272360-UUM-A-0407

4Unitary Products Group

FURNACE USER MAINTENANCE

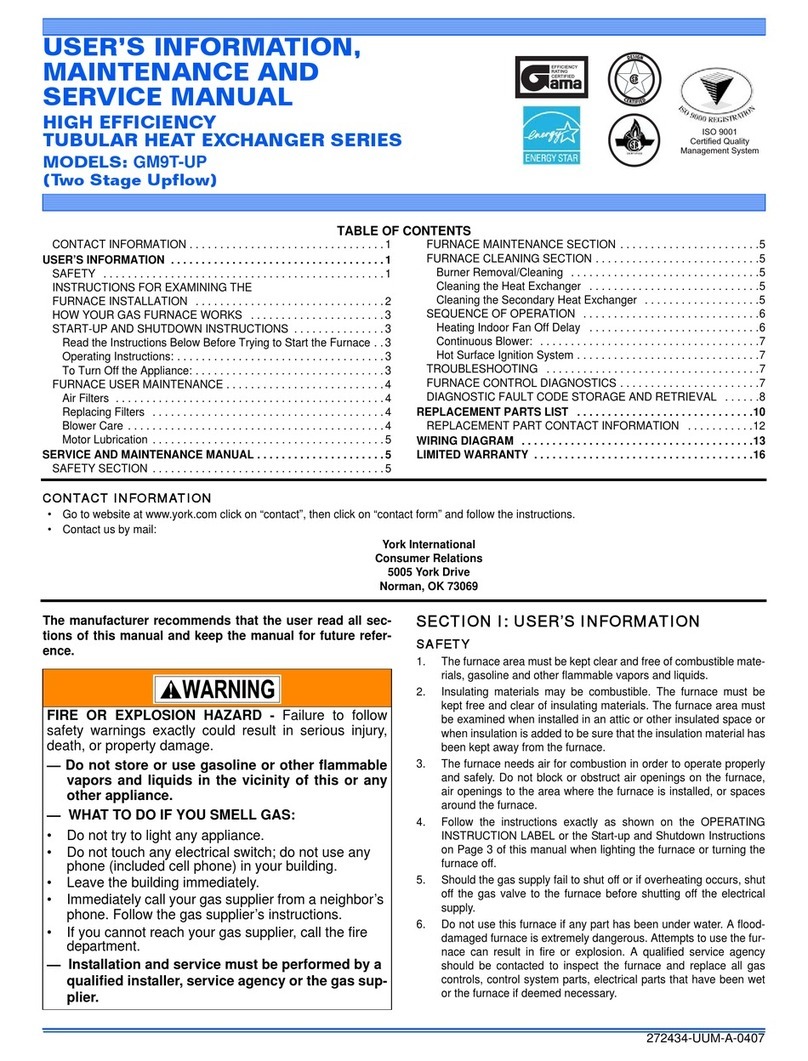

Blower Care

Even with good filters properly in place, blower wheels and motors will

become dust laden after long months of operation. The entire blower

assembly should be inspected annually. If the motor and wheel are

heavily coated with dust, they can be brushed and cleaned with a vac-

uum cleaner. If the blower cannot be properly cleaned without removing

it from the furnace, then this service must be performed by a qualified

service agency.

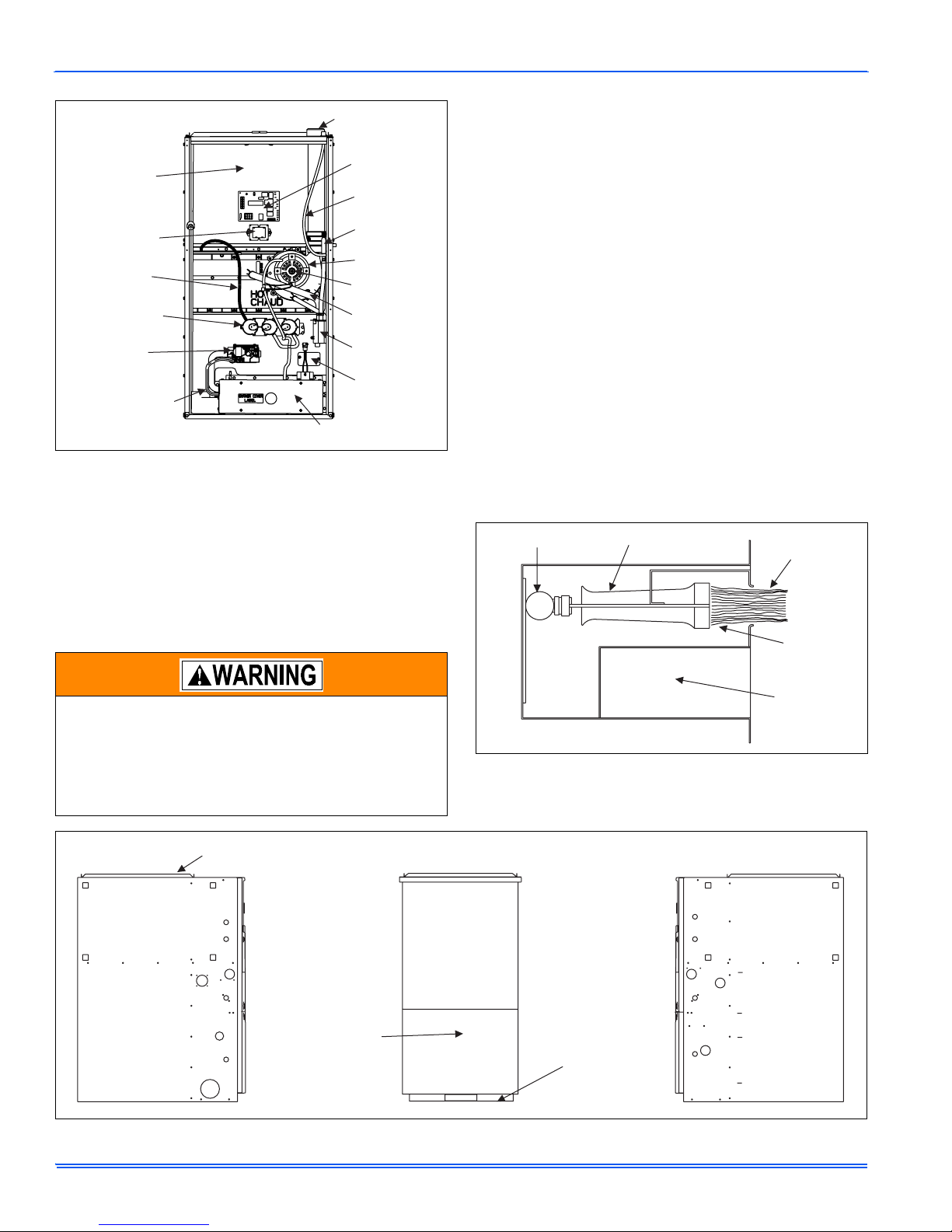

The blower can be serviced/removed through the blower access panel

on the inside of the furnace. If there is a combustion air pipe installed

inside the furnace, it may have to be removed to access the blower

access panel. After the combustion air pipe is removed, it is easy to

remove the inside blower access panel by pushing it up, against a

spring, or removing the screws of the access panel. Blower is now

ready to be serviced through the opening.

If the blower has to be removed through the inside blower access panel,

then the top flange, blower door switch and bottom flange will also have

to be removed on some models, On some other models, top and bot-

tom angles will have to be removed to slide the blower out of the fur-

nace.

Air Filters

The filters should be checked every 3 months. On new construction,

check the filters every week for the first four weeks and every three

weeks after that, especially if the indoor fan is running continuously.

When replacing the filter(s), refer to Table 1 to be sure you install the

right size filter for your furnace. Dirty filters greatly restrict the flow of air

and may cause damage to the moving parts of the furnace. If the filters

become clogged the heat exchangers and blower motor could overheat

resulting in a potentially dangerous situation.

Never operate your furnace without a suitable air filter.

Use the following procedure to determine the filter size.

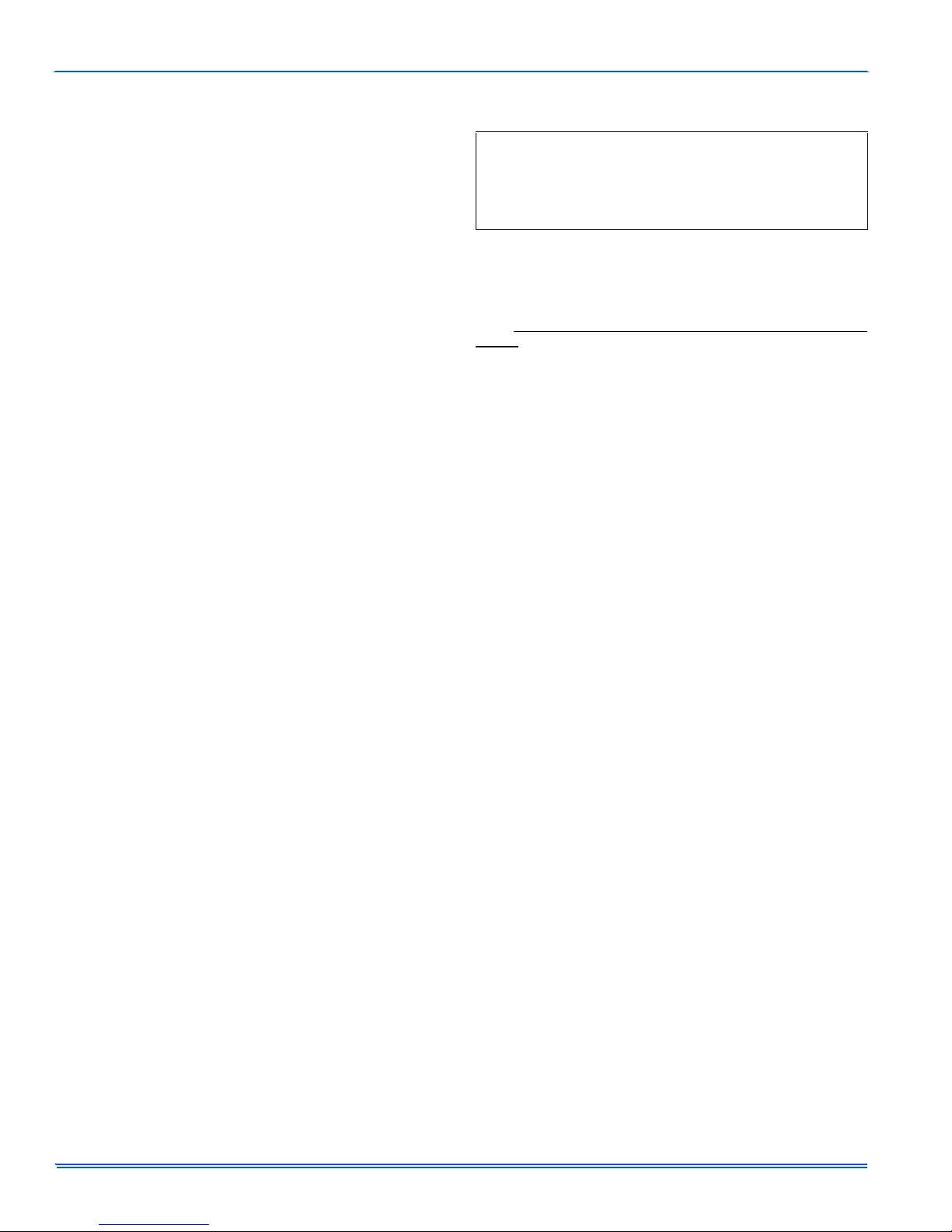

1. Measure the furnace width and use that measurement to deter-

mine the cabinet width.

• A 17-1/2” wide cabinet is a “B” cabinet.

• A 21” wide cabinet is a “C” cabinet.

• A 24-1/2” wide cabinet is a “D” cabinet.

2. After you determine the cabinet size and what return configuration

you have, look up the recommended filter size from Table 1.

Removing Filters

Some downflow furnaces have their filters located on the top of the fur-

nace in an external filter rack. To check filters you should:

1. Follow the instructions to turn off the appliance before servicing.

2. Filters are installed in the return air plenum above the blower

assembly. An “A” frame assembly supports the filters. Lift the filter

slightly and remove for service.

3. Follow the instructions “HOW TO CLEAN YOUR FURNACE’S FIL-

TER”.

4. Reverse the procedure to reinstall filters.

5. Follow the operating instructions to place appliance in operation.

Externally Mounted Air Filters

Some installations may have the air filter in a rack attached to the cas-

ing of the furnace or placed in the return air duct. You can gain access

to the filter by pulling on the door or unscrewing the retaining screw,

then slide the filter(s) out of its channel. Replace throw away filter(s)

with the same size new filter(s). Throw away filter(s) may be replaced

with cleanable filter(s) at this time. Cleanable filter(s) may be cleaned as

described in the manufacturer instructions or as described below and

then re-installed.

How to Clean your Filter

High-velocity filters may be cleaned with a vacuum cleaner or washed

with a garden hose. Be sure to shake off excess water and allow filter to

completely dry before re-installing the filter.

To replace the filter after cleaning you must do the following:

1. Slide filter into place.

2. Snap the door on or place the door in position and tighten the

retaining screws, if provided.

3. Make sure the door is secure to the end of the filter rack.

4. For filter grilles, place the filter into the grilles, close the grille cover

and tighten the retaining screw.

Every time the filters are changed the following items should be visually

inspected:

• Check combustion air and vent pipe for blockage or leakage.

• Check all components to be sure they are in good condition and

that there are no obvious signs of deterioration.

• Check the drain lines to make sure there are no cracks or leaks.

• Check for dirt or lint on any surfaces or on components. Do not try

to clean any of the surfaces or components. Cleaning of the fur-

nace and its components must be done by a qualified service pro-

fessional.

If, during the inspection of your furnace, you find any of the following

conditions:

• Excessive amounts of dust and lint on components.

• Damaged or deteriorated components or surfaces.

• Leaks or blockage in the vent pipe passages.

• Water on any surface inside or outside of the furnace.

Do not operate the furnace, call a certified dealer / servicing contractor

to check and / or clean your furnace, or for more information if you have

questions about the operation of your furnace.

If all components appear to be in good operating condition, replace the

front panels. Turn ON the gas and electrical power supplies to the fur-

nace, and set thermostat to the desired temperature.

Motor Lubrication

The motors in these furnaces are permanently lubricated, and do not

require periodic oiling.

Before proceeding, be sure the area is well ventilated. Turn

the thermostat OFF. If the blower is running, wait until it

stops automatically. Turn OFF the gas and electrical power

supplies to the furnace. Check all metal parts and surfaces

to be sure they have cooled to room temperature before

you begin.

Make sure you DO NOT move the clip-on weight on the

indoor fan wheel when cleaning the wheel. This weight is

used to balance the wheel. Moving the weight will cause

the fan wheel to vibrate.

TABLE 1:

Filter Sizes

Input

BTU/H (kW) CFM

(m3/min) Cabinet

Size Top Return

Filter in(cm)

60 (17.6) 1200 (34) B (2) 14 x 20 (36 x 51)

80 (23.4) 1200 (34) B (2) 14 x 20 (36 x 51)

80 (23.4) 1600 (45) C (2) 14 x 20 (36 x 51)

100 (29.3) 2000 (57) C (2) 14 x 20 (36 x 51)

120 (35.1) 2000 (57) D (2) 14 x 20 (36 x 51)