Unitary products group 90% P DH Manual

Other Unitary products group Furnace manuals

Unitary products group

Unitary products group PACE User manual

Unitary products group

Unitary products group PV9 User manual

Unitary products group

Unitary products group G9T-DH User manual

Unitary products group

Unitary products group AHV8 UH User manual

Unitary products group

Unitary products group PxDU series User manual

Unitary products group

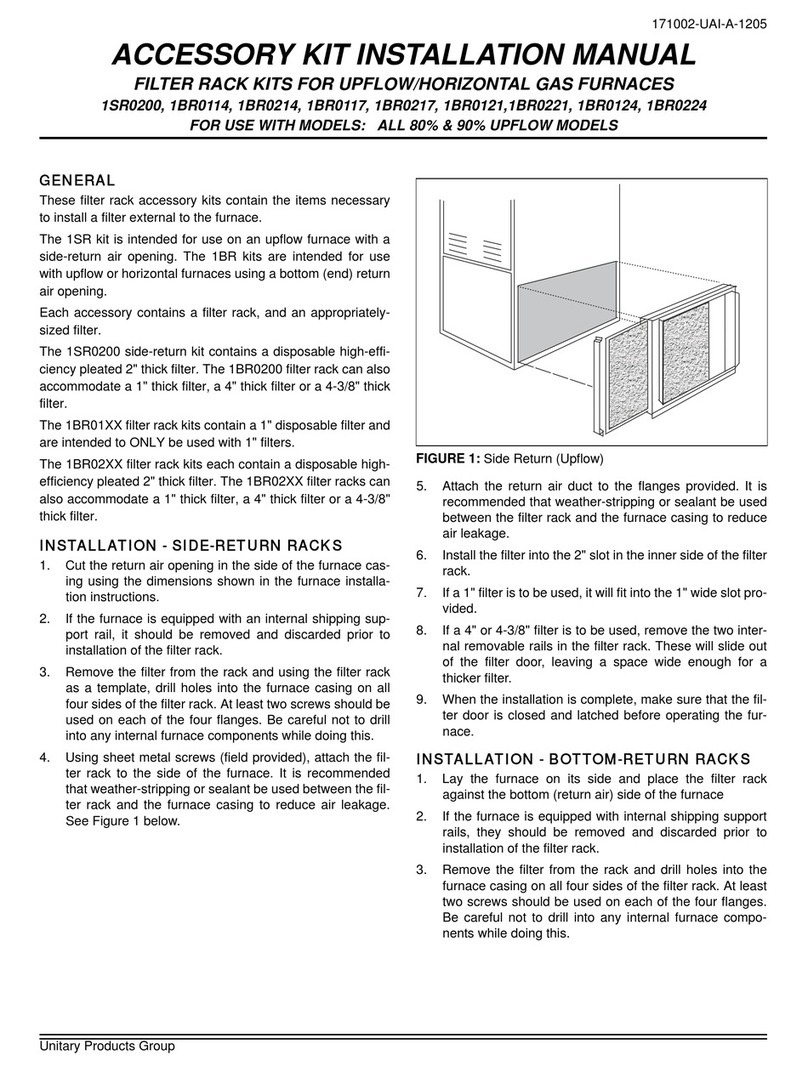

Unitary products group 1SR0200 User manual

Unitary products group

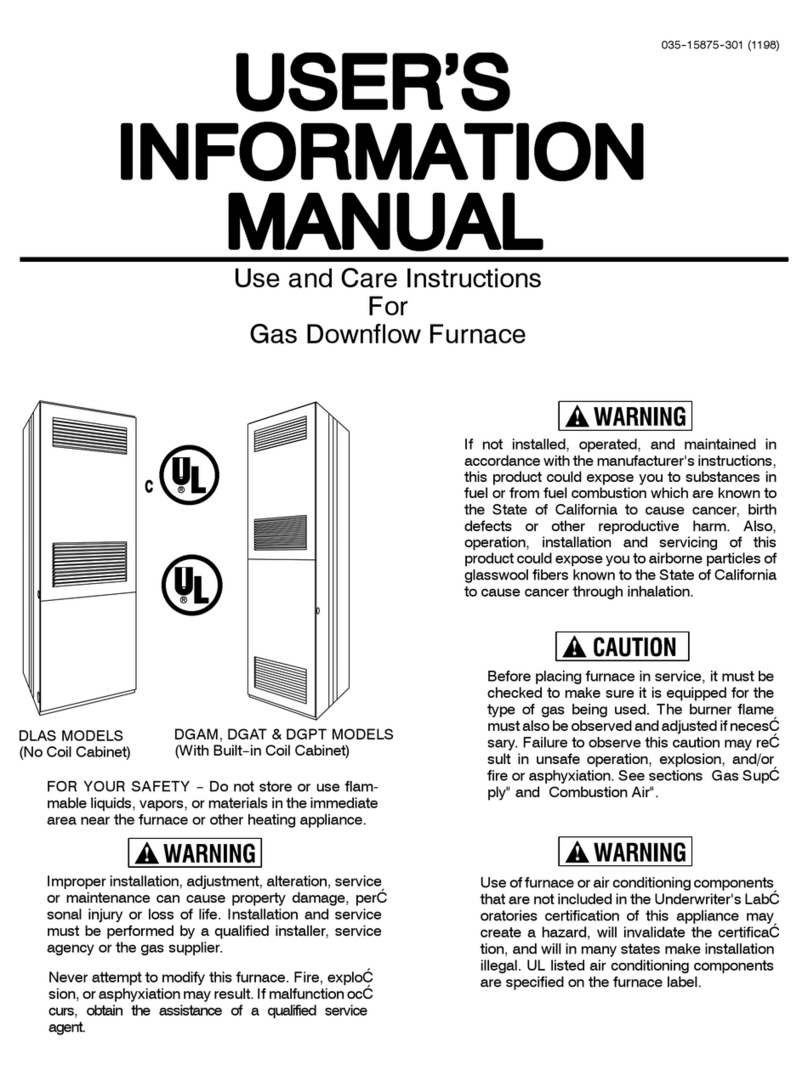

Unitary products group DLAS User manual

Unitary products group

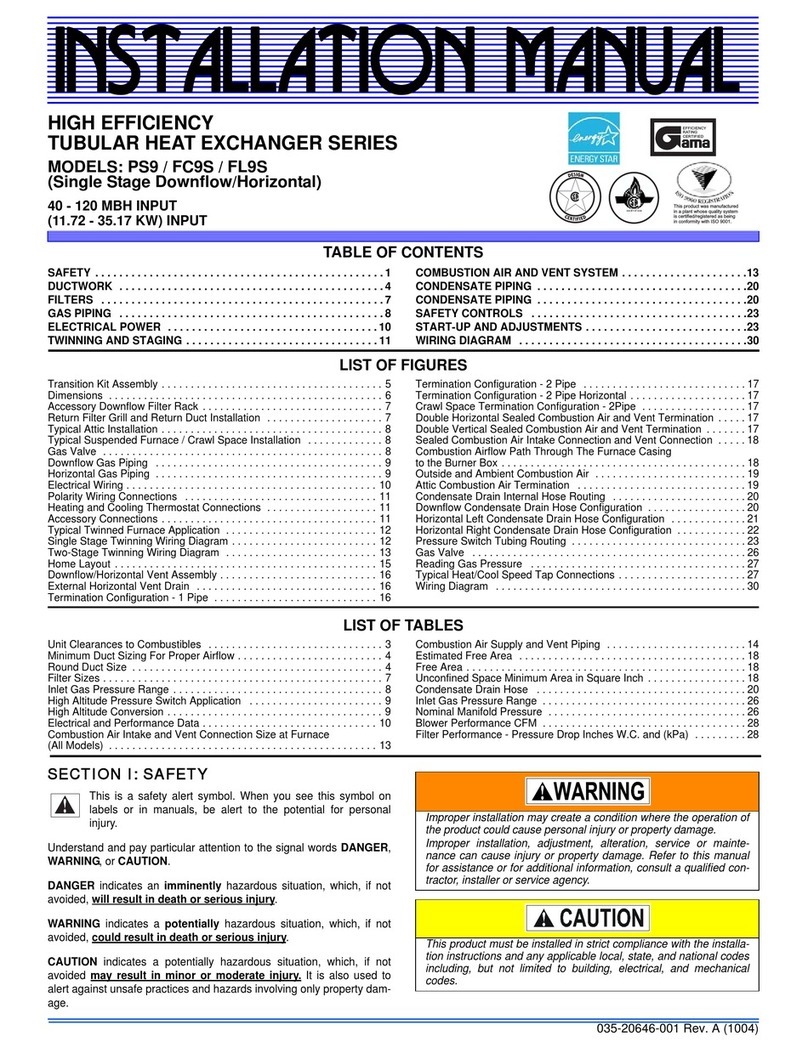

Unitary products group PS9 User manual

Unitary products group

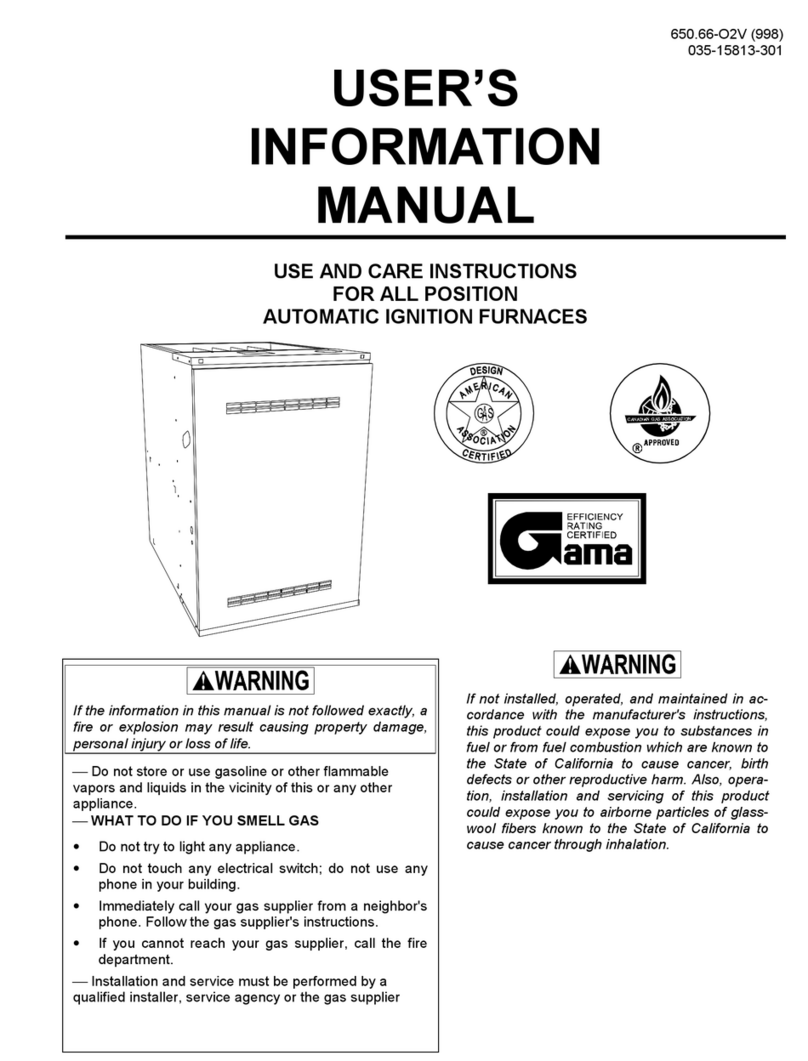

Unitary products group AUTOMATIC IGNITION FURNACES Guide

Unitary products group

Unitary products group GF8 SERIES Quick start guide

Unitary products group

Unitary products group G8C User manual

Unitary products group

Unitary products group EB23C Quick start guide

Unitary products group

Unitary products group EB SERIES User manual

Unitary products group

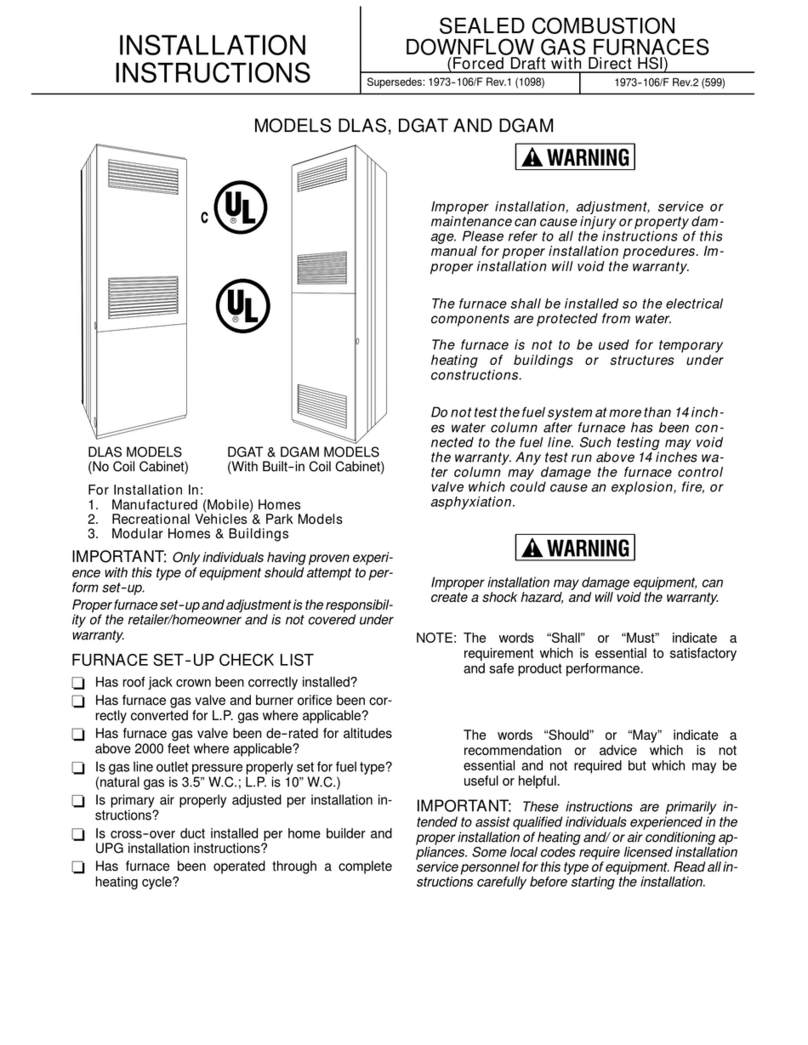

Unitary products group DLAS Installation guide

Unitary products group

Unitary products group PxDUA12V06401 series User manual

Unitary products group

Unitary products group G8C 50 User manual

Unitary products group

Unitary products group G8C User manual

Unitary products group

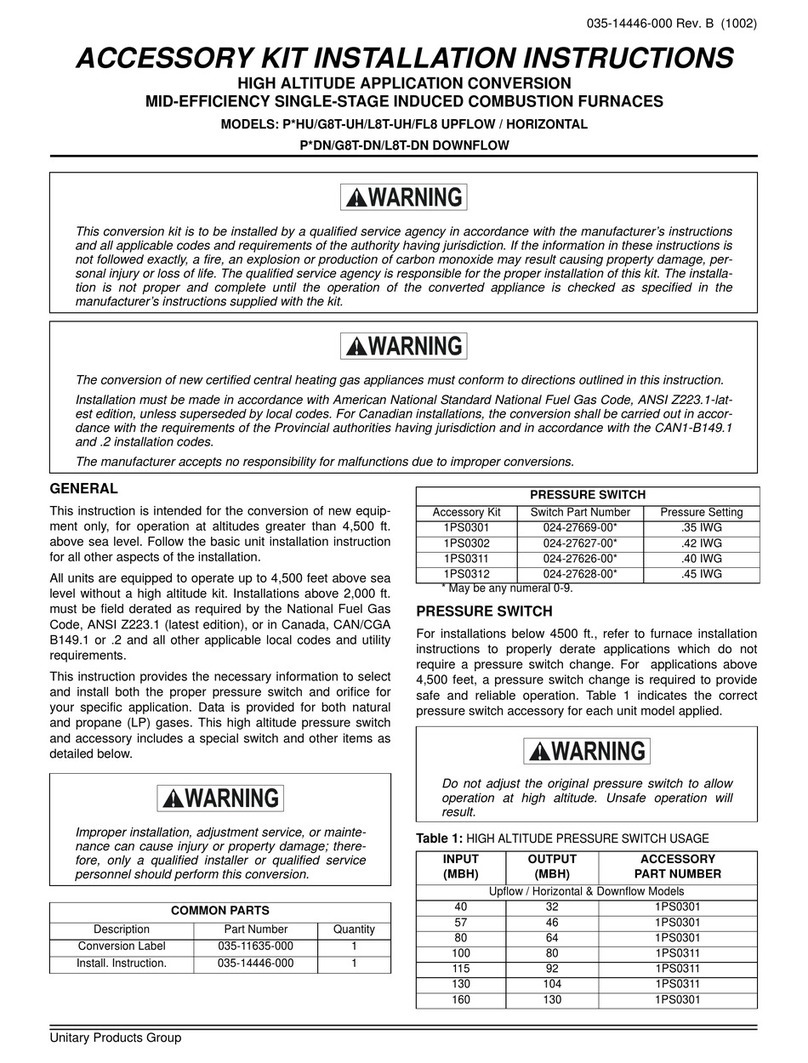

Unitary products group P HU Series User manual

Unitary products group

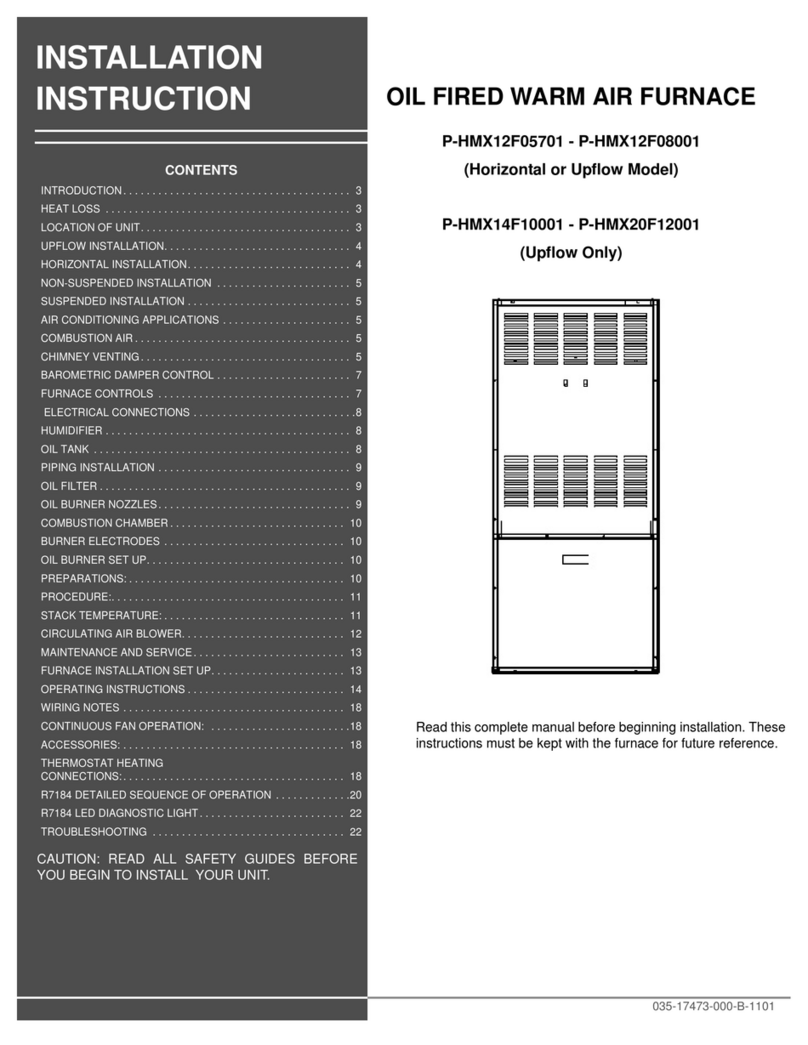

Unitary products group P-HMX12F05701 User manual

Unitary products group

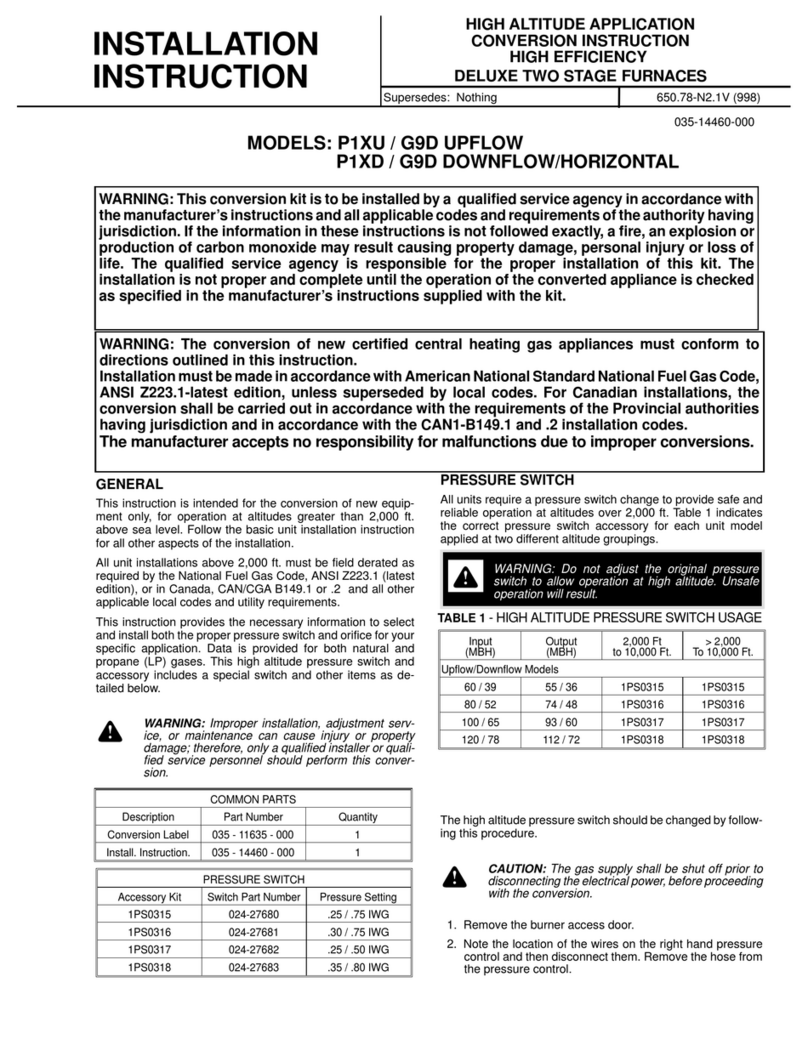

Unitary products group P1XU / G9D UPFLOW User manual

Popular Furnace manuals by other brands

VERDER

VERDER CARBOLITE GERO RHF 14/8 Installation, operation and maintenance instructions

Tempstar

Tempstar B Series Service and technical support manual

Carrier

Carrier Performance 59SP5A Installation, start-up, operating and service and maintenance instructions

Armstrong

Armstrong EG7H SERIES Installation and maintenance instructions

Payne

Payne PG92ESA Installation, start-up, operating and service and maintenance instructions

NANOE

NANOE Zetasinter Operation manual

SUPREME

SUPREME FEM10-M2301CM-A Installation instructions and homeowner's manual

Johnson Controls

Johnson Controls TM9T User's information manual

Fluke

Fluke 9118A user manual

Lennox

Lennox EL195UHE Elite Series Unit information

Intertherm

Intertherm M7RL Series user manual

HDG

HDG Pelletmaster 15 Operation manual

Nortek

Nortek MG2S Series installation instructions

VERDER

VERDER CARBOLITE GERO ABF 8/28 Installation, operation and maintenance instructions

Goodman

Goodman GMV9 Installation & operating instructions

SUPREME

SUPREME SUP10-M2301C Installation instructions and homeowner's manual

Dettson

Dettson AMT400B34-SM1PMA Installation instructions and homeowner's manual

Evcon

Evcon DGD 60 MBH installation instructions