General Venting│Vmax I&O Manual

4.0 GENERAL VENTING

The Vmax VM110 & VM110P are certified as a “Category IV” boiler requiring a “Special Venting System”

designed for pressurized venting. The Exhaust Vent must be piped to the outdoors, using the vent materials and

rules outlined in this section. Under no conditions may this unit vent gases into a masonry chimney, unless it is

vacant, and utilizes the approved venting material and rules described in this section.

Vent and Air-inlet are to be piped separately. The Vmax VM110 & VM110P cannot share

a common vent or air-inlet with multiple boilers. Failure to comply will result in serious

injury or death.

Direct Vent Installation (Best Practice)

When installed as a Direct Vent boiler the combustion air-inlet must also be piped directly to the outdoors using

the methods described in this section and in accordance with the National Fuel Gas Code, ANSI Z223.1 (U.S.) or

CSA B149.1 (Canada) and local requirements.

Installation Using Indoor Combustion Air

When the installation uses Indoor Combustion Air (i.e. piping is not directly connecting the appliance air-inlet

fitting to the outdoors), the combustion air-inlet is drawn from Indoors or Outdoors via the appliance area using

the methods described in this section and in accordance with the National Fuel Gas Code, ANSI Z223.1 (U.S.) or

CSA B149.1 (Canada) and local requirements.

The boiler shall be located so as not to interfere with proper circulation of combustion,

ventilation, and dilution air.

Make up air requirements for the operation of exhaust fans, kitchen ventilation systems,

clothes dryers, and fireplaces shall be considered in determining the adequacy of a space

to provide combustion air requirements. Failure to ensure adequate make up air to all appliances may result in

personal injury or death.

Indoor Combustion Air - Opening Size and Location: The methods detailed below for determining Opening

Size and Location for accessing indoor combustion air, shall be used when the air infiltration rate is adequate, i.e.

greater than 0.4 ACH (air changes per hour) and when the boiler area and communicating spaces have a

minimum volume of 50 cubic ft per 1000 Btu/hr. If the air infiltration rate is known to be less than 0.4 ACH,

refer to the National Fuel Gas Code for further guidance.

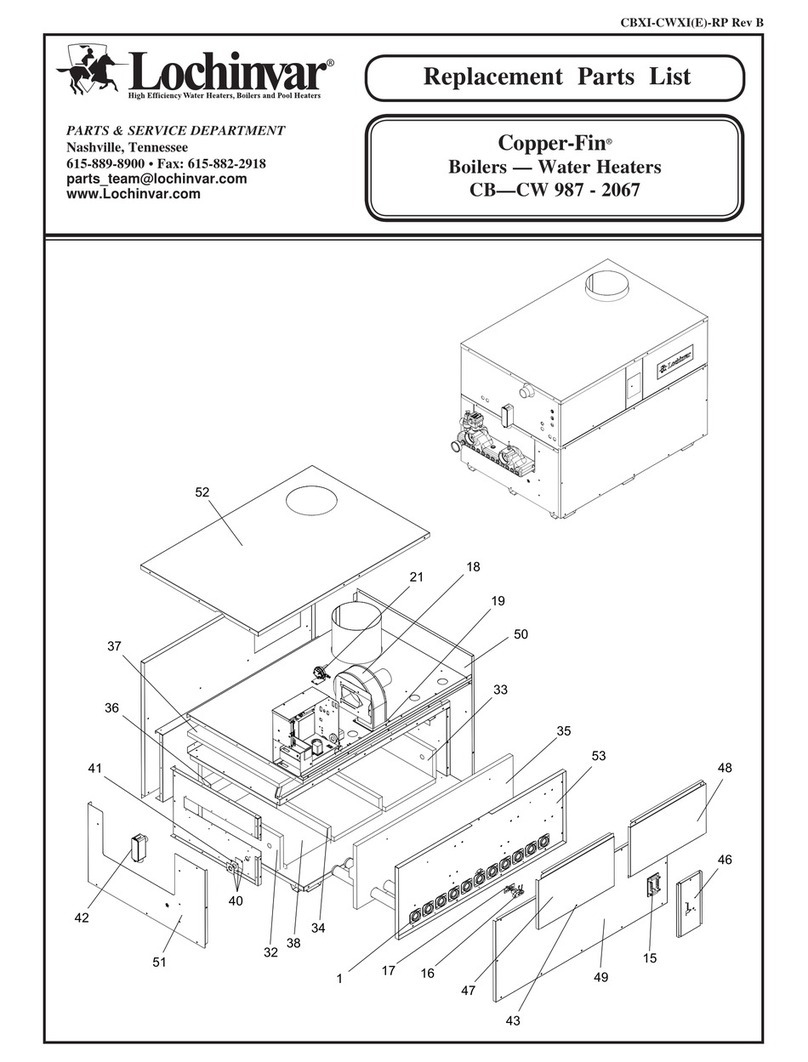

1. Combined spaces on the same story –Each opening shall have a minimum free area of 1in.2/1000 Btu/hr.

of the total input rating of all appliances in the space, but not less than 100 in2. One opening shall commence

within 12 in. of the top, and one opening shall commence within 12 in. of the bottom, of the enclosure, see

Figure 4-1a. The minimum dimension of air openings shall be not less than 3in.

2. Combined spaces in different stories –The volumes of spaces in different stories shall be considered as

communicating spaces where such spaces are connected by one or more openings in doors or floors having a

total minimum free area of 2 in.2 /1000 Btu/hr. ft.

3. Of total input rating of all appliances.

Outdoor Combustion Air –Opening Size and Location: Outdoor combustion air shall be provided through

opening(s) to the outdoors in accordance with the methods detailed below. The minimum dimension of air

openings shall not be less than 3 in.

1. Two Permanent Openings Method –Two permanent openings, one commencing within 12 in. of the top,

and one commencing within 12 in. of the bottom of the enclosure, shall be provided. The openings shall

communicate directly, or by ducts, with the outdoors or spaces that freely communicate with the outdoors, as

follows:

a. Where communicating with the outdoors or where communicating to the outdoors through vertical ducts,

each opening shall have a minimum free area of 1 in2/4000 Btu/hr. of total input rating of all appliances

in the enclosure; see Figures 4-1b and 4-1c.

b. Where communicating with the outdoors through horizontal ducts, each opening shall have a minimum

free area of 1 in2/2000 Btu/hr. of total input rating of all appliances in the enclosure; see Figure 4-1d.