6 BE-AGLxxxF USER MANUAL

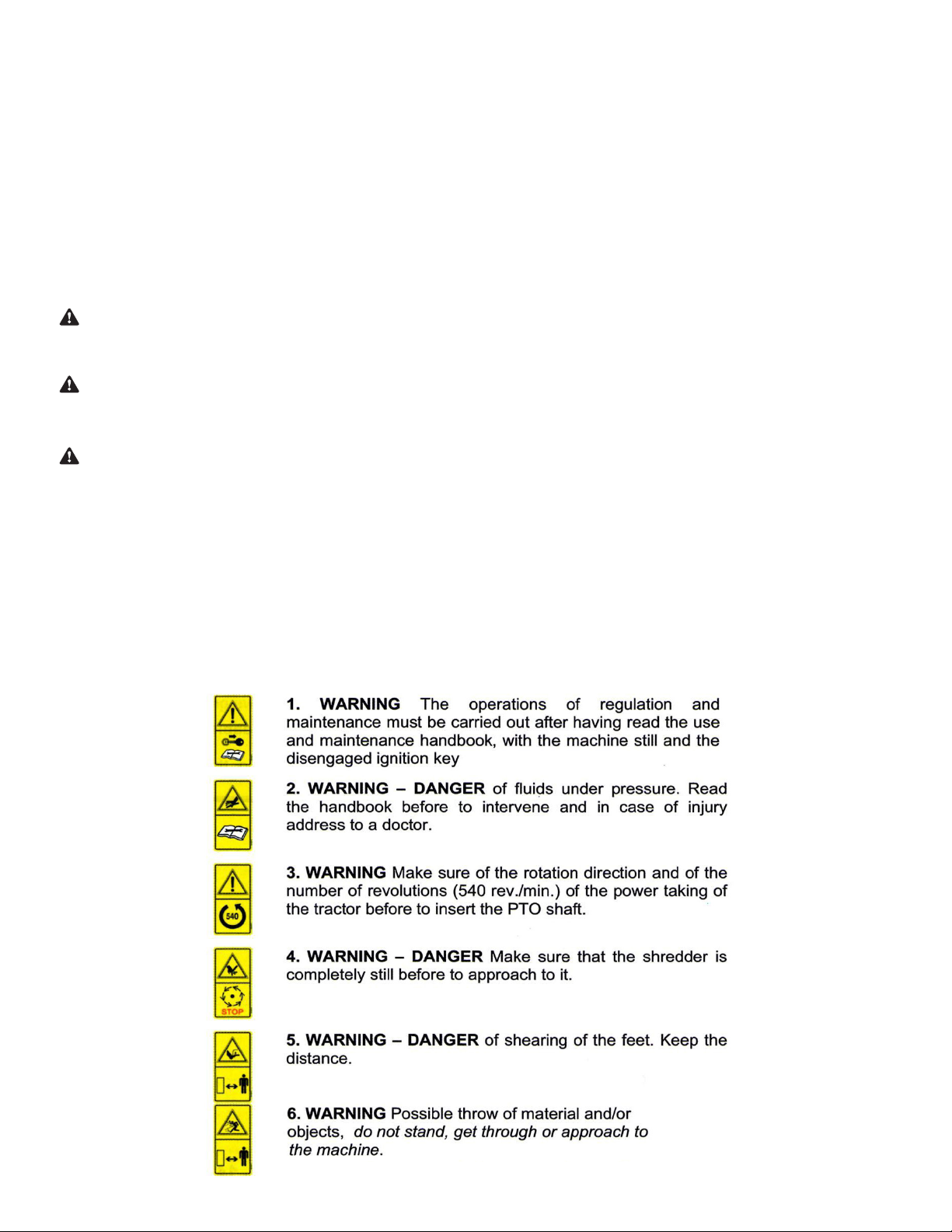

GENERAL SAFETY RULES

ALWAYS CONSIDER THE FEATURES OF THE AREA WHERE WORK IS TAKING PLACE:

When the equipment is running, it is forbidden to stand within the field of action of the shredder or of the

other accessories of which it is provided with.

PREPARE THE WORK:

• Before and when working, do not drink alcohol, take drugs, or any other substances which may alter your

capability of working with machine tools.

• Be sure to have sucient fuel to prevent a forced stopping of the machine, especially during critical

operations.

• Do not use the equipment under unsafe conditions. For instance, it is forbidden to execute makeshift repair

activities just to start working; it is forbidden to work at night with an insuciently illuminated working

area.

• NEVER operate implement without all shields in place and in good operational condition. The operator

must be familiar with the mower and tractor and all associated safety practices before operating the

mower and tractor.

WHEN WORKING OR DURING THE MAINTENANCE ACTIVITIES IT IS NECESSARY TO REMEMBER:

• The labels and stickers providing instructions and pointing out the dangers must not be removed, hidden,

or made illegible.

• Do not remove, except in case of maintenance, the shields, guards, and deflectors equipped on the mower.

When it is necessary to remove them, stop engine, handle with care and reassemble them properly before

restarting the engine and using the equipment. The mower is equipped with protective deflectors to

prevent objects being thrown from the mower by the blades, however, no shielding is 100% eective. All

shields, guards, and deflectors equipped on the mower must be maintained in good operational condition.

• It is forbidden to lubricate, clean and adjust the moving parts while they are running.

• During maintenance or adjustment activities on the equipment it is forbidden to use hands for executing

operations for which there are specific tools.

• Do not use tools in bad condition or inappropriately, for instance pliers rather than monkey spanners, etc.

• When maintenance or repairs are completed, check that no tools, wiping rags, or other materials are left

inside spaces or guides with moving parts.

• While using the equipment, it is forbidden to make more than one person give directions and make signals.

The eventual directions and signals relating to the load handling must be given by one person only.

• Do not unexpectedly call an operator while he is working if not necessary; it is forbidden as well to frighten

or throw objects at the operator.

• Watch out for bystanders, especially children!

• Do not make people get on the machine.

• When the equipment is not needed, stop the vehicle’s engine, park it on flat ground with first speed and

parking brake on, with the machine rested on the ground and PTO disengaged.

• Do not clean, lubricate, repair or adjust with the engine running and the machine lifted.

• Never use the machine on steep slopes which may jeopardize the equipment’s stability.

The manufacturer declines all responsibility for a lack of compliance with these instructions.