A clock is a precision mechanical instrument containing many

slowly moving parts. ere are over a hundred points of contact

where friction works to bring it to a stop.

Take your time assembling this kit, and pay attention to the

details. Great pains have been taken to cra these instructions

to ensure your success. If there are any steps that seem unclear,

please let us know.

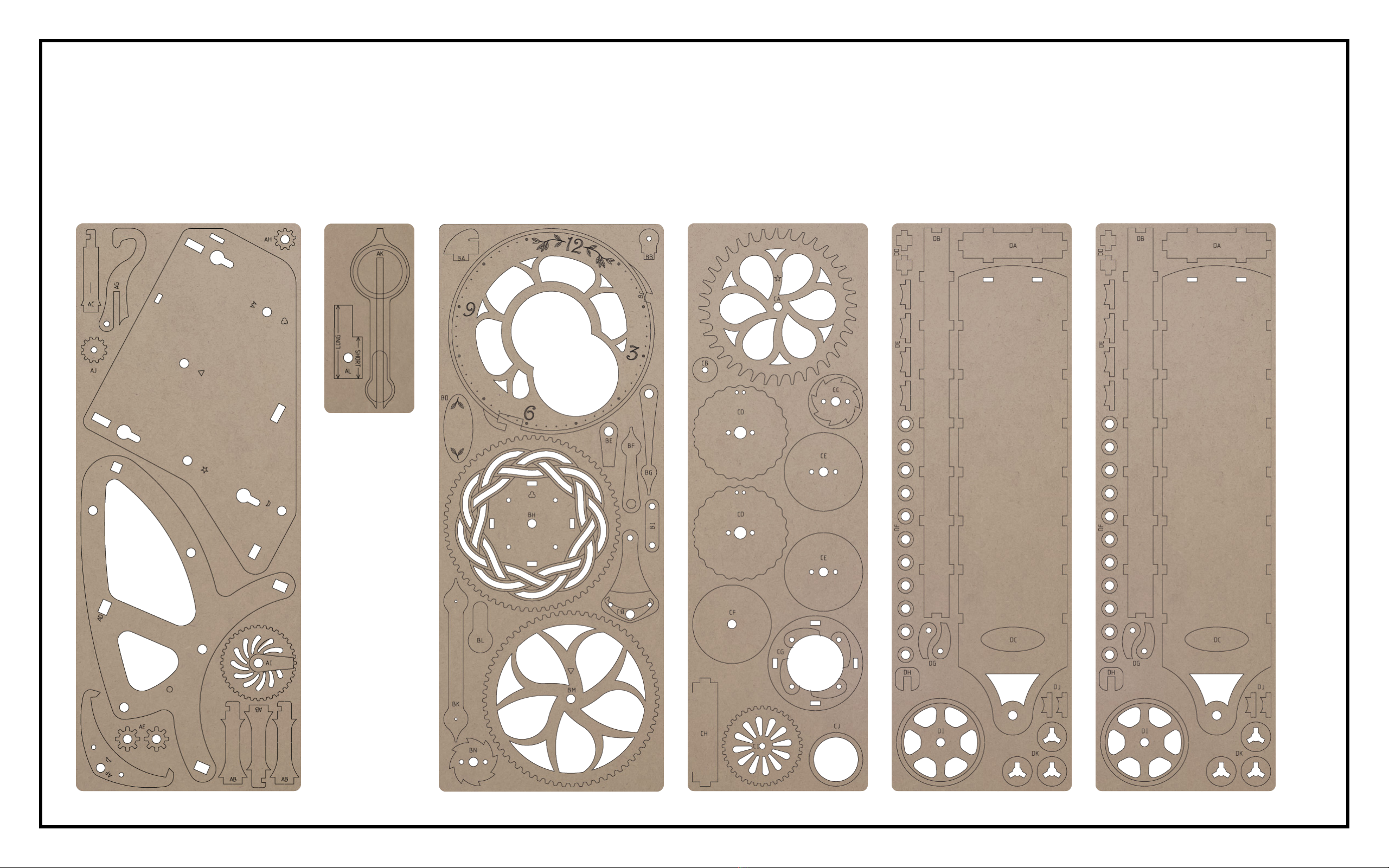

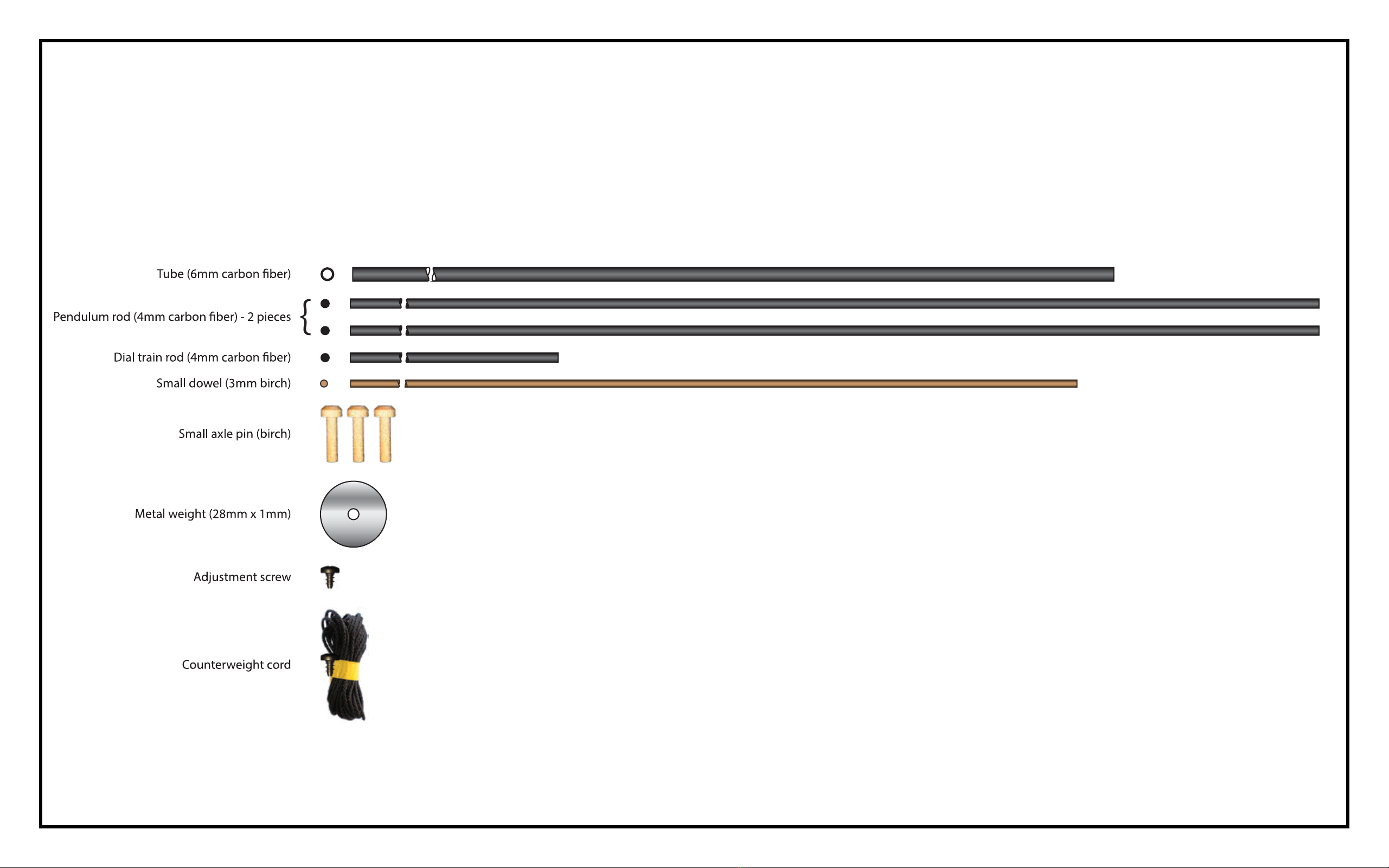

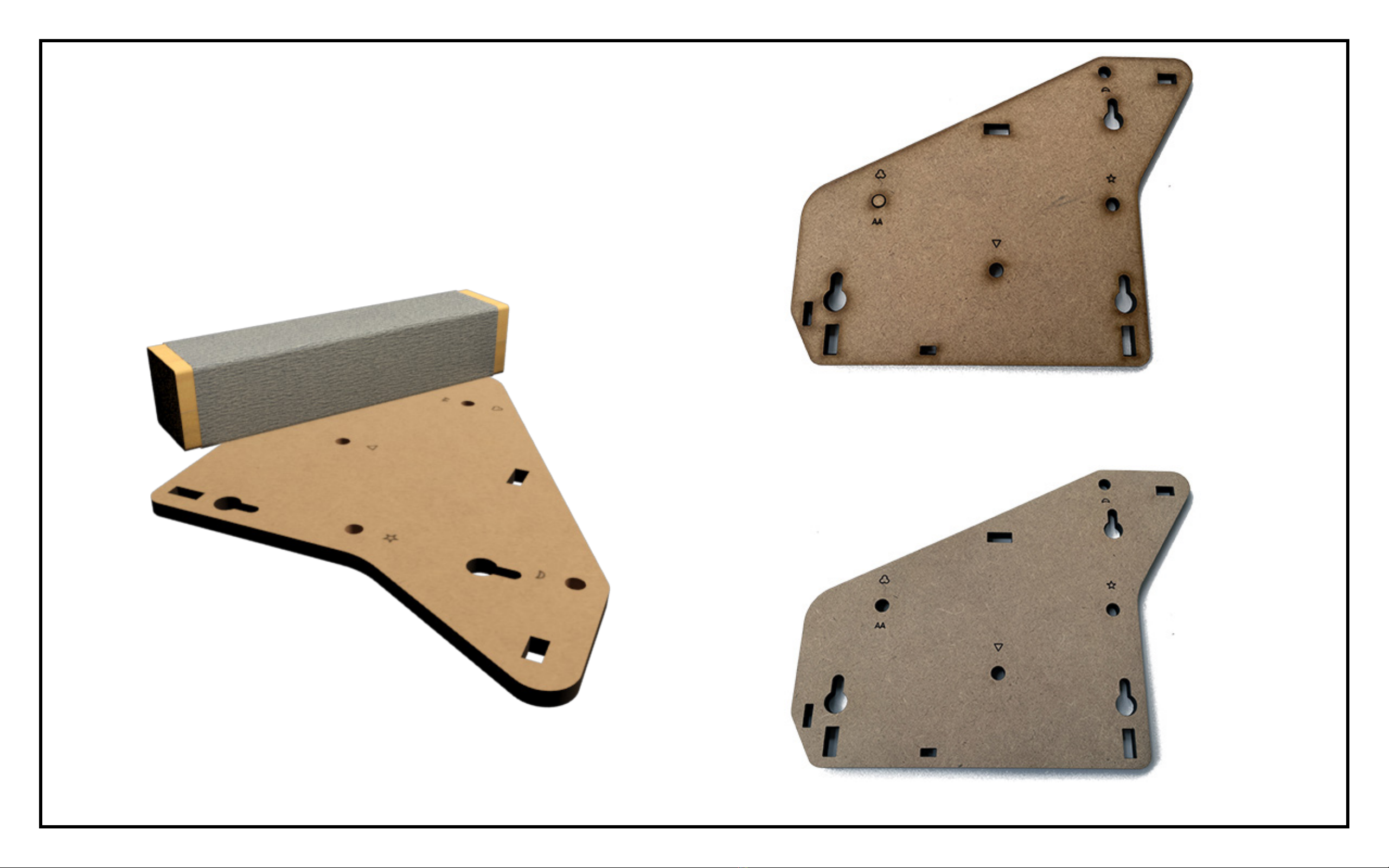

Before you begin, check that there are no missing or damaged

pieces in the kit. A parts list is provided to help identify each

piece.

Finally, read through all the instructions before you begin. is

will help you understand how each piece ts into the nished

clock.

WALL CLOCK KIT

SEBRINGVILLE

DAMAGED OR MISSING PARTS?

email: service@abong.com

Made in Canada by

ABONG, Inc

5-775 Woodlawn Road W

Guelph, ON N1K 1Y7

WARNING!

CHOKING HAZARD - CONTAINS

SMALL PARTS. NOT RECOMMENDED

FOR CHILDREN UNDER 3 YEARS