MAINTENANCE

GREASING TAPS OR THERMOSTATS

If a tap or thermostat becomes stiff to operate, it

must be greased as follows:

-Shut off the mains gas tap;

-remove the burners, unscrew the side screws to

free the hob and lift it;

-undo the two screws at the side to free the hob

and lift it;

-undo the two screws which fix the tap body C;

-remove the pin and the spring D and extract the

cone E with the aid of a pair of pliers;

-clean the cone and its seat thoroughly with a rag

soaked in solvent;

-grease the cone slightly with the appropriate

grease, put it back in place and turn it a few

times;

-remove the cone again and wipe off any excess

grease, checking that the gas passage holes are

not blocked;

-reassemble all parts carefully. (See Fig.16)

7

OPERATING INSTRUCTIONS

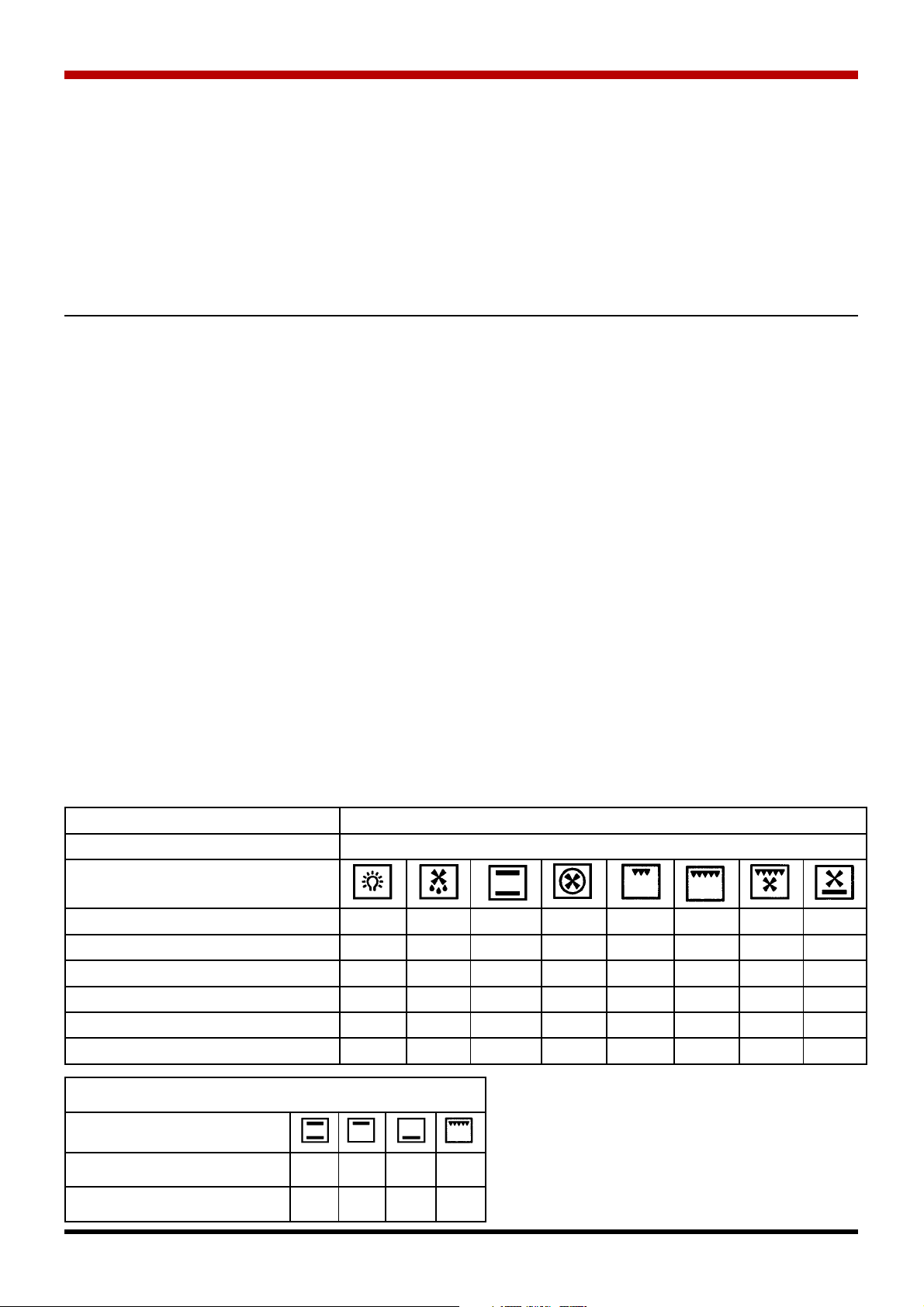

HOB BURNERS

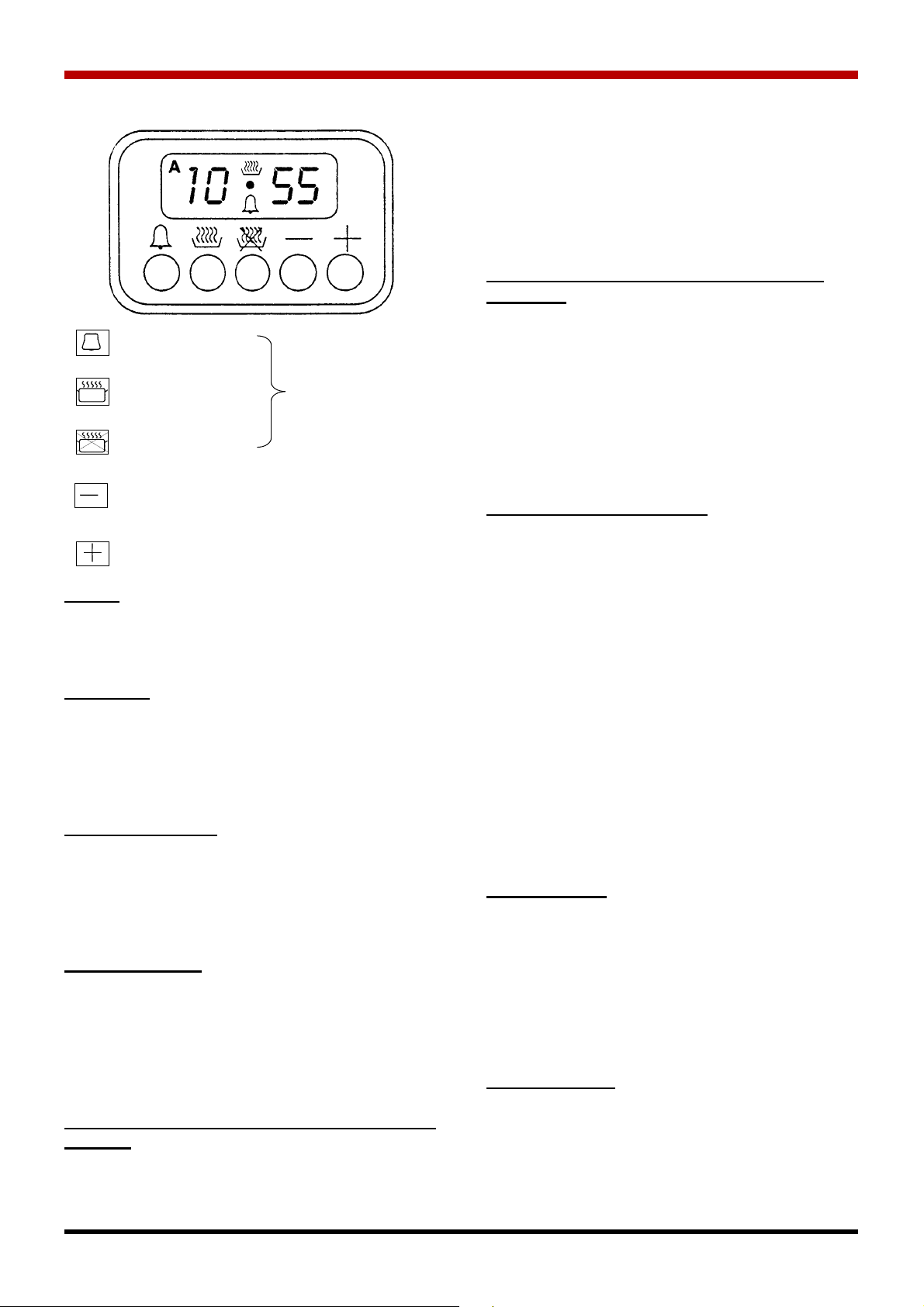

Electric Ignition (burners fitted with safety ther-

mocouple):

Press the corresponding knob down and turn it anti-

clockwise to the maximum setting, the ignition

switch is incorporated in the knobs. Keep the knob

pressed for about 15 seconds. (See Fig.19).

CAUTION: If the burner does not ignite within 15

seconds, wait at least 1 minute before repeating the

procedure. Once the burner has lit, set the flame

power to requirements, ensuring that the knob is

between the maximum and minimum settings, and

never between the maximum setting and zero posi-

tion.

SWITCHING ON THE GRILL ELEMENT:

Press the corresponding switch marked with the

Grill symbol. This switches on the grill element, a

pilot light and the rotisserie motor.

The grill element can only be switched on with the

oven burner off. (A safety switch prevents the use

of the two different heat sources simultaneously).

CAUTION: When the grill is working the accessible

parts may become very hot. Keep children well

away.

CHANGING THE OVEN LAMP

-disconnect the appliance from the electrical

mains;

-unscrew the protective cap 0 which projects into

the oven;

-unscrew the lamp and replace it with another of

the same power and resistant to high tempera-

tures (300oC);

-replace the cap, fitting the notches in the tangs N,

and screw down (See Fig.17).

REMOVING THE OVEN DOOR

Open the oven door, on the hinge there is a hook,

rotate this hook towards the cooker as as much as

possible. Fig 18a shows the hook in the normal posi-

tion, Fig 18b shows the hook rotated for removing

the oven door. Partially close the door and pull

away from the cooker. To reassemble follow the

same procedure in the reverse order.

USING THE ROTISSERIE

Impale the food for cooking on the rotisserie spit,

taking care that it is secured between the two forks

(A and B), and balancing the weight to avoid forcing

the motor unnecessarily. (Fig.24)

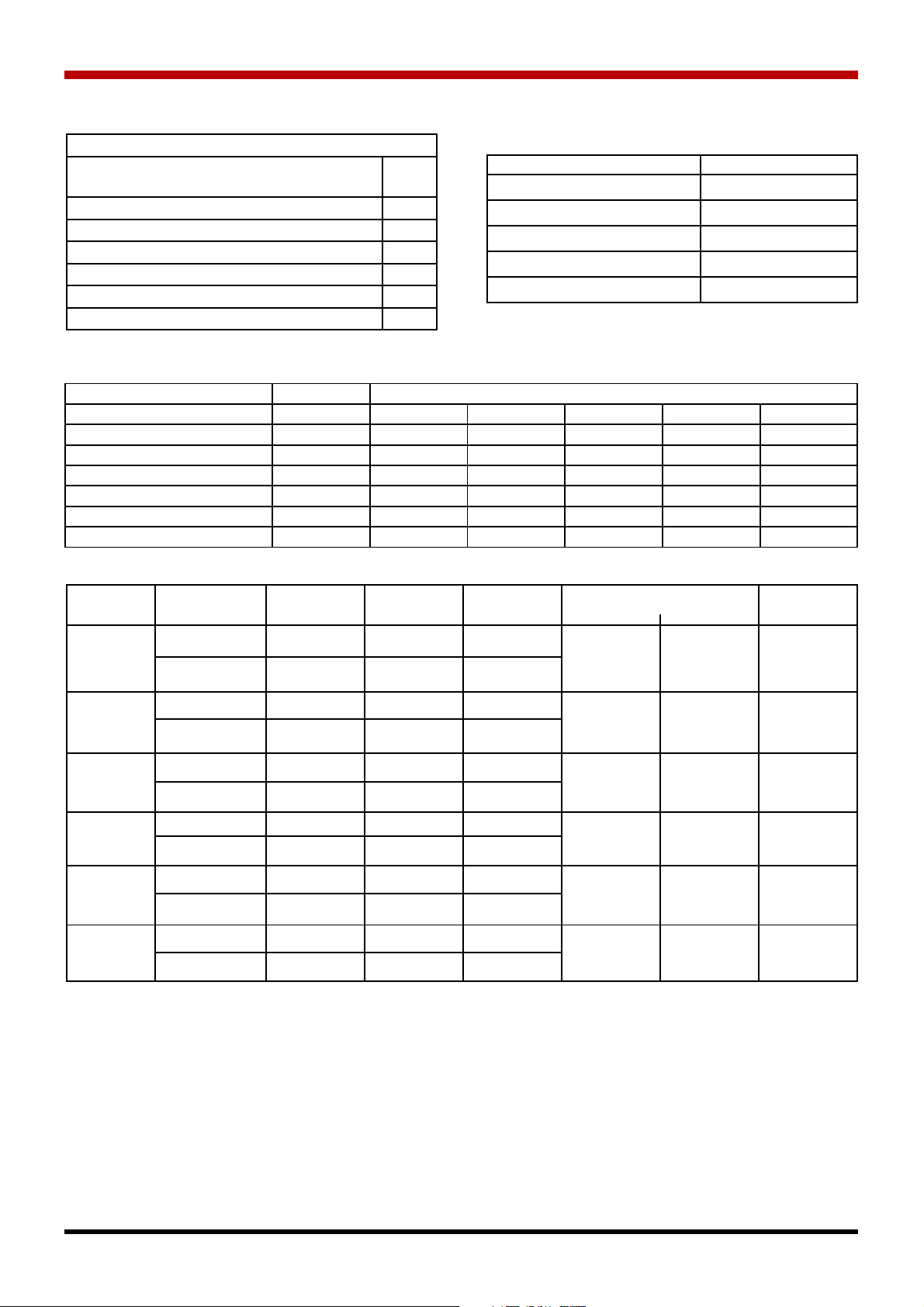

HOBS (Gas burners and electric

hotplates)

To ignite the gas burners, follow the instructions

given in the HOB BURNERS section.

The electric hotplates are switched on by turning the

knob to the setting required. A diagram showing the

relations between the knobs and hotplates is screen

printed on the front panel beside each knob.

The hotplate switch has 5 positions:

- 0 - OFF position

- 1 - MINIMUM power setting

- 2 - MEDIUM-LOW power setting

- 3 - MEDIUM-HIGH power setting

- 4 - MAXIMUM power setting (Fig.25)

When switching on a hotplate for the first time, or if

it has been out of use for a long period, operate it

without a pan on setting 1 for 3 minutes to eliminate

any moisture absorbed by the insulation. To avoid

wasting energy, use flat bottomed pans and do not

use pans smaller in diameter than the hotplates.

(See Fig.26).