Ventura DLB 410 User manual

DLB 410

HANDBOOK MANUAL

USE AND MAINTENANCE

2

•

PREFACE

•

INFORMATION ON THEMANUAL

•

INFORMATION ON THEMACHINE

•

SAFETY INFORMATION

•

INSTALLATION ANDFUNCTION

•

MAINTENANCE SECTION

INDEX

3

TECHNICAL ASSISTANCE

Sito web: www.venturamaq.com

email: [email protected]

This manual will provide you with all the information necessary for the use and maintenance of your machine.

The good working and length of life of your machine will depend on its good maintenance and careful use.

Before leaving the pro-

duction establishment this particular model underwent a stringent tests in order to guarantee maximum

confidence; it

will be necessary, however, to check that during the journey the machine has not undergone any

structural damage that could prejudice its function and its safety.

This manual should be considered an integral part of the machine and should accompany it until its

demolition. In the event of its loss or damage it will be necessary to request a substitute copy from the

VENTURA. The technical information contained in this manual is property of the VENTURA and should be

considered copyright. Any reproduction, even partial of the graphics, text or illustrations is forbidden under the

law. Points discussed in this manual are expressly required

by the Directives for machinery CEE 89/392 and successive

modifications and technical data given are provided by the

manufacturer at the time of writing. This manual is to be kept

in a place that is accessible for all staff designated to drive and maintain the machine.

N.B. THIS MANUAL MUST ACCOMPANY THE MACHINE IF EVER IT IS RESOLD!

• PREFACE

4

• INFORMATIONS ON THE MACHINE

This manual should be considered an integral part of the machine and should accompany it until its demolition.

In the event of its lossor

damage it will be necessary to request a substitute copy. This manual contains information on the machine, safety

precau- tions,

instructions of installation and transport, functioning and maintenance.

Some particulars figuring in the illustration in this manual may be different from those of your machine.

This manual is to be read, learnt and kept in a place that is accessible for all staff designated to drive and

maintain the machine.For any problems on the equipment or the manual, you can get into touch with VENTURA

and ask for the most recent available

information.The manual must accompany the machine if ever it is resold!

In order to make this manual easy to follow it is subdivided into section which are identifiable by graphic symbols.

The manufacturer’s data

VENTURA

Crta. Vilablareix, 18-20 _ 17181 Aiguaviva, Girona

Phone.: +34 972401522

info@venturamaq.com – www.venturamaq.com

Intended use

Professional side mower DLB 410 is suited to clean ditches, slant, edge-road and for the cut of hedges, grass and

bushes up to max. Ø 10cm through shred.

The machine is not suitable to be used in different sectors from the agricultural one and from the road

maintenance one.

Position of the operator

During transport and work operations, the operator will have to start the machine by means of the drive of the

tractor.

Description

These models are transported by the tractor by means of a three-point attachment, and they act on the ground

by virtue of their weight and PTO rotation. The structure consist of a working unit made up of a vertical axle with

chains connected to the axle itself with a specific support plate.

The cutting head with chain is connected to the three-point attachment with a side frame, hydraulically moved

by 2 cylinders

The PTO shaft consist of a single-side clutch (free wheel) which permits motion transmission in only one direction,

freeing the PTO of the tractor in the release stage.

Here below the principal contraindications of use the DLB 410 side mower:

•

besurethatonthegroundtoworkthereisnostonesorrocksofbigdimensions(diametersuperiorto10.15cms);

•

be sure that on the ground to work there is no stumps of leaning trees over 10cm and of diameter superior

to 10. 15 cms;

•

be sure that on the ground to work there is no metallic elements of every type, particularly nets, cables,

ropes, chains, pipes, nailsetc;

•

observe and apply with care the instructions of height adjustment of the machine from the earth ,

•

avoid that in the working ray of the machine can stop people or animals upto 50 meters;

•

we recommend You to never work “shaves earth” on wet ground in order to not jeopardize the output and

the balan- cing of the machine also risking damaging the rotor. In these cases the knives will be excessively

consumed, notable power

iswithdrawnbythemotor andthereistherisktointernallyfilltheprotectivechestoftherotorwith

pressedmud;

Warning!

The machine must be used from just one operator from the tractor place of guide. A different use from the specified one is

considered improper

• INFORMATION ON THE MANUAL

5

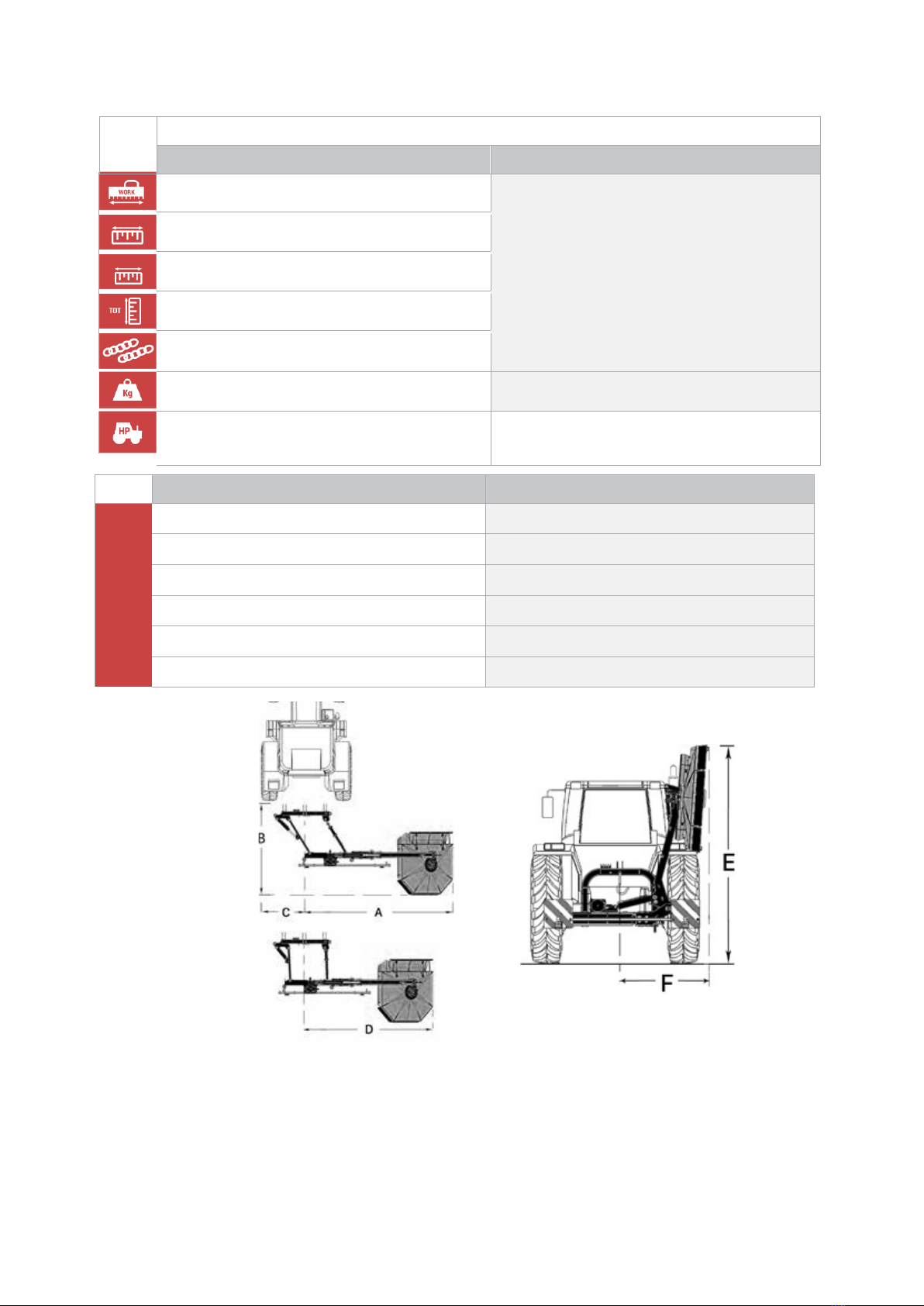

TECHNICAL FEATURES

TECHNICAL SPECIFICATIONS

MODEL

410

WORK WIDTH (cm)

150

ON STREET

ROAD CLEARANCE (m)

2,50

OFFSET

MAXIMUM OFFSET (m)

1,00

TOTAL HEIGHT (m)

3,27

N°CHAINS (m)

2

WEIGHT (Kg)

770

STANDARD GEARBOX

80-

140

SIDE OFFSET (cm)

A

410

B

210

C

75

D

306

E

327

F

123

Residual risks

Theaccuraterisk assessment made by the manufacturer and kept by the heath & safety office has consented to eliminate

the majority

of the risks known to the conditions of use of machine. The manufacturer recommends scrupulous adherence to

the instructions, produces and recommendations contained in this manual and to the safety laws in force

including the use of safety devices and protective guards whether integrated or separate.

Warning!

As precautionary security measure you must carry out regular checks on the correct functioning of safety devices. It is strictly

forbidden to carry

out any kind of mechanical, electric or pneumatic modification in order to avoid additional risks or non foreseen consequent

risks.

6

Applied directives

The following directives are applicable to the machine described in this

manual: CE 98/37 Directive on machines

CE 89/336 Directive on electromagnetic compatibility

CE 73/23 Directive on low voltage

Harmonized technical

The machine has been designed and tested in accordance with the “essential safety and health risks”

mentioned in

Annex I of the European Directive 98/37 EC.The standards used as reference for the design, construction and testing of

the machine are listed in the technical dossier filed in VENTURA.

Noise level

Noise surveys have been 95db.

Warning!

In case of using a traction engine without a cabin, in order to combat the noise level it is obligatory to use protective

earplugs and headphones

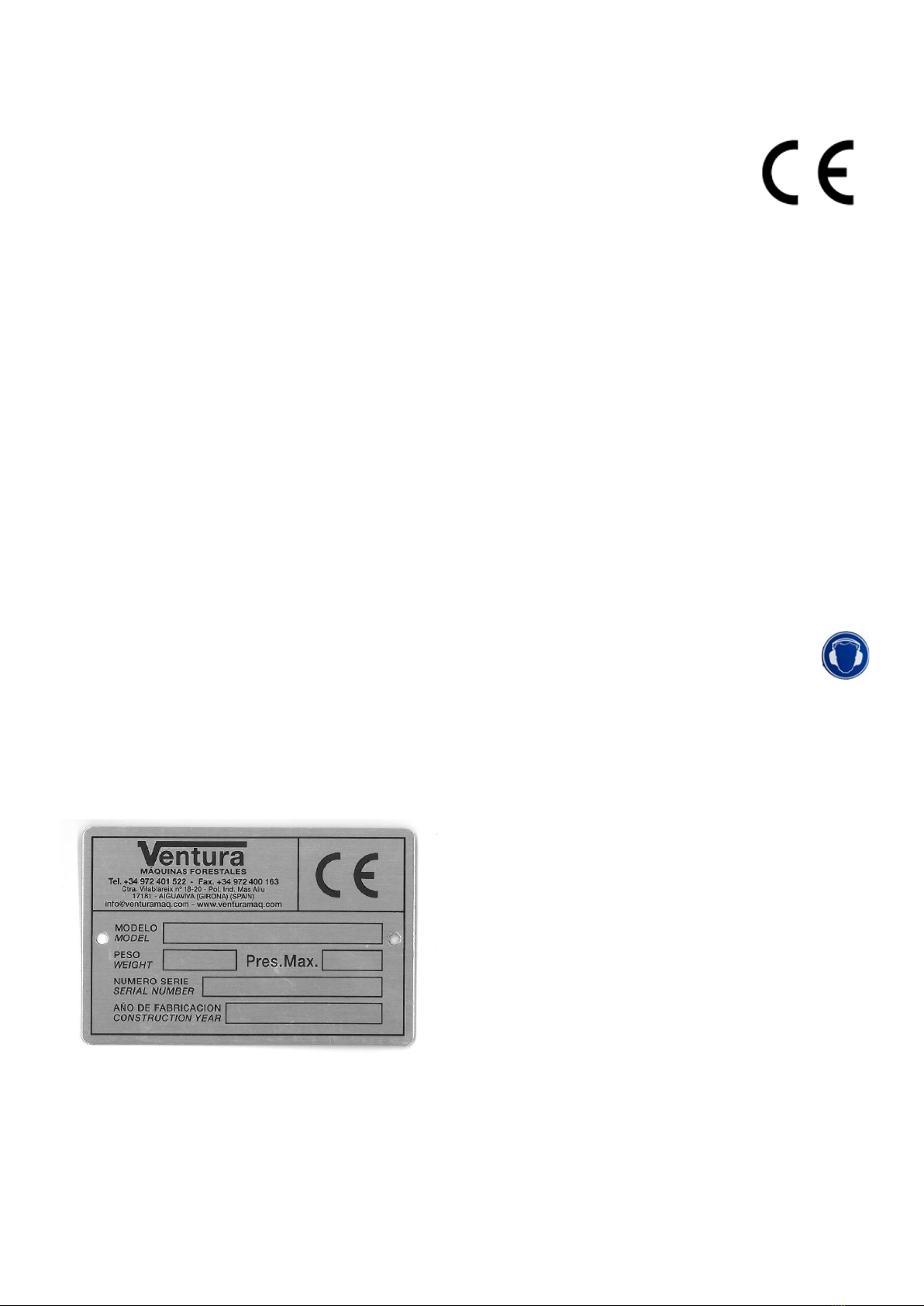

Machine identification plate

/

CE mark

For any communication with the manufacturer it will always be necessary to cite the data on the registration plate

of the machine.

7

• SAFETY INFORMATION

Scrapping of the machine

In case of scrapping the machine it should be disposed of in a lawfully appointed disposal point.

Recoup any used oil and dispose of it in the suitable collection centres. Before proceeding with the

scrapping it is ne- cessary to separate the plastic

and rubber parts as well as electrical and electronic materials.

The parts that are made up solely of plastic, aluminium and steel can be recycled if taken to a collection point.

The lack of observation of rules or basic precaution could cause accidents during use, maintenance or repair of

the machi- ne. An accident can often be avoided by recognising potentially dangerous situations before they

happen. The operator should be vigilant for possible dangers and possess

the training, competence and tools necessary to execute these duties correctly.

Inappropriate use of this machine during its functioning or the lack of maintenance can prove damaging and

cause serious accidents.Never function the machine or do any maintenance on it without having read and

understood the in- structions. Safety precautions and warning are indicated in this

manual and on the machine itself. If attention is not paid to these messages of danger, the operator may incur an

accident with grave consequences for him of herself and for other people.

Safety messages are highlighted with the following symbols:

Warning!

These message, if not heeded could case danger to the operator.

Beware

These message, if not heeded could cause damage to the machine.

The VENTURA cannot foresee every possible circumstance capable of constituting a potential danger.

The warnings in this publication and on the product are however, not exhaustive. If it should happen that tools,

procedu- res, work practices or technical workers nor explicitly recommended by the VENTURA it will be

necessary to ensure that there are no danger for oneself or others.

Information,specifications,illustrationsgiveninthispublicationareprovidedbythemanufactureratthetimeofwriting. Information,

specification, illustrations can vary at any timeand the modificationsoccurred can effect the necessary

maintenance.

Use only original parts VENTURA declines all responsibility if non original parts are used.

8

Warning!

The following instructions cannot completely safeguard anyone operating the machine from all dangers that

might occur. They should be combined with common sense and experience, which are totally indispensable

measures for the prevention of accidents.

•

The operator must ensure that the machine is always maintained clean from any extraneous materials, debris, tools,

oil etc.

•

The machine should be cleaned after each use. During this operation the machine should be stopped and in a

stable position with the ignition keys of the tractor taken out so as to prevent any possibility of anyone causing it to

move.

•

When compressed air or water is used for cleaning purposes protective goggles and mask must be worn and

other person or animals must be kept well away from the vicinity of the machine.

•

Do not use flammable liquids.

•

At the end of the cleaning session a check should be made for wear and tear, damaged or badly fixed parts.

•

Check the state of wear on flexible tubing.

•

The manual should always be at hand so that it may be consulted to check the correct operative cycle every time

a doubt may arise.

•

If this manual is lost or damaged, you will need to ask VENTURA for a replacement copy.

•

Structuraldamage,impropermodifications,alterationsorrepairscanchangethecapacityofproductionofthemachine,the-

reby

cancelling thiscertification.

•

AnymodificationshouldbemadeexclusivelybytechniciansoftheVENTURAortheauthorisedsalesnetwork.

•

This machine is usually fitted on the rearof the tractor. It will therefore benecessary to add extra weight to the front of the

tractor to

prevent the risk of tipping over.

•

Always driveslowly especially on irregulargroundtoprevent loss of balance. Onturning takesufficientcare bearinginmind the

load and

movement of the machine on the axle of the tractor.

•

Ensure that the guards of the power drive are in place and provide for spares in case of damage.

•

Never transport the machine with the rotor blade in motion.

•

These machines may, in certain conditions, throw shredded material and other object gathered from the ground

for great di- stances, which can cause serious injury or even death to anyone in the projectile path of the machine. It

will therefore be neces- sary to block the shredding operation if there are people around either moving or static

within 100 meters of the machine.

•

When the height of the vegetation to be mown prevents the visibility of foreign objects, the mowing should first be made at

intermediate

height in order to allow for an inspection of the ground and the removal of foreign object allowing for a further cut at

the desiredheight.

•

This pre-emptive action will, moreover, notably reduce wear and tear on the machine.

•

Avoid the blades coming into contact with bulky objects.

•

Do not climb onto the tractor or the machine while they moving. Avoid contract with tyres while they are in

motion. Climb on or off the tractor only when it is completely still and the ignition key is taken out. On no account

should anyone climb onto the machine itself.

•

Do not use the machine if there is an oil leak present.

•

Do not search out a leak with bare hands. Use protective gloves and a piece of material or cardboard. Oil under

pressure can penetrate under the skin and cause gangrene. In the event of this happening seek urgent specialist

9

medical attention.

•

Carefully read and respect the manufacturer’s instructions when using oil, solvent, detergents or other chemical

substances.

9

Checks to be carried out on the tractor

•

Ensure that the drive shaft is fitted correctly both on the power drive of the tractor and on the universal shaft of the machine.

•

Check that the universal shaft is exposed for at last 1/3 third of the thread in its most extended position.

•

Ensure that the guards are in perfect order, that they can bemoved freely and that the fixing chains arenot under strain when

themachine

is fully raised or lowered.

•

Check that in the position of continuous working, universal shaft does not make an angle greater than 20°

against the align- ment of the power drive of the tractor.

•

Ensure that the drive shaft does not touch the guard of the power drive of the tractor, the guards of the transmission

shafts or other parts of the machine.

•

No operation regarding the drive shaft or the power drive should be made with the tractor motor running. The

ignition key should be taken out and shaft of the power drive should be in the off position.

•

As soon as the shredding operation is finished the drive shaft must be disengaged from the power drive of the tractor and

returned to

the support supplied for it.

•

During use, maintenance, repairs, on the road, or during delivery of the machine the operator must wear safety

footwear, safety gloves, safety helmet and safety goggles for protection from falling objects or materials projected

from the normal working of the machine.

•

The operator’s clothes should be as close fitting as possible. Never use wide or floppy clothing.

•

Never allow inexperienced or untrained person to usethemachine. All use of the machine mustbe carried out slowly to avoid

carelessness

that might create space that is free from any obstacles.

•

Negligence or lack of attention could endanger your safety.

•

Objects such as ropes, wire, cables, chains etc can hook onto the rotating elements of the cutting mechanism

and be thrown out at high speed causing very dangerous situations for the safety of the operator. You should

avoid the blades coming into contact with suchobject.

•

If wire or similar materials become wrapped around the rotor try to free up the rotor (wearing safety gloves) with

the help of shears. Do not try to carry out the job by inverting the direction of rotation.

•

Take great care during shredding on sloping ground. The machine could sway and make the tractor lose its

balance, causing serious injury or death to the operator. If this should happen do not remain in the vicinity and do

not allow anyone to remain in the rotation or oscillation zone of the machine.

•

Check that there is nobody in the oscillation area of the machine before starting to rotor or the potential enacting

of hydraulic displacement.

•

Do not allow anybody to climb onto the tractor or onto the machine. Do not carry out any operation if there is

anyone nearby or on the machine. Do not allow anyone to come near especially not children.

•

Check the machine periodically inspecting the bolts in general, worn or broken parts, pinched or broken cables loose

con- nections or connections with too much play. Ensure that all the joint pins are adequately blocked. Always keep

the machine

scrupulously clean and freeform foreignobjects.Cleanimmediately,any stains ofoil or any other inflammablematerial, to avoid

danger offire.

•

Serious injury can be caused by neglecting maintenance.

•

Do not continue to use the machine if a cutter is lost or so badly worn as to cause vibration. Consult the relevant

section of the manual for instruction on replacement procedures.

•

Always replacement both the worn blade and the one opposite to it at the same time.

10

•

Always select the rotor stop position before unthreading the drive shaft from a power drive on a tractor or a

completely independent power drive.

•

Makeadailycheckonnuts,bolts,flexibleandotherfixturesystem.Checkingforpotentialdefect,alignment,orbreakage that may

prejudice the safety of the machine. If you do find any such problem you should immediately take measures to

make repairs or

replacements.

•

Any maintenance, repair or checking operation must be carried out with the machine completely still and

isolated from the power drive of the tractor. The ignition key must be taken out. Always position the machine on

points or blocks when such procedures are carried out in order to prevent any potential lowering or raising of

the tractor.

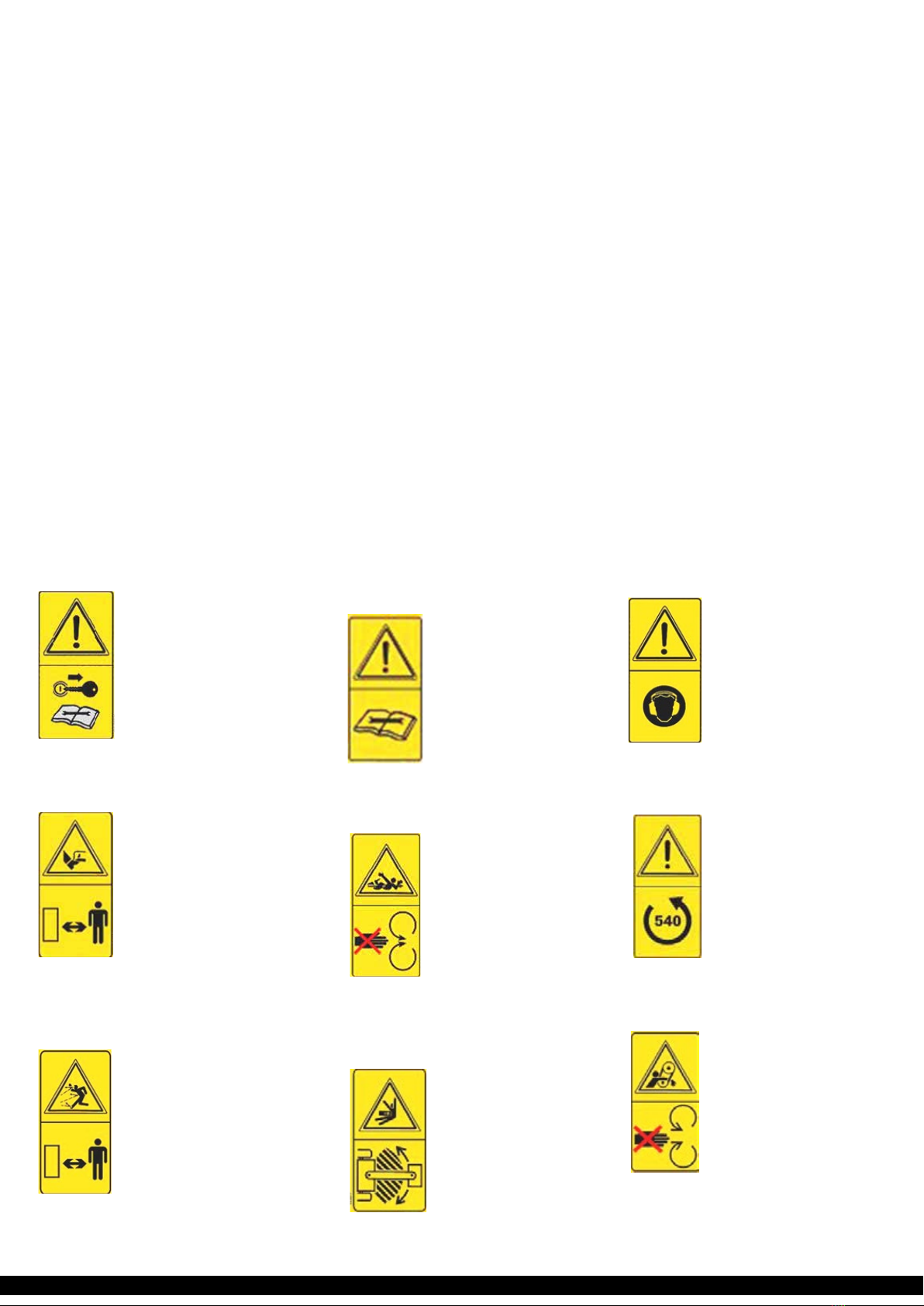

Safety advice stickers

“Warning!

Ensure that all security messages are legible. Clean them using soap and a cloth. Do not use solvents, diesel oil or

petrol. Replace damaged stickers by asking for them from the VENTURA If a stickers happens to be on a part that is

to be replaced, make sure

that another one is applied onto the replacement.”

Stop the motor and

remo- ve the

ignition key before car-

rying out any

maintenance

operations or repairs.

Do not approach any

parts of your body to

the rota- ting parts

when the machine is in

operation or the motor

is running.

Keep at the safe

distance from the

vehicle or tools

Read carefully the

ma- nual of use and

main- tenance

beforestarting the

machine. Observe

safety rules and

securi- ty instructions

during functioning.

Do not open or

remo- ve the safety

guards when the

machine is in

operation or the

motor is running.

Do not remain in the

vi- cinity of swaying

parts of the machine

or the tractor.

Always wear safety

ear protection.

Maximum rotation

spe- ed of P.T.O. shaft:

540 or 1000 rpm.

Do not open or

remove the safety

guards when the

machine is in ope-

ration or the motor is

running

11

Do not approach the danger

zone while the motor is

running.

Keep hands away when the

rotor is rotating.

Personal protective equipment (PPE)

The conductor, maintainers and operators that carry out activities on the machine, they must use the personal

protective equipment to allow them to cancel all the possible risks arising from the various activities according to

the provisions of the factory installation.

“Look Out!

During the operations of management and maintenance, personnel should wear appropriate clothing to prevent the

occurrence of accidents.In order to avoid mechanical hazards such as entrapment or entrainment, it is forbidden to wear

special as bracelets, watches, rings or chains during the cycle”

“Warning!

The clothing of those who work or perform maintenance on the machine must meet the essential safety requirements set by EU

Directives 98/37 EC and applicable laws in the country where the machine is installed.”

12

General rules

It is imperative to execute every maintenance operation with the machine completely still, even when

undoing any ele- ment of the hydraulic circuit.

Warning!

Before any intervention is made, the maintenance person must take the key out of the ignition, after

having ensured that the motor is stopped, and disconnect the drive shaft coupling from the power drive

of the tractor. Only in this way can it be certain that the machine cannot set off unexpectedly while the

maintenance person finds him/herself in position of risk.

During maintenance or replacement of hydraulic components, particular attention should be paid to

avoiding the intro- duction of any foreign object, however small, into the circuit which may cause

malfunction and compromise the safety of the machine.

Excepting particular demands maintenance must always be carried out with the tools of the machine in

resting position and after the pressure of the oleodynamic accumulators / hydraulics has been released.

Warning!

Avoid executing any operation with bare hands.

Beware

In the case of any maintenance operation that may need to be done while one or more functions of the

machine is active, precise and unbreakable imperatives must be adhered in that:

a)

There should always be at least two person present: the operator who has the function of

supervising the security of the person working and the maintenance engineer;

b)

The operator who is at the commands of the machine and the maintenance engineer should be able to see

each other at all

times in order that communication between them will be easy and unequivocal;

c)

The operator acts in accordance to orders given him by the maintenance engineer;

d)

Defore changing from a still activity to a moving activity the maintenance engineer should remain in a

position of safety and only draw close to the moving parts after having secured assurance that his/her

orders have been received exactly by the operator;

e)The maintenance should always be done in adequate light.

f)

The maintenance engineer should be informed of the exact function and movement of every part of the

machine.

WORK CONFIGURATION

• INSTALLATION AND FUNCTION

TRANSPORT CONFIGURATION

13

Installing on back of the tractor

Shredder Roma is also ready to be brought from tractor through rear

connection. Place the machine on flat ground.

Remove lower pins (A) and the top pin (B).

Move back the tractor and actuating the lower bars of the lift, carry at the holes of the bars with the holes on

the attack machine

Beware

The bars lower linkages (C) should get into guides outside of the machine.

Insert lower pins (A) and lock with special safety locks.

Connect the rod of the third point (It) at the top of the

machine. Insert the top pin (B-C) and secure it with a

clamp safety.

Remove the tubes of the hydraulic circuit from the machine

and connecting the special attachment on the tractor

respecting also, for all further installations, the same positioning

of the pipes by means of the color code applied on the same.

Warning!

A placement opposite invert the direction of handling commands placed on the tractor.

Beware

Before starting work, you should warm the tractor engine and hydraulic oil for a few minutes to order of

ensuring the prompt response of the hydraulic components.

Warning!

During work shredding, make sure that the range of the machine there are no people or animals. If the

machine is used with the hood open, make sure that the safety distance is at least 50 meters.

14

Lift the machine

To lift the machine must be attached at placing two hooks in the prepared points marked with this symbol

“Warning!

When the machine has been raised to a height greater than 50 mm, the workers must severely remain at a

safe distance from the perimeter of the same greater than 2 meters.

A break of the lifting system or an uncontrolled movement are in fact a serious danger to the safety of personnel.

When handling components with dimensions do not permit adequate visibility, it is recommended make use of

moreoperators to

provide directions

Before moving the packaging, make sure the lift system and related equipment (ropes, cords, hooks etc.) are

appropriate with the

load. Check the stability of the packaging before lifting.

Fitting the drive shaft

The transmission of the power to the mower will be effected through the drive shaft inserted between the tractor

and the machine. Use an appropriate drive shaft for the distance between the tractor and the machine.

“Attenzione!

When the drive shaft is inserted it must have minimum play of at least 10 cm measured from the “all closed” position and must have a

guard equal

to at least 1/3 log the length in the “all open” position. Check that the guards are

intact and if they have undergone an damage or wear replace them

immediately.”

Clean and lubrificate the power drive.

Lubrificate the drive shaft following the instructions of the drive shaft’s manufacturer.

Engage one end of the drive shaft onto the power drive of the tractor and the other on the

multiplier group of the machine respecting the direction prescribed by the manufacturer and

shown on the outer sleeve of theguard.

Hook the anti rotation chaims

“Warning!

Use only original VENTURA blades”

“Warning!

Ensure that the anti thread security block (push-button) is correctly inserted and locked in its own housing. Work only on

protected drive shaft Check that the guards are intact and if ever there is any damage or breakage, replace immediately.

Ensure that the power drive is inserted to 540.”

15

General rules

It’s imperative to execute every maintenance operation with the machinecompletely still, even when undoing

any element of the hydrauliccircuit.

“Warning!

Before any intervention is made, the maintenance person must take the key out of the ignition, after having censure that the

motor is stopped, and disconnect the drive shaft coupling from the power drive of the tractor. Ony in this way can it be

certain that the machine cannot set off unexpectedly while the maintenance person finds him/herself in position of risk.

During maintenance or replacement of hydraulic components, particular attention should be paid to avoiding the

introduction of any

foreign object, however small into the circuit which may cause malfunction and compromise the safety of the machine.

Excepting particular demands maintenance must always be carried out with the tools of the machine in resting position

and after the pressure of the oleodynamic accumulators/hydraulics has been released. ”

“Warning!

Avoid executing any operation with bare hands.”

“Warning!

In the case of any maintenance operation that may need to be done whil one or more functions of the machine is active,

precise and unbreakable imperatives must be adhered to in that:

There should always be at least two persons present: the operator who has the function of supervising the security of the

person working and the maintenance engineer.”

The operator who is at the commands of the machine and the maintenance engineering should be able to see each

other at all times in order that communication between them will be easy and unequivocal.

The operator acts in accordance to orders given him by the maintenance enginer.

Before changing from a still acivity to a moving activity the maintenance engineer should remain in a position of

safety and only draw closet o the moving parts after havingsecured assurance that his/her rodersi have been

received exactly by the operator. The maintenance should always be done in adeguate light.

The maintenance engineer should be informed of the exact function and movement of every part of the

machine.

Periodic checks

Check all parts of the machine daily, in particolar check the state of wear of the chain.

“Warning!

Broken or excessively worn blades must be replaced.”

“Warning!

The lack of one or more blades can cause a rapid deterioration of the rotor and

cause vibrations Any discrepai must be rectified immediately otherwise the safety

conditions of the operator and the machine may be placed in jeopardy.

Check the state of wear of the chains daily. Clean them often

when the vegetation iswet.

To replace the chains it will be necessary:

-

Raise the machine using the tractor’s 3-point hitch.

-

Remove the protective cover using the four bolts

-

Replace worn chains.

The safety guards of the chains must always be kept in good

condition. A broken, bent or excessively worn safety guard must

be replaced.

• MAINTENANCE SECTION

16

Collision shock absorber

Check the spring lubrication, to maintain correct operation.

Before putting the machine to rest for long periods it is opportune to make as follows:

- carefully wash the machine in all parts;

-

make a general control watching the car in order to individualise possible structural lesions, to notice possible

deep abra-

sions onthepainting,toverifythatthe original safety pictogramsare present intheirpositions, thatits areentireand legible;

-

In case of lesions, abrasions or damages, handle the opportune reparations: in case of necessity, immediately

replace the pictograms or the parts of the machine damaged;

- grease all the mechanical organs, the tightening pivots, the attaching head to the cardan shaft junction;

-

insert the terminal part of the hydraulic pipes in the special supports

-

put, if it is possible, the machine in a covered place and lean the machine on wood tables or cement

ground in stable position;

-

cover the machine with a tarp fastening it.

“Warning!

After completing this operation refit the protective casing blocking the two levers with the correct security screws.”

Lubrification of the VENTURA gear box

Check the oil level every 50 hours by means of the proper dip stick. Replace theoil after the first 150 hours of work and subse-

quently every 1000

hours ofwork.

In order to do this you will need to unscrew the oil filler plug (B) of the drain tank after havinglocated, under the gear box.

The tank has a

capacity of at least 2 litres.

“Warning!

After collection the used oil should be kept in an appropriate container to be disposed of according to the law.

Type of oil: Spartan

220 Quantity: 1.5 litres

17

Warranty

1 Year Warranty. It only includes manufacturing defects in machinery or defective parts (not labour). Being

provided

to the verdict of the company if the flaw was due to misuse or mishandling by the user. The warranty

doesn’t include material subject to natural wear such as blades, counter blades, hammers, belts, pulleys,

etc.

Theacceptanceofanywarrantyclaimandtheright credit willtake placeuponreceiptand verification ofthe defective part.

Table of contents