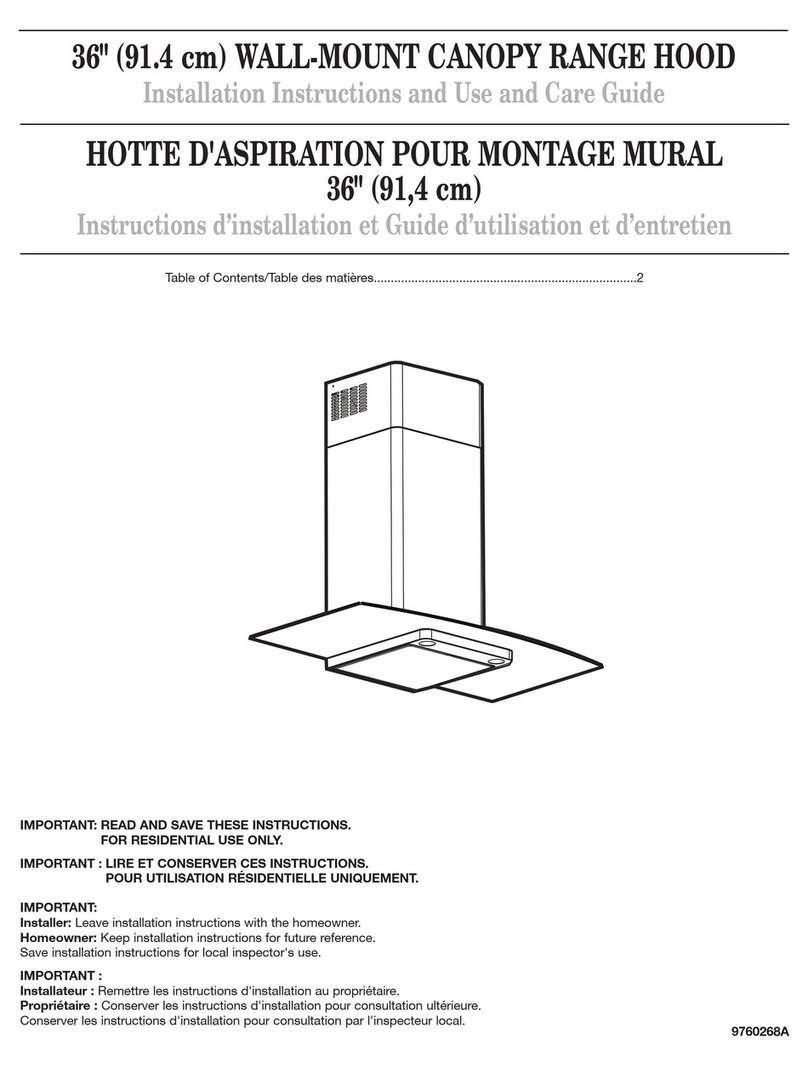

Wall Hung Canopy

Models include W5L09S3, W5S09S3, W5V09S3, W5V12S3, W5R09S2, W5P09S3, W5H09S3, A5M09S3, A5C09S3

and A5N12S3

WARNING

DIMENSIONS ARE ACCURATE AT THE TIME OF PRINTING, PR KITCHEN & WASHROOM SYSTEMS PTY LTD RESERVES

THE RIGHT TO CHANGE SPECIFICATIONS WITHOUT NOTICE. FOR BUILDING PURPOSES THE UNIT SHOULD BE

PROVIDED TO THE CABINET MAKER / BUILDER / KITCHEN DESIGNER FOR EXACT MEASUREMENTS.

STEP 1:

Measure the height of the hood from the base to the top of the mounting hooks.

NOTE:

The height of the underside of the hood body must be a minimum of 600mm above an electric cooktop & 650mm above a

gas cook top and a maximum height of 1200mm. If the instructions of the hob specify a greater distance than the minimum

detailed, this shall be the minimum height for installation. Building codes that stipulate a minimum dimension may vary from

state to state, please check with your local council prior to installation.

STEP 2:

Using a spirit level mark a vertical centre line on the wall where the hood hooks need to be positioned. It is best to centre the

hood unit to the cook top below.

STEP 3:

Mark a horizontal line on the wall for the mounting bracket position. Centre and mark the two (2) xing points to the left and

right of the centre line.

Drill and plug holes with suitable sized wall plugs.

STEP 4:

Fix the wall bracket with two (2) suitable screws into the

wall at the positions marked in step 3 to allow the body of

the hood to be hung on the wall.

STEP 5:

Hang the body of the hood on the wall using the bracket

attached in step 4.

Identify and mark several screw holes located inside the hood.

Remove the hood from the wall and drill and plug holes with

suitable sized wall plugs.

STEP 6:

Replace the hood back on the wall and secure the hood by xing the additional screws inside the hood housing.

STEP 7:

Secure the hood rmly to the wall by tightening the hood hooks.

STEP 8:

Secure the chimney bracket to the wall.

PART 1 : HOOD INSTALLATION GUIDE

Part 1: Hood Installation Guide

Wall Hung Canopy

Models include W5L09S3, W5S09S3, W5V09S3, W5V12S3, W5R09S2, W5P09S3, W5H09S3, A5M09S3, A5C09S3 and A5N12S3

Step 1:

Measure the height of the hood from the base to the top of the mounting hooks.

NOTE: The height of the underside of the hood body must be a minimum of 600mm above an electric cooktop &

650mm above a gas cook top and a maximum height of 1200mm. If the instructions of the hob specify a greater

distance than the minimum detailed, this shall be the minimum height for installation. Building codes that

stipulate a minimum dimenstion may vary from state to state, please check with your local council prior to installation.

Step 2:

Using a spirit level mark a vertical centre line on the wall where the hood hooks need to be positioned. It is best to

centre the hood unit to the cook top below.

Step 3:

Mark a horizontal line on the wall for the mounting bracket position. Centre and mark the two (2) xing points to the

left and right of the centre line. Drill and plug holes with suitable sized wall plugs.

Step 4:

Fix the wall bracket with two (2) suitable screws into the wall at the positions marked in step 3 to allow the body

of the hood to be hung on the wall.

Step 5:

Hang the body of the hood on the wall using the bracket attached in step 4.

Identify and mark several screw holes located inside the hood. Remove the

hood from the wall and drill and plug holes with suitable sized wall plugs.

Step 6:

Replace the hood back on the wall

and secure the hood by xing the

additional screws inside the hood

housing.

Step 7:

Secure the hood rmly to the wall

by tightening the hood hooks.

Step 8:

Secure the chimney bracket to the wall.

Step 9:

Refer to Part 2: Motor Installation Guide.

Step 10:

Place the chimney on the hood and secure to the chimney bracket.

You may need to drill some new holes through the cover and bracket to secure the chimney cover.

Step 11:

Attach the male plug of the rangehood unit to mains power supply. Note to Electricians: Standard 10 Amp

General Power Outlet (GPO) required. Position GPO as close to the hood unit as possible.

WARNING

DIMENSIONS ARE ACCURATE AT THE TIME OF PRINTING BUT HAUS APPLIANCES RESERVES THE RIGHT

TO CHANGE SPECIFICATIONS WITHOUT NOTICE. FOR BUILDING PURPOSES THE UNIT SHOULD BE

PROVIDED TO THE CABINET MAKER / BUILDER / KITCHEN DESIGNER FOR EXACT MEASUREMENTS.

10

1

2

3

5

4

6

7