6

900 1200

kg 180 450

RAL 9010 9010

mm -

RAL 9010 -

mm

mm 2440* 2400

mm 2440* 2500

2. Technical Specications

AM

Weight, Standard unit without panels

Colour, Panel (steel)

Design panel, dimensions 600x500 or 1200x1000

Colour, Case

Dimensions see “Appendix 1 Dimensional Drawings”

Minimum oor-to-ceiling height with wall ducts

Minimum oor-to-ceiling height with roof ducts

* Dimension can be reduced by up to 40 mm when there is no panel and the machine shoes are fully screwed down.

3. Installation

NB! The installation engineer is responsible for

ensuring that the air handling unit is properly secured.

NB! The installation engineer is responsible for

ensuring that any existing functions in the wall/ceiling

(e.g. vapour barrier) are restored and fully functional

once the unit has been installed.

NB! Read this section “Installation” fully before

starting installation!

NB! The walls and oor at the place of installation of

the Airmaster air handling unit must be even and level.

3.1. Positioning of the Unit

The diagram below shows the most important dimensions

relating to the positioning of the unit. (Shown here on an

AM 900).

B

C

A

A: CO2sensor

B: Approximately 1 m

C: Approximately 2 m

NB! The CO2sensor must not be tted close to a window

or door.

NB! Smoke detectors must not be too close to the inlet

and extraction air ow.

NB! For the minimum oor-to-ceiling height for oor-

mounted Airmaster air handling units see section “2.

Technical Specications”.

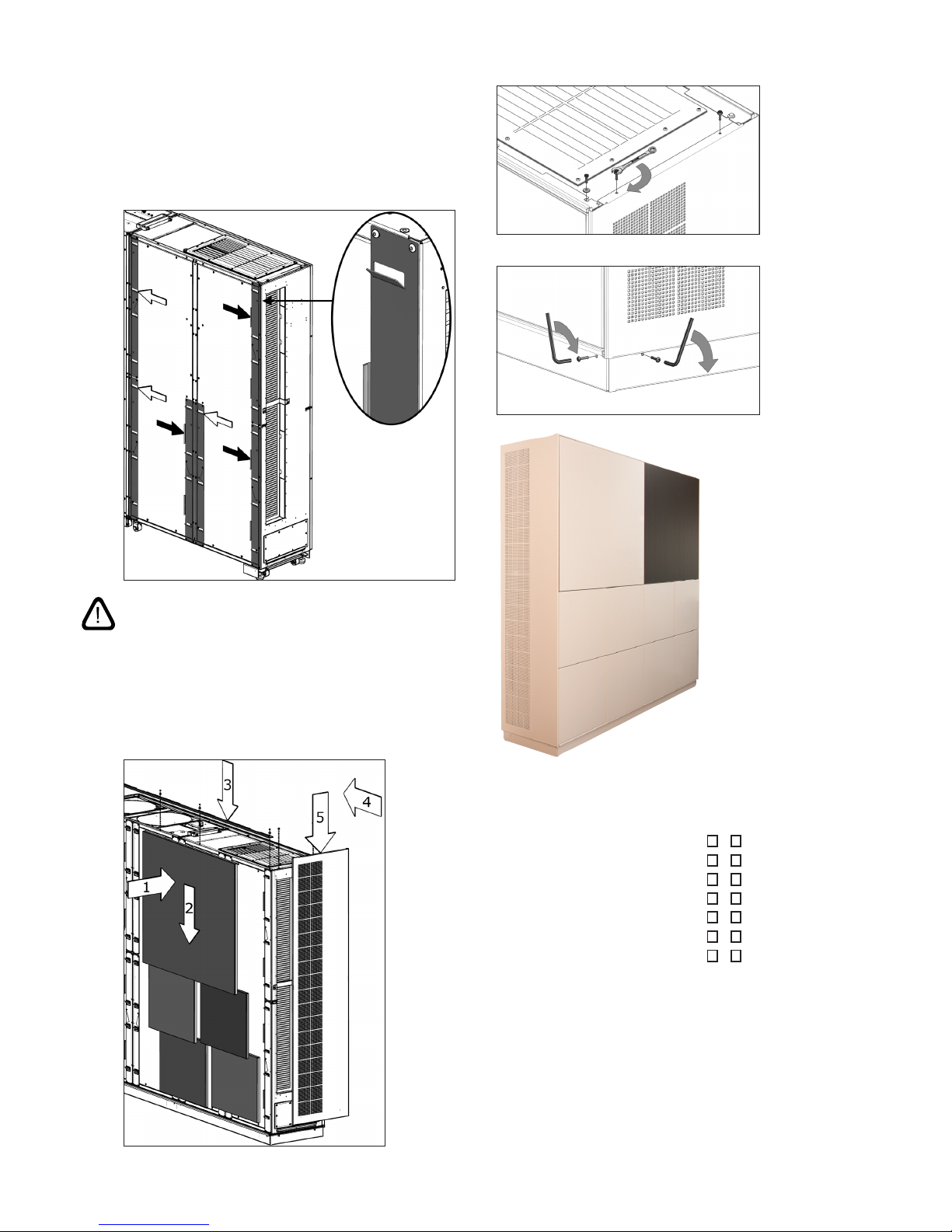

3.2. Duct Holes

NB! It is recommended that the duct holes be drilled

10-15 mm larger than indicated on the drawings as

this will allow for subsequent insulation, will prevent

direct contact with the wall, and will allow for a vapour

barrier, etc., to be restored.

A rubber diaphragm for restoration of the function

of the vapour barrier is optional available and can be

delivered by Airmaster.

Important! Duct holes in the wall must have an outward

downward gradient of 1-2% to prevent heavy rain

from entering the unit.

1. Marking the holes for the ducts.

Dimensions for duct hole positioning can be found in

“Appendix 1 Dimensional Drawings”

2. Drill duct holes.