Electrical control fault

3. Too high environment

temperature

4. Too large environment

humidity

5. Air curtain interference by

surrounding strong air flow

1. Notify the maintenance department to repair

2. Notify the maintenance department to repair

3. Improve the refrigerator service environment

4.Increase defrosting times

5. Avoid strong air flow interference

5

No air curtain and

not refrigerate

1. Fan motor damaged in the

refrigerator

2. Return air inlet blocked

3. Serious frost blocking

1. Notify the maintenance department to repair

2. Move away the blocking objects

3. Forced defrosting

6

Incomplete

defrosting of

evaporator

1. Defrosting controller fault

2. Too low refrigerator

temperature setting

1.Notify the maintenance department to repair

2. Adjust the temperature controller to the set

value

7

Abnormal sound in

the refrigerator

Fan blade loose

Fasten the fan blade after shutdown

8

Refrigeration

failure or high

refrigerator

temperature

Compressor unit fault

Notify the maintenance department to repair

VIII. Electrical principle and microcomputer operating manual

(1) Electrical schematic diagram

____________________________________________________________________________________________

0046-431 22290

info@tradgardsteknik.se

Trädgårdsteknik AB

Helsingborgsvägen 578

SE- 262 96 Ängelholm,

SWEDEN

www.tradgardsteknik.se

Microcomputer Controller Manual

Instructions for microcomputer controller C204-KX

1.1 Display description:

Display two and half digits (at most display -188) and 3 marks (refrigeration, defrosting and alarm).

1.Refrigeration mark: the indicator light on indicates that the system

enters refrigeration and the light flashing (frequency 1Hz) indicates

refrigeration output delay.

2.Alarm, indicating occurrence of alarm.

3.Defrosting mark, indicating whether the system is defrosting.

Note: The alarm icon is flashing at the rate of 2Hz when setting the parameter.

1.2 Technical parameters

Relay output: 30A, 240VAC, maximum load 25A, 240VAC, used for compressor control;

Power supply: 230VAC, 50/60Hz;

Temperature sensor 1: measure the temperature in the refrigerator;

Temperature sensor 2: measure the evaporator temperature

Temperature measurement range: -45~99℃;

Temperature measurement accuracy: ±1℃(@-30~50℃)

Power voltage: 230VAC, 50/60Hz;

Overall power consumption: less than 1.5VA;

Controller operation

FIG 1

____________________________________________________________________________________________

0046-431 22290

info@tradgardsteknik.se

Trädgårdsteknik AB

Helsingborgsvägen 578

SE- 262 96 Ängelholm,

SWEDEN

www.tradgardsteknik.se

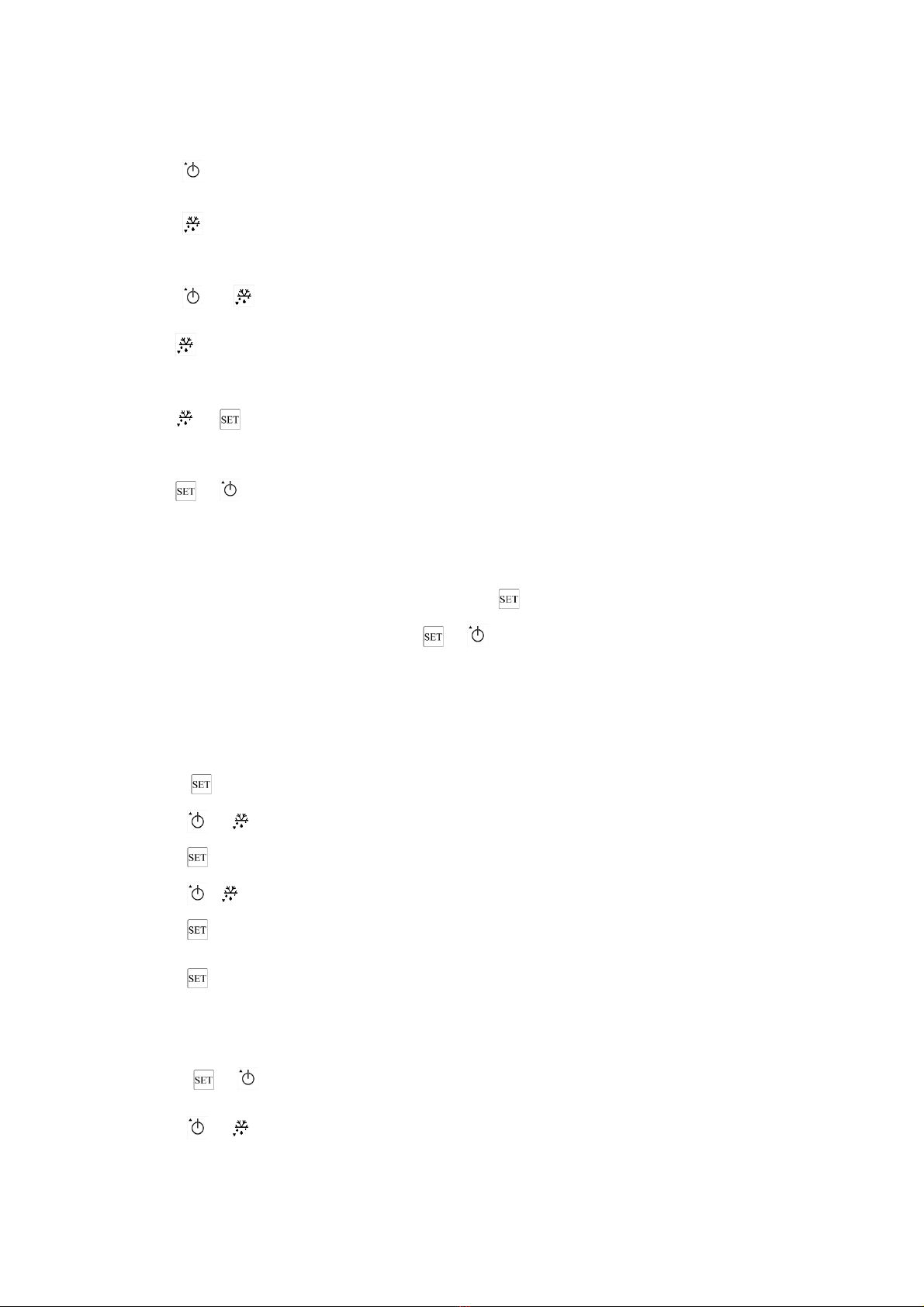

1.3 View the upper and lower limits of the setting temperature:

Press for 1s to view the upper limit of the setting temperature (start refrigeration if the temperature is

higher than the upper limit);

Press for 1s to view the lower limit of the setting temperature (stop refrigeration if the temperature is

below the lower limit);

Press and simultaneously for 1s to view the evaporator temperature.

Press for more than 3s to enter or exit defrosting state (unable to enter the defrosting state if the

parameter D1=0).

Press and simultaneously for more than 3s to enable or disable forced refrigeration (unable to enter

the forced refrigeration state if CC = 0).

Press and simultaneously in power-on to display that the default will be recovered. The nixie tube

displays“CF”.

2. Modify parameters

The controller parameters may be set by the keys. The parameters are classified into types A and B. A

series are common parameters and entered by pressing for 3s. Type B parameters are protected

parameters and shall be entered by pressing and simultaneously for 3s.

☆ Warning:Do not change type B parameter setting at will. Make adjustment, if required, under the

guidance of professional after-sales personnel.

2.1 Visit type A parameters

1. Press for more than 3S and the nixie tube displays the parameter code “P1”;

2 Press and to roll the parameter name;

3 Press to display corresponding parameter value;

4 Press or to increase or decrease the value;

5 Press to temporarily store the modified value and return to display parameter;

6 Repeat 2~5 to modify other parameters;

7 Press for more than 3s to store the modified parameter and exit the parameter setting procedure.

2.2 Visit typeB parameters

1.Press and simultaneously for more than 3S and the nixie tube displays the parameter code“/0”;

2 Press and to roll the parameter name;

____________________________________________________________________________________________

0046-431 22290

info@tradgardsteknik.se

Trädgårdsteknik AB

Helsingborgsvägen 578

SE- 262 96 Ängelholm,

SWEDEN

www.tradgardsteknik.se

3 Press to display corresponding parameter value;

4 Press or to increase or decrease the value;

5 Press to temporarily store the modified value and return to display parameter;

6Repeat 2~5 to modify other parameters;

7 Press for more than 3s to store the modified parameter and exit the parameter setting procedure.

If the defrost sensor is shielded or faulty, defrosting will finish at the maximum defrosting time (parameter

dp).

Note: The parameter dt is not displayed when the parameter/2 is--.

2.3 Fault code

Alarm

code

Fault description

E1

Sensor 1 fault

E2

Sensor 2 fault

Lo

Sensor 1 low temperature

alarm

Hi

Sensor 1 high temperature

alarm

dF

Defrosting display

2.4 Parameter list

Parameter

Description

Category

Minimum

Maximum

Unit

Default

/0

Sensor measurement stability

B

1

15

-

4

/1

Offset of sensor 1

A

-5

5

oC

0

/2

Offset of sensor 2

A

-5

--

oC

--

P1

Upper limit of setting temperature

A

r1

r2

oC

4

P2

Lower limit of setting temperature

A

r1

r2

oC

0

r1

Minimum setting value

B

-40

r2

oC

-10

r2

Maximum setting temperature

B

r1

90

oC

15

r3

Operating mode

B

0

1

-

0

c0

Delay after compressor power-on

B

0

99

Min

0

c1

Minimum downtime of

compressor

B

0

99

Min

4

c2

Shortest running time of

compressor

B

0

99

Min

7

c3

Delay between two adjacent

starts

B

0

99

Min

10

c4

Compressor working time in case

of sensor fault

B

0

99

Min

15

c5

Compressor downtime in case of

sensor fault

B

1

99

Min

5

Note: In case of high

temperature alarm and low

temperature alarm, the alarm

code (Lo or Hi) and the

temperature display alternately.

____________________________________________________________________________________________

0046-431 22290

info@tradgardsteknik.se

Trädgårdsteknik AB

Helsingborgsvägen 578

SE- 262 96 Ängelholm,

SWEDEN

www.tradgardsteknik.se

ct

Time after compressor fault

shutdown

A

10

60

Min

20

cc

Minimum running time of

compressor in forced

refrigeration

A

0

199

Min

0

c6

Alarm shielding time after

termination of forced refrigeration

A

0

199

Min

0

d1

Defrosting cycle

A

0

199

Hour

4

d2

Power-on defrosting

A

0

1

-

0

dp

Defrosting time

A

1

99

Min

15

dt

Defrosting final temperature

A

-40

90

oC

4

d6

Defrosting display

B

0

2

-

2

d8

Alarm shielding time after

defrosting

B

0

99

Min

90

dd

Water drop time

B

0

15

Min

2

A0

Overtemperature alarm

A

0

20

K

0

Ad

Alarm delay

B

0

99

Min

1

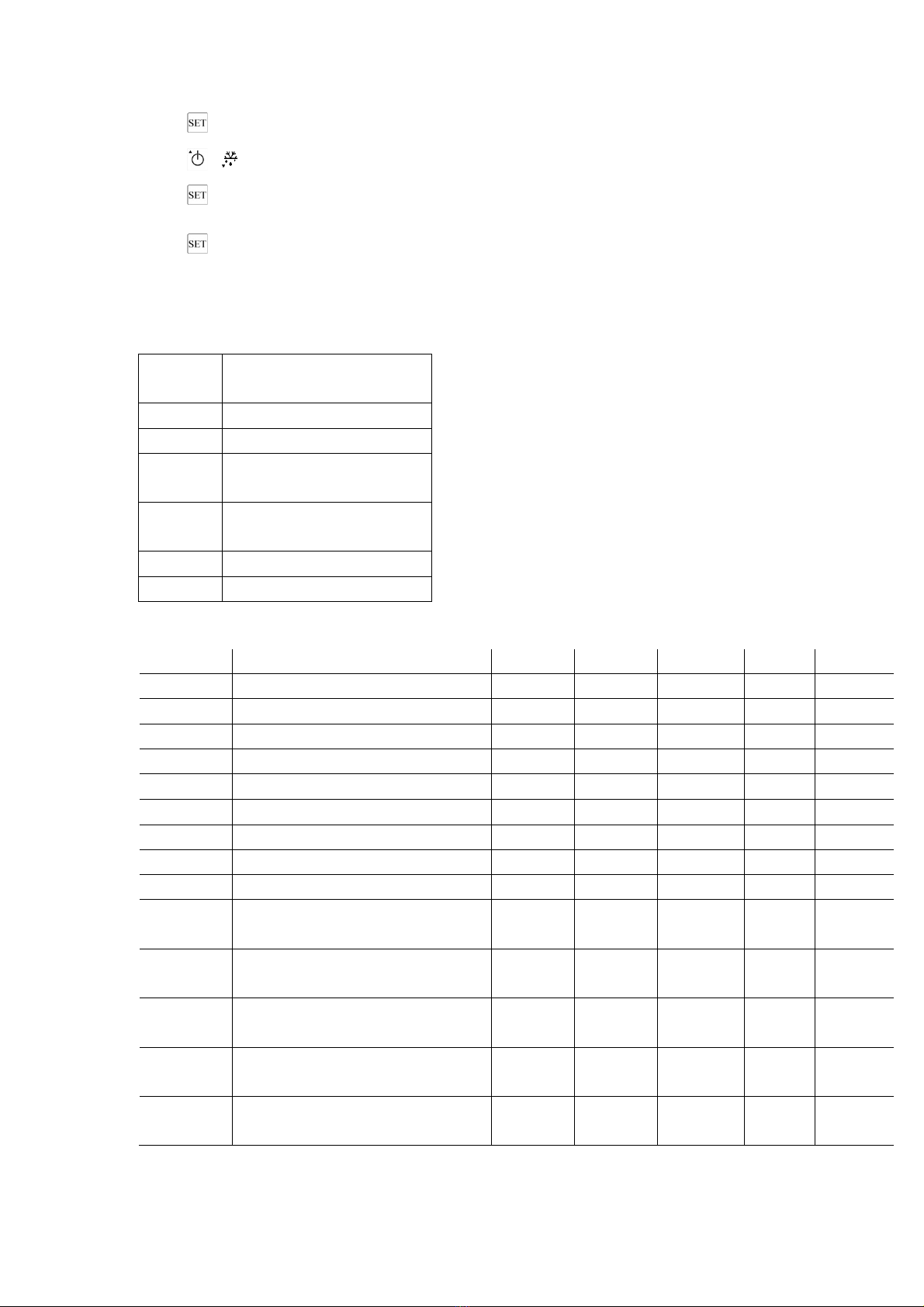

Operating manual of ECS-180neo temperature controller

1. Operation and display panel

2. Technical parameters

1) Te m p era t ur e co n tr ol ra ng e : -50℃~85℃ Temperature resolution: 0.1℃

2) Temperature measurement accuracy:±1℃ at -40℃~50℃,±2℃ at 51℃~

70℃,±3℃ for other temperatures

5) Power voltage: 220VAC±10% 50/60Hz

6) Overall power consumption: <3W

3. Indicator light status description

Indicator light

Symbol

Status

Meaning

Setting indicator

set

On

Parameter setting

Off

Measurement and control

status

Refrigeration

indicator

On

Refrigeration working

Off

Refrigeration stop

Flashing

Refrigeration delay

Defrosting

indicator

On

Defrosting working

Off

Defrosting stop

____________________________________________________________________________________________

0046-431 22290

info@tradgardsteknik.se

Trädgårdsteknik AB

Helsingborgsvägen 578

SE- 262 96 Ängelholm,

SWEDEN

www.tradgardsteknik.se

Fan indicator

On

Fan start

Off

Fan close

Defrosting drip

indicator

drip

On

Defrosting drip start

Off

Defrosting drip finish

Door signal

indicator

On

Door switch open

Off

Door switch close

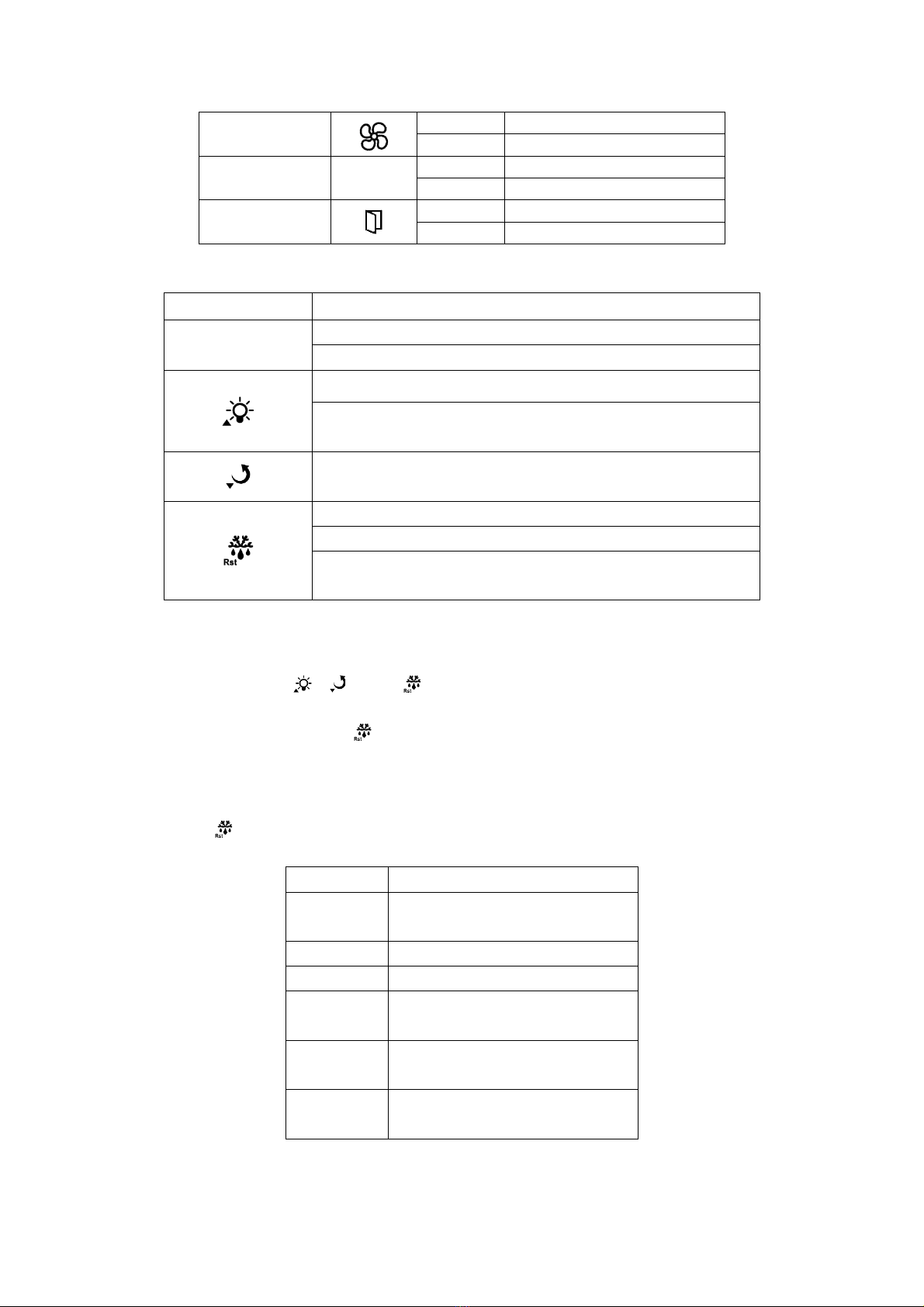

4. Key functions

4.1 Key name

Key name

Function

Set

Enter parameter setting status

Switch menu and parameter

Adjust menu and parameter

Open/close light (only effective to the model with light

controller)

Adjust menu and parameter

View the evaporator sensor temperature

Exit the parameter setting status

Forcibly switch among refrigeration, defrosting/defrosting

delay and defrosting drip if it lasts for 3s

4.2 Parameter adjustment

Press Set for 3s in the measurement and control status to enter the user menu and

display St. Press Set again to display St parameter value. Modify the setting temperature

value by operating or ; press or make keyless operation for 30s to exit the

parameter setting and automatically save the current parameter value.

4.3 Temperature view: press in the measurement and control status to view current

measured value of the evaporator sensor temperature (evaporator sensor is enabled and

normal)

4.4 Manual imperative operation

Press for 3s in the measurement and control status for forcible switch among

refrigeration, defrosting/defrosting delay and defrosting drip

Alarm code

Cause

E1

Refrigerator temperature sensor

fault

E2

Evaporator sensor fault

E3

Condenser sensor fault

cH

Condenser high temperature

alarm

rH

Refrigerator temperature high

temperature alarm

rL

Refrigerator temperature low

temperature alarm

____________________________________________________________________________________________

0046-431 22290

info@tradgardsteknik.se

Trädgårdsteknik AB

Helsingborgsvägen 578

SE- 262 96 Ängelholm,

SWEDEN

www.tradgardsteknik.se

Alarm code

Cause

Er

Copy card programming failed

EP

Inconsistent data in the copy card

with controller model,

programming failed

IX. Warranty and service

Thanks again for selecting our supermarket refrigerator products. To protect your deserved interest

and make you assured, the company will provide you with maintenance services and technical support.

Please carefully read the following content to obtain quick and convenient services.

1 Maintenance service guide

⑴ After buying the supermarket refrigerator, check whether the physical refrigerator is consistent with the

packing list and whether the attached documents are complete. For any objection, please immediately

contact the dealer or the company.

⑵ Please properly keep the repair bill and relevant materials.

⑶ In case of fault in your supermarket refrigerator, observe and check according to the requirements in

the table in Item 6 above. The fault caused by mis operation or use or improper maintenance may be

eliminated by yourself or handled by the maintenance personnel of the company or the dealer.

⑷ If the fault in the equipment cannot be eliminated, immediately contact our maintenance service

department and we will help to solve as soon as possible.

2 Limited warranty clause

(1) “Kaixue” supermarket refrigerator is provided with free warranty for one year after the date of

purchase. The refrigerator that has been declared as disposed product at the purchase is not within

the warranty.

(2) This warranty clause applies to the mainland region of the People’s Republic of China.

(3) This warranty clause applies only to the products directly purchased by the customer from the

company or from the retailer approved by the company.

(4) The warranty bill sealed by the company or by the retailer approved by the company is the unique

voucher for warranty. If you are required by the warranty unit to provide the voucher, you should

show the warranty bill.

(5) The product that has been subject to warranty may be subject to warranty again in the remaining

warranty period or within 90 days after warranty, whichever is longer.

(6) The costs for transporting the product to the warranty unit and transporting back are not free.

(7) The product warranty is only for the quality problems caused by insufficient product quality in

improper construction and installation. The problems caused by improper transportation, installation,

use or management of the consumer and other non-product reasons are not included in the

warranty.

(8) The occurrence of the warranty time is subject to the time when the consumer notifies the company

of the product defect. The products not enjoying warranty may be repaired by the company, but the

____________________________________________________________________________________________

0046-431 22290

info@tradgardsteknik.se

Trädgårdsteknik AB

Helsingborgsvägen 578

SE- 262 96 Ängelholm,

SWEDEN

www.tradgardsteknik.se

costs will be collected according to relevant provisions.

☆ In case of product upgrade, some parameters in the manual may be changed without further

notice. The physical product shall prevail and the company reserves the final power of

interpretation.

Table of contents

Popular Refrigerator manuals by other brands

Hitachi

Hitachi R-WB561PRU9 instruction manual

GE

GE GTS22JBPARCC and Owner's manual and installation instructions

Epic

Epic EFF148W manual

Hotpoint

Hotpoint XEX95 Series operating instructions

Ariston

Ariston ENBY 19*** F O3 operating instructions

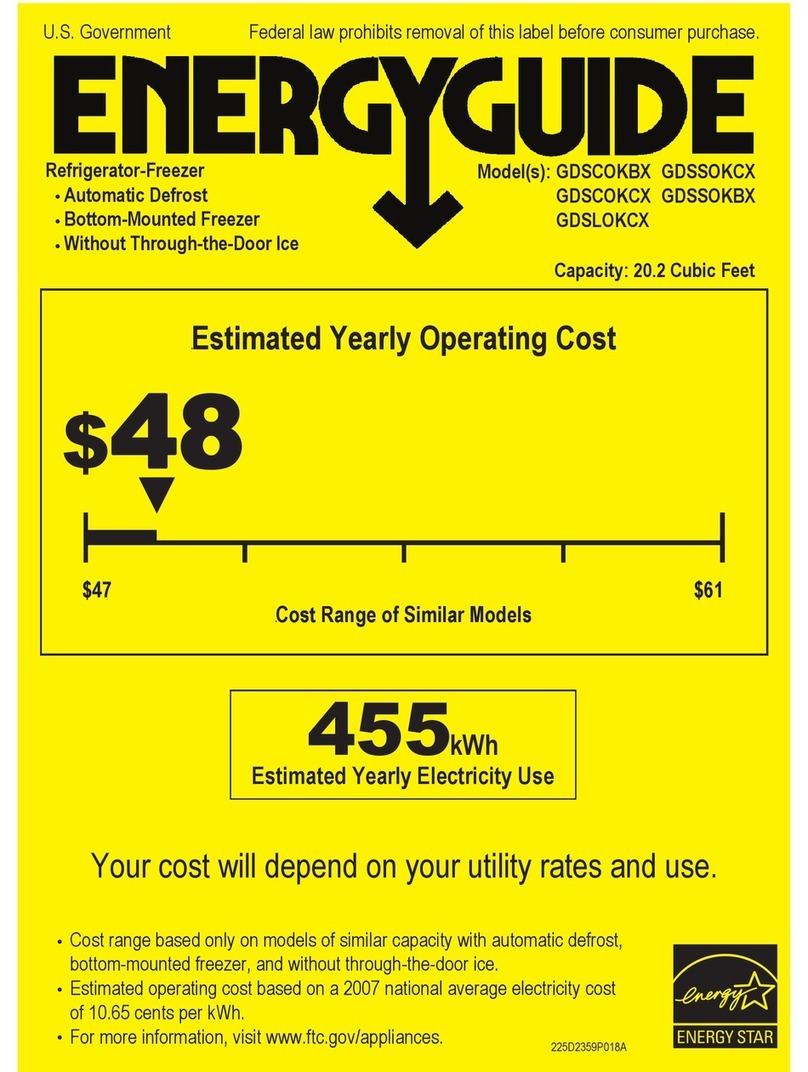

GE

GE GDSC0KCXWW - r 20.2 cu. Ft. Bottom Freezer... Energy guide