Aerox Sky-Ox User manual

Aerox®Aviation Oxygen Systems, LLC

12871 Trade Way Drive, Suite 8

Bonita Springs, FL 34135

www.aerox.com

Page 2

Thank You

ThankyouforinvestinginaSky-Ox®PortableSystemfromAerox Aviation

Oxygen Systems. Your Portable Oxygen System, includingthe Click &

Breath™regulatorintroducedin2008,is designed,engineered, and

manufactured to the highest quality standards in the industry and we

are committed to serving your needs with equally high customer

service.

Table of Contents

Page Subject Content

3 ................... System Components

4 ................... Operating Instructions

7 ................... Refilling the Aluminum Cylinder

8 ................... Refilling the Steel Cylinder

9 ................... After Using the System

10 ................... Oxygen Cylinder Maintenance

13.................... Care of Your Portable Oxygen System

13 ................. Care of Your Oxygen Cannula

14 ................. Table 1: Capacity Table

14 ................. Table 2: Volume Content Table

REGISTER YOUR SYSTEM

Registering your purchase will help us keep you up to date on product

information and will activate your warranty. To register your product

within 60 days of purchase please go visit us at:

https://www.aerox.com/warranty/

Aerox®Aviation Oxygen Systems, LLC

12871 Trade Way Drive, Suite 8

Bonita Springs, FL 34135

www.aerox.com

Page 3

System Components

The cylinder contains high pressure oxygen - a strong oxidizing

agent and improper use of Oxygen Breathing Equipment can be

dangerous!

Do not use this device until you are familiar with its proper

operations. Do not smoke! Keep away from open flame, oil,

grease, or other combustibles that could contribute to violent

combustive action. Use in well-ventilated area.

Cylinder contains high pressure (up to 2,000 pounds per square

inch- psi) oxygen. Do not drop and protect the unit from shock or

damage. Keep away from anyone who may not be familiar with

the hazards of its improper use or handling.

Maintain equipment using an Aerox-Approved FAA Authorized

Aviation Oxygen Repair Station. Follow their recommendations

on proper use.

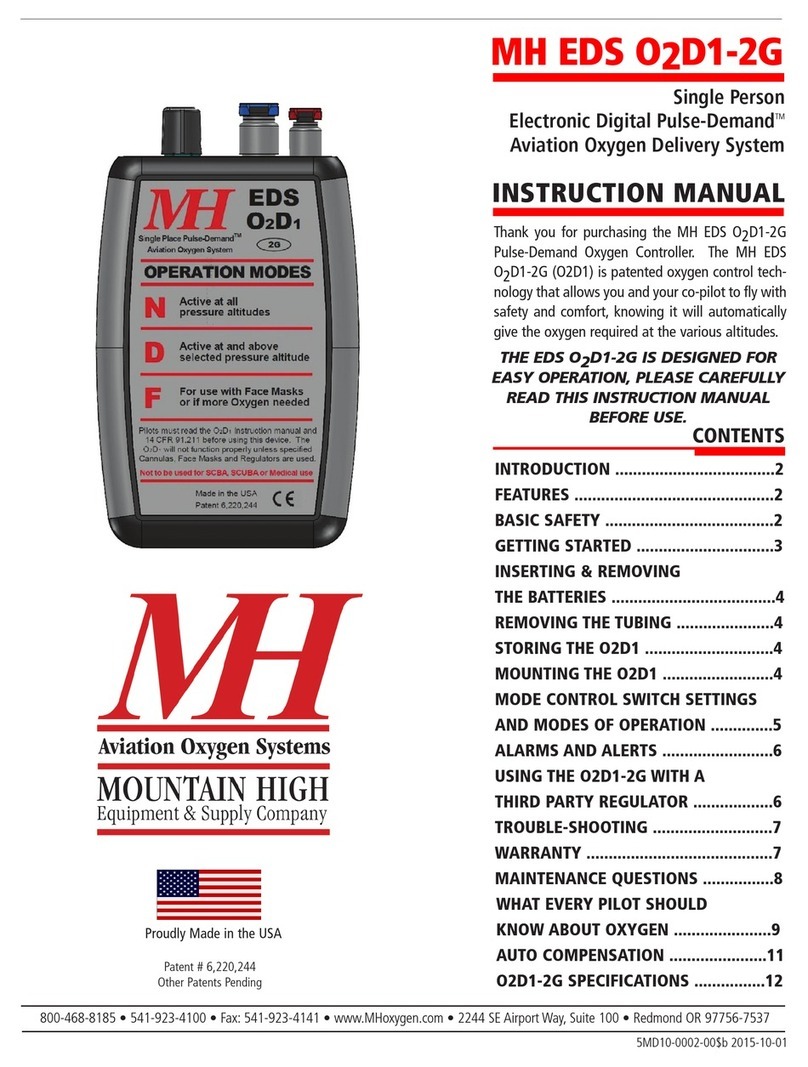

(7) Flow Adjustment Control For

setting altitude or flow setting.

Do Not use as a shut off

valve.

(6) Quick Disconnect Port for

Cannula or Mask

(5) Regulator

Available with 2-port or 4 port receptors

(4) Hand Tightening Grip

(3) On/Off Valve

(2) Cylinder Content Gauge

(1) Pressurized Cylinder or Tank

!

DANGER

!

Aerox®Aviation Oxygen Systems, LLC

12871 Trade Way Drive, Suite 8

Bonita Springs, FL 34135

www.aerox.com

Page 4

Operating Instructions

Referring to the illustration above, the Sky-Ox® portable

oxygen system includes the following components:

•a cylinder (1) with an On/Off Valve (3)

•a cylinder pressure gauge (2)

•Click-a-Breath Regulator (5) with either a 2-port

or 4- port Quick Disconnect female receptor (6)

that will accept a male fitting of a cannula or

mask in each port.

Sky-Ox®Portable Oxygen Systems are shipped with two or four pendent style

Oxysaver® Cannulas (see photo) and one mask. Each Sky-Ox® cannula comes

complete and assembled with a connector, flow-indicator, and pendant cannula.

The pendent style offers more freedom plus comfort and the ability to drink water,

coffee, a can of soda, or to eat a sandwich .

The size of cylinder you specified is based on projected flight hours of use. Based

on your order, the cylinder arrives either filled with oxygen or empty . If empty, the

cylinder must be filled with aviator-grade oxygen before using.

Ready to Use: Filled Cylinders are ready to use.

1.

Turn the On-Off Valve (3) counterclockwise until fully on. Turn clockwise to

shut it off.

2.

Check the cylinder’s content level on the cylinder Pressure gauge (2). This

gauge will indicate how much oxygen remains in the cylinder. If the indicator

needle is in the red area, the cylinder is getting very low on oxygen. If the

indicator needle is all the way to 2,000 psi, the cylinder is full. (All cylinders

filled with 2000 psi) . Do not over pressurize the cylinder.

3.

Activate the oxygen flow with the regulator’s Flow Adjustment Control knob

(7) by turning it clockwise. You will hear it click between precise oxygen flow

settings from .3 LPM to 5.0 LPM (see table or on the Regulator’s body).

4.

Insert the quick disconnect element onthe mask or cannula into

anopenport(6)

ontheregulatorhead.Oxygenwillnotflow

untilthefitting onthebreathing

devicesaresecurely connected.

Theoxygenflowwillstopwhenthecannula

ormaskisdisconnectedfromtheport.Itdoesnotmatterwhetherone,two,

three orfourcannulaareconnectedbecauseonlythoseconnected

will

dispenseoxygen.

Aerox®Aviation Oxygen Systems, LLC

12871 Trade Way Drive, Suite 8

Bonita Springs, FL 34135

www.aerox.com

Page 5

5.

Ifyouareusing the Oxysaver®

Cannula, set it to

the flow rate indicatedonthe

Regulator.

Note:

For simplicity, it is recommended that the flow indicator be set at (0.5 liters

per minute) for altitudes up to 15,000 feet. If you are flying at a lower

altitude, you can adjust it downward if desired –always verify your blood

oxygen saturation (SpO2) with a pulse oximeter.

You do not need to adjust the Regulator when multiple ports are being used.

The regulator automatically compensates when additional (1-2-or 3)

breathing units are attached. A setting of (0.5) liters per minute will deliver

0.5 liters of oxygen from each port.

The following table is

found on the Regulator

Liters per minute when using

Oxysaver®Cannula

Mask

.3 LPM up to 10,000 FT.

1.0 LPM up to 10,000 FT.

.4 LPM - 12,000 FT.

1.5 LPM - 15,000 FT.

.5 LPM - 15,000 FT.

2.0 LPM - 20,000 FT.

.6 LPM - 18,000 FT.

2.5 LPM - 25,000 FT.

Altitude Gauge Settings

When Using The Oxysaver®

Cannula

Up to 10,000 feet

.3 Liters / minute

Up to 12,000 feet

.4 Liters / minute

Up to 15,000 feet

.5 Liters / minute

At 18,000 feet

.6 Liters / minute

Note: FAA recommends 1.8 Liters at 18,000

feet when using a mask or regular

cannula.

Aerox®Aviation Oxygen Systems, LLC

12871 Trade Way Drive, Suite 8

Bonita Springs, FL 34135

www.aerox.com

Page 6

6.

A flow indicator is located in line with the cannula. Iftheindicatorisred, thereis

nooxygenflowing.Ifthe indicatorisgreen,itindicatesthat

oxygenisflowingfrom

thecylinder to the cannula.

Sky-Ox® Flow Indicator (showing no-oxygen flow)

7.

Acannula(eitherapendentoramustachestyle)canbeused onlyupto18,000ft.

Above18,000ft.,youmustswitchoverto

amask.

8.

Whenusingthemask,settheflowadjustmentcontroltothe

altitude you are flying.

(See table on Regulator - also printed on

page5.) ByturningtheFlowAdjustment

Control(7)knobon top of the Regulator until the indicator number is properly

positioned.

Liters Per Minute indicator number readout on Regulator

Aerox®Aviation Oxygen Systems, LLC

12871 Trade Way Drive, Suite 8

Bonita Springs, FL 34135

www.aerox.com

Page 7

Refilling the Aluminum Cylinder

Do not use any tools –all fittings should be hand-tight. Always turn off the system

before proceeding with refilling the cylinder. Completely close the On/Off Valve (3)

before attempting to disconnect the regulator

Do Not Remove the On/Off Valve (3).

Remove the Regulator (5) from the valve by loosening the green Hand-Tightening

Grip (4) (see figure below) between the On/Off Valve and the Regulator. (Turn Grip

Counterclockwise. The valve is a standard fitting for oxygen (CGA 540) and no

tools are required.

Aerox recommends using only aviator grade oxygen. The oxygen supplier is

responsible for testing their storage and charging systems.

Aerox®Aviation Oxygen Systems, LLC

12871 Trade Way Drive, Suite 8

Bonita Springs, FL 34135

www.aerox.com

Page 8

To fill Aluminum Portable Cylinders

A standard oxygen filler line or pigtail is attached to the valve opening and the

On/Off Valve is opened for charging. Whenfully charged, the On/Off Valve (3) is

closed and the charging line disconnected.

When filling the cylinder, the oxygen supplier will inspect your cylinder and, if

needed, will hydrostatically test the unit. Note: Aluminum cylinder must be

hydrostatically tested every five years and steel cylinders every five years. The

oxygen supplier will label each cylinder when it is hydrostatically tested.

After cylinder is refilled, make sure the regulator assembly is reattached to the

cylinder valve and tighten securely with Hand Tightening Grip (4) - No wrench is

needed.

Refilling the Steel Cylinder

Use the same procedures for refilling steel cylinders asfor aluminum cylinders. See

above illustration for the location of On/Off Valve (3). To remove the Regulator for

refilling, loosen the hand tightening grip (4) between the On/Off Valve(3) and the

Regulator (5). The grip is located to the left of the On/Off Valve in the above

illustration.After refilling, make sure this Regulator (5) is securely fastened - hand

tightening (4) only needed. - No wrench is needed.

Aerox®Aviation Oxygen Systems, LLC

12871 Trade Way Drive, Suite 8

Bonita Springs, FL 34135

www.aerox.com

Page 9

After Using System

1. When finished using the Sky-Ox® portable oxygen system, turn the Flow

Adjustment Control ( 7 ) to zero (0).

2. Turn the On/Off Valve (3) off by turning the knob clockwise.

3. If you have removed all of the quick disconnect units, reinsert one to bleed-

off the oxygen still in the line. The flow indicator turns to red when no more

oxygen is flowing.

4. When the system will be inactive for more than 24 hours, it is recommended

that the system be shut down as described above.

Aerox®Aviation Oxygen Systems, LLC

12871 Trade Way Drive, Suite 8

Bonita Springs, FL 34135

www.aerox.com

Page 10

Oxygen Cylinder Maintenance

Initial Filling

Charge the oxygen cylinder as follows;

Slowly pressurize the cylinder to the rated regulator pressure. Do not exceed the

cylinders rated pressure.

Note: To prevent over heating, caused by compression, it is recommended that

filling be accomplished in stages as shown in Table 1. Each stage should take no

less than 3 minutes to accomplish with a 2 minute rest between each stage.

Stage

PSI

1

500

2

1000

3

1500

4

1800

5

2000

6

2250

TABLE 1

CAUTION

Keep Hands and Filling Equipment Clean And Free From Oil. Keep Away

From Flame Or Sources Of Ignition. Failure To Comply With All Cautions

Could Result In Injury And Death.

Routine Maintenance

•It is important to maintain positive pressure in oxygen cylinders at all

times.

•Do not allow the cylinder pressure to fall below 50 PSI if possible.

•A fully depleted oxygen cylinder may require a dry air or nitrogen

purge to remove moisture.

•Table 2 Provides Hydrostatic Test and Service Life

requirements for listed cylinders.

Aerox®Aviation Oxygen Systems, LLC

12871 Trade Way Drive, Suite 8

Bonita Springs, FL 34135

www.aerox.com

Page 11

Cylinder

Type

Hydrostatic Test &

Inspection Rqmt

Maximum

Service Life

DOT 3AL

Every 5 Years

Unlimited

6061T6 Alum

49 CFR § 180.209

DOT 3HT

Every 3 Years

24 Years

Steel

49 CFR § 180.209

DOT-E 8162

Every 5 Years

15 Years

Kevlar/Comp

49 CFR § 180.209

(10,000 Cycles)

DOT-E 10945

Every 5 Years

15 Years

Carbon/Comp

49 CFR § 180.209

(10,000 Cycles)

Cylinder Purge

Cylinder pressures below 50 PSI may allow air into the cylinder. Air contains

moisture and under certain temperature extremes can freeze and plug oxygen

ports and lines.

The most effective method to purge the cylinder of any suspected moisture is to

remove the regulator/valve and with the cylinder turned so the threads are

down, blow hot air (heat gun or hair dryer) into the cylinder for about 20 minutes

or until all moisture has evaporated.

Where a cylinder has been exposed to an extended period of low storage

pressure, a cleaning and inspection by a licensed maintenance facility is

recommended.

Re-Filling

Verify the condition and cleanliness of all ports and fittings prior to performing

re-filling operations.

When re-installing the regulator or valve, assure that the proper approved o-

ring or seal has been installed.

Charge the oxygen cylinder as discussed in Initial Filling.

Upon completion of filling operations, check for leakage using a liquid leak

detector or a mild soapy water formula.

Aerox®Aviation Oxygen Systems, LLC

12871 Trade Way Drive, Suite 8

Bonita Springs, FL 34135

www.aerox.com

Page 12

General

Fill only with Gaseous Aviators Breathing Oxygen, per MIL- PRF-27210.

Note that certain state, federal and international regulations may apply to the

handling and maintenance of oxygen cylinders based on installation and

application.

Further information regarding oxygen cylinder maintenance and use is available

upon request.

Aerox®Aviation Oxygen Systems, LLC

12871 Trade Way Drive, Suite 8

Bonita Springs, FL 34135

www.aerox.com

Page 13

Care of Your Portable Oxygen System

•If the temperature in the plane is expected to rise above 130oF, remove the

cylinder from the aircraft when not in use. (A padded carrying bag for your

system is available as an option —below.)

•If the temperature falls to, or expected to drop to minus 25oF, it is advisable

to remove the cylinder from the plane.

•Note padded carrying bag can be used to help secure the cylinder inside

the plane. Place both straps of the carrying bag around the seat and secure

tightly. The portable oxygen system will operate properly in either an upright

or a horizontal position.

•Always secure and restrain your system as a precaution should in- flight

turbulence be experienced.

Reminder: The system is under 2000 PSI of pressure when full. As a safety

measure, the regulator is equipped with a pressure relief valve that’s

designed to activate under a reduced pressure rate to depressurize the

cylinder.

Care of Your Oxygen Cannula

Do Not bend, fold, or crimp the clear hoses of the cannula because they may

become cracked or damaged.

To clean your cannula after use, wipe with a soft cloth and a soft non-detergent

soap. Do Not Use alcohol which may damage the unit. DO NOT SUBMERGE

THE CANNULA.

Replacement of the cannula is recommended after 3 years or 200 hours of use.

Aerox®Aviation Oxygen Systems, LLC

12871 Trade Way Drive, Suite 8

Bonita Springs, FL 34135

www.aerox.com

Page 14

System Capacity Table

Table 1: This table provides valuable capacity information relating to the

Sky Ox Portable Oxygen Systems.

Model

Number

Oxymizer Cannula

Duration Hours

at 15,000 Ft.

Cylinder

Capacity

With Mask

Duration Hours

at 15,000 Ft.

Approx.

Size (H X D)

Approx.

Weight

SK 12-6

5:28 hrs.

6 CU. FT. AL

1:49 hrs.

18 -1/2" x 3-1/4"

6 Lbs.

SK 12-9

8:07 hrs.

9 CU. FT. AL

2:45 hrs.

18-0" x 4-3/8"

7 Lbs.

SK 12-15

13:48 hrs.

15 CU. FT. AL

4:36 hrs.

24-0"x 4-3/8"

11 Lbs.

SK 12-24

22:42 hrs.

24 CU. FT. AL

7:34 hrs.

32-1/2" x 4-3/8"

14 Lbs.

SK 11-20

17:33 hrs.

20 CU. FT. Steel

5:51 hrs.

17-0" x 5-1/4"

15 Lbs.

SK 11-40

39:27 hrs.

40 CU. FT. Steel

13:09 hrs.

21-0" x 7"

28 Lbs.

SK 11-50

46:21 hrs.

50 CU. FT. Steel

15:27 hrs.

26-0" x 7"

36 Lbs.

Volume Content Table

Table 2: Content volume of oxygen in each cylinder when filled to capacity at 2000 psi.

Oxygen Content By System

Model When Full (2000 psi)

Model Number

Liters

SK-11-50

1415

SK-11-40

1132

SK-12-24

682

SK-11-20

566

SK-12-15

415

SK-12-9

248

SK-12-6

164

Aerox®Aviation Oxygen Systems, LLC

12871 Trade Way Drive, Suite 8

Bonita Springs, FL 34135

www.aerox.com

Page 15

For more information on Sky-Ox Products, visit us at www.aerox.com/sky-ox/

Oxysaver®, Aerox®, Sky-Ox®, and Click-a-Breath® are registered trademarks of Aerox Aviation

Oxygen Systems, LLC. © Aerox Aviation Oxygen Systems, LLC 2022

Table of contents

Other Aerox Oxygen Equipment manuals