OPERATING INSTRUCTIONS:

RUNNING A PROGRAM:

The furnace has 9 three stage programs and one single temperature hold program. The furnace is sold with the program

parameters set to the factory defaults which can be used for testing. First time operation will require the user to enter

their desired parameters into one of these programs.

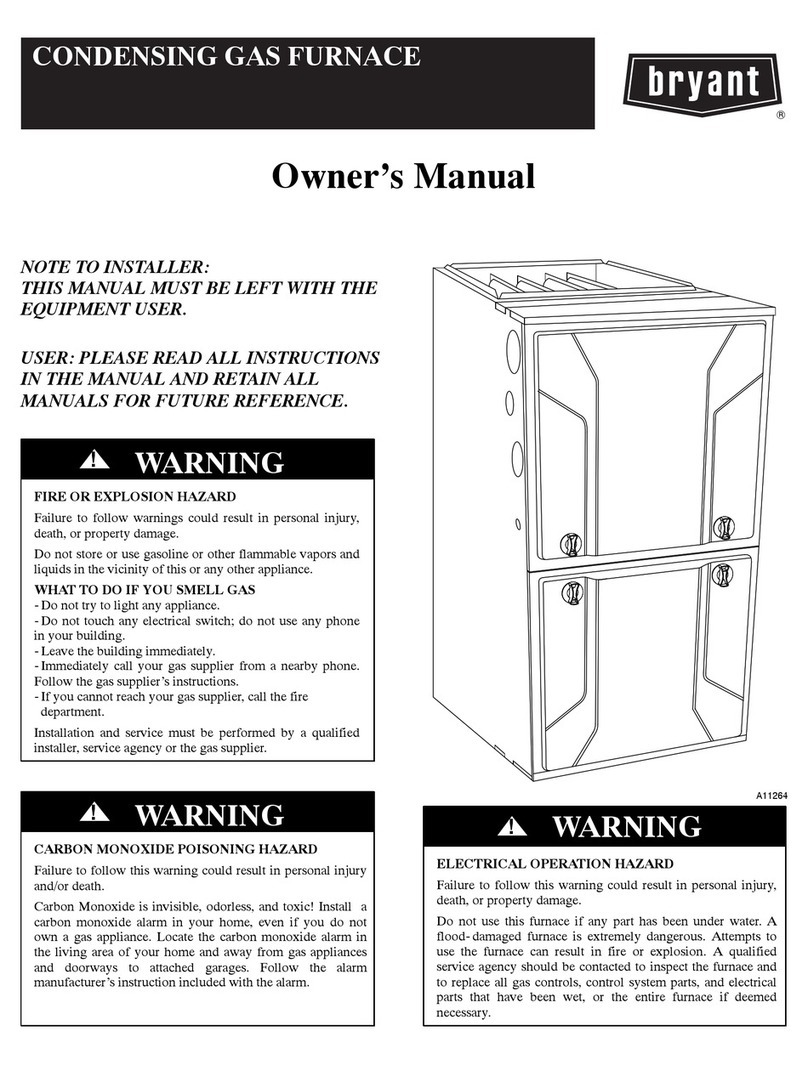

1. Turn on green power switch (right-hand side of control panel)

After a short delay for internal testing, the furnace will display approximate room temperature, program time

(hours:minutes), and program number. All red EDs are off. (If any of the EDs are on, the furnace was already running

a program when it was last turned off.)

2. Select or change the program to the desired number by pressing the digit key (1-9) for the desired program followed by

the ENTER key. The display will be updated to show the new program number and its approximate run time.

3. Pressing the green Start key will start this program. The red EDs will come on and the time will start to count

down. The green power switch will light when the door is closed. The EDs will be turned off as each segment of each

stage of the program is completed.

• During program operation, the total program cycle time is counting down as indicated by the flashing colon in

the time.

• If a program is started when the muffle is already heated, the furnace will heat or cool at the first ramp rate to

the first temperature from the current muffle temperature. It will not cool to room temperature before starting.

• The program will end by maintaining the last muffle temperature, displaying “Hold”, beeping every 3 seconds

and flashing the last Temp ED. See information on End Of Program options (point 1) in the “Setup &

Maintenance” section if other operations are preferred.

4. Pressing the key will change the temperature display from °C to °F and back. This key is not active during

parameter programming.

5. A short power outage during the operation of a program will not terminate or abort the program unless the muffle

temperature drops more than 32°C (58°F). If the power outage occurs when the muffle temperature is close to, or at

room temperature (e.g. during Delay Start operation) the furnace will continue the program when power is restored

regardless of the temperature drop or the amount of time that has expired.

6. Pressing the Escape key cancels beeping at the end of a program. It also will return the furnace to a display of

the current conditions during programming operations.

7. Opening the door during a cycle interrupts power to the heating elements.

STOPPING A PROGRAM:

1. Pressing the red Stop key will stop the program that is currently running. The red EDs will go out and the

display will show the current program number, approximate cycle time, and the current muffle temperature.

PROGRAMMING:

The furnace increases productivity and reliability for the operator because cycles or programs can be preprogrammed and

operated automatically. Once programmed, the parameters are retained in memory even with the loss of power.

Parameters are not retained in memory if entered during the operation of a program.

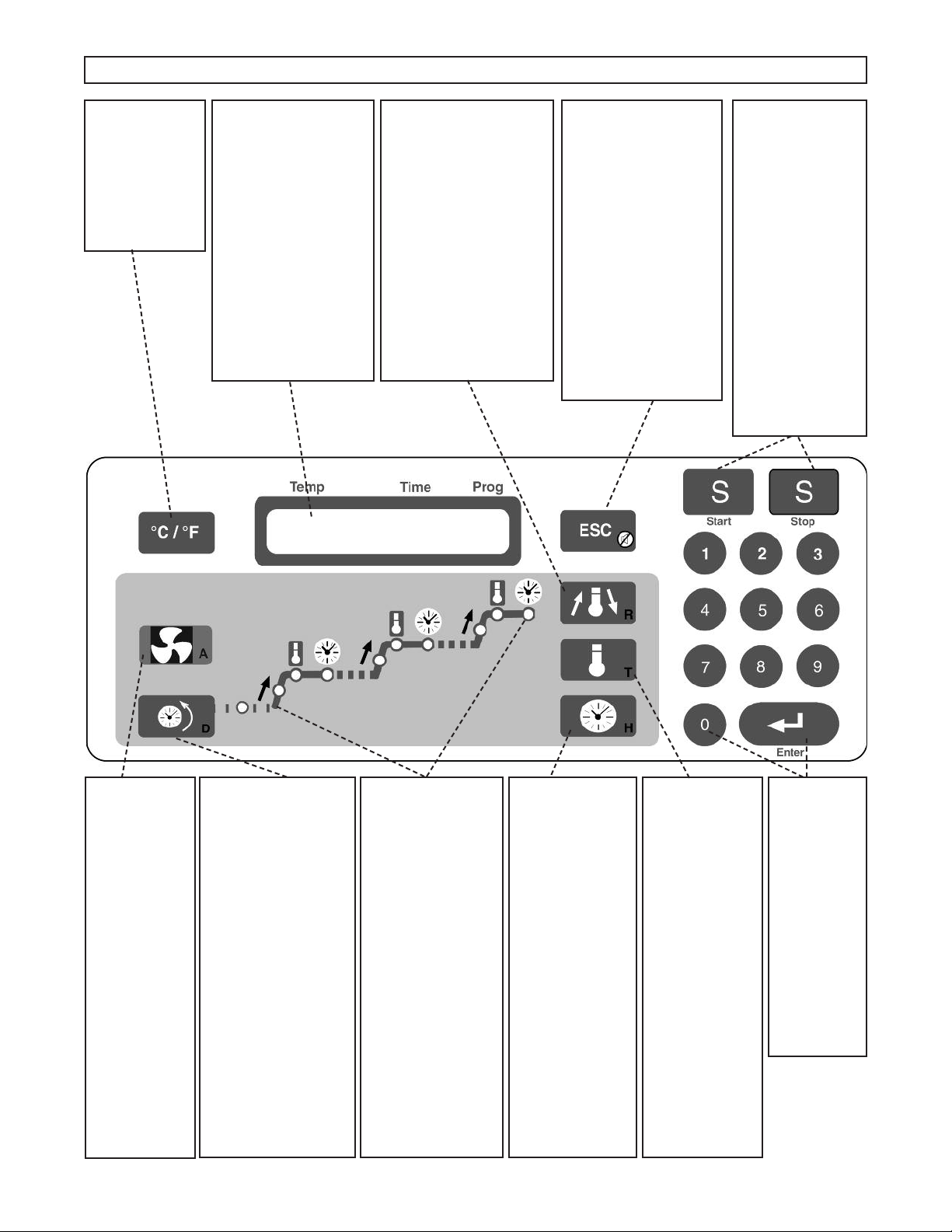

Each program is made up of 3 stages which require 3 parameters each. The parameters are grouped into ramp rates (R1,

R2, R3), temperatures (T1, T2, T3), and dwell or hold times (H1, H2, H3). The 1,2,3 indicates the stage number or

sequence. The temperatures can be programmed in either °C or °F; the ramp rates in °C per minute or °F per minute; and

the hold times in hours and minutes (hh:mm).

RAMP RATES (R) (0 - 40°C/minute)

1. Pressing the Rate key makes the display show the current value of the R1 parameter followed by 3 blanks for a

new value.

• For example: R1 8.0°C/M ->_ _ _

• The corresponding ED will also light to indicate the selected stage and parameter.

2. Use the digit keys (0,1,2,...,9) to enter the desired parameter value followed by the ENTER key. The new

parameter is now stored in memory.

• If a value is entered that is out of the acceptable range, the furnace will beep and display the acceptable range.

• Programming a Rate to 0 will cause the furnace to terminate the remainder of the program stages. For example, if R2

is set equal to 0 then at the end of the first hold time (H1) the furnace will go to the end of the program, making the

S

S

7