3

Gather the required tools and parts before starting

installation. Read and follow the instructions provided with

any tools listed here.

TOOLS AND PARTS

Tools Needed

¼” nut driver

Level

Screwdriver

Tape Measure

Sealant

UL listed wire nuts

Parts Needed

Check local codes, check existing electrical supply, and read

“Ductwork Requirements,” and “Electrical Requirements,”

before purchasing parts.

NOTE: When the unit is installed in a very humid space and

used in cooling applications, excessive sweating may occur on

outside of unit. To prevent excessive sweating wrap unit with

1” fiberglass insulation. All openings should be sealed to

prevent air leakage that could cause condensate to form inside

the cabinet.

If installed in an unconditioned space, sealant should be

applied around the electrical wires, refrigerant tubing,

and condensate lines where they enter the cabinet.

Electrical wires should be sealed on the inside where

they exit the conduit opening. Sealant is required to

prevent air leakage and from condensate from forming

inside the blower, control box, and on the electrical

controls.

The blower section and its complementing coil must be

installed in such a way as to allow free access to the

blower/control compartment.

The blower section and its complementing coil must be

installed with a ¾” drop in the horizontal position towards

the drain pan to ensure proper condensate drainage.

The blower section and coil should also be tilted ½” from

back to front toward the drain line.

LOCATION REQUIREMENTS

IMPORTANT

The Clean Air Act of 1990 bans the intentional venting of

refrigerant (CFC’s and HFC’s) as of July 1, 1992.

Approved methods of reclaiming must be followed.

Fines and/or incarceration may be levied for non-

compliance.

Unpacking

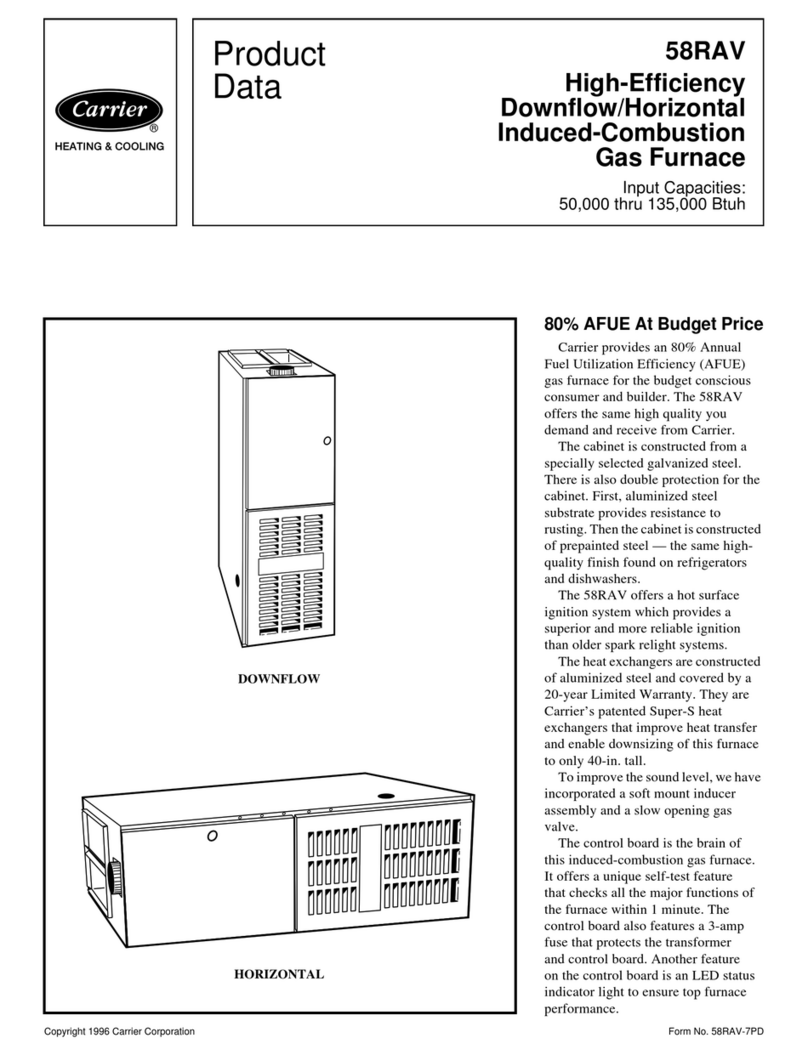

The blower section is completely factory assembled, and all

components are performance tested. Each unit consists of a

blower assembly and controls, in an insulated galvanized steel

factory finished enclosure. Knockouts are provided for

electrical wiring entrance.

1. Check the unit rating plate to confirm specifications are

as ordered.

2. Upon receipt of equipment, thoroughly inspect it for

possible shipping damage. Closely examine the unit

inside the carton if the carton is damaged.

3. If damage is found, it should be noted on the carrier’s

freight bill. Damage claims should be filed with carrier

immediately. Claims of shortages should be filed with the

seller within 5 days.

NOTE: If any damages are discovered and reported to the

carrier, do not install the unit because your claim may be

denied.

Location

The blower section should be centered in its locations and

may be installed in a closet, alcove, utility room, base-

ment, crawl space or attic. Minimum clearances must be

met.

If the unit is installed in an unconditioned space such as

an attic or crawl space, you must ensure that the area

provides sufficient air circulation to prevent moisture

collections on the cabinet during high dew point condi-

tions.

Ductwork

Install the conditioned air plenum, ducts and air filters

(not provided) in accordance with NFPA 90B Standard for

the installation of Warm Air Heating and Air-Conditioning

Systems (latest edition).

Air filters must be listed as Class 2 furnace air filters.

Supply and return ductwork must be adequately sized

to meet the system’s air requirements and static

pressure capabilities. Ductwork should be insulated

with a minimum of 1” thick insulation with a vapor

barrier in conditioned areas or 2” minimum in uncondi-

tioned areas.

If installing the blower section without an evaporator

coil, the supply plenum should be the same size as the

flanged opening provided around the blower outlet and

should extend ideally at least 3 ft. from the blower

section before turning or branching off plenum into duct

runs. The plenum forms an extension of the blower

housing and minimizes air expansion losses from the

blower.

INSTALLATION INSTRUCTIONS

![Roberts Gorden UHD[X][S][R] 150 Installation & operation Roberts Gorden UHD[X][S][R] 150 Installation & operation](/data/manuals/2k/4/2k4sh/sources/roberts-gorden-uhd-x-s-r-150-manual.jpg)