7805-0039C Rev F

FLOW CONTROL MANIFOLD COVER INSTALLATION

A. Loosen thumb screws, located on the sides, DO NOT COMPLETELY REMOVE

THUMBSCREWS. Lift the cover off the manifold.

B. To install cover, align the slots on the cover with the thumb screws on the valve

manifold assembly.

C. Tighten thumbscrews on each side of cover. DO NOT OVERTIGHTEN.

CAPTIVE O-RING DESIGN (COR)

Below are instructions for the latest revision of the Taprite bar dispenser handle.

The Stem O-rings are located on top of the handle, under the button plate.

The revision includes.

1. Retainers

266-0329 Retainer, O-Ring 5BRC,7BRC,8BRC,10Button

266-0260 Retainer, O-Ring 12Button

266-0361 Retainer, O-Ring 14Button

2. Stem, plunger

265-0865 Stem, Plunger Valve BG Captive

BUTTON AND BUTTERFLY PLATE REMOVAL/RE-ASSEMBLY

The Taprite Bar Dispenser handle can be configured into numerous combinations of

carbonated and non-carbonated products. All combinations can be made without

shutting down the system.

Begin by removing the (2) 6-32x0.5” button plate screws located on top of the handle, do

not discard, see Fig. 9 below.

A. To change the butterfly plate(s). Remove the (2) 6-32x.0375” screws and (2) butterfly

(black)retainers, Fig.10.

B. Remove butterfly plates from handle Fig. 11, save screws and butterfly retainers for re-installing.

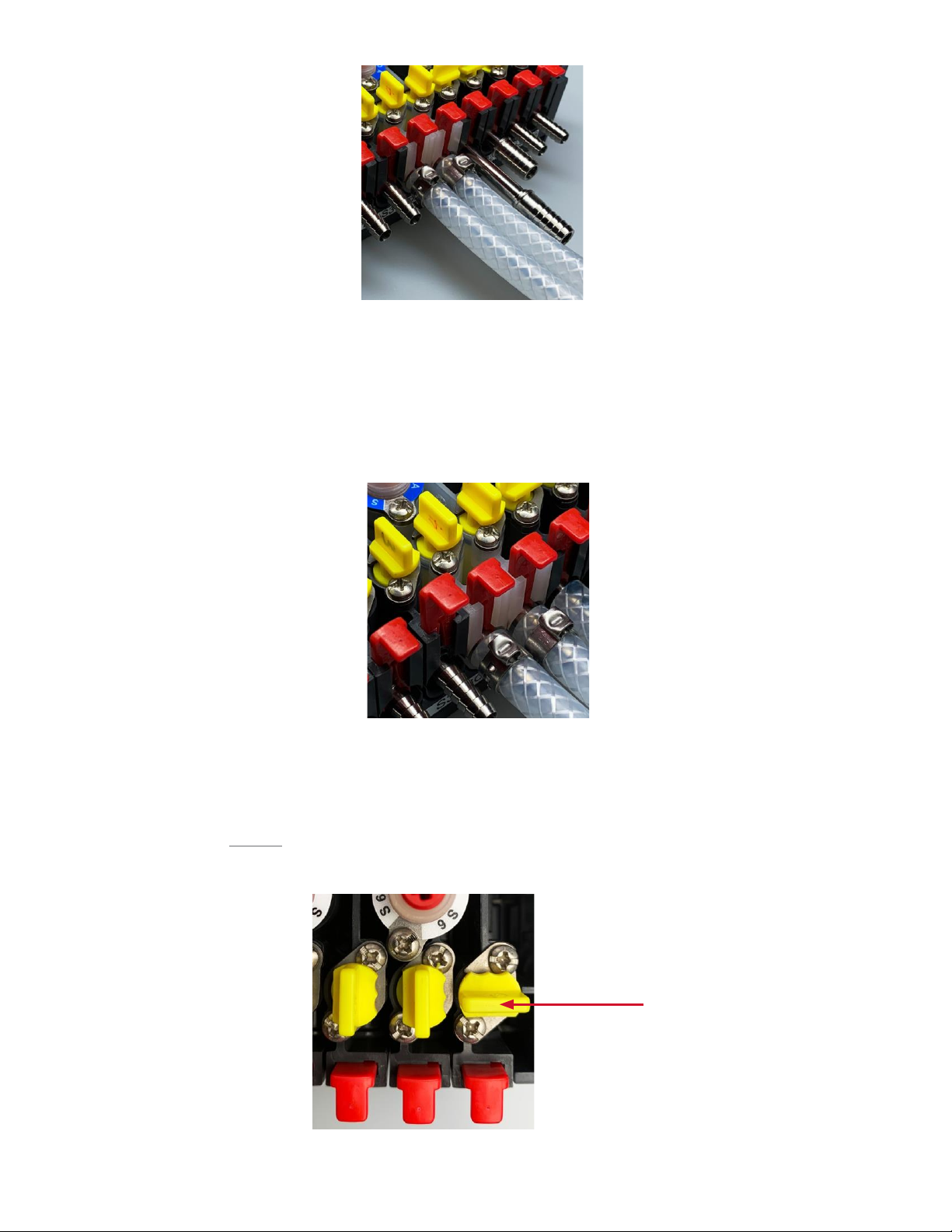

C. Ensure that the o-ring retainer(s), Fig. 12, below the butterfly plates, are correctly in place before

replacing butterfly plates as required.

D. Align the pivot balls, at the bottom of the butterfly plates, with the divots in the o-

ring retainer.

E. Secure butterfly plate(s). Use the (2) 6-32x.0375” screws and (2) butterfly

(black)retainers. DO NOT OVERTIGHTEN.

F. Replace button plate and re-attach with the (2) 6-32x0.5”.