ACOPOWER Midas Y Series User manual

Midas Y Series

User Manual

MPPT Solar Charge Controller

Models:MY20/MY30/MY40

Add: 4120 Valley Blvd, Walnut, CA 91789,USA

Tel: 1.626.575.7722 Email:sales@acopower.com Web:www.acopower.com

01 02 03 04 05 06 07

08 09 10 11 12 13 14 15 16 17

18 19 20 21 22 23 24 25 26 27

28 29 30 31 32 33 34 35 36

Important Safety Instructions

Please keep this manual for future review.

This manual contains all instructions of safety, installation and operation for Midas

Y series Maximum Power Point Tracking (MPPT) controller ("the controller" as

referred to in this manual).

General Safety Information

Read carefully all the instructions and warnings in the manual before

installation.

No user serviceable components inside the controller. DO NOT disassemble or

attempt to repair the controller.

Mount the controller indoors. Avoid exposure the components and do not allow

water to enter the controller.

Install the controller in a well ventilated place. The controller’s heat sink may

become very hot during operation.

Suggest installing appropriate external fuses/breakers.

Make sure to switch off all PV array connections and the battery fuse/breakers

before controller installation and adjustment.

Power connections must remain tight to avoid excessive heating from loose

connection.

01 02 03 04 05 06 07

08 09 10 11 12 13 14 15 16 17

18 19 20 21 22 23 24 25 26 27

28 29 30 31 32 33 34 35 36

01 02 03 04 05 06 07

08 09 10 11 12 13 14 15 16 17

18 19 20 21 22 23 24 25 26 27

28 29 30 31 32 33 34 35 36

CONTENTS

1. General Information

1.1 Overview

1.2 Characteristics

1.3 Product Classification

2. Installation Instructions

2.1 General Installation Notes

2.2 PV Array Requirements

2.3 Wire Size

2.4 Mounting

3. Adanced Display unit

4. Control Parameters Setting

4.1 Battery types

4.1.1 Support battery types

4.1.2 Battery Voltage Control Parameters

4.1.3 Settings

4.2 Load working modes

4.2.1 LCD setting

4.2.2 R485 communication setting

4.3 Accessories (optional)

5. Protections, Troubleshooting and Maintenance

5.1 Protection

5.2 Troubleshooting

5.3 Maintenance

6. Technical Specifications

Annex I Conversion Efficiency Curves

Annex II Mechanical Dimension Diagram

01

01

02

03

03

03

04

05

07

11

16

16

16

17

19

20

20

21

23

24

24

27

28

29

31

34

1. General Information

1.1 Overview

Midas Y series controller adopt the advanced MPPT control algorithm, it can

minimize the maximum power point loss rate and loss time, quickly track the

maximum power point(MPP) of the PV array and obtain the maximum energy from

solar array under any conditions; and it can increase the ratio of energy utilization

in the solar system by 20%-30% compared with PWM charging method.

Limiting the charging power & current and reducing charging power functions

ensure the system stable with over PV modules in high temperature environment.

IP33 Ingress protection and isolated RS485 design further improve the controller’s

reliability and meet the different application requirements.

Midas Y series controller owns self-adaptive three-stage charging mode based on

digital control circuit, which can effectively prolong the lifespan of battery and

significantly improve the system performance. It also has comprehensive electronic

protection for overcharge, overdischarge, PV & battery reverse polarity etc, to

ensure the solar system more reliable and more durable. This controller can be

widely used for RV, household system, field monitoring and many other applications.

CE certification(LVD EN/IEC62109,EMC EN61000-6-1/3)

100% charging and discharging in working environment temperature range

High quality and low failure rate components of ST or IR to ensure service life

Advanced MPPT technology & ultra-fast tracking speed guarantee tracking

efficiency up to 99.5%

Maximum DC/DC transfer efficiency is as high as 98.5%★, full load efficiency is

up to 97.2%★

Advanced MPPT control algorithm to minimize the MPP lost rate and lost time

Accurate recognizing and tracking of multi-peaks maximum power point

Wide MPP operating voltage range

Support the lead-acid and lithium batteries, programmable temperature

compensation

Limit charging power & current over rated value

Real-time energy statistics functiont

Power reduction automatically over temperature value

Multiple load work modes

Comprehensive electronic protection

Features:

01 02 03 04 05 06 07

08 09 10 11 12 13 14 15 16 17

18 19 20 21 22 23 24 25 26 27

28 29 30 31 32 33 34 35 36

1. General Information

1.1 Overview

1.2 Characteristics

1.3 Product Classification

2. Installation Instructions

2.1 General Installation Notes

2.2 PV Array Requirements

2.3 Wire Size

2.4 Mounting

3. Adanced Display unit

4. Control Parameters Setting

4.1 Battery types

4.1.1 Support battery types

4.1.2 Battery Voltage Control Parameters

4.1.3 Settings

4.2 Load working modes

4.2.1 LCD setting

4.2.2 R485 communication setting

4.3 Accessories (optional)

5. Protections, Troubleshooting and Maintenance

5.1 Protection

5.2 Troubleshooting

5.3 Maintenance

6. Technical Specifications

Annex I Conversion Efficiency Curves

Annex II Mechanical Dimension Diagram

Isolated RS485 with 5V/200mA protected output for no power devices, with

Modbus protocol

Support monitoring and setting the parameters via APP or PC software

IP33▲Ingress protection

1.2 Characteristics

Figure 1 Product Characteristics

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

RTS port

PV Terminals

Battery Terminals

Load Terminals

★RS485 communication port

Terminal protection cover

Display units

Mounting Hole Φ5mm

★If the temperature sensor is short circuit or damaged, the controller will charge

or discharge according the voltage setting point at the default temperature setting

of 25 ºC(no temperature compensation).

01 02 03 04 05 06 07

08 09 10 11 12 13 14 15 16 17

18 19 20 21 22 23 24 25 26 27

28 29 30 31 32 33 34 35 36

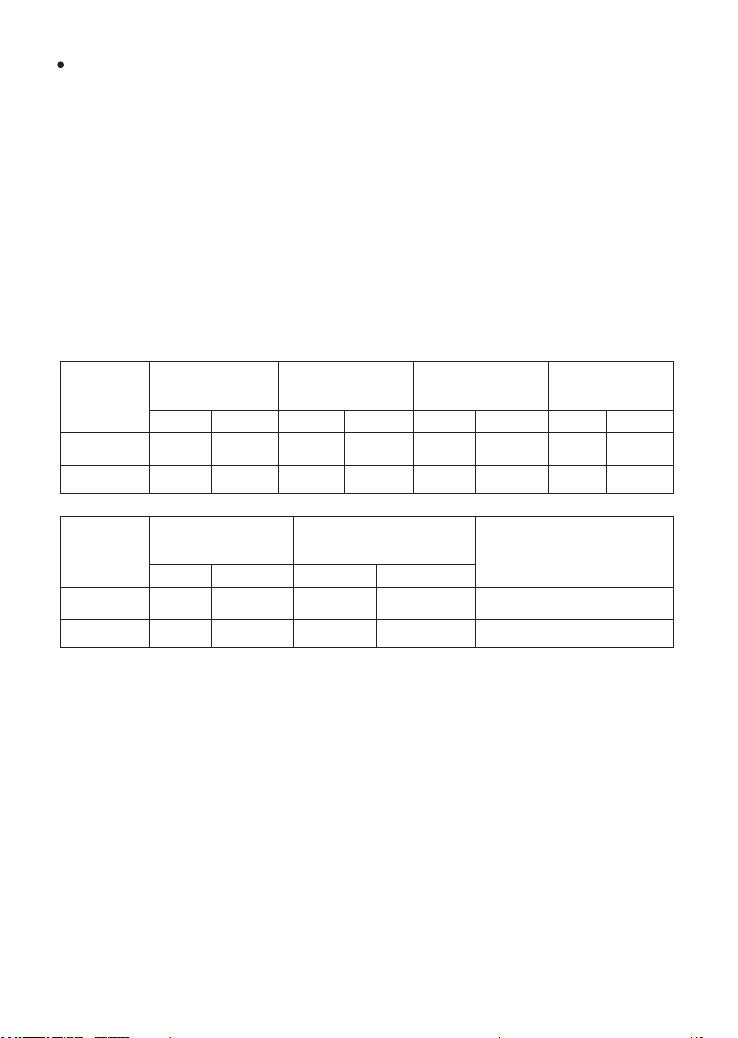

1.3 Product Classification

Model Picture Display

MY20

MY30

MY40

LED Indicators: PV & battery & load working status

Buttons: View or set the parameters or clear the error information.

LCD: PV display: voltage/current /generated energy/power

Battery display: voltage/current/temperature/capacity

Load display: voltage/current/power/consumed energy/load

working mode.

Please read the entire installation instructions to get familiar with the installation

steps before installation.

Be very careful when installing the batteries, especially flooded lead-acid battery.

Please wear eye protection, and have fresh water available to wash and clean

any contact with battery acid.

Keep the battery away from any metal objects, which may cause short circuit of

the battery.

Explosive battery gases may come out from the battery during charging, so

make sure ventilation condition is good.

Ventilation is highly recommended if mounted in an enclosure. Never install the

controller in a sealed enclosure with flooded batteries! Battery fumes from

vented batteries will corrode and destroy the controller circuits.

Loose power connections and corroded wires may result in high heat that can

melt wire insulation, burn surrounding materials, or even cause fire. Ensure tight

connections and use cable clamps to secure cables and prevent them from

swaying in mobile applications.

The controller can work with lead-acid battery and lithium battery within its

control scope.

Battery connection may be wired to one battery or a bank of batteries. The

following instructions refer to a singular battery, but it is implied that the battery

connection can be made to either one battery or a group of batteries in a battery

bank.

Multiple same models of controllers can be installed in parallel on the same

battery bank to achieve higher charging current. Each controller must have its

own solar module(s).

2. Installation Instructions

2.1 General Installation Notes

01 02 03 04 05 06 07

08 09 10 11 12 13 14 15 16 17

18 19 20 21 22 23 24 25 26 27

28 29 30 31 32 33 34 35 36

(1) Serial connection (string) of PV modules

As the core component of solar system, controller could be suitable for various

types of PV modules and maximize converting solar energy into electrical energy.

According to the open circuit voltage (Voc) and the maximum power point voltage

(VMpp) of the MPPT controller, the series number of different types PV modules

can be calculated. The below table is for reference only.

Select the system cables according to 5A/mm2 or less current density in

accordance with Article 690 of the National Electrical Code, NFPA 70.

MY20/MY30/MY40:

12V 4 2 2 1 2 1 2 1

24V 4 3 2 2 2 2 2 2

36 cell

Voc<23V

48 cell

Voc<31V

54 cell

Voc<34V

60 cell

Voc<38V

Max Best Max Best Max Best Max Best

System

voltage

12V 2 1 1 1 1

24V 2 1 1 1 1

72 cell Voc<46V 96 cell Voc<62V

Max Best Max Best

System

voltage

Thin-Film Module

Voc>80V

NOTE: The above parameter values are calculated under standard test conditions

(STC (Standard Test Condition):Irradiance 1000W/m2,Module Temperature 25

℃,Air Mass1.5.)

01 02 03 04 05 06 07

08 09 10 11 12 13 14 15 16 17

18 19 20 21 22 23 24 25 26 27

28 29 30 31 32 33 34 35 36

(2) Maximum PV array power

The MPPT controller has the function of charging current/power-limiting, that is,

during the charging process, when the charging current or power exceeds the

rated charging current or power, the controller will automatically limit the

charging current or power to the rated range, which can effectively protect the

charging parts of controller, and prevent damages to the controller due to the

connection of some over-specification PV modules. The actual operation of PV

array is as follows:

2.2 PV Array Requirements

Condition 1:

Actual charging power of PV array ≤ Rated charging power of controller

Condition 2:

Actual charging current of PV array ≤ Rated charging current of controller

When the controller operates under “Condition 1”or“Condition 2”, it will carry out

the charging as per the actual current or power; at this time, the controller can work

at the maximum power point of PV array.

WARNING: When the power of PV is not greater than the rated

charging power, but the maximum open-circuit voltage of PV array is

more than 100V (at the lowest environmental temperature), the

controller may be damaged.

Condition 3:

Actual charging power of PV array>Rated charging power of controller

Condition 4:

Actual charging current of PV array>Rated charging current of controller

When the controller operates under “Condition 3”or“Condition 4”,it will carry out

the charging as per the rated current or power.

WARNING: When the power of PV module is greater than the rated

charging power, and the maximum open-circuit voltage of PV array is

more than 100V (at the lowest environmental temperature), the

controller may be damaged.

According to “Peak Sun Hours diagram”, if the power of PV array exceeds the rated

charging power of controller, then the charging time as per the rated power will be

prolonged, so that more energy can be obtained for charging the battery. However,

in the practical application, the maximum power of PV array shall be not greater

than 1.5 x the rated charging power of controller. If the maximum power of PV

array exceeds the rated charging power of controller too much, it will not only

cause the waste of PV modules, but also increase the open-circuit voltage of PV

array due to the influence of environmental temperature, which may make the

probability of damage to the controller rise. Therefore, it is very important to

configure the system reasonably. For the recommended maximum power of PV

array for this controller, please refer to the table below:

01 02 03 04 05 06 07

08 09 10 11 12 13 14 15 16 17

18 19 20 21 22 23 24 25 26 27

28 29 30 31 32 33 34 35 36

Model

Rated Charge

Current

Rated Charge

Power

Max. PV Array

Power

Max. PV open circuit

voltage

MY20

MY30

MY40

260W/12V

520W/24V

390W/12V

780W/24V

520W/12V

1040W/24V

390W/12V

780W/24V

580W/12V

1170W/24V

780W/12V

1560W/24V

20A

30A

40A

92V

100V

①

②

① At 25℃environment temperature

② At minimum operating environment temperature

2.3 Wire Size

The wiring and installation methods must conform to all national and local electrical

code requirements.

PV Wire Size

Since PV array output can vary due to the PV module size, connection method or

sunlight angle, the minimum wire size can be calculated by the Isc* of PV array.

Please refer to the value of Isc in the PV module specification. When PV modules

connect in series, the Isc is equal to a PV modules Isc. When PV modules connect in

parallel, the Isc is equal to the sum of the PV modules’Isc. The Isc of the PV array

must not exceed the controller’s maximum PV input current. Please refer to the

table as below:

NOTE: All PV modules in a given array are assumed to be identical.

*Isc=short circuit current(amps) Voc=open circuit voltage.

Model Max. PV input current Max. PV wire size*

MY20

MY30

MY40

20A

30A

40A

6mm /10AWG

10mm /8AWG

16mm /6AWG

2

2

2

*These are the maximum wire sizes that will fit the controller terminals.

CAUTION: When the PV modules connect in series, the open circuit

voltage of the PV array must not exceed 92V at 25℃environment

temperature.

01 02 03 04 05 06 07

08 09 10 11 12 13 14 15 16 17

18 19 20 21 22 23 24 25 26 27

28 29 30 31 32 33 34 35 36

Battery and Load Wire Size

The battery and load wire size must conform to the rated current, the reference

size as below:

Model

Rated Charge

Current

Rated discharge

current Battery wire size Load wire

size

MY20

MY30

MY40

20A

30A

40A

20A

30A

40A

6mm /10AWG

10mm /8AWG

16mm /6AWG

2

2

2

6mm /10AWG

10mm /8AWG

16mm /6AWG

2

2

2

CAUTION: The wire size is only for reference. If there is a long distance

between the PV array and the controller or between the controller and

the battery, larger wires can be used to reduce the voltage drop and

improve performance.

CAUTION: For the battery, the recommended wire will be selected

according to the conditions that its terminals are not connected to any

additional inverter.

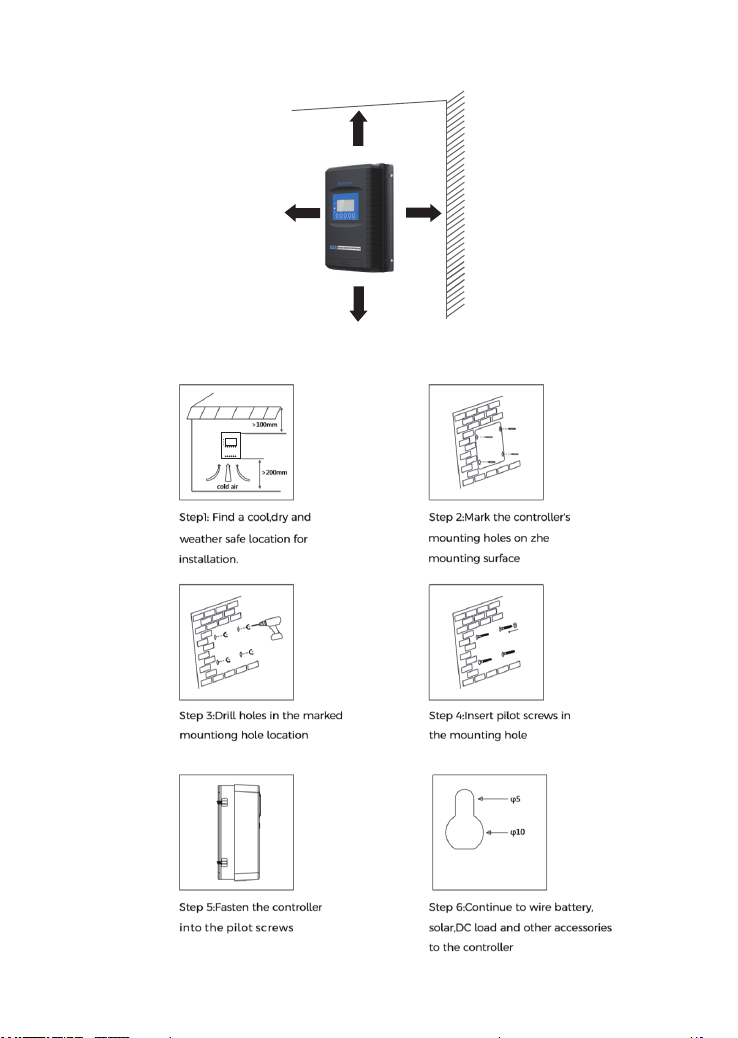

2.4 Mounting

WARNING: Risk of explosion! Never install the controller in a sealed

enclose with flooded batteries! Do not install in a confined area where

battery gas can accumulate.

WARNING: Risk of electric shock! When wiring the solar modules, the

PV array can produce a high open circuit voltage, so turn off the

breaker before wiring and be careful when wiring.

CAUTION:The controller requires at least 150mm of clearance above

and below for proper air flow. Ventilation is highly recommended if

mounted in an enclosure.

01 02 03 04 05 06 07

08 09 10 11 12 13 14 15 16 17

18 19 20 21 22 23 24 25 26 27

28 29 30 31 32 33 34 35 36

Installation Procedure:

Mounting Instruction

Figure 2-1 Mounting

150mm

150mm 150mm

150mm

01 02 03 04 05 06 07

08 09 10 11 12 13 14 15 16 17

18 19 20 21 22 23 24 25 26 27

28 29 30 31 32 33 34 35 36

Step 1: Determination of Installation Location and Heat-dissipation Space

Determination of installation location: The controller shall be installed in a place

with sufficient air flow through the radiators of the controller and a minimum

clearance of 150 mm from the upper and lower edges of the controller to ensure

natural thermal convection. Please see Figure 2-1: Mounting

CAUTION: If the controller is to be installed in an enclosed box, it is

important to ensure reliable heat dissipation through the box.

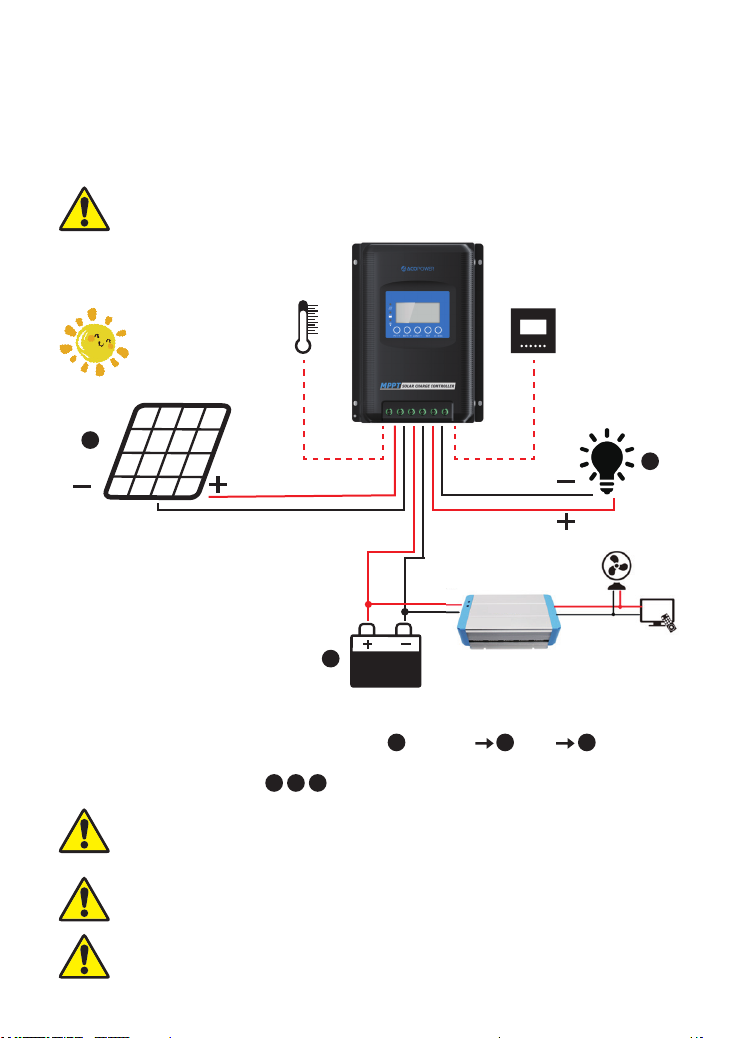

Figure 2-2 Schematic of wiring diagram

Step 2:Connect the system in the order of battery load PV array

in accordance with Figure 2-2,”Schematic Wiring Diagram” and disconnect the

system in the reverse order .

1

1

1

2

2

2

3

3

3

CAUTION: While wiring the controller do not close the circuit breaker or

fuse and make sure that the leads of "+" and "-" poles are connected

correctly.

CAUTION: A fuse which current is 1.25 to 2 times the rated current of the

controller, must be installed on the battery side with a distance from the

battery not greater than 150 mm.

CAUTION: If the controller is to be used in an area with frequent lightning

strikes or unattended area, it must install an external surge arrester.

01 02 03 04 05 06 07

08 09 10 11 12 13 14 15 16 17

18 19 20 21 22 23 24 25 26 27

28 29 30 31 32 33 34 35 36

CAUTION: If an inverter is to be connected to the system, connect the

inverter directly to the battery, not to the load side of the controller.

Step 3:Grounding

Midas Y series is a common-negative controller, where all the negative terminals of

PV array, battery and load can be grounded simultaneously or any one of them will

be grounded. However, according to the practical application, all the negative

terminals of PV array, battery and load can also be ungrounded, but the grounding

terminal on its shell must be grounded, which may effectively shield the electro-

magnetic interference from the outside, and prevent some electric shock to human

body due to the electrification of the shell.

CAUTION: For common-negative system, such as motorhome, it is

recommended to use a common-negative controller; but if in the

common-negative system, some common-positive equipment are used,

and the positive electrode is grounded, the controller may be damaged.

Step 4:Connect accessories

Connect the remote temperature sensor cable

Temperature Sensor Remote Temperature Sensor

Cable (Optional)

Connect the remote temperature sensor cable to the interface ①and place the

other end close to the battery.

CAUTION: If the remote temperature sensor is not connected to the

controller,, the default setting for battery charging or discharging

temperature is 25 °C without temperature compensation.

Connect the accessories for RS485 communication

Refer to chaper4 “Control Parameters Setting”.

Step 5:Powered on the controller

Closing the battery fuse will switch on the controller. Then check the status of the

battery indicator (the controller is operating normally when the indicator is lit in

green). Close the fuse and circuit breaker of the load and PV array. Then the system

will be operating in the preprogrammed mode.

CAUTION: If the controller is not operating properly or the battery

indicator on the controller shows an abnormality, please refer to 5.2

“Troubleshooting”

01 02 03 04 05 06 07

08 09 10 11 12 13 14 15 16 17

18 19 20 21 22 23 24 25 26 27

28 29 30 31 32 33 34 35 36

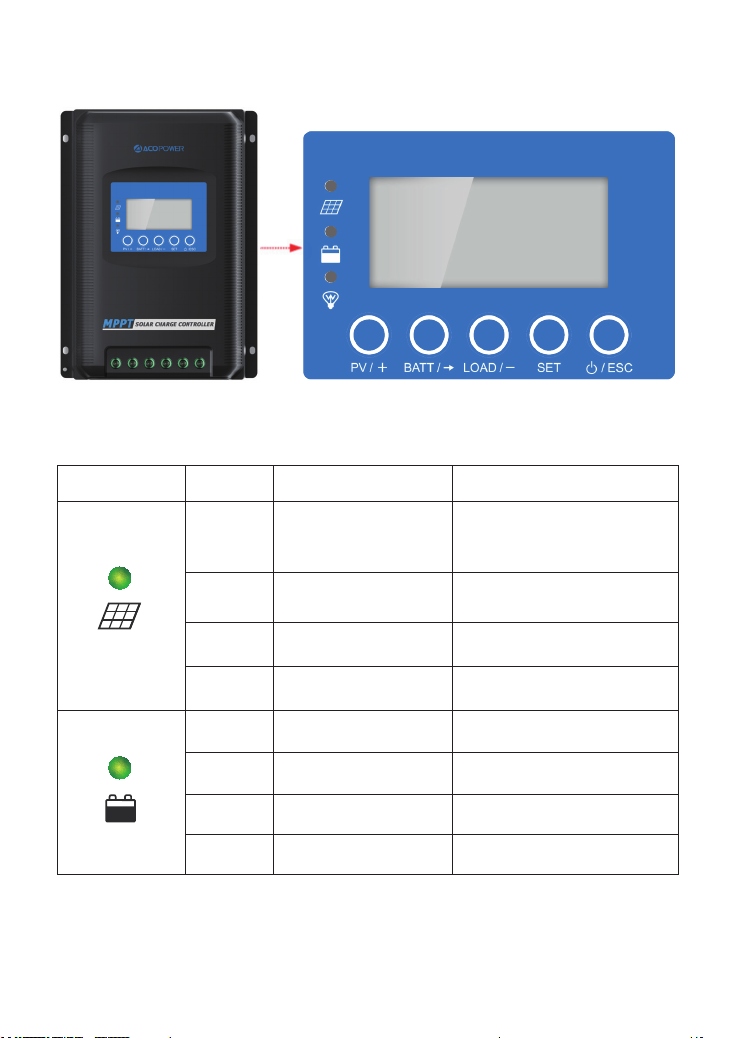

3. Adanced Display unit

(1) Indicator

Green

Green

Green

Green

Green

Green

Green

Orange

Indicator Color Status Instruction

On Solid

OFF

Slowly Flashing(1Hz)

Fast Flashing(4Hz)

PV connection normal but low

voltage(low irradiance) from

PV, no charging

No PV voltage(night time) or

PV connection problem

In charging

PV Over voltage

On Solid

On Solid

Slowly Flashing(1Hz)

Fast Flashing(4Hz)

Normal

Full

Over voltage

Under voltage

01 02 03 04 05 06 07

08 09 10 11 12 13 14 15 16 17

18 19 20 21 22 23 24 25 26 27

28 29 30 31 32 33 34 35 36

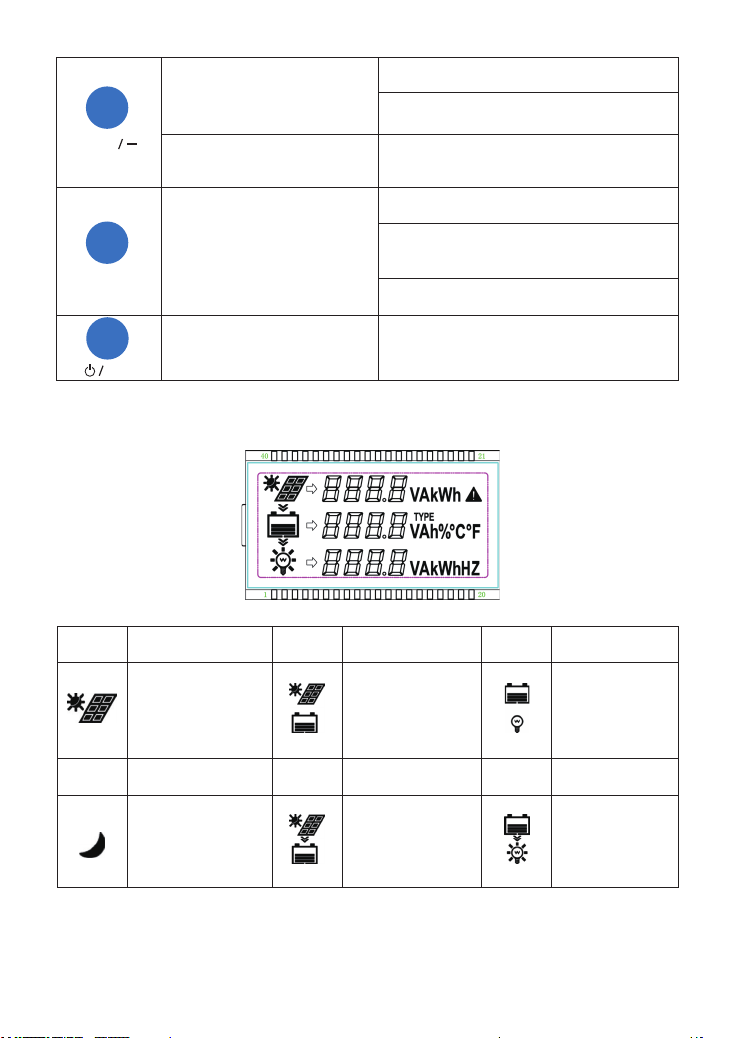

Red

Red

Yellow

Yellow

Indicator Color Status Instruction

On Solid

Slowly Flashing(1Hz)

Over discharged

Battery Overheating

Lithium battery Low tempera-

ture①

On Solid

OFF

Load ON

Load OFF

PV&BATTLED fast flashing

Controller Overheating

System voltage error②

① When a lead-acid battery is used, the controller doesn’t have the low temperature

protection.

② When a lithium battery is used, the system voltage can’t be identified

automatically

(2) Button

Press the button

Press the button and

hold 5s

PV browsing interface

Setting data +

Setting the LCD cycle time

Press the button

BATT browsing interface

Cursor displacement during setting

Press the button and

hold 5s

Setting the battery type, battery

capacity level and temperature unit.

PV

BATT

01 02 03 04 05 06 07

08 09 10 11 12 13 14 15 16 17

18 19 20 21 22 23 24 25 26 27

28 29 30 31 32 33 34 35 36

Press the button

Press the button and

hold 5s

Controller load browsing interface

Setting data -

Setting the load working mode

Press the button

Enter into setting interface

Setting interface switch to the

browsing interface

Press the button Exit the setting interface

Setting parameter as enter button

(3) Display

Icon Information Icon Information Icon Information

Icon Information Icon Information Icon Information

Day Not charging Not discharging

Night Charging Discharging

LOAD

ESC

SET

01 02 03 04 05 06 07

08 09 10 11 12 13 14 15 16 17

18 19 20 21 22 23 24 25 26 27

28 29 30 31 32 33 34 35 36

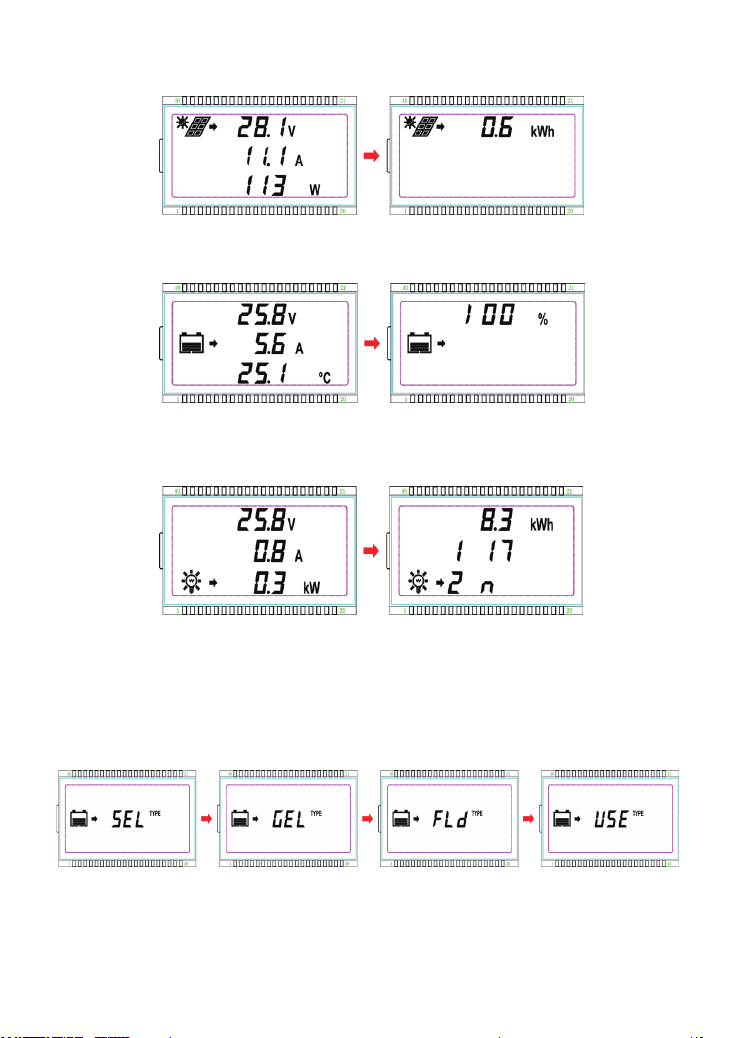

1) PV parameters

Display:Voltage/Current/Temperature/Battery capacity level

2) Battery parameters

Display:Voltage/Current/Temperature/Battery capacity level

3)Load parameters

Display:Voltage/Current/Power/ Consumed energy/Load working mode-Timer1/

Load working mode-Timer2

(4)Setting parameters

1)Battery type

Sealed (Default) Gel Flooded User

01 02 03 04 05 06 07

08 09 10 11 12 13 14 15 16 17

18 19 20 21 22 23 24 25 26 27

28 29 30 31 32 33 34 35 36

Operation:

Step 1: Press the button for the setting interface.

Step 2: Press the button and hold 5s for the battery type interface.

Step 3: Press the or button to choose the battery type.

Step 4: Press the button to confirm the battery type.

CAUTION:Please refer to chapter 4.1 for the battery control voltage

setting, when the battery type is User.

2)Battery capacity

Operation:

Step 1: Press the button for the setting interface.

Step 2: Press the button and hold 5s for the battery type interface.

Step 3: Press the button for the battery capacity interface.

Step 4: Press the or button to set the battery capacity.

Step 5: Press the button to confirm the parameters.

3) Temperature units

Operation:

Step 1: Press the button for the setting interface.

Step 2: Press the button and hold 5s for the battery type interface.

Step 3: Press the button twice for the temperature unit interface.

Step 4: Press the or button to set the temperature units.

Step 5: Press the button to confirm the parameters.

BATT

PV

PV

LOAD

LOAD

SET

BATT

SET

SET

SET

PV LOAD

BATT

SET

SET

SET

SET

01 02 03 04 05 06 07

08 09 10 11 12 13 14 15 16 17

18 19 20 21 22 23 24 25 26 27

28 29 30 31 32 33 34 35 36

4) LCD cycle time

NOTE: The LCD cycle default time is 2s,the setting time range is 0~20s.

Operation:

Step 1: Press the button for the setting interface.

Step 2: Press the button and hold 5s for the LCD cycle time interface.

Step 3: Press the or button to set the LCD cycle time.

Step 4: Press the button to confirm the parameters.

5) Local load working mode

Operation:

Step 1: Press the button for the setting interface.

Step 2: Press the button and hold 5s for the load working mode interface.

Step 3: Press the or button to set the working mode.

Step 4: Press the button to confirm the parameters.

NOTE:Please refer to chapter 4.2 for the load working mode.

4. Control Parameters Setting

4.1 Battery types

4.1.1 Support battery types

PV

PV

LOAD

SET

SET

PV LOAD

LOAD

SET

SET

01 02 03 04 05 06 07

08 09 10 11 12 13 14 15 16 17

18 19 20 21 22 23 24 25 26 27

28 29 30 31 32 33 34 35 36

1 Lead-acid battery

2 Lithium battery

Sealed(default)

Gel

Flooded

User

LiFePO4(4S/12V;8S/24V)

Li(NiCoMn)O2 (3S/12V;6S/24V)

User

CAUTION: When the default battery type is selected, the battery voltage

control parameters will be set by default and can’t be changed. To

change these parameters, select "User" battery type.

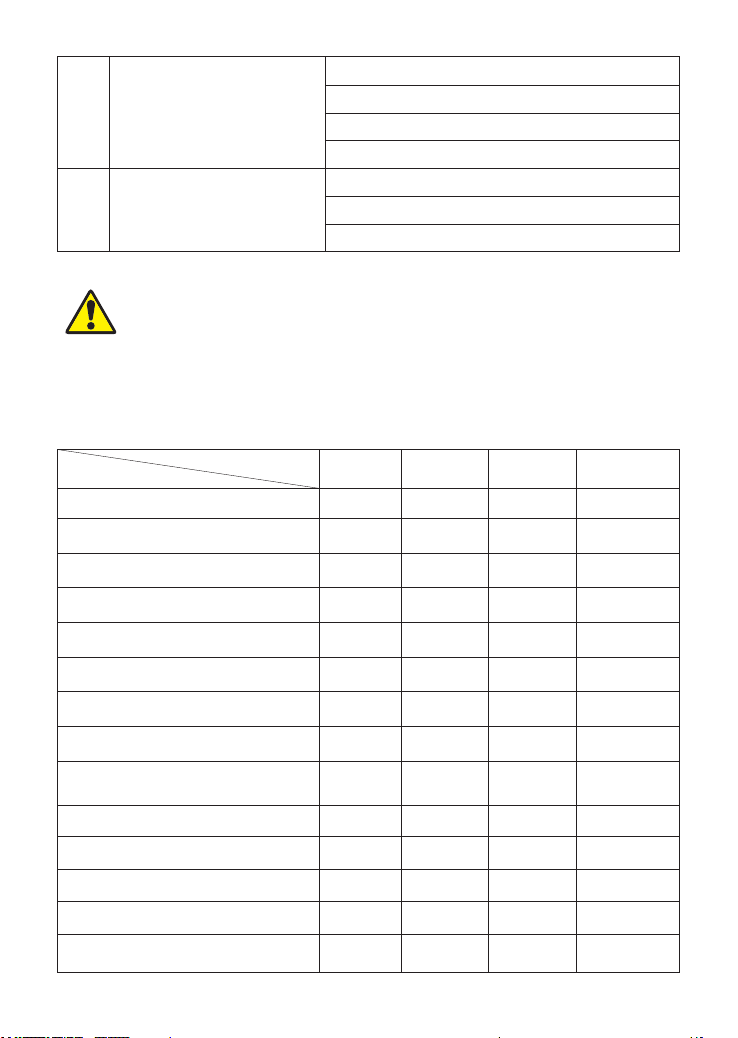

4.1.2 Battery Voltage Control Parameters

Lead-acid battery parameters

The parameters are in 12V system at 25 ºC, please double the values in 24V system.

Voltage

Battery type Sealed Gel Flooded User

Over Voltage Disconnect Voltage 16.0V 16.0V 16.0V 9~17V

Charging Limit Voltage 15.0V 15.0V 15.0V 9~17V

Over Voltage Reconnect Voltage 15.0V 15.0V 15.0V 9~17V

Equalize Charging Voltage 14.6V —— 14.8V 9~17V

Boost Charging Voltage 14.4V 14.2V 14.6V 9~17V

Float Charging Voltage 13.8V 13.8V 13.8V 9~17V

Boost Reconnect Charging Voltage 13.2V 13.2V 13.2V 9~17V

Low Voltage Reconnect Voltage 12.6V 12.6V 12.6V 9~17V

Under Voltage Warning

Reconnect Voltage

Under Voltage Warning Voltage 12.0V 12.0V 12.0V 9~17V

Low Voltage Disconnect Voltage 11.1V 11.1V 11.1V 9~17V

Discharging Limit Voltage 10.6V 10.6V 10.6V 9~17V

Equalize Duration 120 min —— 120 min 0~180 min

Boost Duration 120 min 120 min 120 min 10~180 min

12.2V 12.2V 12.2V 9~17V

01 02 03 04 05 06 07

08 09 10 11 12 13 14 15 16 17

18 19 20 21 22 23 24 25 26 27

28 29 30 31 32 33 34 35 36

This manual suits for next models

3

Table of contents

Other ACOPOWER Inverter manuals