AFFINIS GROUP SaniServ 704 User manual

SaniServ P.O. Box 1089 Mooresville, Indiana 46158

Operation Manual

Frozen Beverage Dispensers

SaniServ®

An AFFINIS GROUP Company

“Reliability from the team that Serves the Best”

Distributor Name: ______________________________________________________

Address: _____________________________________________________________

Phone: _______________________________________________________________

Date of Installation: ____________________________________________________

Model Number: ________________________________________________________

Serial Number: _________________________________________________________

Installer/Service Technician: _____________________________________________

SERVICE: Always contact your SaniServ dealer or

distributor for service questions or service agency

referral. If your SaniServ dealer or distributor cannot

satisfy your service requirements, he is authorized to

contact the factory for resolution.

Note: It is the Owner’s responsibility to maintain the

Service Record located on the inside rear cover of this

manual. An accurate record of service performed can

greatly expedite troubleshooting of problems and

significantly reduce repair costs.

PARTS: Always order parts from your SaniServ dealer

or distributor. When ordering replacement parts,

specify the part numbers, give the description of the

part, the model number and the serial number of the

machine.

WARRANTY: Remove the Check Test Start (CTS)

form and fill it out in its entirety. Return the original

(white) copy to SaniServ. The Dealer/Distributor retains

the second (yellow) copy and the Owner/Operator

retains the third (pink) copy.

The Manufacturer's Limited Warranty is printed on the

reverse side of the Owner/Operator copy.

TO VALIDATE THE WARRANTY, THE CTS FORM

MUST BE COMPLETED AND RETURNED TO THE

FACTORY WITHIN 30 DAYS OF INSTALLATION.

Note: The Check Test Start function must be

performed by a qualified technician.

WARRANTY INFORMATION i

IMPORTANT

STATEMENT OF INTENDED USE

All SaniServ Machines covered in this manual are designed for one specific end use - to

freeze and dispense frozen beverages.

SPECIFICATIONS

704 707 709 724

Width

Inches (mm) 20.4

(518) 14

(356) 17.0

(432) 26.0

(660)

Height

Inches (mm) 32.8

(832) 31

(787) 32.5

(826) 55.9

(1419)

Depth

Inches (mm) 33.6

(854) 24

(610) 28.6

(726) 30.8

(781)

Machine Weight

lb (kg) 310

(141) 159

(72) 207

(94) 501

(228)

Circuit Amps -

Minimum 25 15 20 15*

Circuit Amps -

Maximum 30 15 25 15*

714

17.0

(432)

58.1

(1477)

24.8

(629)

305

(139)

15

15

SPECIFICATIONS

*Amps per side - this machine has two independent refrigeration systems

ii

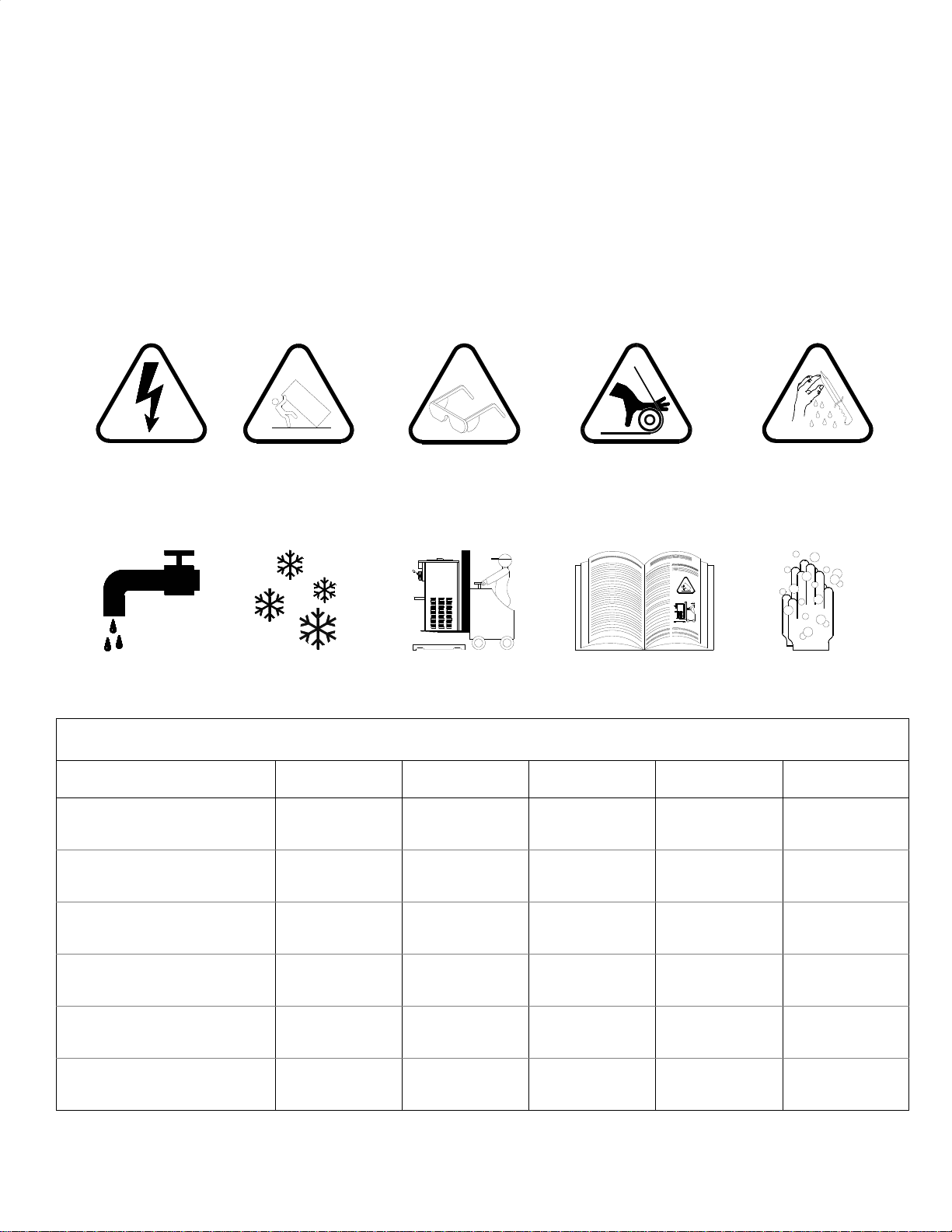

PICTOGRAM LEGEND

ELECTRICAL

SHOCK HAZARD TIP AND CRUSH

HAZARD HAND PINCH OR

ENTRAPMENT HAZARD SHARP MACHINE

PARTS HAZARD

CLEANOUT

OPERATION FROZEN

PRODUCT USE MECHANICAL

LIFT EQUIPMENT READ AND

UNDERSTAND WASH HANDS

BEFORE PROCEEDING

PROTECT EYES

SPLASH HAZARD

Table of Contents

Introduction and Installation..............................................................................................................1

Installer’s Preoperational Check .......................................................................................................3

Disassembly and Cleaning ...............................................................................................................3

Assembly and Lubrication.................................................................................................................8

Sanitizing .......................................................................................................................................12

Operation (Filling and Starting).......................................................................................................13

Helpful Hints ...................................................................................................................................14

Consistency Adjustment .................................................................................................................15

Routine Maintenance......................................................................................................................17

Troubleshooting..............................................................................................................................19

Troubleshooting Glossary...............................................................................................................20

Service Record ...............................................................................................................................21

TABLE OF CONTENTS iii

iv

Illustrations

Fig. 1 Leg Installation..................................................................................................................1

Fig. 2 Control Switch...................................................................................................................2

Fig. 3 Front Plates.......................................................................................................................2

Fig. 5 Do Not Insert Objects!.......................................................................................................3

Fig. 6 Restrictor Tube..................................................................................................................3

Fig. 7 Control Switch...................................................................................................................3

Fig. 8 Dispensing Product...........................................................................................................3

Fig. 9 Control Switch...................................................................................................................4

Fig. 10 Dispensing Product...........................................................................................................4

Fig. 11 Front Plate Assembly........................................................................................................4

Fig. 12 O-Ring Removal................................................................................................................4

Fig. 13 High Capacity Machine Front Plate Assembly ..................................................................5

Fig. 14 Large Barrel Machine Front Plate Assembly.....................................................................5

Fig. 15 Restrictor Tube..................................................................................................................5

Fig. 16 Dasher Assembly..............................................................................................................6

Fig. 17 Scraper Blade Removal....................................................................................................6

Fig. 18 Large Barrel Machine Dasher Assembly...........................................................................6

Fig. 19 High Capacity Machine Dasher Assembly ........................................................................6

Fig. 20 Drip Tray Assembly...........................................................................................................6

Fig. 21 Cleaning ALL Ports and Holes..........................................................................................7

Fig. 22 Dasher Lubrication............................................................................................................8

Fig. 23 Dasher Assembly..............................................................................................................8

Fig. 24 Scraper Blade Installation .................................................................................................9

Fig. 25 Scraper Blade Installation .................................................................................................9

Fig. 26 Scraper Blade Wear Mark.................................................................................................9

Fig. 27 Dasher Installation ............................................................................................................9

Fig. 28 Dasher Installation ............................................................................................................9

Fig. 29 Dasher with Blade (Front View).......................................................................................10

Fig. 30 Spigot Plunger Lubrication..............................................................................................10

Fig. 31 Front Plate Assembly......................................................................................................10

Fig. 32 Large Barrel Machine Front Plate Assembly...................................................................10

Fig. 33 Large Barrel Machine Front Plate Assembly...................................................................11

Fig. 34 Drip Tray Assembly.........................................................................................................11

Fig. 35 Restrictor Tube Lubrication.............................................................................................11

Fig. 36 Do Not Insert Objects!.....................................................................................................12

Fig. 37 Dispensing Product.........................................................................................................13

Fig. 38 MIXOUT Light .................................................................................................................13

Fig. 39 Mechanical Consistency Control.....................................................................................15

Fig. 40 Electronic Consistency Control .......................................................................................16

Fig. 41 Scraper Blade Wear Mark...............................................................................................17

Fig. 42 Drip Chute.......................................................................................................................17

Fig. 43 Clean Sharp Condenser Fins..........................................................................................17

Fig. 54 Spring Adjustment Mechanism .......................................................................................18

ILLUSTRATIONS

INTRODUCTION and INSTALLATION

ALWAYS USE A SUFFICIENT NUMBER OF PEOPLE

OR MECHANICAL LIFTING EQUIPMENT TO

PROTECT ALL PERSONNEL FROM PERSONAL

INJURY DURING THE REMAINING STEPS.

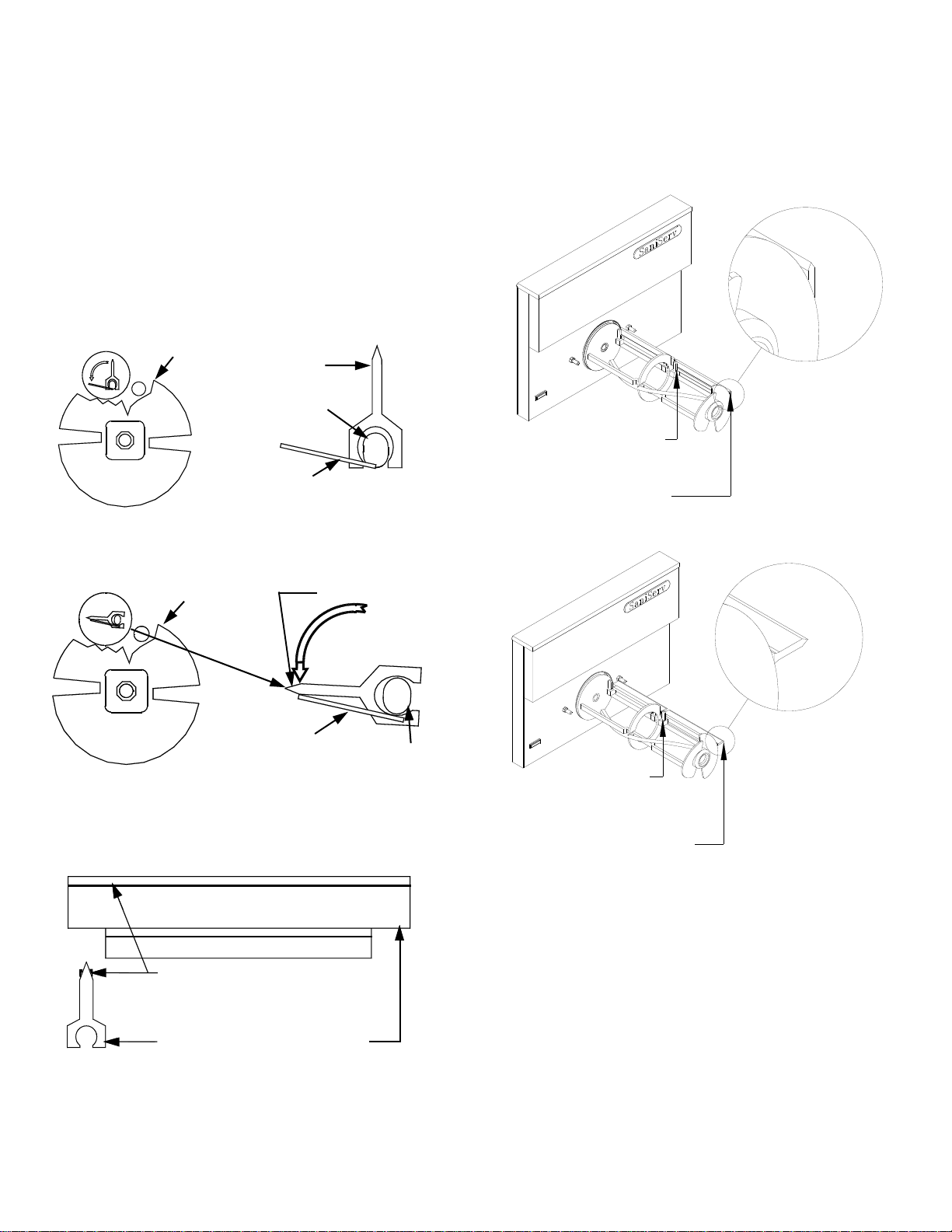

1. Raise the machine to install the four legs packed in

the mix pan or the four casters packed in a box on the

skid or on the front mounted drip tray. Be certain all

four are tight! Thread lock is suggested.

2. Carefully lower the machine to the floor and place it

where it will be installed.

3. Level the unit by turning the bottom part of each leg

clockwise or counterclockwise (Fig. 1). The machine

MUST be level to operate properly.

A MINIMUM 6” (152 MM) CLEARANCE MUST BE

MAINTAINED AT THE REAR AND SIDES OF THE

MACHINE FOR ADEQUATE VENTILATION.

ALWAYS CHECK ELECTRICAL SPECIFlCATIONS

ON THE DATA PLATE OF THE MACHINE. THE

DATA PLATE SPECIFICATIONS WILL ALWAYS

SUPERSEDE THE INFORMATION IN THIS MANUAL.

4. Electrical and refrigeration specifications are

located on the data plate on the rear panel of the

individual machines. Consult local authorities for

information regarding plumbing and electrical codes in

your area. Remove the left and right side panels for

power hook-up.

Note: All SaniServ machines should have their

own dedicated circuits to prevent low voltage

conditions caused by other operating equipment.

5. The water line connections on water-cooled

machines is located on the back side of the

machine. The IN/OUT lines are clearly marked and

equipped with 3/4” garden hose fittings.

FAILURE TO PROVIDE FOR PROPER EARTH

GROUND ACCORDING TO LOCAL ELECTRICAL

CODES COULD RESULT IN SERIOUS ELECTRICAL

SHOCK OR DEATH. DO NOT USE EXTENSION

CORDS. INSTALL THE PROPER SIZE WIRE FOR

THE REQUIRED MACHINE AMPS. BE CERTAIN TO

OBSERVE LOCAL CODES IN SELECTING WIRE OR

CORD SIZE AND TYPE.

DO NOT TURN MACHINE

ON UNTIL THE

INSTALLER’S PRE-

OPERATIONAL

CHECK SECTION IS

COMPLETE.

Installation

Fig. 1

Minimum

Clearance

4”(102 mm) for

This manual provides a general system description of the SaniServ Frozen Beverage Dispensers. It has been prepared

to assist in the training of personnel on the proper installation, operation, and maintenance of the machines.

Read and fully understand the instructions in this manual before attempting

to install, operate, or perform routine maintenance on the machines.

The following sections of the manual must be performed in sequence:

1. Installation 4. Assembly & Lubrication

2. Installer's Preoperational Check 5. Sanitizing & Operation

3. Disassembly & Cleaning 6. Consistency Adjustment

Introduction

PAGE 1

WARNING

WARNING

IMPORTANT

Installer’s Preoperational Check

THE FOLLOWING ITEMS MUST BE PERFORMED BEFORE ATTEMPTING TO OPERATE THE EQUIPMENT:

INSTALLERS PREOPERATIONAL CHECK

PAGE 2

Fig. 3a

High Capacity

Machine Front

Plate

Fig. 3c

Machine Front

Plate 5” (127 mm)

Barrel

Fig. 3b

Large Barrel

Machine Front

Plate

Fig. 2

Control Switch

AUTO

CLEANOUT

O

F

F

O

F

F

1. Make certain that proper electrical connections have

been made. Plug power cord into power outlet.

2. Set each control switch (Fig. 2) to the “CLEANOUT”

position momentarily to verify the direction of rotation of

the dasher. Looking at the front of the machine, the

dasher should rotate counter-clockwise.

3. Set each control switch to the “OFF” position.

In the event the dasher turns clockwise, STOP and

do not proceed any further. On three-phase units,

reverse the polarity.

WARNING

UNDER NO CIRCUMSTANCES SHOULD THE UNIT

BE OPERATED IN THE “AUTO” POSITION FOR MORE

THAN THREE MINUTES WITH EMPTY FREEZING

CYLINDERS . DOING SO WILL RESULT IN DAMAGE

TO THE MACHINE.

CAUTION

Emptying Machine

Prior to the disassembly and cleaning of parts, the

machine must be emptied of product. Use the following

procedures (Steps 1 through 3). If this is first time

operation, disregard these steps.

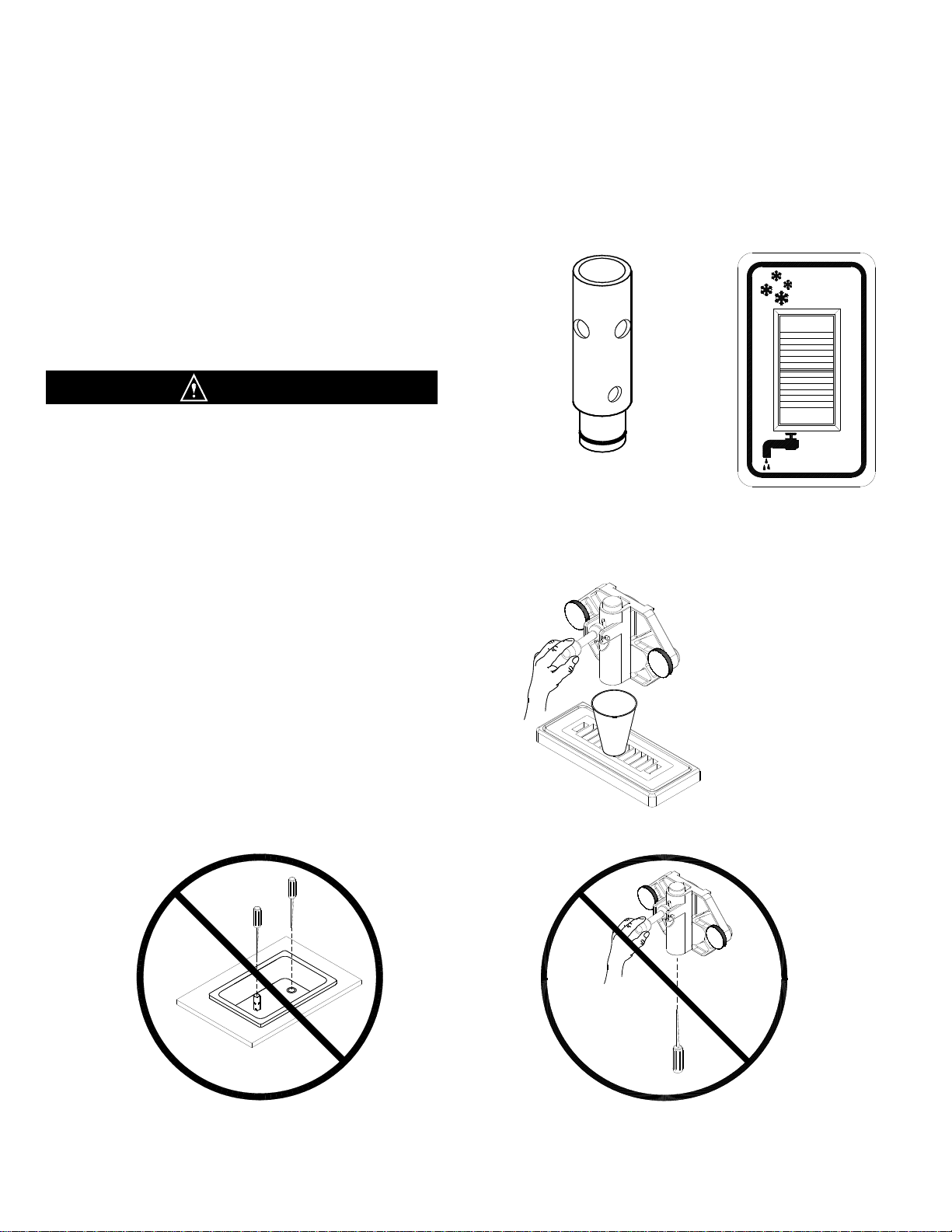

DO NOT INSERT ANY OBJECTS OR TOOLS (FIG. 5)

INTO THE MIX INLET HOLE, RESTRICTOR TUBE

HOLE, OR FRONT PLATE DISPENSING HOLE WHILE

THE MACHINE IS RUNNING. DAMAGE TO THE

MACHINE OR PERSONAL INJURY MAY RESULT

1. For Models 108 & 704, remove the restrictor tube (Fig.

6) from the mix inlet holes and lay in the bottom of the mix

pans. Note: Some units have these tubes welded in

place

2. Set each control switch (Fig. 7) to the “CLEANOUT”

position and dispense all product from the freezing

cylinder by pulling downward on the spigot handle

(Fig. 10) to empty the machine.

3. Set each control switch to the “OFF” (center) position.

Close the spigot handle(s) (Fig. 8) before proceeding to

cleaning.

CONSULT YOUR LOCAL HEALTH AGENCY FOR LOCAL CLEANING AND SANITIZING REQUIREMENTS.

This unit does not come pre-sanitized from the factory. Before serving product, the dispenser must be disassembled,

cleaned, lubricated, and sanitized. Please be aware that these instructions are general guidelines. Cleaning and sanitizing

procedures must conform to local Health Authority requirements.

DISASSEMBLY and CLEANING

Fig. 6

Model 108 & 704

Restrictor Tube

Fig. 8

Dispensing Product

Fig. 7

Control Switch

Disassembly and Cleaning

AUTO

CLEANOUT

O

F

F

O

F

F

Fig. 5

Do Not Insert Objects or Tools

CAUTION

PAGE 3

DISASSEMBLY and CLEANING

Disassembly and Cleaning Procedure

1. Fill the machine with cold water and set each control

switch (Fig. 9) to the “CLEANOUT” position. DO NOT

use hot water which could damage the machine. Let the

machine agitate 1 to 2 minutes, then drain the water by

pulling downward on the spigot handle (Fig. 10). Repeat

the above procedure as necessary to make certain all

product is removed from the machine. After the machine

is empty, set each control switch to the “OFF” position.

2. Prepare a suitable detergent and water solution at a

temperature of approximately 125°F. (52°C.) to 130°F.

(55°C.). For best cleaning results select a concentrated

anti-bacterial dishwashing detergent containing

biodegradable anionic and nonionic surfactants. Avoid

detergents containing phosphates. DO NOT use an

abrasive detergent on any part of the dispenser.

DO NOT USE HOT WATER.

DOING SO MAY DAMAGE THE MACHINE.

3. Make certain that the machine is “OFF”. Fill the mix

pan(s) with the cleaning solution. Clean the mix pan(s)

thoroughly with a brush as the solution drains into the

freezing cylinder(s). Clean the mix inlet tube(s) and the

restrictor tube holes with the brush provided.

4. Set the control switch to the “CLEANOUT” position

and agitate for approximately 1 to 2 minutes and then

drain the water by pulling down on the spigot handle.

After the unit is empty, set each control switch to the

“OFF” position.

DO NOT USE ANY TOOLS OR SHARP OBJECTS TO

REMOVE ANY O-RINGS FROM THIS MACHINE.

SHARP OBJECTS WILL DAMAGE THE O-RINGS.

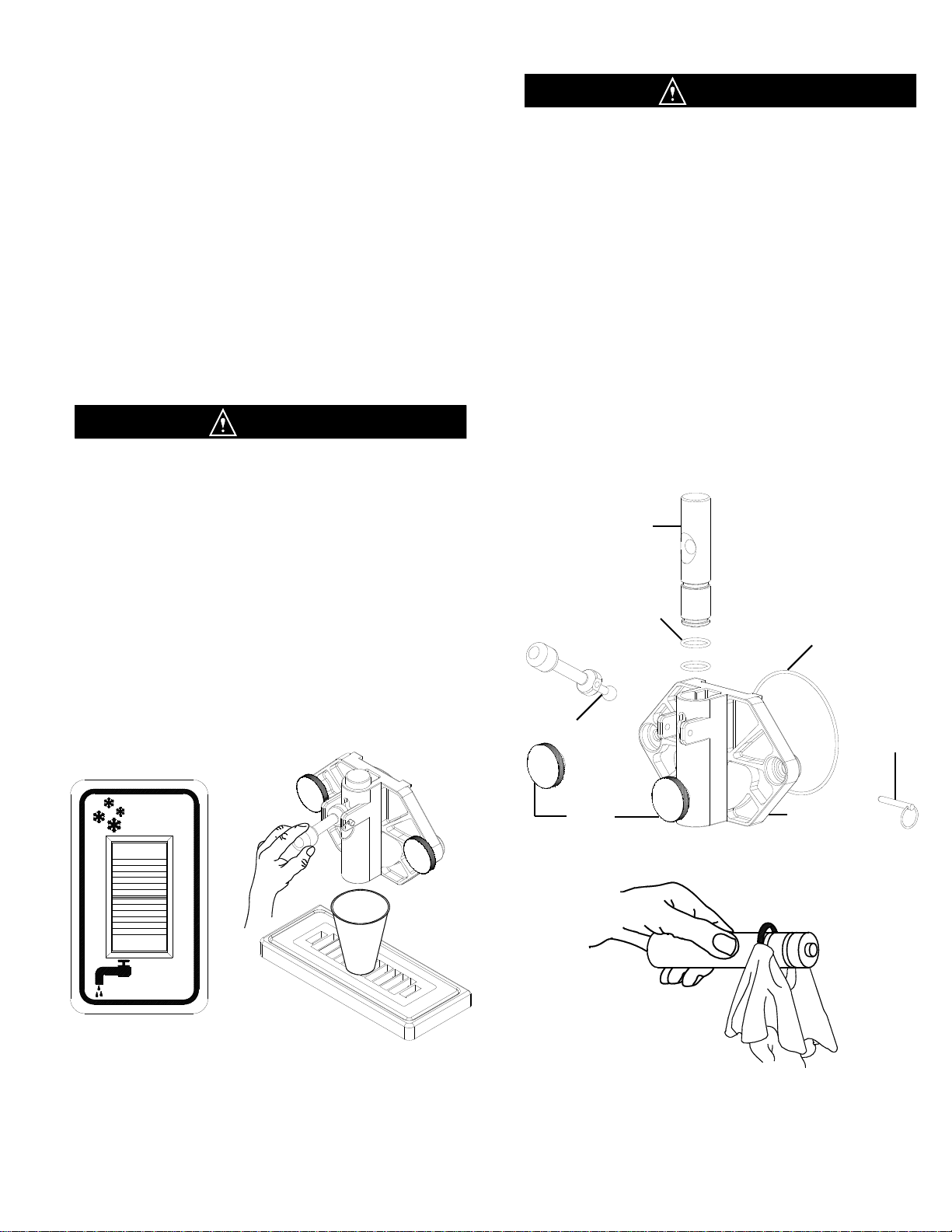

5. Remove the front plate by turning the black plastic

knobs in a counterclockwise direction (Fig. 11).

Disassemble the front plate in the following manner:

a. Remove the faspin and spigot handle.

b. Remove the front plate o-ring.

c. With the spigot handle removed, push the spigot

plunger out the top of the front plate and remove all

lubricant from the spigot plunger.

d. Remove the o-rings from the spigot plunger by

grasping the part with one hand and with a dry

cloth in the other hand, squeeze the o-ring upward.

When a loop is formed, grasp the o-ring with the

other hand and roll it out of its groove and off the

spigot plunger (Fig. 12).

Fig. 10

Dispensing Product Fig. 12

O-Ring Removal

Spigot Plunger

Faspin

Spigot

Handle

Front Plate

Front Plate O-ring

DO NOT LUBRICATE

Spigot Plunger

O-rings

Front Plate

Knobs

Fig. 9

Control Switch

Fig. 11

Front Plate Assembly

AUTO

CLEANOUT

O

F

F

O

F

F

CAUTION

CAUTION

PAGE 4

DISASSEMBLY and CLEANING

6. The front plate for the high capacity series machines

(Fig. 13) is disassembled in the same manner as the front

plate shown in Fig. 11.

7. Disassemble the large barrel machine front plate

(Fig. 14) in the following manner:

a. Remove the four front plate knobs.

b. Remove front plate from machine

c. Remove front plate O-Ring

d. Open spigot handle.

e. Clean spigot openings with the cleaning brush.

(Fig. 15)

8. Remove the restrictor tube from the mix pan and

remove the o-ring in the same manner used to remove

the o-rings from the spigot plunger. Clean the inside of

the tube with the brush provided.

Fig. 13

High Capacity Machine

Front Plate Assembly

Fig. 14

Large Barrel Machine

Front Plate Assembly

Spigot Plunger

Spigot Plunger

O-rings

Front Plate

O-ring

Spigot Handle

Knob

Front Plate

FasPin

Front Plate

O-ring

Spigot Nut

O-Ring

Spigot

Assembly

Front Plate

Knob x 4

Fig. 15

Cleaning Large Barrel

Front Plate Assembly

PAGE 5

10. Remove the mix pan lid, drip tray and drip tray

insert (Fig. 20).

9. Remove the dasher assembly (Fig. 16) being careful

not to damage the scraper blades, then disassemble in

the following manner:

a. Remove and take apart the rear seal assembly.

b. Remove the stator rod from the dasher.

c. Remove the blades from the dasher (Fig. 16)

by first rotating blade upward (Fig. 17) and then

Dasher Front

View Scraper Blade

Blade Support

Tab

Support

Rod

Blade Support

Tab

Support

Rod

Dasher Front

View

Scraper Blade

Fig. 20

Drip Tray Assembly

Fig. 17

Scraper Blade Removal

Fig. 16

Dasher Assembly

DISASSEMBLY and CLEANING

Dashers in the high capacity and large barrel

machines have no stator rods, but both have front

bushings (Fig. 18 and Fig. 19).

Rear Seal

Rear Bearing

Front Bushing

Scraper Blade

Dasher

Scraper Blade

Rear Seal

Rear Bearing

Dasher

Stator Rod

Rear Seal

Front Bushing

Dasher

Scraper Blade

Rear Bearing

Fig. 19

High Capacity Machine

Dasher Assembly

Fig. 18

Large Barrel Machine

Dasher Assembly

Drip Tray Insert

Drip Tray

Drip Tray Support

Remains Attached

To Machine Front

PAGE 6

12. Place all parts in a three partition sink filled with the

following solutions:

a. In one partition, detergent solution diluted to the

manufacturer’s suggested concentration for use.

b. In a second partition, clear rinse water.

c. In a third partition, sanitizing rinse solution which

will produce a 200 parts per million (PPM) Chlorine

residual or whatever Chlorine residual is required by

your Local Health Authority.

13. Use the brushes to clean all holes and ports in the

parts (Fig. 21).

DO NOT use an abrasive detergent

14. After thoroughly washing the parts in the detergent

solution, rinse them in the clear rinse water. Place the

parts in the sanitizing solution for at least five minutes or

whatever your Local Health Authority requires, and then

air dry the parts before for assembly and lubrication.

DO NOT ALLOW THE PARTS TO SOAK IN

SANITIZER FOR SEVERAL HOURS.

DO NOT WIPE THE PARTS DRY - AIR DRY ONLY.

15. The remainder of the machine including the mix pan

and freezing cylinder must be cleaned in place using a

mild detergent solution followed by a clear rinse. Clean

the exterior with a damp cloth.

DO NOT use an abrasive cleaner on the exterior of the

machine or on any of the panels (guards).

WHEN CLEANING THE MACHINE, DO NOT ALLOW

EXCESSIVE AMOUNTS OF WATER AROUND ANY

ELECTRICALLY OPERATED COMPONENTS OF THE

MACHINE. ELECTRICAL SHOCK OR DAMAGE TO

THE MACHINE MAY RESULT.

11. For best cleaning results select a concentrated

anti-bacterial dishwashing detergent containing

biodegradable anionic and nonionic surfactants.

NOTE: Avoid detergents containing phosphates.

WEAR SAFETY GLASSES

- DO NOT SPLASH

DETERGENT SOLUTION

IN EYES

Be certain to follow the

manufacturer’s mixing

instructions when adding

the dishwashing detergent

concentrate to water.

DISASSEMBLY and CLEANING

CAUTION

Fig. 21

Clean ALL Holes and Ports

with Brushes

CAUTION

CAUTION

CAUTION

CAUTION

WARNING

PAGE 7

1. Lubricate and assemble the dasher assembly in the

following manner:

a. Apply a generous amount of lubricant to the

shoulder of the dasher and the area of the shaft

where the white plastic portion of the assembled

rear seal contacts the shaft (Fig. 22). This is easily

performed by running a 1/4” (6 mm) bead of

lubricant around the shoulder of the dasher.

b. Lubricate the two areas of the stator rod (Fig. 22a)

and slide the stator rod into the dasher (Fig. 23).

Make certain that the end of the stator rod is

inserted into the hole at the rear of the dasher.

c. Assemble and install the rear seal with the rubber

portion toward the rear of the freezing cylinder as

indicated in Fig. 23.

DO NOT LUBRICATE THE RUBBER PORTION OF

THE REAR SEAL. LUBRICATION ON THE REAR

SEAL WILL DAMAGE THE MACHINE.

d. Install the o-ring on the rear of the dasher shaft.

DO NOT LUBRICATE DASHER O-RINGS

e. Install the front bearing on the dasher of the large

barrel and the high capacity machines.

Use a food grade lubricant* ONLY. Haynes Lubri-Film (SaniServ part number 1150) is recommended and is available

from the factory or your local authorized SaniServ dealer or distributor. Lubrication must be performed daily.

* The SaniServ recommended product is a colorless to white, odorless, tasteless food contact lubricant accepted by the

United States Food and Drug Administration (FDA) with a USDA rating of H1 and certified for food contact by NSF

International.

ASSEMBLY and LUBRICATION

Fig. 22a

Stator Rod and Dasher Lubrication

Assembly and Lubrication

Fig. 22c

Large Barrel Machine

Dasher Assembly

Lubricate Shaded

Areas Including

Rear of Shoulder

Lubricate

Shaded

Areas

Lubricate Shaded

Areas Including

Rear of Shoulder

Scraper

Blade

Dasher

Stator Rod

Rear Bearing

Rear Seal

Fig. 23

Dasher Assembly

Fig. 22b

High Capacity Machine

Dasher Assembly

CAUTION

PAGE 8

f. Install the scraper blades onto the dasher

assembly by holding the blades perpendicular to

the tabs (Fig. 24) and then snapping them over the

flat area of the support rod. Then rotate the blades

downward in a counterclockwise direction as

viewed from the front of the dasher (Fig. 25). BE

CERTAIN THAT THE SCRAPER BLADES REST

UPON THE DASHER TABS ON ALL DASHERS

EXCEPT HIGH CAPACITY MACHINE DASHERS.

THOSE BLADES REST UPON PINS.

Note: Reverse the blades at each cleaning to maintain

sharpness. In addition, the blades are equipped

with a wear mark (Fig. 26). When the blade is

worn to this wear mark, it must be replaced.

Blade Support

Tab

Support Rod

Dasher Front View

Scraper Blade

Dasher Front

View

Blade Support

Tab Support Rod

Scraper Blade

Rotate Down

Counter

Clockwise

Scraper Blade Wear Mark

End

View Side

View

ASSEMBLY and LUBRICATION

Fig. 25

Scraper Blade Installation

Fig. 24

Scraper Blade Installation

Fig. 26

Scraper Blade Wear Mark

g. Insert the dasher assembly into the freezing

cylinder as far as possible (Fig. 27) being careful

not to damage the scraper blades. Damage will

occur to the scraper blades and the dispenser will

not operate properly if the scraper blades are

installed facing in a clockwise direction (Fig. 28).

Note: The stator rod has been deleted from Fig. 29 and

Fig. 30 for clarity only. The stator rod must be installed

for proper machine operation.

h. While maintaining force against the dasher, rotate it

slowly until the tongue of the dasher engages the

groove in the drive system at the rear of the

cylinder. The outer most portion of the dasher

should be recessed approximately 1/4” (6 mm) to

3/8” (10 mm) inside the freezing cylinder. No part

of the dasher should extend outside the cylinder.

Scraper blades should be visible, extending

approximately 1/8” (3 mm) beyond the dasher

(Fig. 29).

Fig. 27

Dasher Installation

CORRECT

Blades

Resting On Tabs

Blades Pointing In A

Counterclockwise

Direction

Fig. 28

Dasher Installation

Blades Should

Rest On Tabs

Blades Should Not Point

In A Clockwise Direction

INCORRECT

PAGE 9

2. Lubricate and assemble the front plate assembly in

the following manner:

a. Install the two o-rings on the spigot plunger by

rolling them onto the plunger. Seat the o-rings in

the grooves. Be certain that they are not twisted.

Smooth the lubricant into the grooves and over

the sides of the plunger assembly (Fig. 30).

b. Slide the lubricated spigot plunger into the front

plate (Fig. 31) making certain that the spigot handle

slot is aligned to the front.

C. Insert the spigot handle and secure with the faspin.

d. Install the front plate o-ring.

DO NOT LUBRICATE THE FRONT PLATE O-RING

e. Secure the front plate assembly with the two

plastic knobs. Simultaneously, turn the knobs in a

clockwise direction. Tighten the knobs evenly.

DO NOT tighten one knob all the way down and

then the other. Doing so may result in front plate

breakage. Only moderate force is required.

DO NOT over tighten. Close the spigot plunger.

3. The high capacity machine front plate is lubricated

and assembles in the same manner.

4. Assemble the large barrel machine front plate in the

following manner:

Fig. 29

Dasher with Blade (Front View)

Spigot Plunger

Faspin

Spigot

Handle

Front Plate

Front Plate O-ring

DO NOT LUBRICATE

Spigot Plunger

O-rings

Front Plate

Knobs

Fig. 31

Front Plate

Assembly

Fig. 32

Large Barrel Machine

Front Plate Assembly

ASSEMBLY and LUBRICATION

Approximately 1/8 inch

Exposed

Fig. 30

Spigot Plunger Lubrication

Lubricate Shaded Area

Front Plate

O-ring

Spigot Nut

O-Ring

Spigot

Assembly

Front Plate

PAGE 10

5. Install the drip tray and drip tray insert (Fig. 34).

6. Install the o-ring on the restrictor tube (Fig. 35) if

removable . Apply lubricant sparingly over the o-

ring. Place the restrictor tube in the bottom of the

mix pan for sanitizing. Make certain that lubricant

does not block the mix inlet hole on the restrictor

tube.

7. Proceed to the “Sanitizing” section of this manual.

Fig. 33

Large Barrel Machine

Spigot Assembly

ASSEMBLY and LUBRICATION

Fig. 35

Restrictor Tube

Lubrication

Lubricate Shaded

Area Including

O-ring

Drip Tray Support

Remains Attached

To Machine Front

Drip Tray

Fig. 34

Drip Tray

Assembly

Drip Tray Insert

Assemble gasket on spigot side.

Warning: Machine damage possible if nut

installed incorrectly!

Lubricate flat side of nut with Sani-Gel.

Install flat side of nut toward spigot.

Front Plate

O-ring

Spigot

Assembly

Front Plate

PAGE 11

1. First, wash hands with a

suitable antibacterial hand soap.

For best results select a

concentrated anti-bacterial hand

soap containing biodegradable

anionic and nonionic surfactants.

2. Prepare approximately 2 to 3

gallons (8 to 12 liters) of sanitizing

solution equivalent to 200 ppm

chlorine residual or the residual

required by your local health

agency.

3. Carefully pour the solution

into the mix pan.

4. Using a sanitary brush, wipe

the solution onto the sides of

the mix pan, over the mixout

probe in the bottom of the mix

pan, and the underside of the

mix pan lid.

5. Set the control switch

(Fig. 39) to the “CLEANOUT”

position and let the unit agitate

for approximately three to five

minutes.

NOTE: DO NOT set the control switch to the “AUTO”

position. Doing so would freeze the sanitizing solution

and may result in damage to the machine.

DO NOT INSERT ANY TOOLS OR OBJECTS INTO

THE MIX INLET HOLE, RESTRICTOR TUBE HOLE,

OR THE DISPENSING HOLE IN THE FRONT PLATE.

DAMAGE TO THE MACHINE OR PERSONAL

INJURY MAY RESULT (FIG. 36)

6. Set the control switch to the “OFF” position and

drain the solution from the machine. Proceed directly

to the “Operation” section of this manual.

DO NOT RINSE OUT THE MACHINE

DO NOT ALLOW SANITIZING SOLUTION TO

REMAIN IN THE MACHINE FOR SEVERAL HOURS.

DOING SO COULD DAMAGE THE MACHINE.

Prior to operation, the machine must be sanitized. The unit must have already been cleaned and lubricated.

Note: Sanitize immediately before use, not several hours before or the previous evening.

SANITIZING

Sanitizing

Fig. 36

Do Not Insert Objects or Tools

WARNING

WARNING

PAGE 12

Always start with a cleaned and sanitized dispenser as per previous instructions. Following these instructions is critical to

the maximum operating efficiency of the machine.

1. Remove the restrictor tube from the bottom of the

mix pan and set aside in a sanitary location.

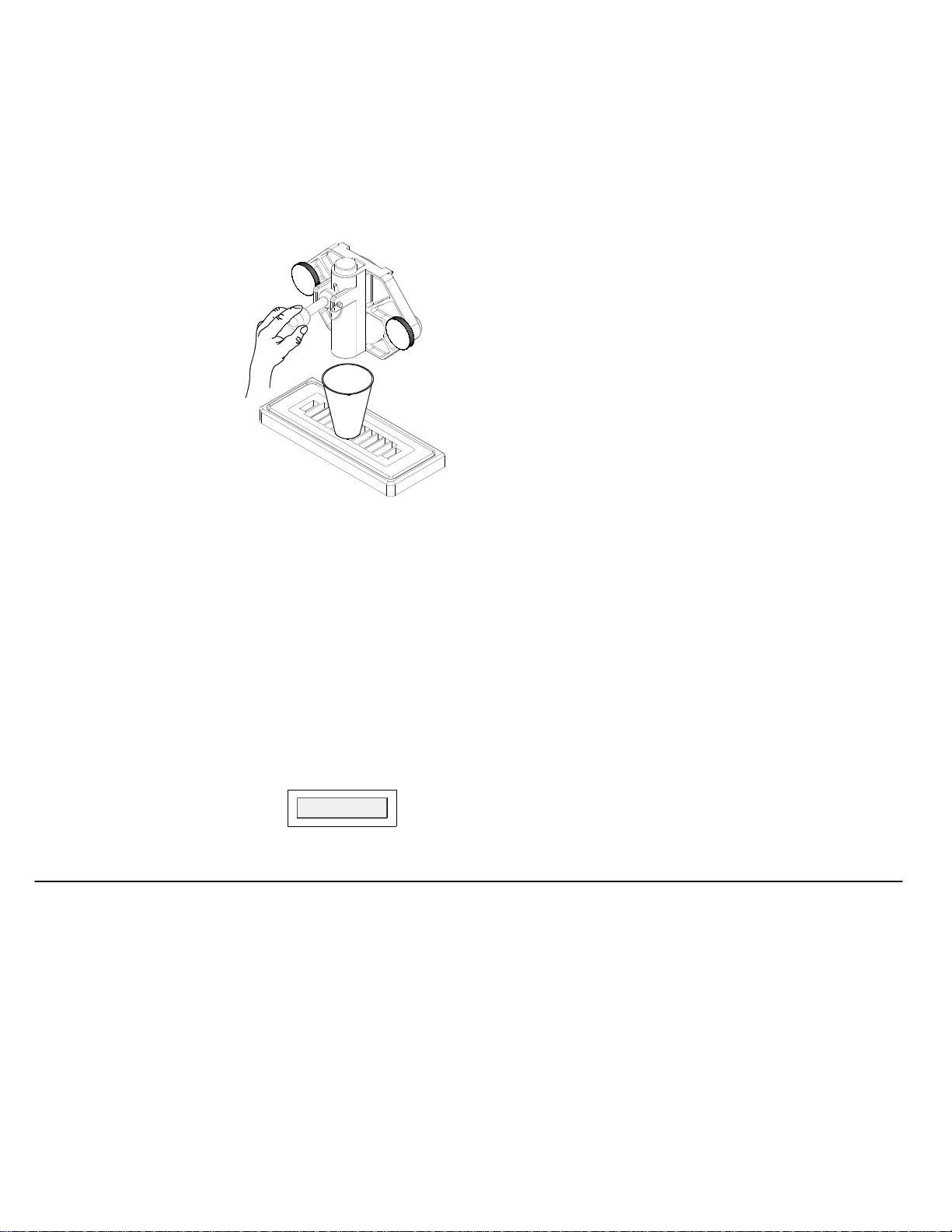

2. Place a 16 oz. Cup under the spigot and open the

spigot handle. Pour

approximately one quart

of fresh product mix into

the mix pan. (This will

chase the sanitizing

solution from the mix pan

and freezing cylinder.)

Close the spigot handle

when the sanitizer is

purged from the system.

3. Fill the freezing

cylinder until the mix

comes out of the

recirculation hole on

units with two mix inlet

holes or until the freezing

cylinder stops bubbling on units with only one mix inlet

hole.

4. Install the removable restrictor tube with a gentle

twisting motion into the front hole if the mix pan has two

mix inlet holes. For units with only one hole, simply

insert the restrictor tube in the only mix inlet hole.

5. Fill the mix pan with chilled, properly mixed product.

Keep the mix level in the mix pan at least one inch

(25 mm) deep at all times to avoid starving the freezing

cylinder. A MIXOUT light (Fig. 38) located on the front

of the machine (one per freezing cylinder) is activated

when the mix solution drops to a potentially damaging

level.

6. Set the control switch to the “AUTO” position to

start the machine.

7. Allow the compressor to cycle 3 or 4 times

dispensing a sample of the product after each cycle to

check for consistency. If the machine is not dispensing

the product at the desired consistency after four full

cycles, refer to the Consistency Control Section of this

manual. Initial pull-down time may vary due to model,

product and ambient conditions.

8. Replace the mix pan lid and always operate the

machine with the lid on the mix pan reservoir.

Note: SaniServ dispensers are designed to run frozen

beverage products having a Brix (sugar content) range

of 12.5 to 14 with a dispense temperature of 26°F to 28

°F (-3.3°C to -2.2°C).

Brix reading is taken by placing a small sample of

normally diluted concentrate on the viewer of a

refractometer. If a refractometer is not available,

contact the mix supplier.

Do not use a mix with a Brix reading of less than

12.5. Doing so may result in serious damage to the

machine.

If the Brix reading is above 14.0 or the alcohol content

is too high, the freezing point of the solution may be too

low to form slush.

DO NOT ATTEMPT TO MAKE FROZEN BEVERAGE

USING ARTIFICIALLY SWEETENED PRODUCT.

OPERATION

Fig. 37

Dispensing Product

Operation (Filling and Starting)

If the liquid level sensor detects a low level condition, it

will flash the “MIXOUT” light and activate the beeper

for three minutes or until the mix pan is filled to satisfy

the mix level probe. If the beeper is activated for more

than three minutes, the light will begin to glow

continuously, the beeping tone will slow down, and the

machine will no longer dispense product.

Control Switch Positions

“CLEANOUT” Position: The dasher motor operates

continuously and the compressor will not come on.

The mix out level sensor will turn on the “MIXOUT”

light but will not activate the beeper.

“AUTO” Position: The dasher motor operates

continuously. Upon machine start up the compressor

will run until proper product consistency is reached.

Then the compressor will shut off.

MACHINE OPERATIONS WITH ELECTRONIC CONSISTENCY CONTROL

Fig. 38

MIXOUT Light

PAGE 13

Closed Hours/Shut-Down: If the machine is turned

off during closed hours, to resume operation:

1. Set the control switch to the "CLEANOUT" position.

2. Dispense two quarts (2 liters) of product into a

sanitized pitcher and pour it back into the mix pan.

Doing so serves as a mixing process to eliminate any

overnight separation.

NOTE: NEVER POUR FROZEN PRODUCT INTO

THE MIX PAN. LET IT MELT FIRST.

3. Set the control switch to the "AUTO" position and

resume operation.

Mixing: Make certain that the product is prepared per

label instructions. The machine is designed to operate

with frozen product base having a brix range of 12.5 to

14.0. To ensure consistency and quality, use a mixing

container large enough to hold 5 gallons (20 liters) with

1 gallon (4 liter) markings to allow accurate mixing of

the frozen beverage base. Stir well before adding to

the mix solution to the mix pan. Refrigerate the base

after diluting. Keep the empty gallon bottles with their

lids or caps installed and refill them with diluted base

for easy access during busy operating periods.

Filling: Always fill the machine at the start of each

day. Fresh prechilled mix will produce the best results.

Mix Pan Lid: Be sure to leave the lid in place on top of

the machine to prevent any foreign materials from

contaminating the mix.

Drip Tray: This should be removed daily and cleaned

to remove residue (Fig. 37).

Front Plate: This component (Fig. 33) is the plastic

device from which the product is dispensed. It is

designed and made for strength and durability.

However, through improper use, it can be damaged.

Use the following information for proper care.

1. Do not lubricate the large o-ring on the rear of the

front plate. If lubricated, it will not seal properly and

product will leak from the front plate (Fig. 33).

2. Do not over tighten the knobs.

3. Always tighten the front plate knobs evenly. Do

not attempt to turn one knob all the way down and then

the other(s). Doing so will bind the front plate and

result in breakage.

4. Improper installation of the stator rod can cause

breakage. The stator rod must be properly seated in

the dasher before installing the front plate. If the stator

rod is improperly installed, subsequent tightening of the

knobs will break the front plate.

5. Do not attempt to wash the front plate or any other

machine components in a dishwasher.

Mix Out Light: When the mix out light comes on, fill

the mix pan. The mix pan must be filled immediately to

prevent air from entering the freezing cylinder. If air

enters the freezing cylinder, it will create the condition

known as “starving the machine”, causing freeze-up

and vibration. If this condition occurs, set the control

switch to the "OFF" position and add mix to the

mix pan. Allow the freezing cylinder to refill and return

the control switch to the "AUTO" position.

HELPFUL HINTS

Helpful Hints

PAGE 14

This manual suits for next models

4

Table of contents

Popular Beverage Dispenser manuals by other brands

CDS AUTOMATEN

CDS AUTOMATEN ML-16C2-C user manual

Siemens

Siemens GA 3000 OPERATING & SERVICE MANUAL

Bunn

Bunn IMIX Service & repair manual

Fizz Creations

Fizz Creations Slush Puppie Instructions for use

Cornelius

Cornelius IntelliCarb Cold Beverage Dispenser Training manual

TAPRITE

TAPRITE Rattler II Instructional manual